Polysaccharide modified ferromanganese bimetallic material as well as preparation method and application thereof

A bimetallic and modified technology, applied in the field of soil and groundwater pollution remediation, can solve the problems of difficult technical operation, limited availability, limited solid properties, etc., to improve physical stability, prevent particle aggregation, and increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

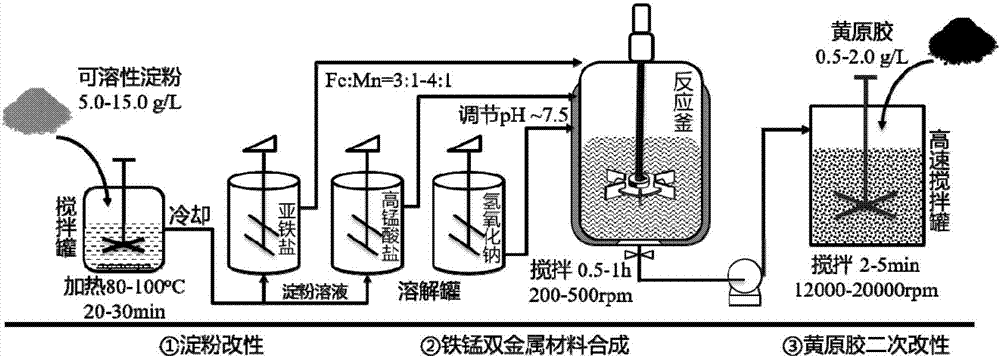

[0032] As shown in the following table, different raw material ratios and synthesis conditions were used to prepare the materials:

[0033] ①Starch modification solution preparation: Weigh 5.0, 10.0, 15.0g soluble starch respectively, first disperse in a small amount of cold water, then add 1L of deionized water heated to 20 (room temperature), 40, 60, 80, 100°C, magnetically Continue heating under stirring conditions for 10, 20, 30 minutes. The results show that a clear and transparent starch solution can be obtained by stirring at 80-100° C. for 20-30 minutes. Cool to room temperature for the modification of the material.

[0034] ②Synthesis of starch-modified iron-manganese bimetallic material: Weigh 0.04-0.10mol FeSO 4 ·7H 2 O was dissolved in 500 mL of the above ① starch solution, KMnO 4 The molar ratio is 1 / 3 and 1 / 4 of the ferrous salt, which are respectively dissolved in an equal amount of starch solution, and then the ferrous sulfate starch solution is slowly added ...

Embodiment 2

[0040] Measure 10 mL of the materials in Example 1 and add them to 90 mL of As(III) and As(V) solutions with a concentration of 0.5 to 100 mg / L. The pH of the solution was adjusted to 7.0 with 0.1 mol / L NaOH in advance. Place the centrifuge tube in a water bath constant temperature oscillator at 25°C for 12 hours and rotate at 200rpm, take a sample through a 0.22μm water-based needle filter membrane, and set the As-containing starch solution without the above materials as a blank control, and use an atomic fluorescence spectrometer to measure Total As concentration. As adsorption amount of the material at different adsorption equilibriums=(CK-As concentration in the filtrate at adsorption equilibrium)×0.1L / mass of the material. The isotherm adsorption curve of described material to As(III) and As(V) is as follows Figure 4 As shown, the Langmuir equation is used to fit the isothermal adsorption data of the material to As, and the calculation can be obtained that its saturated...

Embodiment 3

[0044] The three tested soils were collected from Chenzhou (CZ) in Hunan, Zhuzhou (ZZ) in Hunan, and Fengshan in Guangxi (FS), all of which were As-contaminated soils caused by nearby mineral mining and processing activities, industrial waste residues and tailings. The total As content was 193mg / kg, 572mg / kg, 3384mg / kg respectively. Weigh 500g of different test soils respectively, add the materials described in Example 1 according to the solid-to-liquid ratio of 1:0.25, 1:0.5, 1:1, and 1:2, stir evenly, and seal the mouth of the beaker with a hydrophobic and air-permeable film. Cultivate at room temperature, fully stir once a day, and add an equal amount of deionized water as a control. After continuous cultivation for 15 days, samples were taken for solid-liquid separation, and placed in a centrifuge at 3,000 rpm for 15 minutes. The supernatant was passed through a 0.22 μm aqueous needle filter to determine As content, and the bottom soil was subjected to TCLP toxicity leachi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com