Micro-foamed sealant with low odor and low voc

A sealing strip and micro-foaming technology, which is applied in the field of rubber production and processing, can solve the problems of large odor and VOC of the sealing strip, waste materials in processing, increase pollution products, etc., and achieve a good feel, reduce processing costs and reduce VOC content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

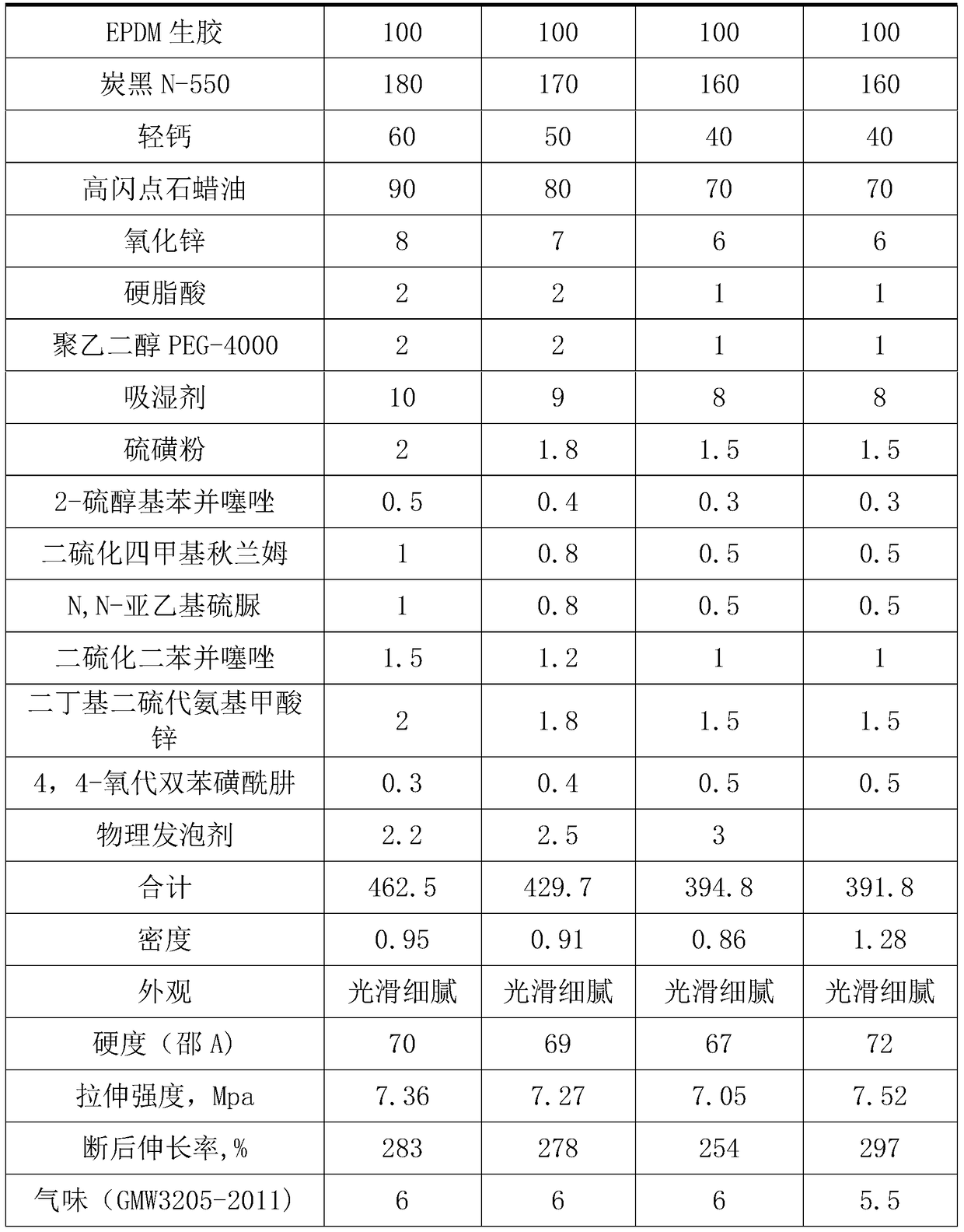

[0013] A low-odor and low-VOC micro-foaming sealing strip disclosed by the invention comprises the following raw materials in parts by mass: 100 parts of EPDM raw rubber, 160-180 parts of carbon black, 40-60 parts of light calcium, paraffin wax 70-90 parts of oil, 6-8 parts of zinc oxide, 1-2 parts of stearic acid, 1-2 parts of surfactant PEG-4000, 8-10 parts of hygroscopic agent, 1.5-2 parts of sulfur powder 0.5-1 part of accelerator TMTD, 0.5-1 part of accelerator NA-22, 1-1.5 parts of accelerator DM, 1.5-2 parts of accelerator ZDBC, and 0-3 parts of physical foaming agent. It also includes 0.3-0.5 parts of accelerator MBT and 0.3-0.5 parts of foaming agent OBSH. Preferably, the accelerator MBT is 0.3-0.4 parts, and the blowing agent OBSH is 0.4-0.5 parts.

[0014] Of course, the range of mass fractions of some raw materials can also be appropriately narrowed, that is, raw materials including the following mass fractions: 100 parts of EPDM raw rubber, 170-180 parts of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com