Poly(propylene-grafted polar monomer) composition and preparation method thereof

A technology of polar monomer and polyolefin elastomer, applied in the field of polymer composition and its preparation, can solve the problem that polypropylene material cannot have high cohesive force, high elasticity and low elasticity at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] A preferred embodiment of the present invention, according to GB / T 18474-2001, the xylene insoluble content of the poly(propylene grafted polar monomer) composition is 5-40% by weight.

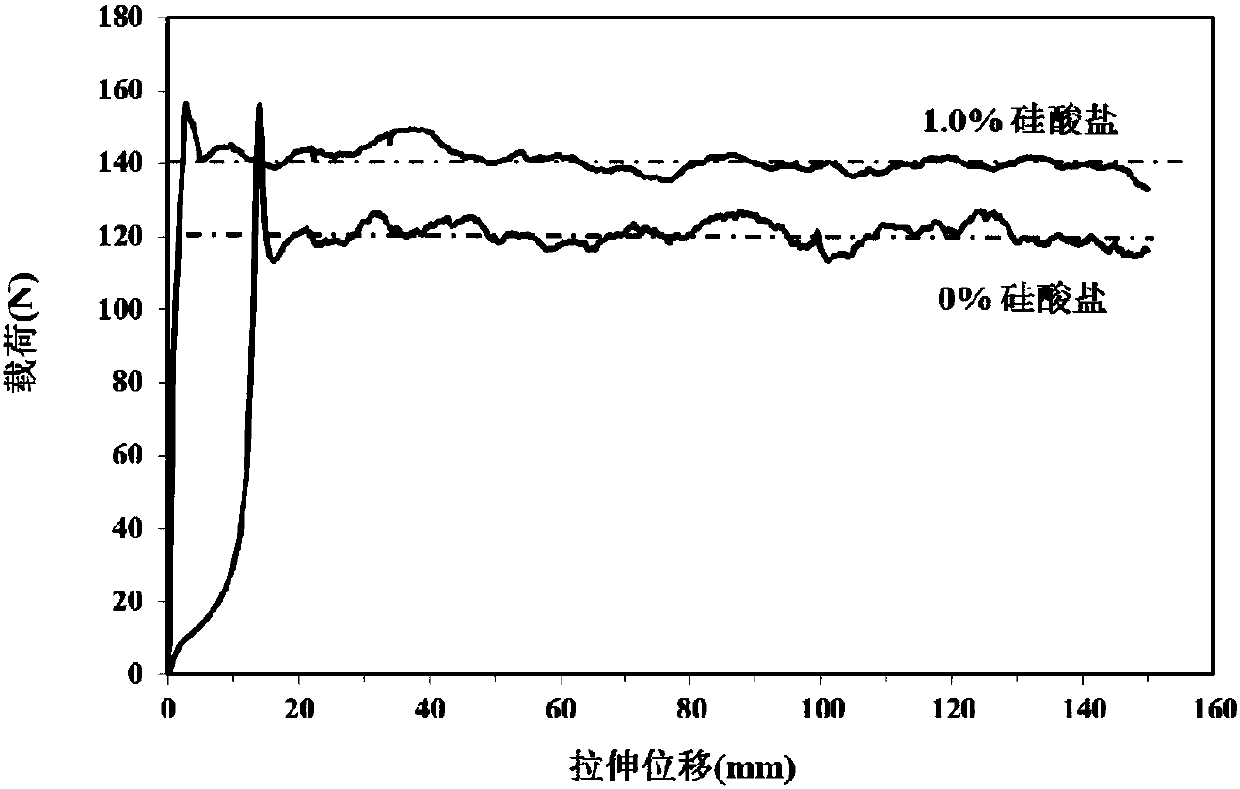

[0024] In a preferred embodiment of the present invention, according to GB / T 2791-1995, the peel strength between the poly(propylene-grafted polar monomer) composition and metal is ≥118N / 25mm, preferably 118-150N / 25mm. Preferably the peel strength is measured between the poly(propylene grafted polar monomer) composition and Al or Fe.

