Composite material for automobile interior skin and its preparation method and use

A technology for automobile interior and skin, which is applied in the field of composite materials for automobile interior skin and its preparation and use, and can solve the problems of low composite fastness, high odor, and large amount of flame composite agent used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

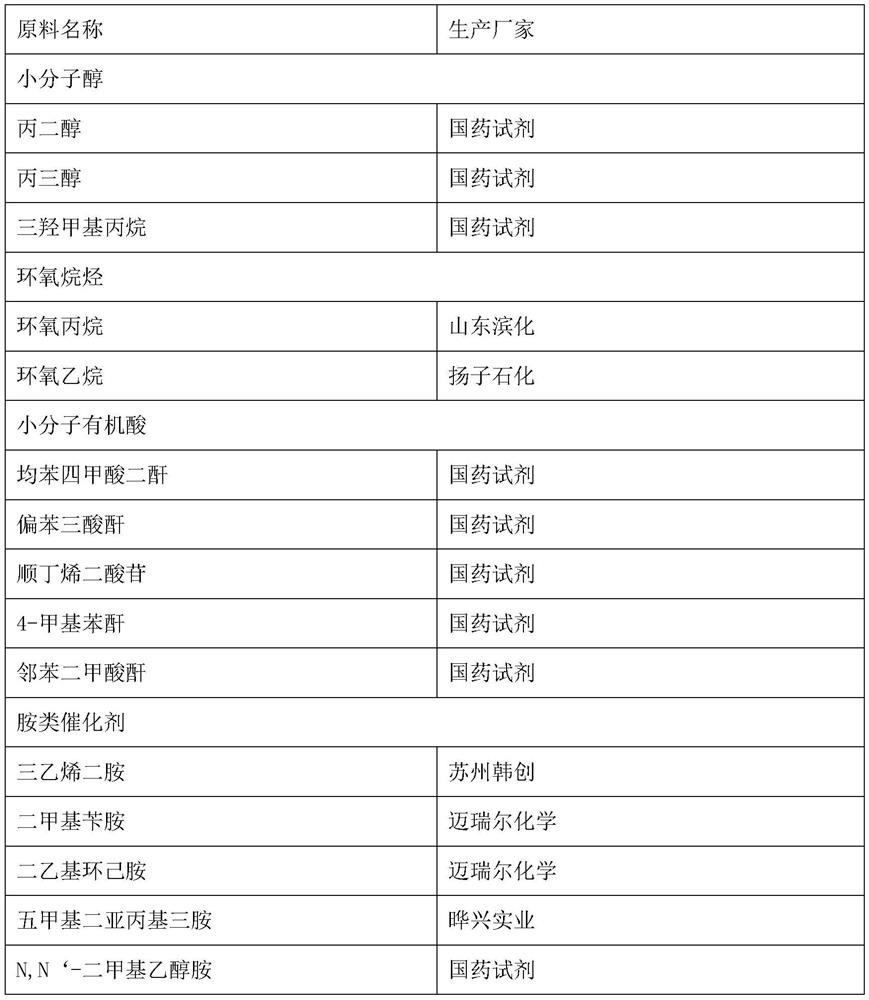

preparation example Construction

[0040] The preparation method of polyether polyol B1 comprises the following steps: (1) 100 parts by weight of propylene glycol react with 767 parts by weight of ethylene oxide to form low-molecular polyether polyol, the reaction time is 8h, and the reaction temperature is 120°C; ( 2) In step 1, 100 parts of low-molecular polyether polyol and 90 parts by weight of phthalic anhydride are polymerized to form polyol I, the reaction time is 8 hours, and the reaction temperature is 120° C.; (3) 100 parts of polyol I in step 2 React with 93 parts by weight of propylene oxide to form polyether polyol B, the reaction time is 6 hours, and the reaction temperature is 125°C.

