Chemical substance-resistant low odor polypropylene composite material and preparation method thereof

A technology of chemical resistance and composite materials, applied in the field of polypropylene composite materials and its preparation, can solve problems such as low production efficiency, uncontinuous process, complicated steps, etc., achieve improved strength and stiffness, good chemical resistance, and improved adsorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

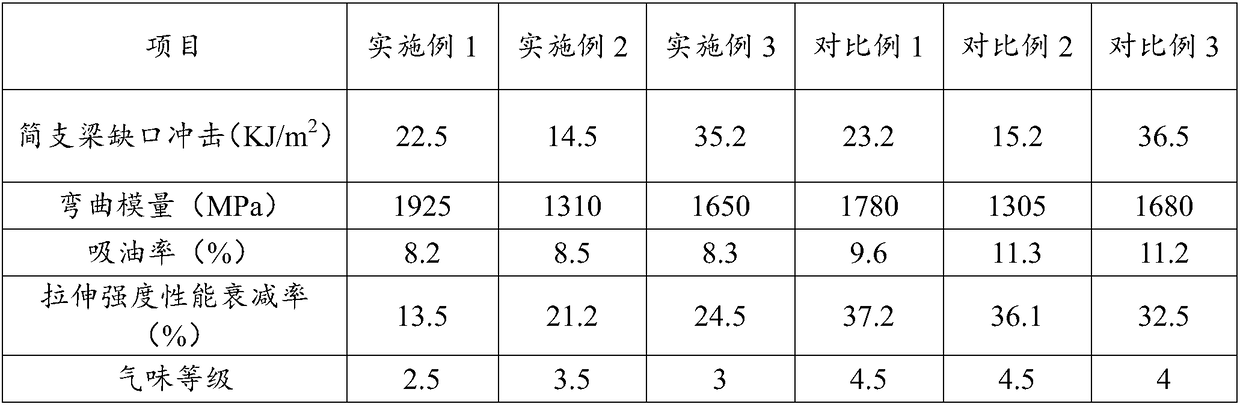

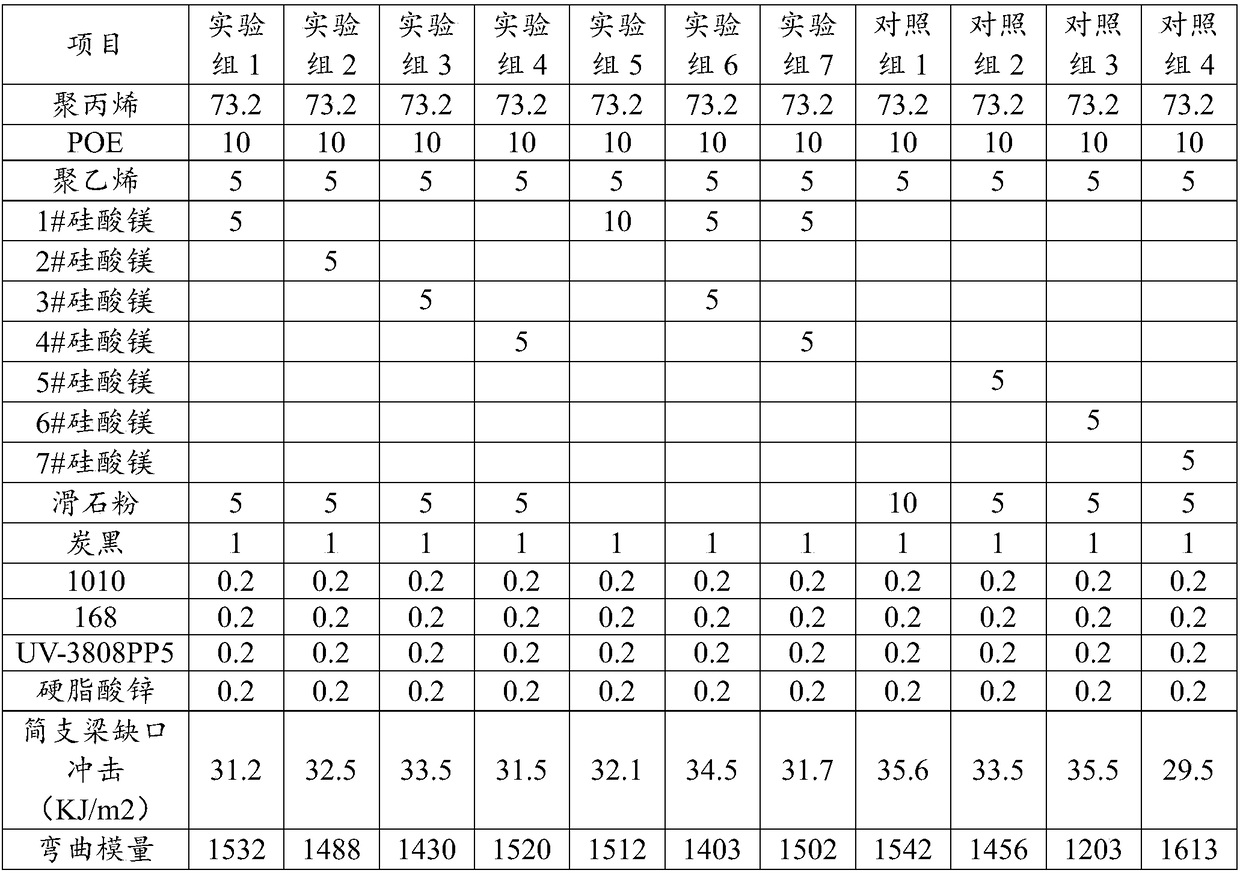

Examples

Embodiment 4

[0046] The present embodiment sets experimental group 1~7 and control group 1~4, the formula of experimental group 1~7 and control group 1~4 and the performance data measured are as shown in table 4 (the test method of performance is the same as above) :