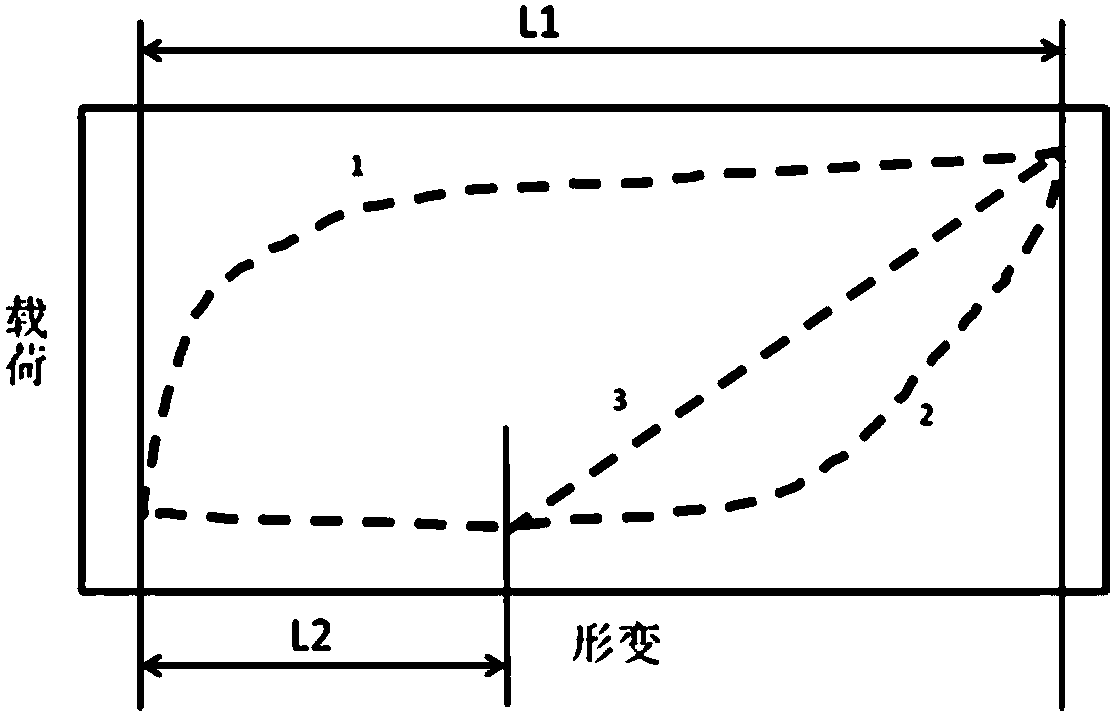

[0025] In a preferred embodiment of the present invention, the 100% tensile deformation recovery rate of the poly(propylene-grafted polar monomer) composition is 50%-75%.

[0026] According to the present invention, preferably, the silicate is at least one of sodium silicate, aluminum silicate, magnesium silicate and calcium silicate.

[0027] Preferably, the silicate is a microporous silicate with a specific surface area of 200-600m 2 / g, preferably ...

Embodiment 1

[0073] This example illustrates the preparation of the poly(propylene grafted polar monomer) composition of the present invention.

