Low-odor polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, applied in the field of low-odor polypropylene composite materials and its preparation, and polypropylene composite materials, can solve problems such as unpleasant and irritating odors, achieve the improvement of special irritating odor problems, low cost, The effect of lowering the odor level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

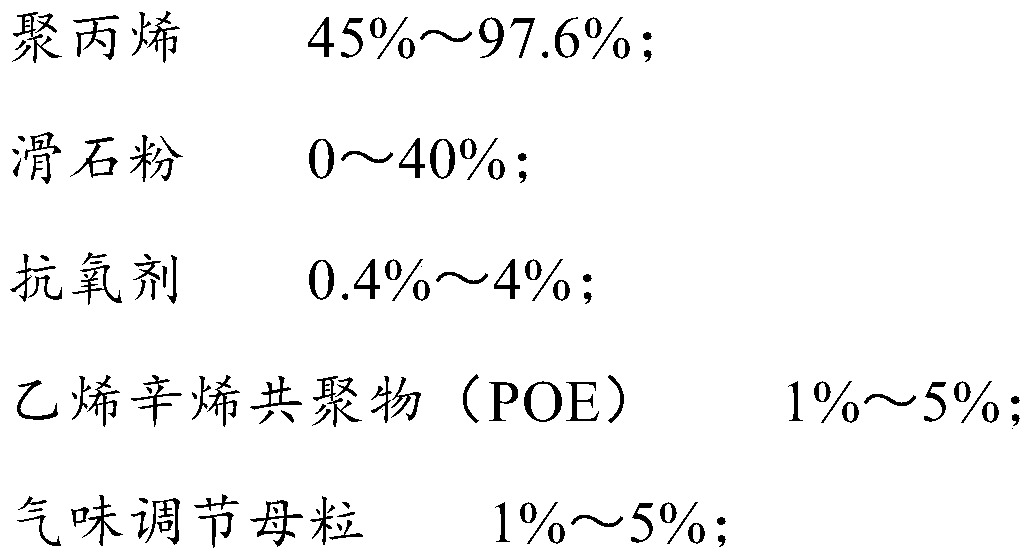

Method used

Image

Examples

experiment example 1

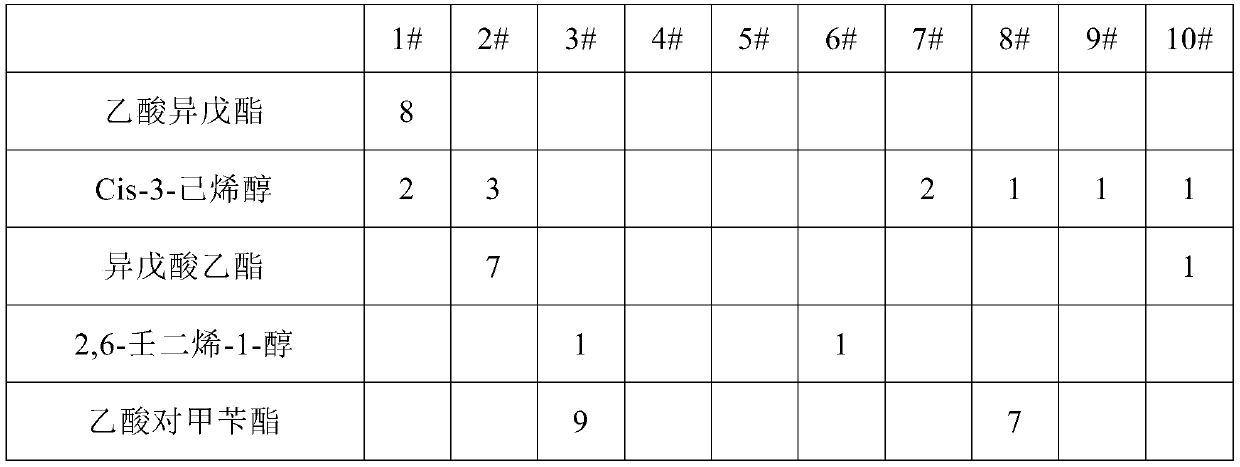

[0030] Experimental Example 1: Preparation of low-odor masterbatch

[0031] Dissolve the odor modifier in Table 1 in an aqueous ethanol solution with a mass fraction of 10% to 60%; then physically blend it with the carrier polypropylene in a proportion of 0.01% to 1.0%, and place it in a vacuum oven at 50° C. Under vacuum drying for 24h, the odor regulating master batch of polypropylene was obtained;

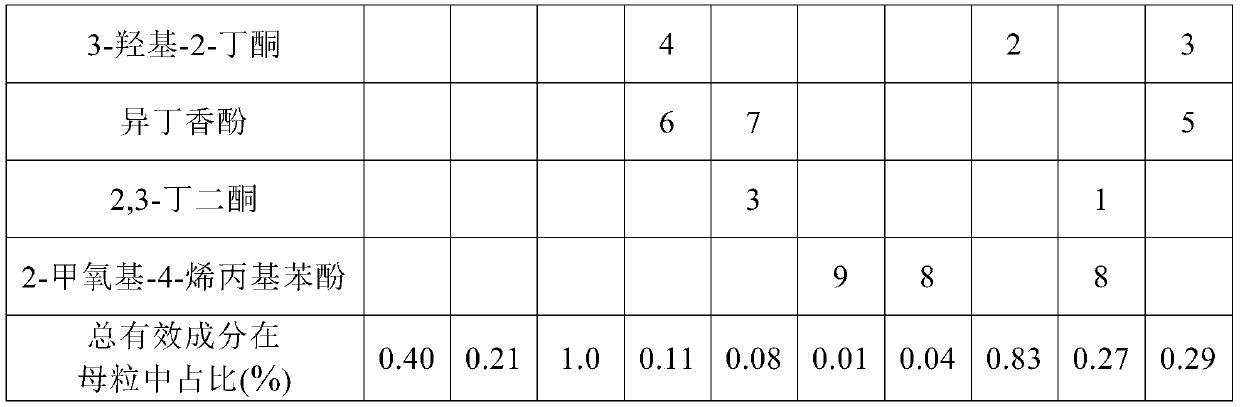

[0032] Table 1 The mass ratio of active ingredients in the odor regulating masterbatch 1#~10#

[0033]

[0034]

Embodiment 1~10

[0035] Examples 1-10 and Comparative Examples 1-3

[0036] Table 2 is the mass ratio of each component ratio in Examples 1-10 and Comparative Examples 1-3, wherein the odor regulating masterbatch is 2 parts by mass.

[0037] The specific preparation methods of Examples 1 to 10 are the same as those of Comparative Examples 1 to 3.

[0038] The raw materials are weighed according to the proportions of the components shown in Table 2, mixed uniformly in the high-speed mixer, placed in the main feeding bin of the meshing co-rotating twin-screw extruder, and fed into the extruder through the feeding screw. In the barrel, the talcum powder reinforced system is added to the extruder from the side feeding port. The diameter of the extruder screw is 35mm, the length-diameter ratio L / D is 40, and the vacuum degree is not lower than -0.08MPa. The temperature of each zone from the feeding port to the outlet of the machine head is set as: 180 ℃-230 ℃, the main engine speed is 400-550 r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com