Low-odor low-TVOC polypropylene composite material and preparation method thereof

A polypropylene and low-odor technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of poor odor stability, large difference in volume of small molecules of odor, and limited effect, and achieve stable odor levels , The effect of thoroughly removing the smell and avoiding the burnt smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

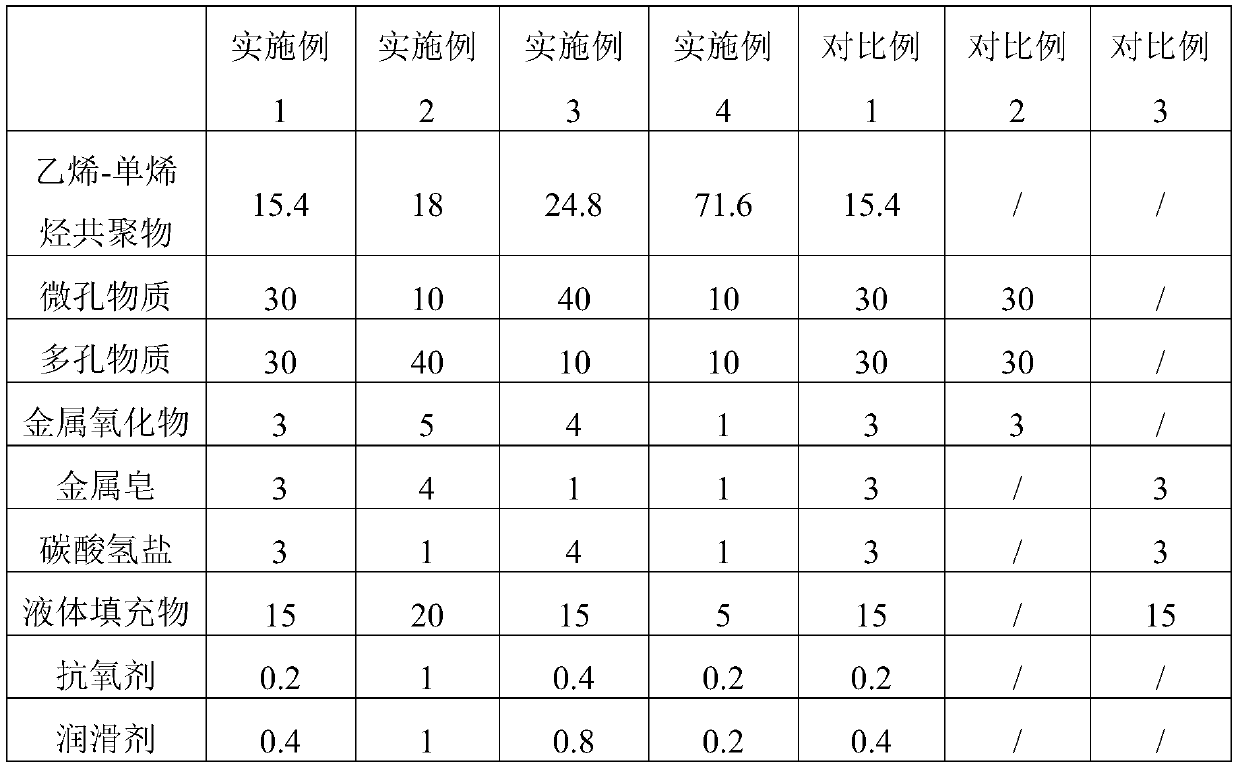

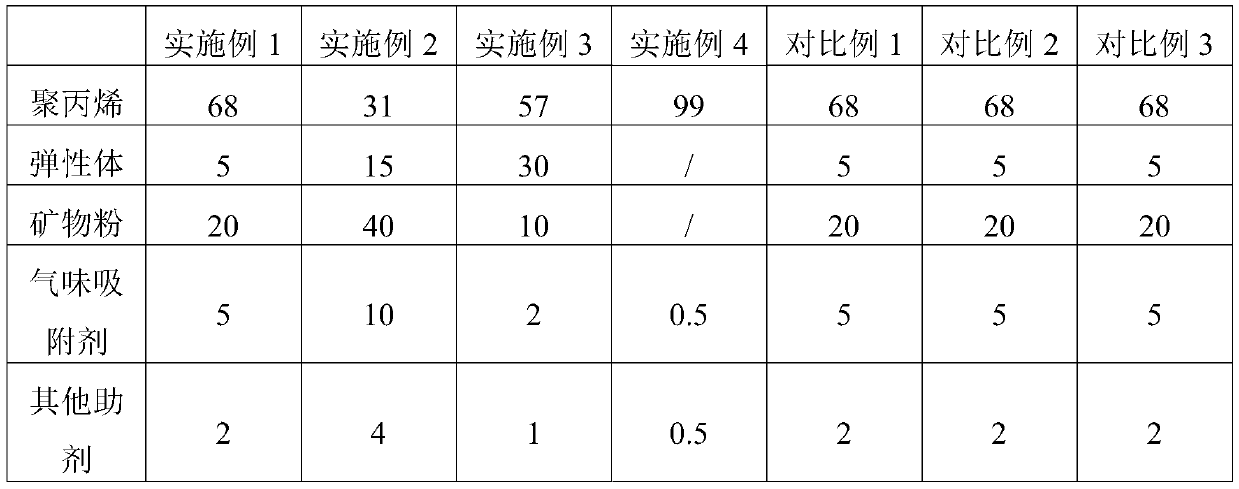

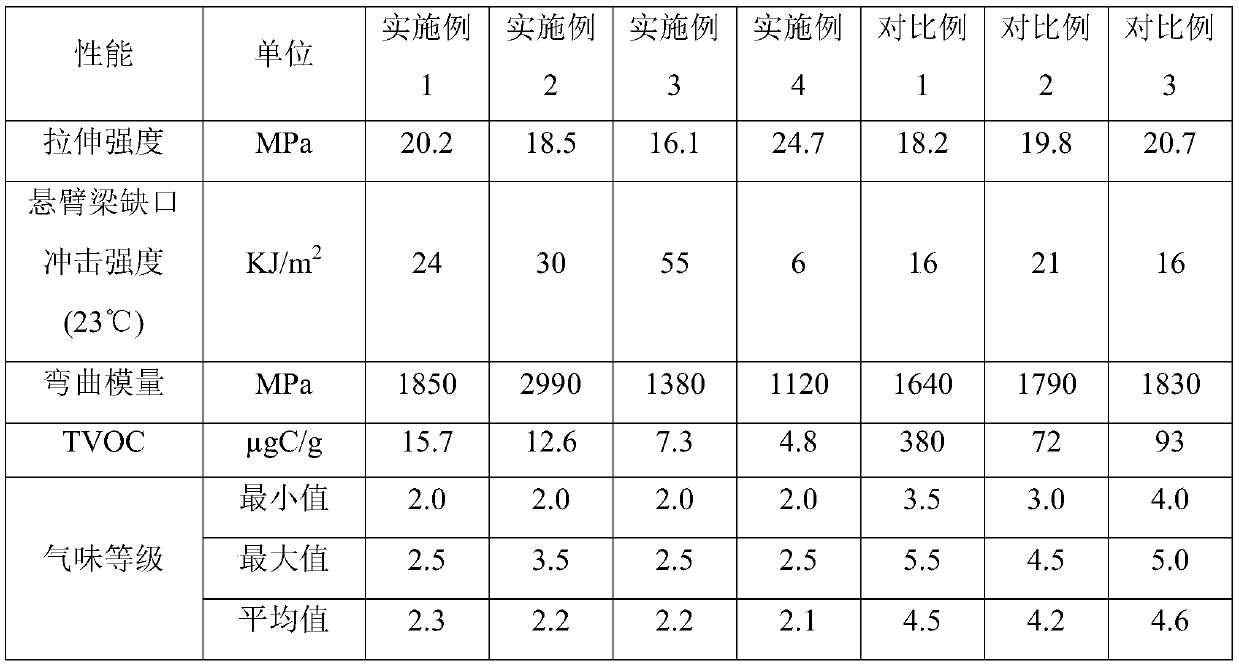

Embodiment 1

[0030] Heat the microporous substance and the porous substance at 400°C for 60 minutes respectively, and then place them in an odorless environment to cool to room temperature; add bicarbonate to the liquid filling 1 for dissolution to form a bicarbonate solution, and then The hydrogen salt solution is added to the cooled microporous substance and mixed evenly, and the excess bicarbonate solution is removed to obtain a mixture of bicarbonate and microporous substance; the metal soap is added to the liquid filling material 2 for dissolution to form a metal soap solution , then the metal soap solution is added to the cooled porous substance and mixed uniformly, and the excess metal soap solution is removed to obtain a metal soap and a porous substance mixture; The material mixture is mixed evenly, and then metal oxide, ethylene-monoolefin copolymer, antioxidant, and lubricant are added in sequence to mix evenly, and finally the above mixture is added to an internal mixer or meshi...

Embodiment 2

