Low-emission low-odor glass-fiber-reinforced polypropylene composite material and preparation method therefor

A technology of polypropylene material and low odor, which is applied in the field of polymer materials and can solve the problems of frosting and whitening on the surface of materials, low odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

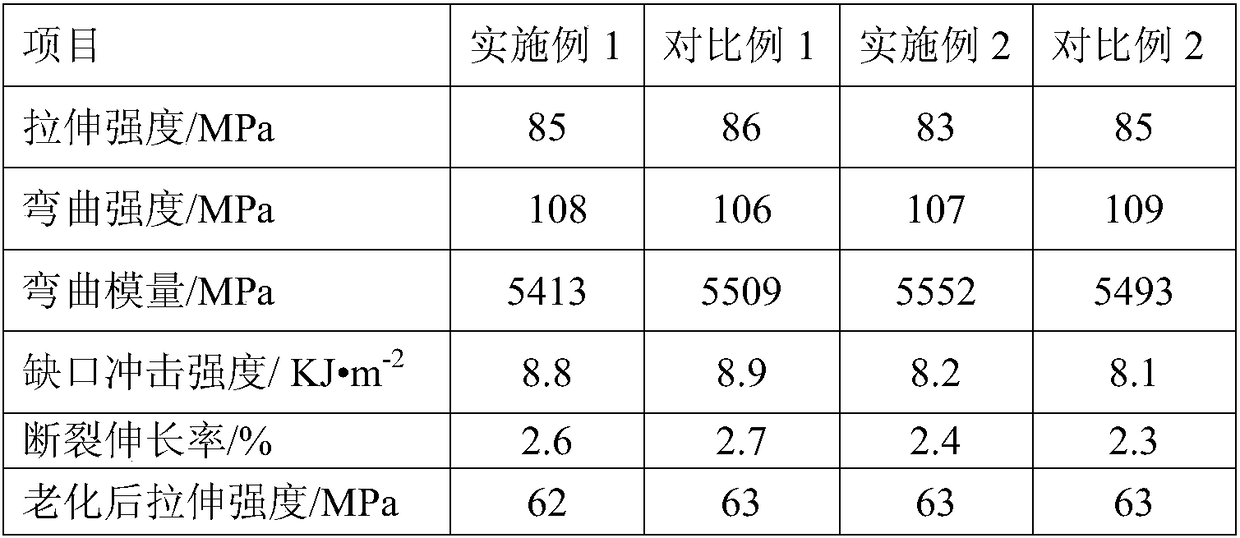

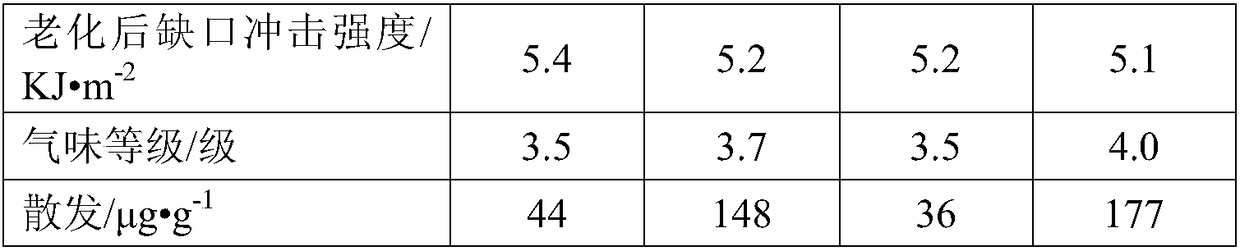

Examples

Embodiment 1~2

[0024] This embodiment relates to a low emission and low odor glass fiber reinforced polypropylene composite material and its preparation method, the method is as follows:

[0025] Step 1, weighing the raw materials according to the weight ratio, each component and its data are shown in Table 1;

[0026] Step 2, the raw material polypropylene, glass fiber, compatibilizer and antioxidant weighed according to the weight ratio are added to the high-speed mixer in proportion and fully mixed, and then the above mixture is added to the extruder, and the extruder is passed through the extruder After plasticizing, extrude, draw, cool, and pelletize to 3-5mm long cylindrical particles, and finally obtain low-emission and low-odor glass fiber reinforced polypropylene composite materials. The temperature of the screw extruder is 100-220° C., and the rotation speed of the main engine is 300 rpm.

[0027] Among them, the polypropylene is provided by Sinopec Company, the brand is M60T; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com