TPEE modified thermoplastic elastomer automobile sealing strip

A thermoplastic elastomer, automotive sealing strip technology, applied in the field of TPEE modified thermoplastic elastomer automotive sealing strip, can solve the problems of affecting melt fluidity, poor plasticization, high price, etc., achieving obvious cost-effective advantages, extrusion The mold hole is large and the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) A TPEE-modified thermoplastic elastomer automobile sealing strip of the present invention is composed of base material and additives, wherein the base material is composed of PP and two kinds of thermoplastic polyene elastomer (TPE-A) and polyester elastomer TPEE (TPE-B) Composite composition; the additives include lubricants, toughening agents, compatibilizers, coupling agents, and antioxidants.

[0039] The weight ratio of the above components is preferably: TPE-A 26; TPE-B 29; PP36; Run 6; toughening agent 1.1; compatibilizer 1.2; coupling agent 0.4; antioxidant 0.3.

[0040] The toughening agent is a methacrylate-acrylate copolymer.

[0041] The lubricant is white oil.

[0042] The compatibilizer is ST-2.

[0043] The coupling agent is Si-69.

[0044] The antioxidant is tetraerythritol fat and bisphenol composition.

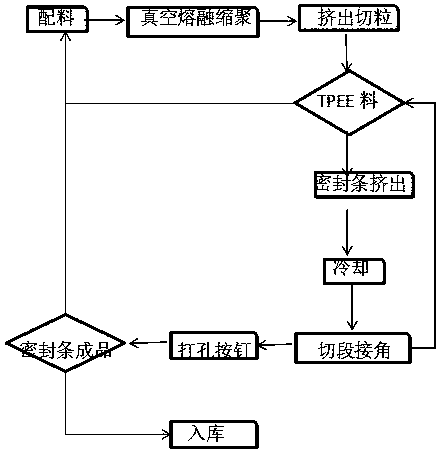

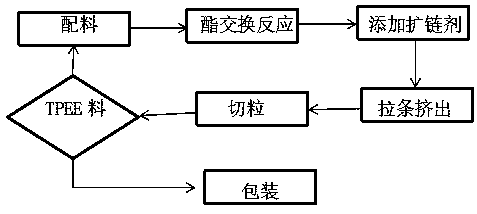

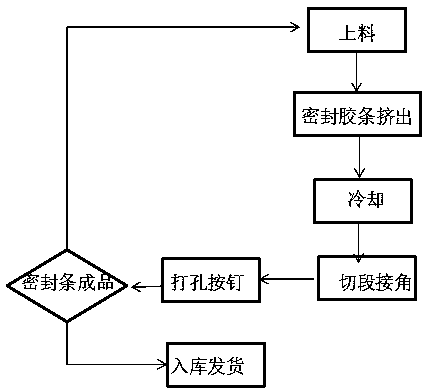

[0045] The manufacture technology of described TPEE modified thermoplastic elastomer automobile sealing strip is as follows figure 1 , figur...

Embodiment 2

[0054] A TPEE modified thermoplastic elastomer automobile sealing strip, which is composed of base material and additives, wherein the base material is composed of PP, that is, resin, and two kinds of thermoplastic polyene elastomer TPE-A and polyester elastomer TPE-B. ; The additives include lubricants, toughening agents, compatibilizers, coupling agents, antioxidants.

[0055] The weight ratio of each component is: TPE-A 35; TPE-B 530; PP540; lubricant 10; toughening agent 3; compatibilizer 2; coupling agent 0.5; antioxidant 0.5;

[0056] The toughening agent can adopt one of methacrylate-acrylic acid ester copolymer or methyl methacrylate-butadiene-styrene ternary graft copolymer or maleic anhydride grafted ethylene-octene copolymer kind.

[0057] Described lubricant can adopt a kind of in paraffin oil, white oil. Mainly used to adjust viscosity and plasticize.

[0058] The compatibilizer can be ST-2, which is used for compatibility and toughening of PE, PP and their mod...

Embodiment 3

[0071] A TPEE modified thermoplastic elastomer automobile sealing strip, which is composed of base material and additives, wherein the base material is composed of PP, that is, resin, and two kinds of thermoplastic polyene elastomer TPE-A and polyester elastomer TPE-B. ; The additives include lubricants, toughening agents, compatibilizers, coupling agents, antioxidants.

[0072] The weight ratio of the above components is: TPE-A 25; TPE-B 20; PP30; lubricant 5; toughening agent 1; compatibilizer 1; coupling agent 0.1; antioxidant 0.1.

[0073] The toughening agent can adopt one of methacrylate-acrylic acid ester copolymer or methyl methacrylate-butadiene-styrene ternary graft copolymer or maleic anhydride grafted ethylene-octene copolymer kind.

[0074] Described lubricant can adopt a kind of in paraffin oil, white oil. Mainly used to adjust viscosity and plasticize.

[0075] The compatibilizer can be ST-2, which is used for compatibility and toughening of PE, PP and their ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com