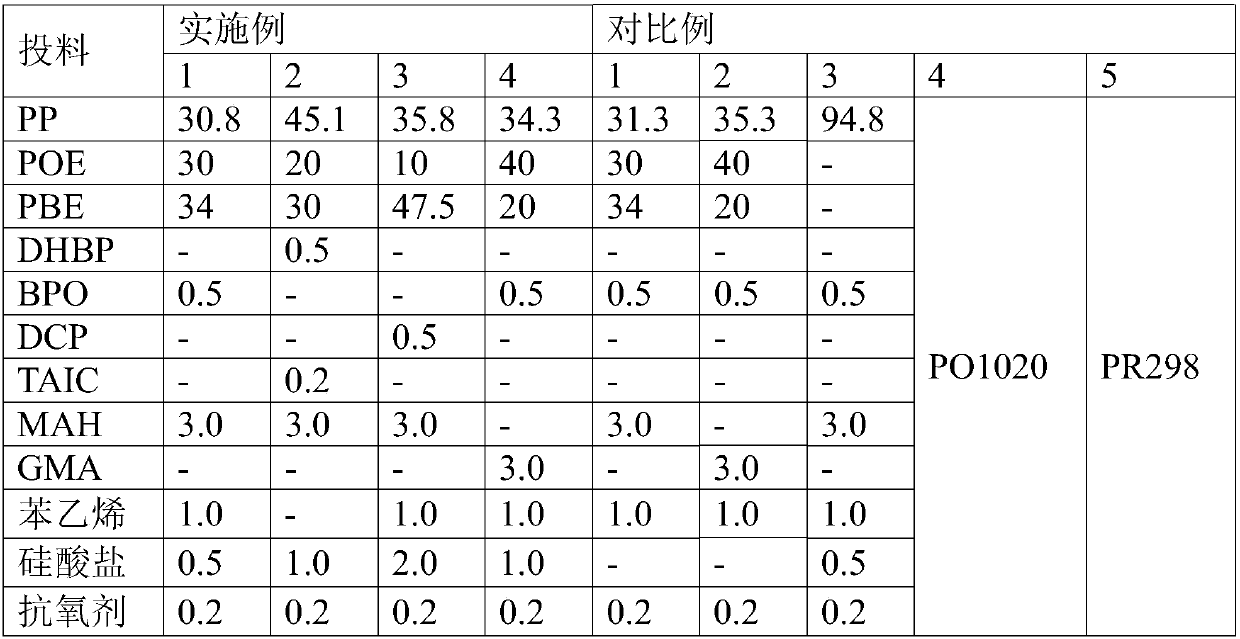

[0074] 30.8 parts by weight of homopolypropylene (PPH, grade L5E89 (Shenhua), MI=3.0g / 10min, 2.16kg, 230°C), 30.0 parts by weight of vinyl elastomer (POE, Engage 8200, MI=2.0g / 10min, 2.16kg, 190°C) and 34.0 parts by weight of propylene-based elastomer (PBE, Vistamaxx 6102, MI=1.4g / 10min, 2.16kg, 190°C) made of polyolefin elastomer (vinyl structure content is 37.6% by weight , the propenyl structure content is 44.6% by weight), 0.5 parts by weight of benzoyl peroxide (BPO), 3.0 parts by weight of maleic anhydride, 1.0 parts by weight of styrene, 0.5 parts by weight of JH100A (the specific surface area is 500m 2 / g, the average pore diameter is 0.4nm), 0.2 parts by weight of antioxidant (including antioxidant 1010 and antioxidant 168 with a weight ratio of 1:1) are fully mixed in a high-speed mixer, and then added to the twin-screw extruder machi...

Embodiment 2

[0078] This example illustrates the preparation of the poly(propylene grafted polar monomer) composition of the present invention.

[0079] 45.1 parts by weight of random copolymerized polypropylene (PPR, C4220 (Sinopec), MI=0.5g / 10min, 2.16kg, 230°C), 20 parts by weight of vinyl elastomer (POE, Engage 8200, MI=2.0g / 10min, 2.16kg, 190°C) and 30 parts by weight of propylene-based elastomer (PBE, Vistamaxx 6102, MI=1.4g / 10min, 2.16kg, 190°C) made of polyolefin elastomer (vinyl structure content is 34.4% by weight , propenyl structure content is 50.4% by weight), 0.5 parts by weight of 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane (DHBP), 0.2 parts of triallyl isocyanate (TAIC) , 3.0 parts by weight of maleic anhydride, 1.0 parts by weight of JH100A, 0.2 parts by weight of antioxidant (including antioxidant 1010 and antioxidant 168 with a weight ratio of 1:1) are fully mixed in a high-speed mixer, and then added double The screw extruder is used to carry out reaction extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com