Low-odor glass fiber reinforced modified resin ASA composite material and preparation method thereof

A technology for modifying resin and glass fiber, which is applied in the field of glass fiber reinforced modified resin ASA composite material, low odor glass fiber reinforced modified resin ASA composite material and its preparation field, which can solve the problems that need to be studied, are expensive, and have low VOC. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

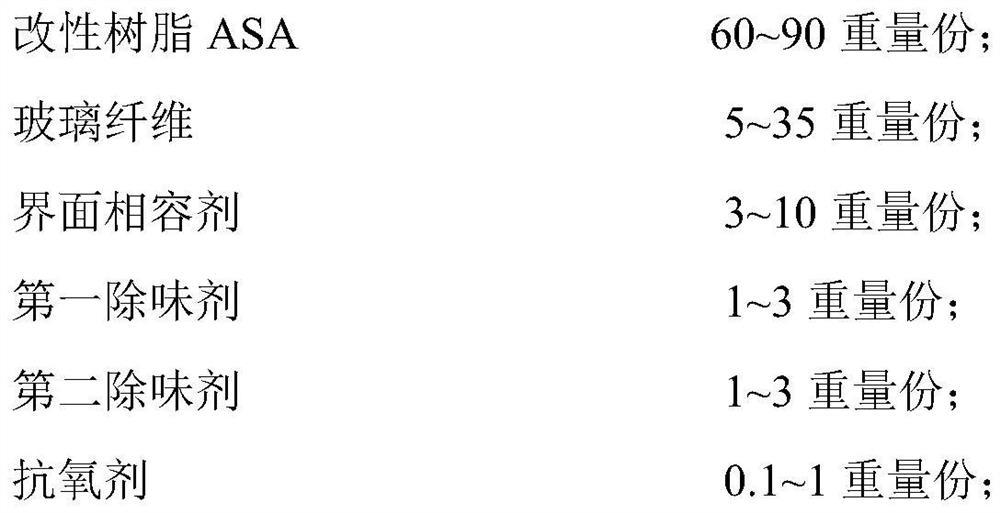

Method used

Image

Examples

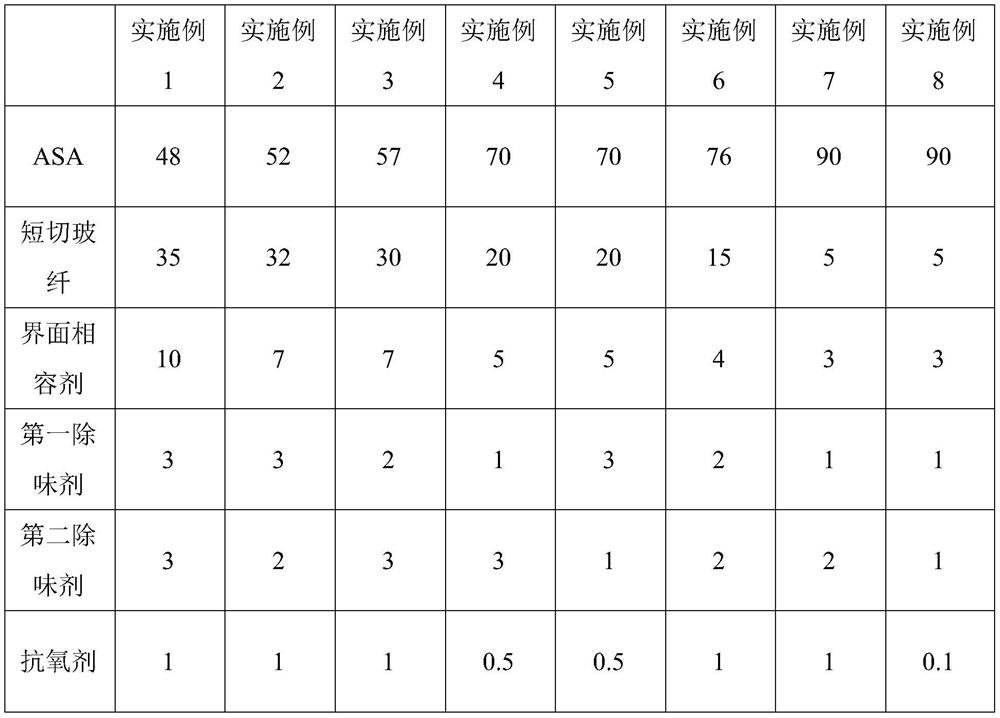

Embodiment 1

[0042] Weigh each component according to the data of Example 1 shown in Table 1, mix the components other than the chopped glass fiber reinforced system uniformly in a high-speed mixer, and put them into the main feeding bin of the twin-screw extruder , the chopped glass fiber reinforced system is put into the side feeding bin, the screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 35, and the temperature of each zone of the main barrel from the feed port to the exit of the machine head is set as: 180°C , 210°C, 230°C, 240°C, 240°C, 240°C, 240°C, the speed of the host machine is 150 rpm, after melt extrusion, cooling, granulation, and drying, the low-odor glass fiber reinforced modified Resin ASA composite material.

Embodiment 2

[0044] Weigh each component according to the data of Example 2 shown in Table 1, mix the components other than the chopped glass fiber reinforced system uniformly in a high-speed mixer, and put them into the main feeding bin of the twin-screw extruder , the chopped glass fiber reinforced system is put into the side feeding bin, the screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 35, and the temperature of each zone of the main barrel from the feed port to the exit of the machine head is set as: 180°C , 210°C, 230°C, 240°C, 240°C, 240°C, 240°C, the speed of the host machine is 150 rpm, after melt extrusion, cooling, granulation, and drying, the low-odor glass fiber reinforced modified Resin ASA composite material.

Embodiment 3

[0046] Weigh each component according to the data of Example 3 shown in Table 1, mix the components other than the chopped glass fiber reinforced system uniformly in a high-speed mixer, and put them into the main feeding bin of the twin-screw extruder , the chopped glass fiber reinforced system is put into the side feeding bin, the screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 35, and the temperature of each zone of the main barrel from the feed port to the exit of the machine head is set as: 180°C , 210°C, 230°C, 240°C, 240°C, 240°C, 240°C, the speed of the host machine is 150 rpm, after melt extrusion, cooling, granulation, and drying, the low-odor glass fiber reinforced modified Resin ASA composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com