Low-odor, low-VOC and scratch-resistant polypropylene interior material for vehicle and preparation method of polypropylene interior material

An interior material, polypropylene technology, applied in the field of polymer modified materials, can solve the problems of desorption of small molecular compounds, high material cost, low impact, etc., reduce odor level and TVOC, improve scratch resistance, The effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

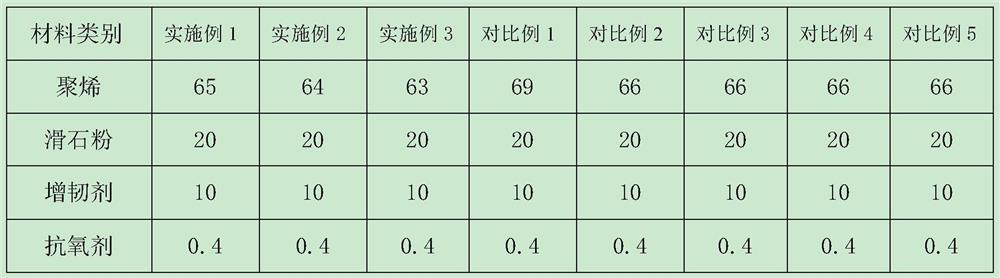

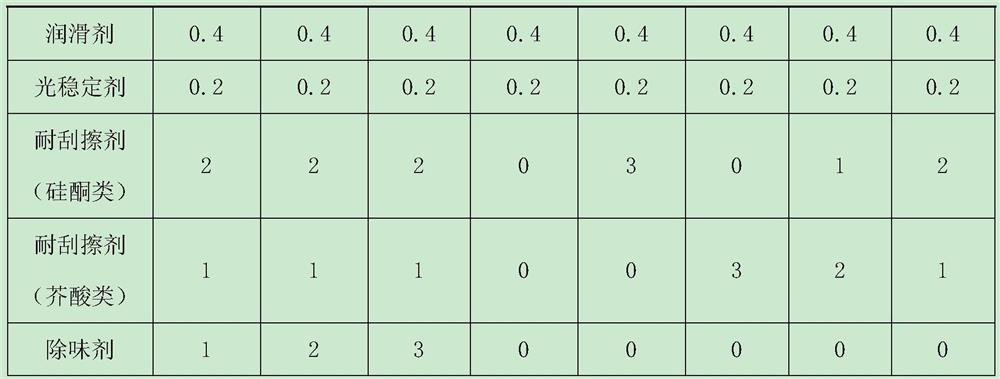

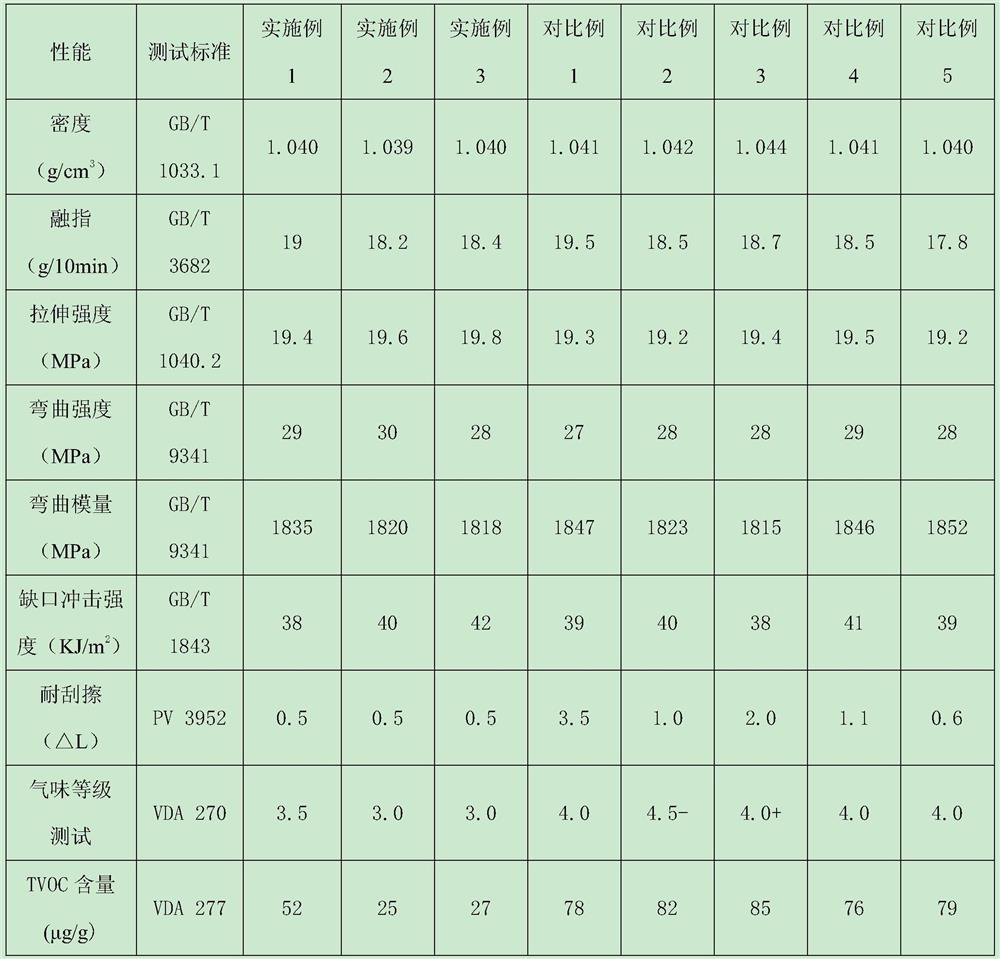

Embodiment 1

[0036] A low-odor, low-VOC, scratch-resistant polypropylene interior material for vehicles, which consists of: 65% polypropylene copolymer, 20% talcum powder, 10% toughening agent, 0.4% antioxidant, and 0.4% lubricant , Light stabilizer 0.2%, silicone scratch-resistant agent 2%, erucic acid scratch-resistant agent 1%, deodorant 1%.

[0037] According to the following method, a low-odor, low-VOC scratch-resistant polypropylene interior material for automobiles is prepared:

[0038] (1) Weigh copolymerized polypropylene, talcum powder, toughening agent, antioxidant, lubricant, anti-scratch agent, deodorant by weight percentage, join in high-speed mixer and carry out high-speed stirring and mix uniformly, obtain premix ;

