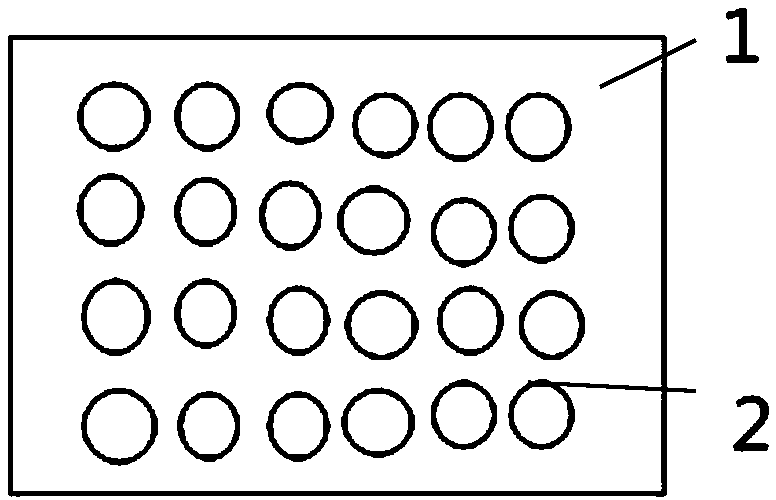

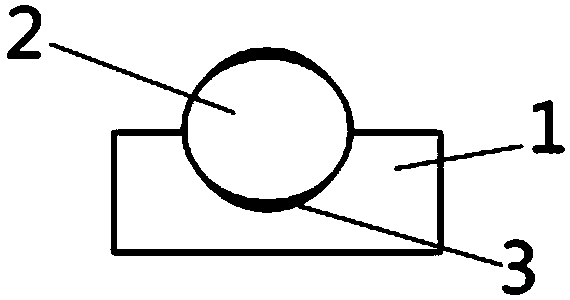

Composite structure comprising fabric layer and spherical activated carbon layer and preparation method thereof

A spherical activated carbon, composite structure technology, used in textiles and papermaking, clothing, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0107] 1.1 Preparation of spherical polymer matrix

[0108] Add 18 liters of water into a 50-liter polymerization kettle, heat it to 45°C, add 10g of magnesium carbonate, 20g of gelatin and 0.15g of methylene blue under stirring, and add 3kg of methylstyrene and 1kg of dipentamyl olefin and 20g of benzoyl peroxide mixed into the oil phase, then add 1.0kg of paraffin, close the polymerization kettle, feed clean compressed air into the polymerization kettle, and keep the gas phase pressure in the kettle at 0.02MPa. Then, start the stirring, adjust the liquid beads in the kettle to an appropriate particle size, raise the temperature to 80°C, keep the temperature for 12 hours, then raise the temperature to 100°C, keep the temperature for 20 hours, filter, wash, dry and sieve to obtain the white spherical polymer 2.35 kg.

[0109] 1.2 Sulfonation and carbonization

[0110] Mix the spherical polymer obtained in step 1.1 with a mass ratio of 1:1 with concentrated sulfuric acid, the...

preparation example 2

[0120] 2.1 Preparation of spherical polymer matrix

[0121] Add 20 liters of water into a 50 liter polymerization kettle, heat it to 40°C, add 10g of calcium carbonate, 20g of polyvinyl alcohol and 0.15g of petroleum calcium sulfonate under stirring, and add 3kg of styrene and 1kg of isoprene ethylene and 20g of azobisisobutyronitrile mixed into the oil phase, then add 1.6kg of glycerin, close the polymerization kettle, feed clean compressed air into the polymerization kettle, and keep the gas phase pressure in the kettle at 0.04MPa. Then, start stirring, adjust the liquid beads in the kettle to an appropriate particle size, raise the temperature to 80°C, keep it warm for 12 hours, then raise the temperature to 100°C, keep it warm for 20 hours, filter, wash, dry and sieve to obtain a white spherical polymer 2.67 kg.

[0122] 2.2 Sulfonation and carbonization

[0123] The spherical polymer obtained in step 2.1 with a mass ratio of 1:1.5 and SO 3 Mix, then put the mixture int...

preparation example 3

[0133] 3.1 Preparation of spherical polymer matrix

[0134] Add 20 liters of water into a 50-liter polymerization kettle, heat to 40°C, add 12g of magnesium carbonate, 25g of sodium carboxymethylcellulose and 0.18g of calcium dodecylbenzenesulfonate under stirring, and add the 3.6kg divinylbenzene, 1.2kg diethylene glycol divinyl ether and 25g sodium persulfate mixed oil phase, then add 2.2kg sodium carbonate, close the polymerization kettle, feed clean compressed air into the polymerization kettle, Keep the gas phase pressure in the kettle at 0.05MPa. Then, start the stirring, adjust the liquid beads in the kettle to an appropriate particle size, raise the temperature to 90°C, keep the temperature for 9 hours, then raise the temperature to 120°C, keep the temperature for 20 hours, filter, wash, dry and sieve to obtain the white spherical polymer 3.12 kg.

[0135] 3.2 Sulfonation and carbonization

[0136] Add the polymer obtained in step 3.1 into a 50-liter reactor, add 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com