Method for vacuum-cleaning using a hand vacuum cleaner and dust filter or dust collection compartment especially for use in a method of this type

A technology of dust filter bags and dust collection chambers, which is applied in the field of dust collection with hand-held vacuum cleaners and especially in the field of dust filter bags or dust collection chambers, which can solve problems such as high pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

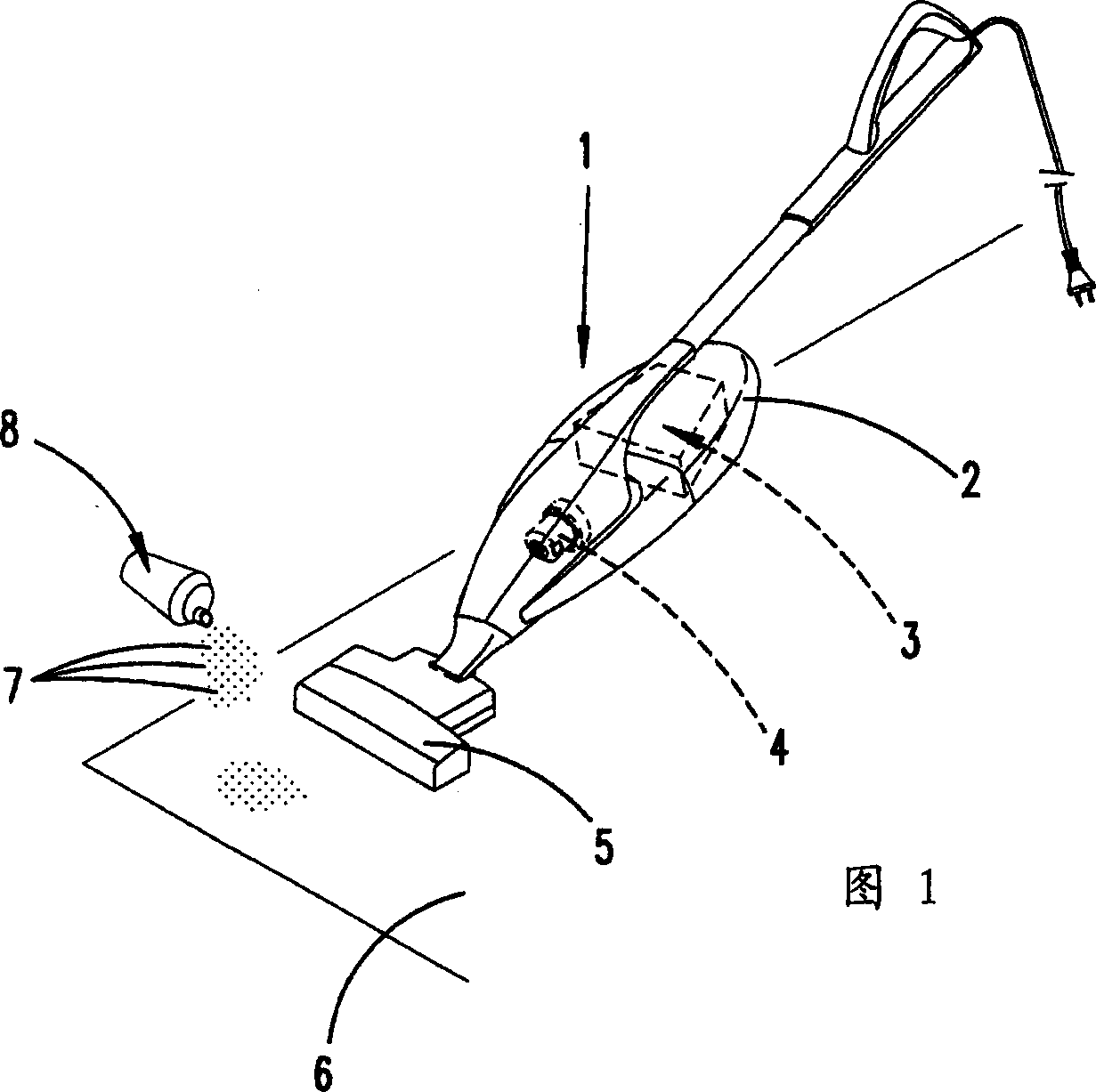

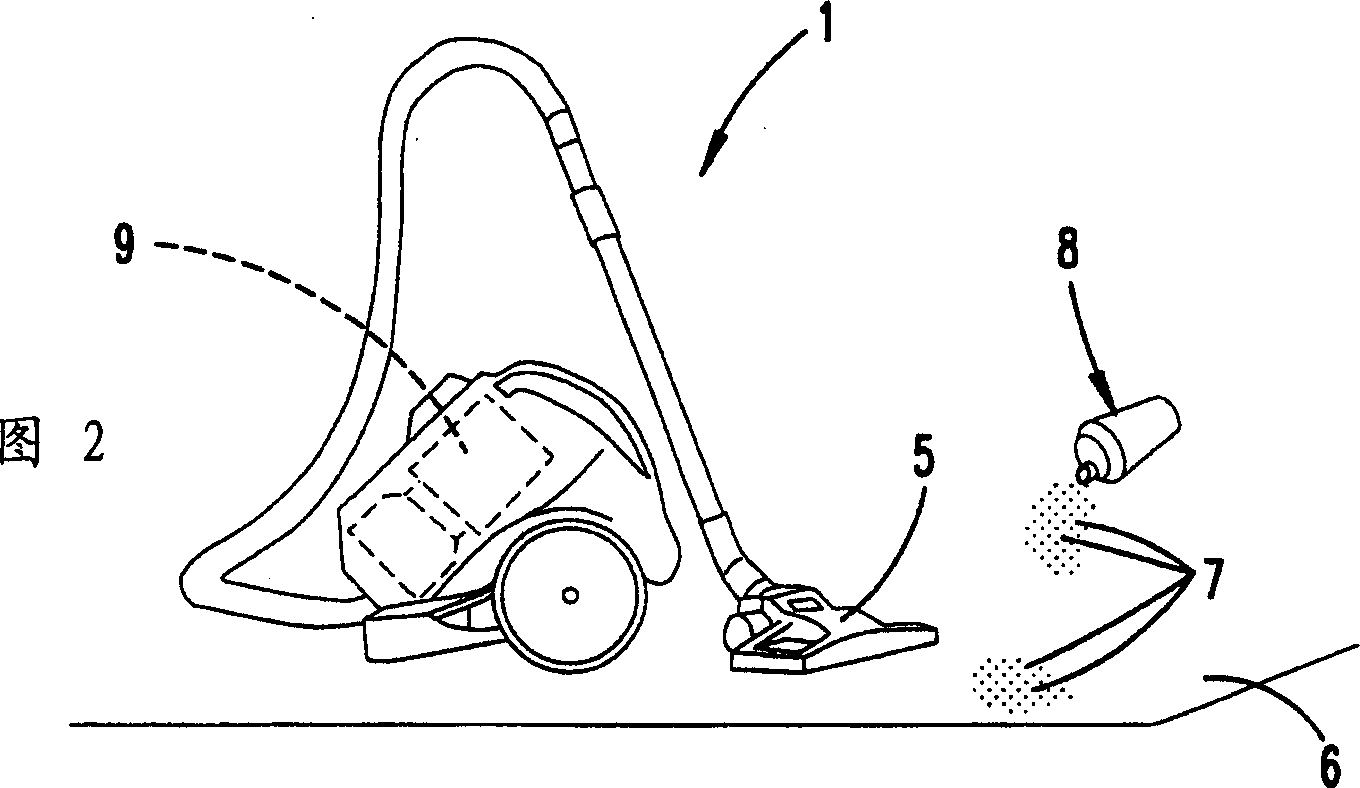