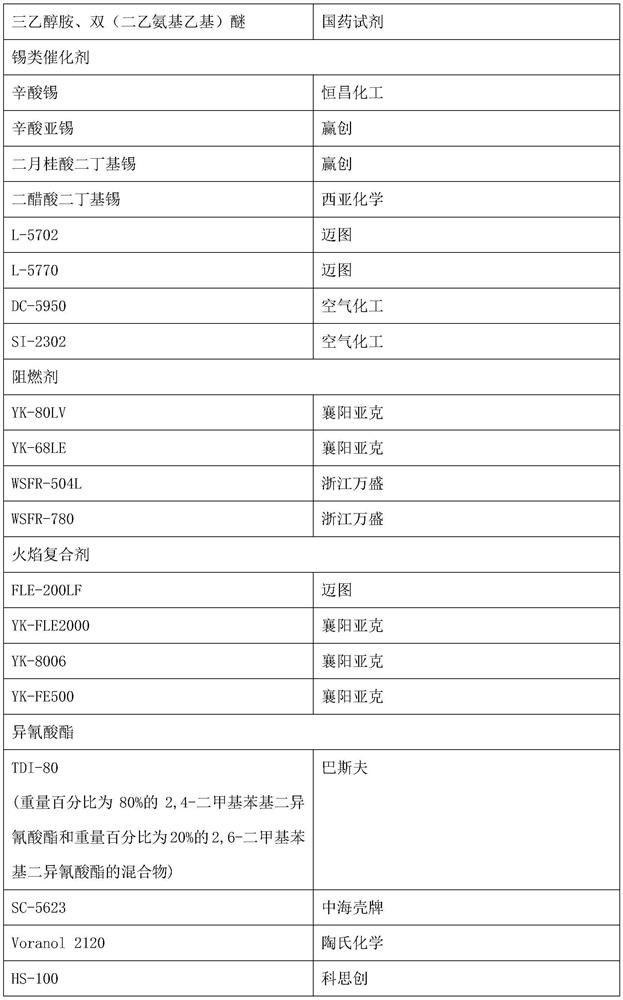

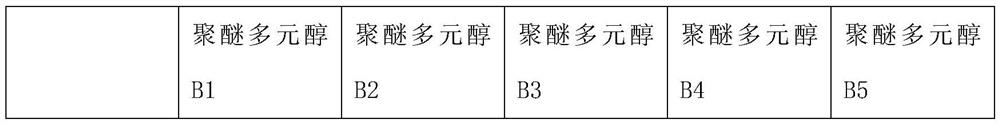

[0041] The preparation methods of polyether polyol B2 to polyether polyol B4 were carried out according to the steps in Example 1. The only difference was that the reaction raw materials, reaction types, raw material ratios, reaction time and reaction temperature were different. See Table 2 for details.

[0042] Ta...

Embodiment 1

[0047] a) Prepare component I: In container A, add polyether polyol A1: 30 parts, polyether polyol B1: 30 parts, polymer polyol C1: 20 parts, water: 1.8 parts in container A, Dimethylbenzylamine: 0.17 parts, diethylcyclohexylamine, 0.18 parts, dibutyltin dilaurate: 0.12 parts, SI-2302: 0.7 parts, YK-68LE: 5 parts, FLE-200LF: 1 part, uniform Stirring, the stirring speed is 2500rpm / min, and the temperature of the mixed material is 25°C;

[0048] b) Preparation of component II: In container A, add 80% by weight of 2,4-dimethylphenyl diisocyanate and 20% by weight of a mixture of 2,6-dimethylphenyl diisocyanate The number is 28 parts, stirred for 6 seconds to obtain material I, and the stirring speed is 3000rpm / min;

[0049] c) Quickly pour the material I into a foaming box for aging for 48 hours. After aging, a composite material for automotive interior skin is prepared. The performance data of the prepared automotive interior skin composite materials are shown in Table 5.

[...

Embodiment 2-10

[0052] Embodiments 2 to 10 were carried out according to the steps in Embodiment 1. The only difference was that the reaction raw materials, reaction types, catalyst types, raw material ratios, reaction time and reaction temperature were different. See Table 3 for details. The prepared automobile interior decoration The performance data of the skin composite materials are shown in Table 5.

[0053] The parts by weight of raw materials of each component in table 3 embodiment 1-10

[0054]

[0055]

[0056]

[0057]

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com