Low odor and low VOC flame retardant modified HIPS material and preparation method thereof

A low-odor, modified technology, applied in the field of polymer materials, can solve the problems of strong odor and poor flame retardant performance, and achieve the effects of reduced odor, low VOC content, and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

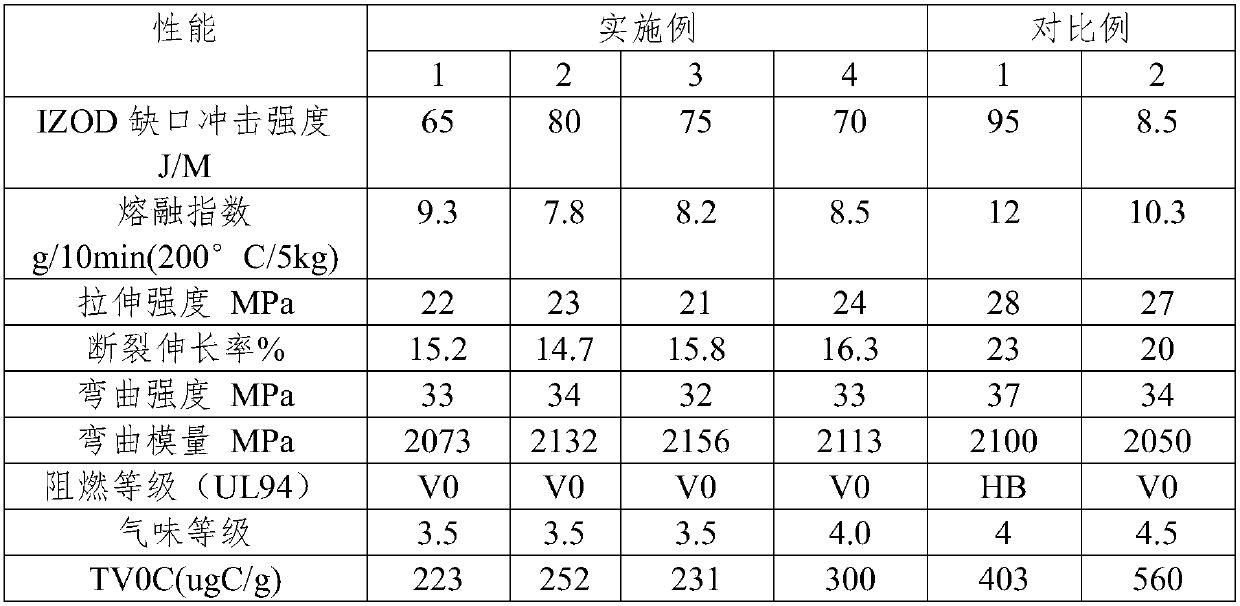

Examples

Embodiment 1

[0054] In this embodiment, the low-odor, low-VOC flame-retardant modified HIPS material is made of the following raw materials in parts by weight: 74.7 parts of HIPS resin, 15 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 3 parts of toughening agent SBS, processed 2 parts of additives, 0.3 parts of antioxidant, 3 parts of zeolite powder;

[0055] The preparation method of the low-odor, low-VOC flame-retardant modified HIPS material of this embodiment comprises the following steps:

[0056]S1. Weigh each raw material according to parts by weight, put HIPS, toughening agent, processing aid, and antioxidant into a mixer and mix for 4 minutes to obtain a mixed material;

[0057] S2. Feed the mixed material prepared in step S1 from the main feeding port of the twin-screw extruder, feed the flame retardant and odor adsorbent from the side material port of the twin-screw extruder, mix, extrude and granulate That's it.

[0058] Among them, the length-to-diameter rati...

Embodiment 2

[0060] In this embodiment, the low-odor, low-VOC flame-retardant modified HIPS material is made of the following raw materials in parts by weight: 74.7 parts of HIPS resin, 15 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 3 parts of toughening agent SBS, processed 2 parts of additives, 0.3 parts of antioxidant, 3 parts of hydrotalcite;

[0061] The preparation method of the low-odor, low-VOC flame-retardant modified HIPS material in this example is the same as that in Example 1.

Embodiment 3

[0063] In this embodiment, the low-odor, low-VOC flame-retardant modified HIPS material is made of the following raw materials in parts by weight: 74.7 parts of HIPS resin, 15 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 3 parts of toughening agent SBS, processed 2 parts of additives, 0.3 parts of antioxidant, 3 parts of carbon black;

[0064] The preparation method of the low-odor, low-VOC flame-retardant modified HIPS material in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com