Low-odor flame-retardant nylon 6 composite material and preparation method thereof

A technology of flame retardant nylon and composite materials, applied in the field of nylon composite materials, can solve the problems of inability to apply and the smell of brominated flame retardants, and achieve the effects of low odor, improved flame retardant effect, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

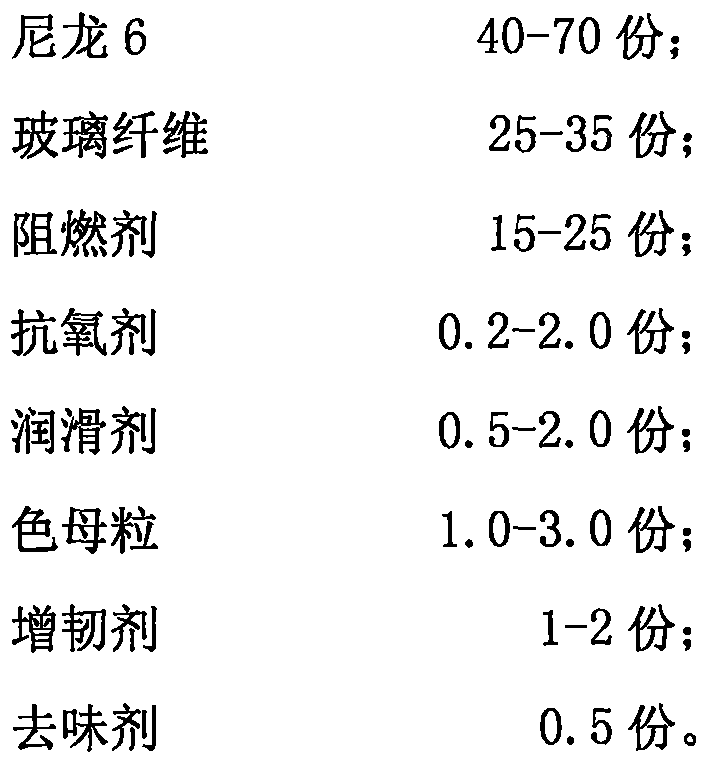

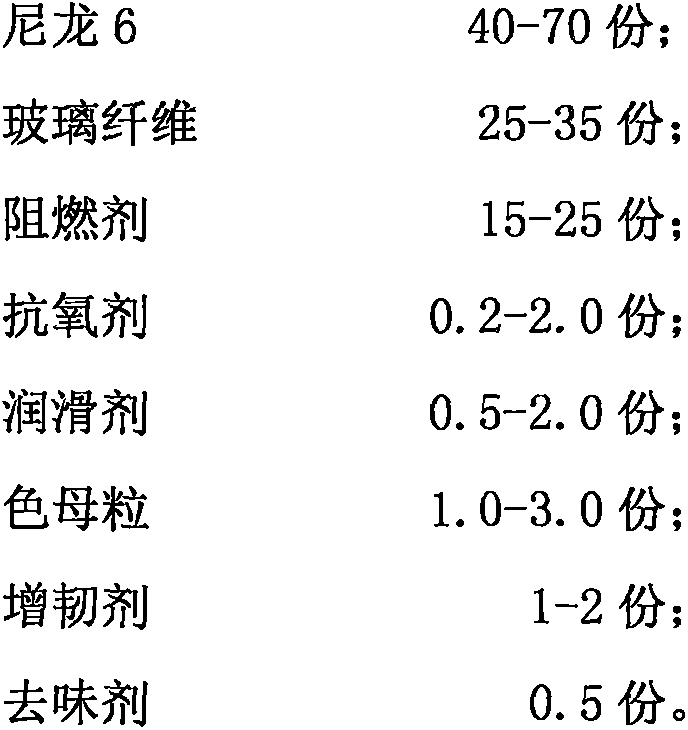

Method used

Image

Examples

Embodiment 1

[0027] Step 1. First place the regenerated nylon 6 (relative viscosity 2.7) in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 1‰; then weigh 50kg of dried nylon 6 and 1.5kg of ethylene octene for copolymerization Elastomer-maleic anhydride copolymer (toughener), 0.25kg N,N'-1,6-hexylene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propane Amide] (antioxidant), 0.25kg three (2,4-di-tert-butylphenyl) phosphite (antioxidant), 15kg melamine cyanurate (flame retardant), 1.5kg silicone powder ( lubricant), 6kg melamine polyphosphate (flame retardant), 2kg black masterbatch, 0.5kg deodorant, 1.0kg bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite (antioxidant), And add them together in a high-speed mixer and stir until they are evenly mixed to obtain a mixture;

[0028] Step 2. Add the mixture obtained in Step 1 and 30kg of alkali-free chopped glass fibers into a twin-screw extruder with a length-to-diameter ratio of 40:1 through the main feed an...

