Rubber composition for low-smell tire and tire thereof

A rubber composition and low-odor technology, applied in the field of rubber tire manufacturing, can solve the problem that tire odor is difficult to remove or even reduce, and achieve the effect of blocking aging cracks and using a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

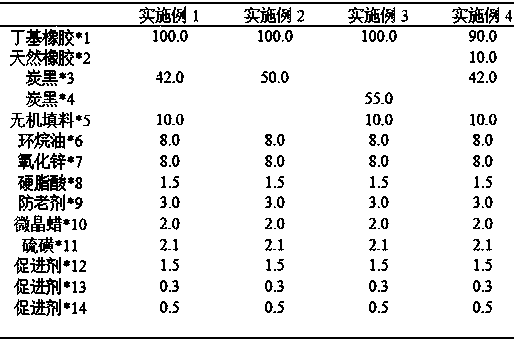

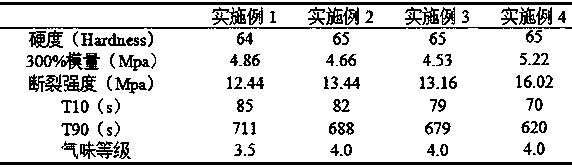

Embodiment 1-4

[0066] The preparation of embodiment 1-4 rubber composition follows the steps:

[0067] This process uses a series type one-time method internal mixer, controls the rotor speed of the internal mixer to 50rpm, and the pressure on the top bolt is 55N / cm 2 , The cooling water temperature of the internal mixer is 30~40°C.

[0068] Upper auxiliary machine process:

[0069] 1. Add rubber, carbon black, inorganic filler, zinc oxide, stearic acid, anti-aging agent, microcrystalline wax, press the top bolt to raise the temperature of the rubber to 100°C;

[0070] 2. Raise the top bolt to add naphthenic oil and keep it for 5 seconds;

[0071] 3. Press the top bolt to raise the temperature of the rubber to 140°C;

[0072] 4. Press the top bolt to make the rubber mix at a constant temperature of 150 ° C ~ 155 ° C for 120 seconds;

[0073] 5. Discharge the rubber material to the lower auxiliary machine.

[0074] Lower auxiliary machine process:

[0075] 1. Raise the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com