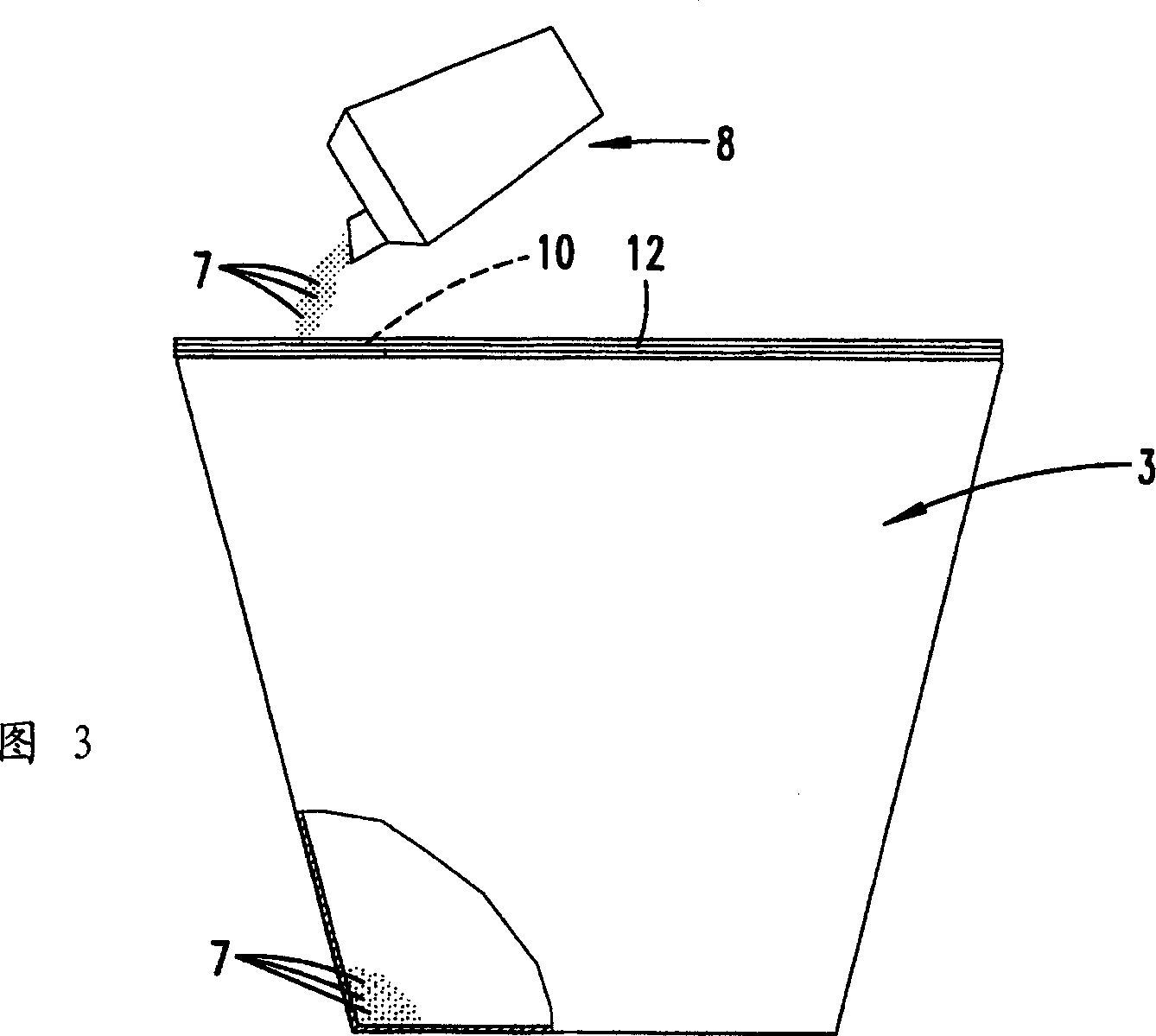

[0026] First, a vacuum cleaner 1 with a dust filter bag 3 fixed in a filter chamber 2 will be described with reference to FIG. 1 . When the vacuum cleaner 1 is in operation, the schematically indicated motor / fan unit 4 generates a negative pressure in the region of the suction nozzle 5 on the floor side, by means of this negative pressure dust and dirt particles are removed from the floor 6 to be cleaned, and suction The air flow is conveyed into the dust filter bag 3 via a suction duct (not shown). The motor / fan unit 4 is connected downstream of the dust filter bag 3 in the airflow direction.

[0027] The dust that packs into the dust filter bag 3 stays there for a certain period of time. Odor-generating substances are generated during this period due to microbial degradation of substances contained in various dusts, and these are absorbed as described in detail later.

[0028] To this end, an absorbent 7 in the form of activated carbon, zeolites or porous polymers is intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com