Embodiment 2

[0030] Step 1. First place the regenerated nylon 6 (relative viscosity 2.7) in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 1‰; then weigh 50kg of dried nylon 6 and 1.5kg of ethylene octene for copolymerization Elastomer-maleic anhydride copolymer (toughener), 0.25kg N,N'-1,6-hexylene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide ] (antioxidant), 0.25kg three (2,4-di-tert-butylphenyl) phosphite (antioxidant), 10kg melamine cyanurate (flame retardant), 1.5kg silicone powder (lubrication agent), 5kg melamine polyphosphate (flame retardant), 5kg sodium hypophosphite (flame retardant), 2kg black masterbatch, 0.5kg deodorant, 1.0kg bis(2,4-di-tert-butylphenyl) pentaerythritol di Phosphite (antioxidant), and it is added together in the high-speed mixer and stirred and mixed until uniform, to obtain the mixture;

[0031] Step 2. Add the mixture obtained in Step 1 and 30kg of alkali-free chopped glass fibers into a twin-screw extruder with ...

Embodiment 3

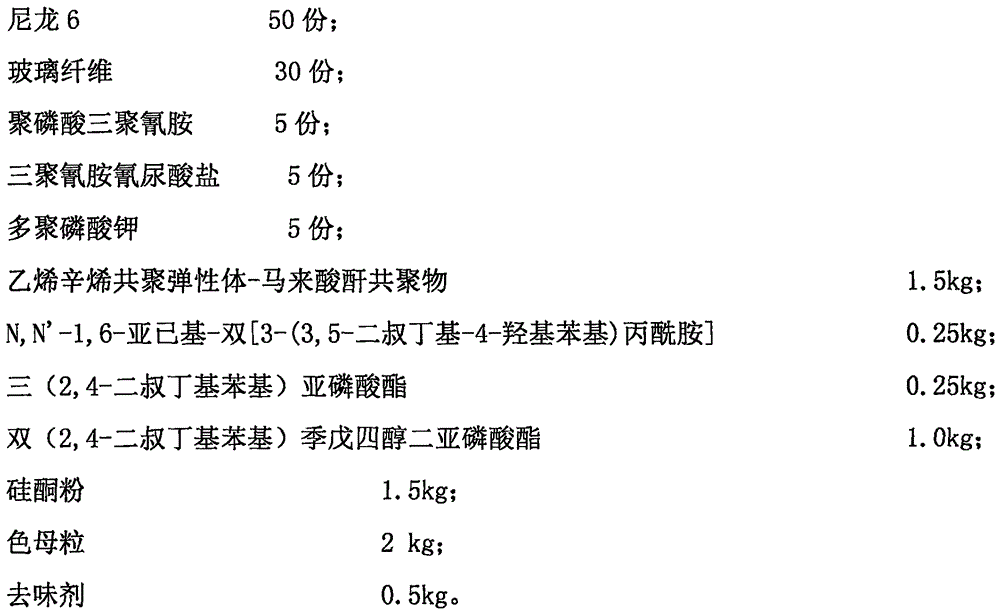

[0033] Step 1. First place the regenerated nylon 6 (relative viscosity 2.7) in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 1‰; then weigh 50kg of dried nylon 6 and 1.5kg of ethylene octene for copolymerization Elastomer-maleic anhydride copolymer (toughener), 0.25kg N,N'-1,6-hexylene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide ] (antioxidant), 0.25kg three (2,4-di-tert-butylphenyl) phosphite (antioxidant), 5kg melamine cyanurate (flame retardant), 1.5kg silicone powder (lubricating agent), 5kg melamine polyphosphate (flame retardant), 5kg potassium polyphosphate, 2kg black masterbatch, 0.5kg deodorant, 1.0kg bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite ( Antioxidant), and it is added together in the high-speed mixer and is stirred and mixed until uniform, and the mixture is obtained;

[0034] Step 2. Add the mixture obtained in Step 1 and 30kg of alkali-free chopped glass fibers into a twin-screw extruder with a lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com