Preparation method of cigarette flavor compensating particles

A particle and aroma technology, applied in the field of filter materials and the preparation of the materials, can solve the problems of unsatisfactory functionality, limited reduction of tar, introduction of miscellaneous gases, etc., and achieve the effect of convenient industrial application and good adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

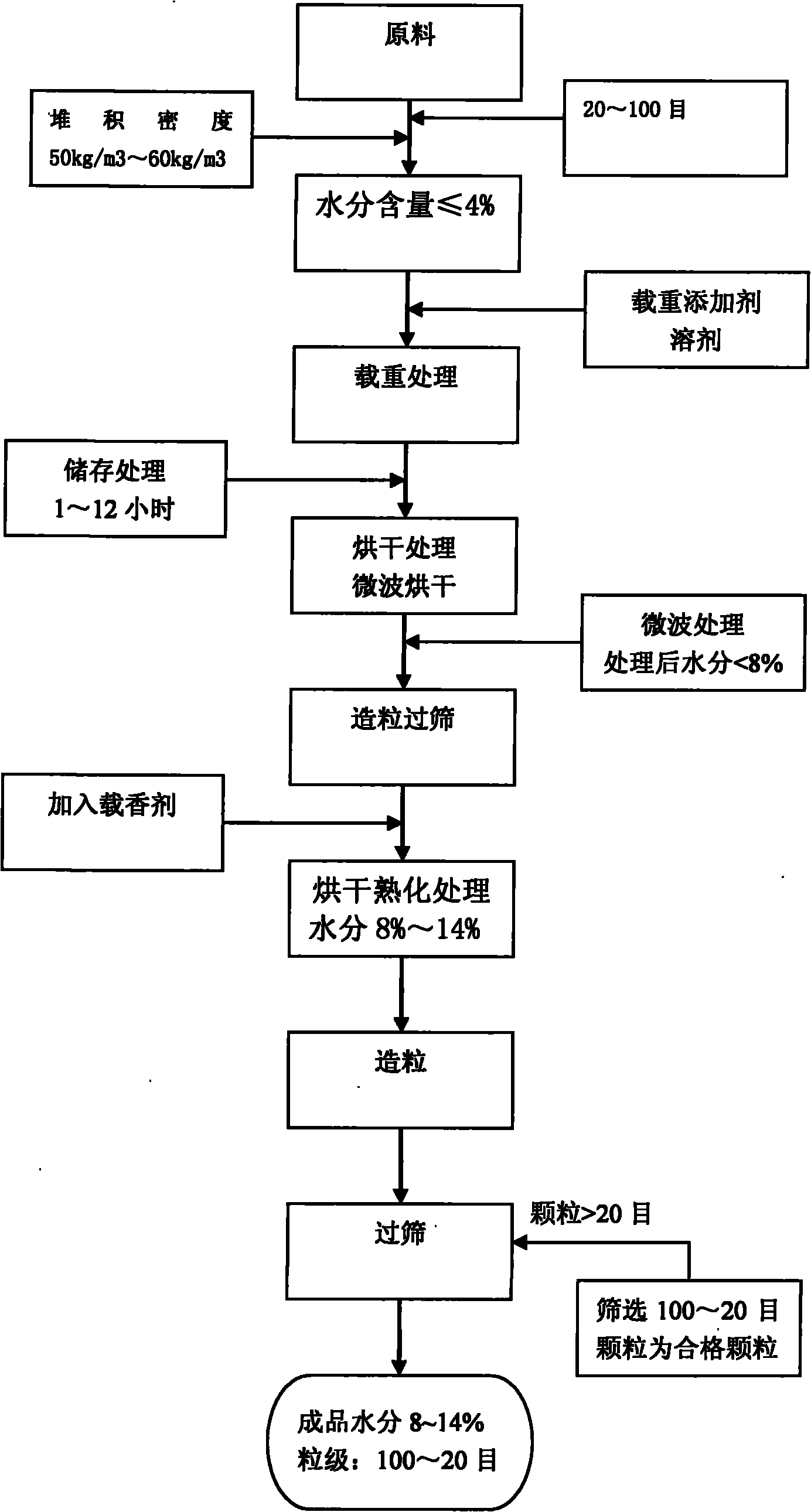

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing cigarette aroma compensating granules according to the present invention is the aroma compensating granules produced through the following process:

[0034] a. Raw materials are screened, the selected density is uniform, and the bulk density is 0.01g / cm 3 For expanded silicate rock, the particle size of the material should be between 80 and 20 mesh;

[0035] b. 1kg of sodium chloride, 1kg of sodium malate, and 12kg of water are prepared as a loading agent;

[0036] c. Add the prepared loading agent to the expanded silicate rock;

[0037] d. Stir evenly and store for 6 hours;

[0038] e. Microwave drying treatment, the moisture is dried to below 4.0%, and the silicate rock substrate is obtained;

[0039] f. Sieve the baked silicate rock, select a product with a particle size of 20 to 80 mesh, and granulate again if the particle size is greater than 20 mesh;

[0040] g, dry high-quality ginkgo leaves, licorice are pulverized, and the water of ...

Embodiment 2

[0047] The method for preparing cigarette aroma compensating granules according to the present invention is the aroma compensating granules produced through the following process:

[0048] a. Raw material screening, selection of uniform density, density 0.2g / cm 3Silicate rock, the particle size of the material should be between 80 and 20 mesh;

[0049] b. Mix 500g of sodium chloride, 1kg of sodium malate, and 12kg of water into a uniform loading agent;

[0050] c. Add the prepared loading agent to the silicate rock;

[0051] d. Stir evenly and store for 1 hour;

[0052] e. Microwave drying treatment, the moisture is dried to below 6.0%;

[0053] f. Sieve the baked silicate rock, select 20 to 40 mesh particles, and granulate again if the particle size is greater than 20 mesh;

[0054] g. Grinding dried high-quality Momordica grosvenori and Radix Glycyrrhizae, using weight ratio as 65% ethanol, 15% propylene glycol and remaining water, mixed solvent reflux extraction for 2 h...

Embodiment 3

[0061] The method for preparing cigarette aroma compensating granules according to the present invention is the aroma compensating granules produced through the following process:

[0062] a. Select a bulk density of 0.1g / cm 3 For silicate rock, the particle size of the material should be below 40 mesh;

[0063] b. Mix 2kg of sodium chloride, 500g of sodium citrate, and 12kg of water into a uniform loading agent;

[0064] c. Add the prepared loading agent to the silicate rock;

[0065] d. Stir evenly and store at normal temperature and pressure for 2 hours;

[0066] e. Microwave drying treatment, the moisture is dried to below 10.0%;

[0067] f. Sieve the baked silicate rock, and select 40 to 60 mesh particles to obtain silicate rock substrate particles;

[0068] g. Grinding dry and high-quality Momordica grosvenori, licorice, honeysuckle, and loquat leaves, and extracting 75% ethanol, 5% propylene glycol and the rest of the water with a mixed solvent for reflux extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com