Polyformaldehyde composition and preparation method thereof

A technology of polyoxymethylene composition and polyoxymethylene resin, which is applied in the field of engineering plastics and can solve problems such as formaldehyde emission, odor, and mechanical properties research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

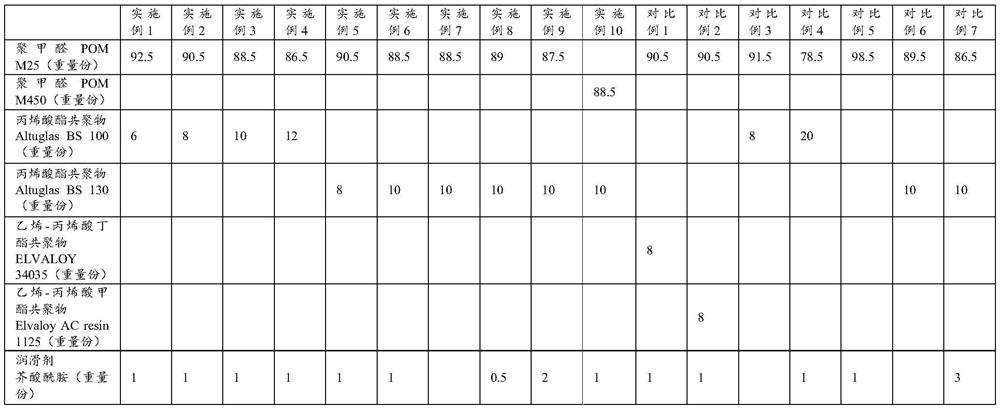

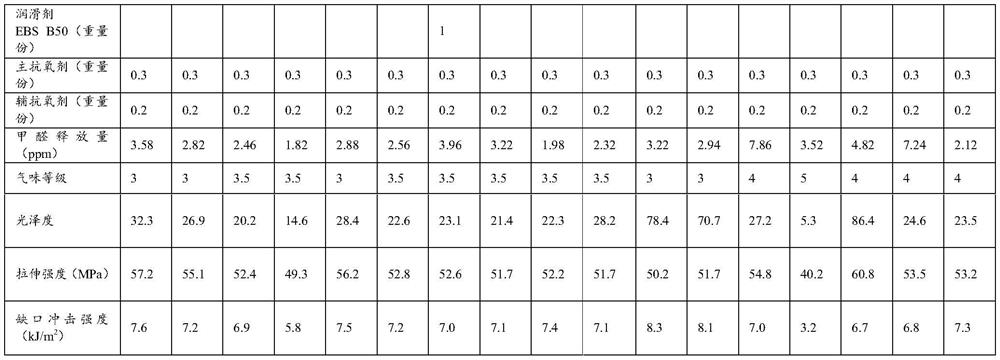

[0021] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. Those skilled in the art should understand that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0022] In the examples, the experimental methods used are conventional methods unless otherwise specified, and the materials and reagents used are commercially available unless otherwise specified.

[0023] The source of raw materials used in the following examples and comparative examples is as follows:

[0024] Polyoxymethylene resin:

[0025] POM M25, purchased from Yunnan Yuntianhua Co., Ltd., with a melt index of 2.5g / 10min (ISO1133-2011, 190°C / 2.16kg) and a density of 1.4g / cm 3 ;

[0026] POM M450, purchased from Yunnan Yuntianhua Co., Ltd., with a melt index of 45g / 10min (ISO1133...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com