[0047] Table 4 Formulas and measured performance data results of experimental groups 1-7 and control groups 1-4

[0048]

[0049]

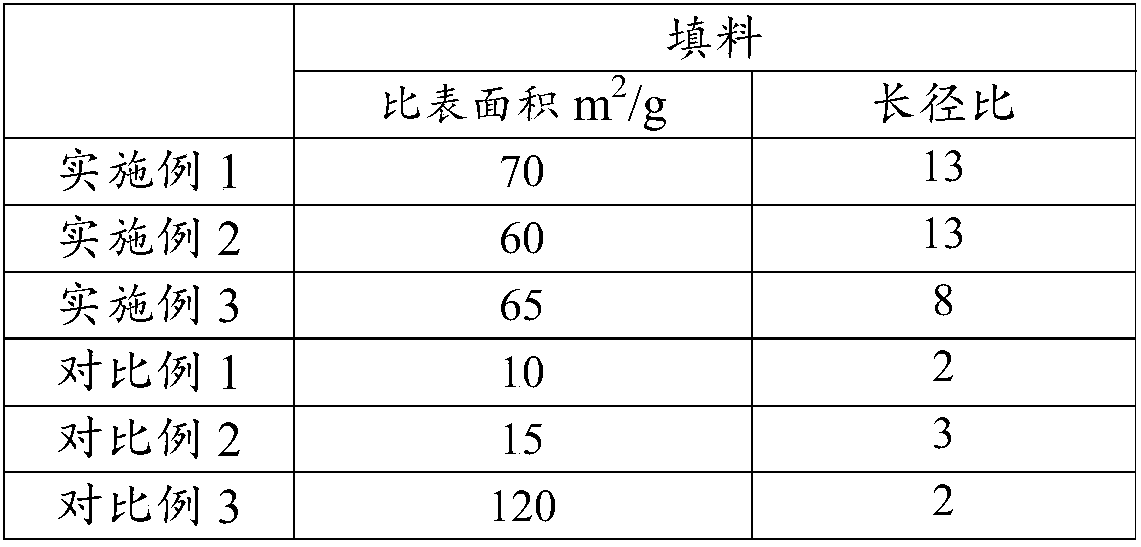

[0050] Wherein, the performance indexes of the magnesium silicate adopted by experimental groups 1-7 and matched groups 2-4 are as shown in table 5:

[0051] Table 5 Performance indicators of magnesium silicate used in experimental groups 1 to 7 and control groups 2 to 4

[0052] Magnesium silicate grade

1#

2#

3#

4#

5#

6#

7#

Specific surface area m 2 / g

70

60

65

55

15

120

18

13

13

8

13

3

2

25

[0053] As can be seen from Table 4 and Table 5, the experimental groups 1, 2, and 5 select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com