Low-odor and low-VOC (Volatile Organic Compound) polyvinyl chloride composite material and preparation method thereof

A polyvinyl chloride and composite material technology, applied in the field of new materials, can solve the problems of difficulty in ensuring the selection and consistency of raw materials, many raw materials, and the VOC index has not been significantly improved, so as to reduce the odor and VOC of the whole vehicle, reduce the Odor level, increase the effect of thermal cycle drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

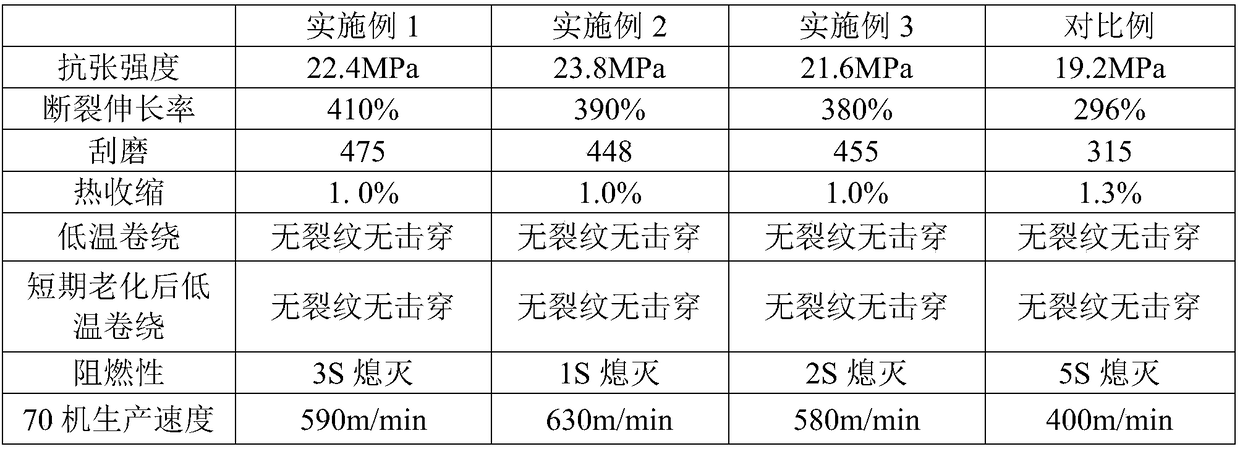

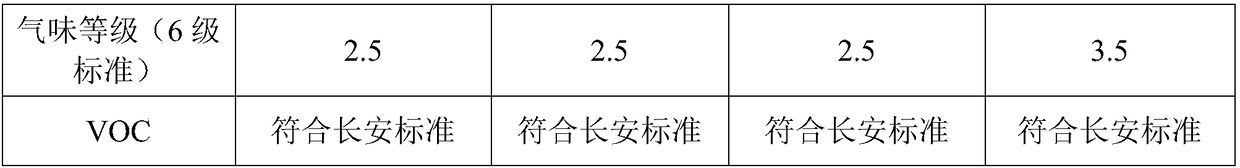

Examples

Embodiment 1

[0022] The low odor and low VOC polyvinyl chloride composite material of this embodiment includes the following components in parts by weight:

[0023] 100 parts of polyvinyl chloride resin;

[0024] 35 parts of plasticizer bis(2-propylheptyl) phthalate;

[0025] 5 parts of calcium zinc stabilizer;

[0026] 0.5 parts of high melting point PE wax as lubricant;

[0027] Flame retardant antimony trioxide 2 parts;

[0028] 20 parts of inorganic filler;

[0029] 0.3 parts of antioxidant.

[0030] Among them, the degree of polymerization of polyvinyl chloride resin is 1300.

[0031] Inorganic fillers include 19 parts of calcium carbonate, 0.5 parts of zeolite powder, 0.5 parts of anatase nano-titanium dioxide; among them, calcium carbonate is a composite of nano-calcium carbonate, active light calcium carbonate, and heavy calcium carbonate at a mass ratio of 8:3:1. Calcium carbonate.

[0032] Antioxidants are antioxidant 1010 (tetra [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaeryt...

Embodiment 2

[0038] The low odor and low VOC polyvinyl chloride composite material of this embodiment includes the following components in parts by weight:

[0039] 100 parts of polyvinyl chloride resin;

[0040] Plasticizer: 45 parts of trioctyl trimellitate;

[0041] 8 parts of calcium zinc stabilizer;

[0042] 0.8 parts of lubricant high melting point PE wax;

[0043] Flame retardant antimony trioxide 4 parts;

[0044] 40 parts of inorganic filler;

[0045] 1.0 part of antioxidant.

[0046] Among them, the degree of polymerization of polyvinyl chloride resin is 1300.

[0047] Inorganic fillers include 30 parts of calcium carbonate, 5 parts of zeolite powder, and 5 parts of anatase nano-titanium dioxide. Among them, calcium carbonate is a composite of nano-calcium carbonate, active light calcium carbonate, and heavy calcium carbonate at a mass ratio of 8:4:1. Calcium carbonate.

[0048] Antioxidants are antioxidant 1010 (tetra [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol este...

Embodiment 3

[0054] The low odor and low VOC polyvinyl chloride composite material of this embodiment includes the following components in parts by weight:

[0055] 100 parts of polyvinyl chloride resin;

[0056] 32 parts of plasticizer bis(2-propylheptyl) phthalate (DPHP) and 10 parts of plasticizer trioctyl trimellitate (TOTM);

[0057] 6 parts of calcium zinc stabilizer;

[0058] 0.3 parts of lubricant high melting point PE wax;

[0059] Flame retardant antimony trioxide 3.5 parts;

[0060] 35 parts of inorganic filler;

[0061] 0.8 parts of antioxidant.

[0062] Among them, the degree of polymerization of polyvinyl chloride resin is 1300.

[0063] Inorganic fillers include 32 parts of calcium carbonate, 2.0 parts of zeolite powder, 1.0 parts of anatase nano-titanium dioxide; among them, calcium carbonate is a composite of nano-calcium carbonate, active light calcium carbonate, and heavy calcium carbonate at a mass ratio of 8:5:1. Calcium carbonate.

[0064] Antioxidants are antioxidant 1010 (tetra [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com