[0039](2) Add the obtained premixed material into the parallel twin-screw extruder from the main feeding hopper. The twin-screw extruder requires a length-to-diameter ratio of 48:1, so that all component materials are sheared in the parallel twin-screw extrude...

Embodiment 2

[0042] A low-odor, low-VOC, scratch-resistant polypropylene interior material for vehicles, which consists of 64% by weight of polypropylene copolymer, 20% of talcum powder, 10% of toughening agent, 0.4% of antioxidant, and 0.4% of lubricant , Light stabilizer 0.2%, silicone scratch-resistant agent 2%, erucic acid scratch-resistant agent 1%, deodorant 2%.

[0043] According to the preparation method of Example 1, a low-odor, low-VOC scratch-resistant polypropylene interior material for vehicles was prepared.

Embodiment 3

[0045] A low-odor, low-VOC, scratch-resistant polypropylene interior material for vehicles, which consists of 63% by weight of polypropylene copolymer, 20% of talcum powder, 10% of toughening agent, 0.4% of antioxidant, and 0.4% of lubricant , Light stabilizer 0.2%, silicone scratch-resistant agent 2%, erucic acid scratch-resistant agent 1%, deodorant 3%.

[0046] According to the preparation method of Example 1, a low-odor, low-VOC scratch-resistant polypropylene interior material for vehicles was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com