Low odor PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

An alloy material, low-odor technology, applied in the field of modified polymer materials, can solve problems such as unpleasantness, affecting in-vehicle experience and environmental health, achieving low odor, reducing the use of toughening agents and compatibilizers, and high toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

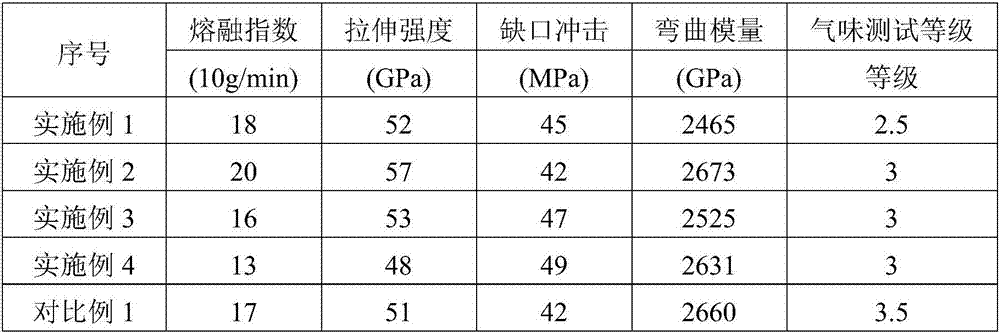

Embodiment 1

[0030] Polycarbonate (PC2805) 73.8wt%, polyacrylonitrile resin (SAN) 15wt% (Zhenzhou Chimei), styrene-butadiene rubber (SBR) 5wt% (Yueyang Petrochemical), toughening agent (EM500) 2wt% (LG Chemical ), dispersant (high molecular weight methyl siloxane (4-7081, Dow Corning)) 1wt%, processing aid (phosphite antioxidant S9228) 0.2wt%, join in high-speed mixer and mix, mixing temperature Not higher than 50°C, the stirring speed is 300r / min, and the mixing time is 15min; from the main feeding port of the twin-screw extruder, add 2.5wt% zeolite and 0.5wt% sodium oxalate by metering, and mix thoroughly from the twin-screw extruder The side feed port of the screw extruder is added, and the twin-screw extruder is melted and blended, cooled and granulated to obtain a low-odor modified PC / ABS alloy material. The conditions of the melt blended are preferably the temperature of each heating section Between 230 and 260°C, the screw speed of the host machine is 300 to 450r / min. The propertie...

Embodiment 2

[0032] Polycarbonate (PC2805) 73.3wt%, polyacrylonitrile resin (SAN) 15wt% (Zhenzhou Chimei), styrene-butadiene rubber (SBR) 5wt% (Yueyang Petrochemical), toughening agent (EM500) 2wt% (LG Chemical ), dispersant (high molecular weight methyl siloxane (4-7081, Dow Corning)) 1wt%, processing aid (phosphite antioxidant S9228) 0.2wt%, join in high-speed mixer and mix, mixing temperature Not higher than 50°C, the stirring speed is 300r / min, and the mixing time is 15min; from the main feeding port of the twin-screw extruder, add 2.5wt% zeolite and 1wt% sodium oxalate, and mix them thoroughly from the twin-screw extruder The side feed port of the extruder is added, melted and blended through the twin-screw extruder, cooled and granulated to obtain a low-odor modified PC / ABS alloy material, and the conditions of the melt blended are preferably that the temperature of each heating section is between Between 230 and 260°C, the screw speed of the host machine is 300 to 450r / min. The pro...

Embodiment 3

[0034] Polycarbonate (PC2805) 72.8wt%, polyacrylonitrile resin (SAN) 15wt% (Zhenzhou Chimei), styrene-butadiene rubber (SBR) 5wt% (Yueyang Petrochemical), toughening agent (EM500) 2wt% (LG Chemical ), dispersant (high molecular weight methyl siloxane (4-7081, Dow Corning)) 2wt%, processing aid (phosphite antioxidant S9228) 0.2wt%, join in high-speed mixer and mix, mixing temperature Not higher than 50°C, the stirring speed is 300r / min, and the mixing time is 15min; from the main feeding port of the twin-screw extruder, add 2.5wt% zeolite and 0.5wt% sodium oxalate by metering, and mix thoroughly from the twin-screw extruder The side feed port of the screw extruder is added, and the twin-screw extruder is melted and blended, cooled and granulated to obtain a low-odor modified PC / ABS alloy material. The conditions of the melt blended are preferably the temperature of each heating section Between 230 and 260°C, the screw speed of the host machine is 300 to 450r / min. The propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com