[0035] Heat the microporous substance and the porous substance at 500°C for 120 minutes respectively, and then place them in an odorless environment to cool to room temperature; add bicarbonate to the liquid filling 1 to dissolve, forming a bicarbonate solution, and then The hydrogen salt solution is added to the cooled microporous substance and mixed evenly, and the excess bicarbonate solution is removed to obtain a mixture of bicarbonate and microporous substance; the metal soap is added to the liquid filling material 2 for dissolution to form a metal soap solution , then the metal soap solution is added to the cooled porous substance and mixed uniformly, and the excess metal soap solution is removed to obtain a metal soap and a porous substance mixture; The material mixture is mixed evenly, and then metal oxide, ethylene-monoolefin copolymer, antioxidant, and lubricant are added in sequence to mix evenly, and finally the above mixture is added to an internal mixer or meshing...

Embodiment 3

[0040] Heat the microporous substance and the porous substance at 600°C for 180 minutes respectively, and then place them in an odorless environment to cool to room temperature; add bicarbonate to the liquid filling 1 for dissolution to form a bicarbonate solution, and then The hydrogen salt solution is added to the cooled microporous substance and mixed evenly, and the excess bicarbonate solution is removed to obtain a mixture of bicarbonate and microporous substance; the metal soap is added to the liquid filling material 2 for dissolution to form a metal soap solution , then the metal soap solution is added to the cooled porous substance and mixed uniformly, and the excess metal soap solution is removed to obtain a metal soap and a porous substance mixture; The material mixture is mixed evenly, and then metal oxide, ethylene-monoolefin copolymer, antioxidant, and lubricant are added in sequence to mix evenly, and finally the above mixture is added to an internal mixer or mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com