Low odor passenger car rubber seal

A technology for rubber sealing strips and passenger cars, applied in the field of rubber modification, can solve the problems of unpleasant smell, breakage, ozone aging resistance, etc., and achieve the effects of reducing the dosage, improving the odor level and increasing the vulcanization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

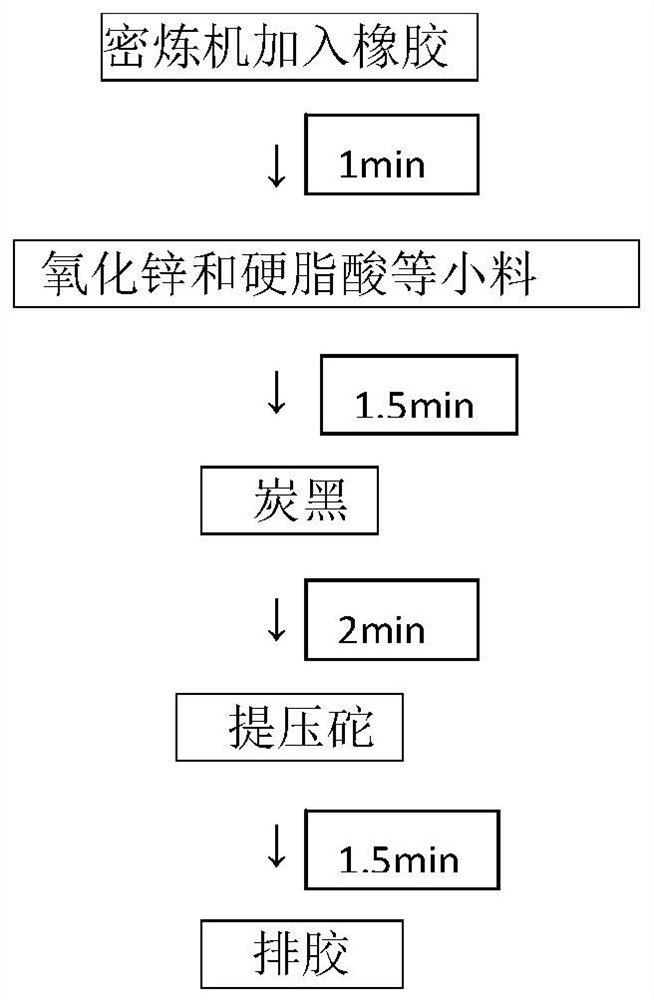

[0028] Weigh 60 parts of HVPBR glue solution and mix with 40 parts of BIR glue solution, then add 25 parts of cashew nut shell oil, stir, and dry by steam condensation. After the compound rubber was masticated in the mixer for 1 minute, small materials such as zinc oxide and stearic acid were added for 1 minute, and 50 parts of carbon black were weighed for 3 minutes, discharged, and sulfur and accelerator were added to the mixer for 5 minutes. The back piece is left, and after 16 hours of parking, the rubber composite material is obtained by vulcanization.

Embodiment 2

[0030] Weigh 70 parts of HVPBR rubber and mix with 30 parts of BIR glue, then add 5 parts of cashew nut shell oil, stir, and dry by steam condensation. After the compound rubber was masticated in the mixer for 1 minute, small materials such as zinc oxide and stearic acid were added for 1 minute, and 50 parts of carbon black were weighed for 3 minutes, discharged, and sulfur and accelerator were added to the mixer for 5 minutes. After 24 hours of parking, the rubber composite material was obtained by vulcanization.

Embodiment 3

[0032] Weigh 80 parts of HVPBR rubber and mix with 20 parts of BIR glue, then add 30 parts of cashew nut shell oil, stir, and dry by steam condensation. After the compound rubber was masticated in the mixer for 1 minute, small materials such as zinc oxide and stearic acid were added for 1 minute, and 50 parts of carbon black were weighed for 3 minutes, discharged, and sulfur and accelerator were added to the mixer for 5 minutes. The back piece is put down, parked for 20 hours, and then vulcanized to obtain a rubber composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com