Skin layer composition, foaming layer composition and low-odor PVC artificial leather prepared from skin layer composition and foaming layer composition

A composition and skin layer technology, applied in the field of low-odor PVC artificial leather, can solve the problems of high odor level, affecting the user's pleasantness, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

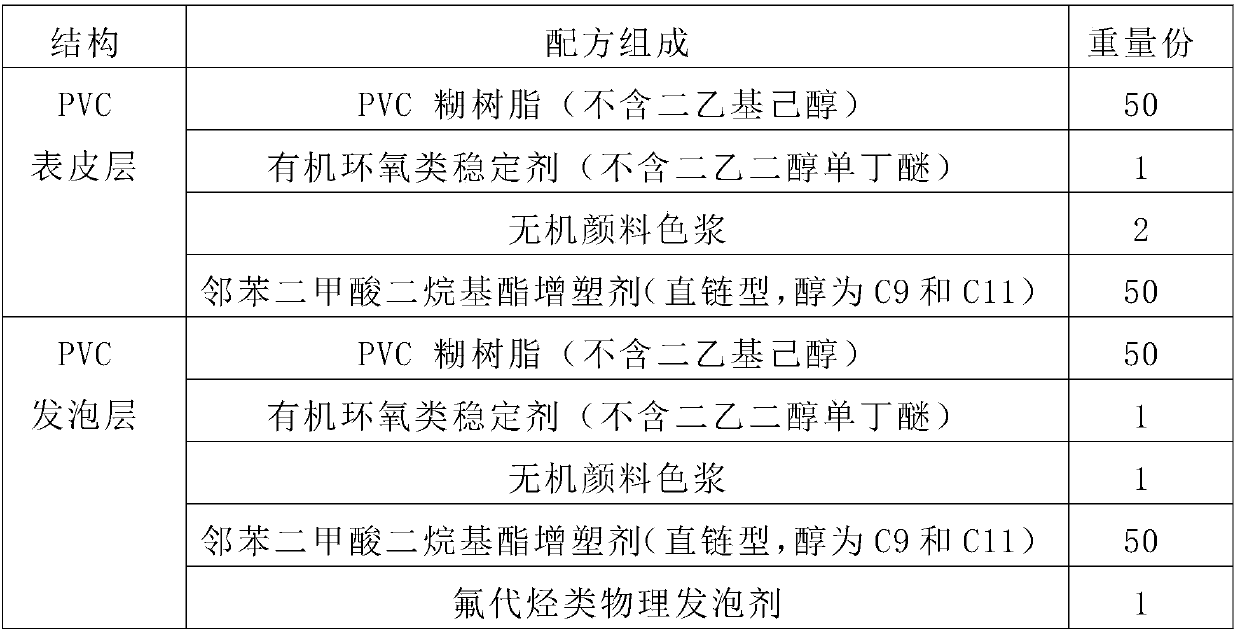

Embodiment 1

[0049] Follow the steps below to prepare low-odor PVC artificial leather:

[0050] Slurry mixing: According to the formulas of the PVC skin layer and the foam layer given in Table 1, the slurry of the PVC skin layer and the slurry of the PVC foam layer were prepared respectively by conventional stirring and mixing.

[0051] Coating: send the release paper, after the sent release paper is stored by the release paper (through the storage of the release paper, there is no need to stop when the release paper is replaced, so as to realize continuous production), firstly coat on the coating machine Spread the slurry of the PVC skin layer and dry it in a drying pipeline at 180°C for 30 seconds. After cooling, it is further sent to the coating machine, and the slurry of the PVC foam layer is coated on the PVC skin layer, and baked in a drying pipeline at 180° C. for 30 seconds. After cooling, the surface of the PVC foam layer is coated with a backcoat with water-based polyurethane sy...

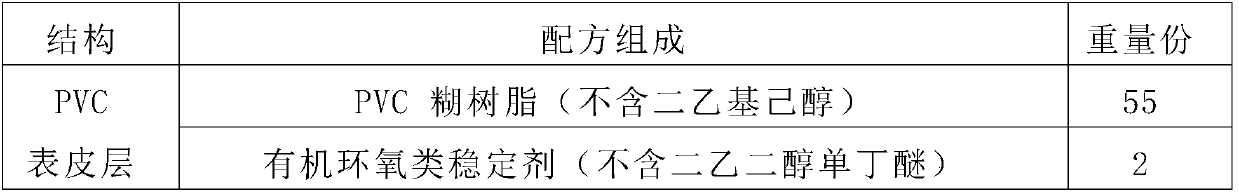

Embodiment 2

[0059] According to the formula of PVC skin layer and foam layer given in Table 2, according to the preparation method of PVC artificial leather in Example 1, prepare PVC artificial leather product. The PVC artificial leather thus obtained can be applied to automobile door panels.

[0060] Table 2

[0061]

[0062]

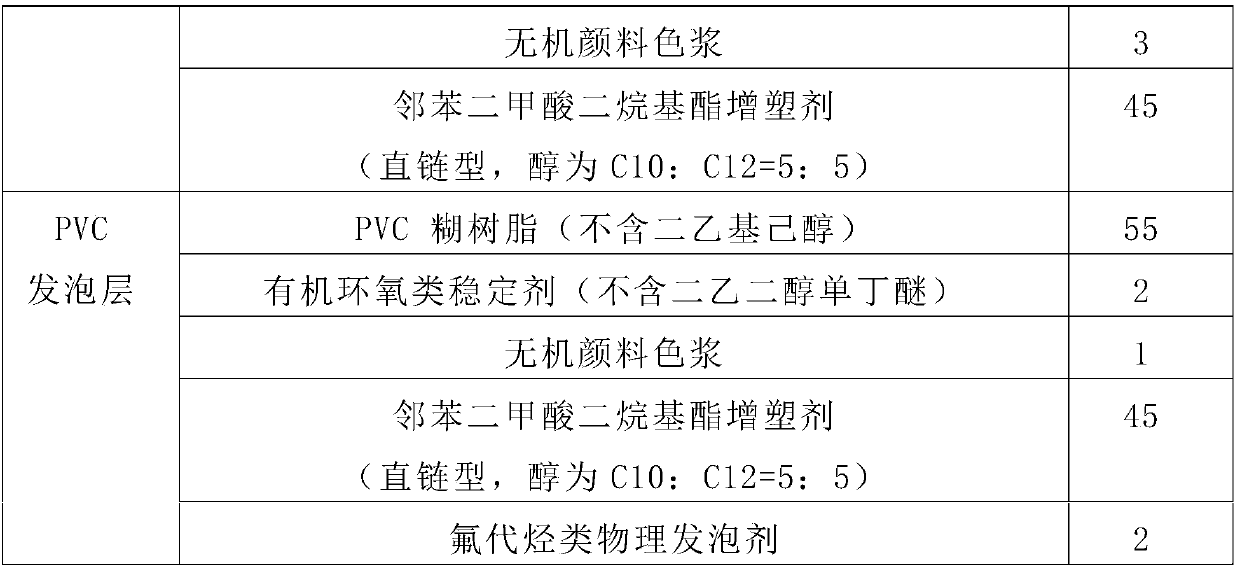

Embodiment 3

[0064] According to the formula of the PVC skin layer and the foaming layer given in Table 3, according to the preparation method of PVC artificial leather in Example 1, a PVC artificial leather product was prepared. The PVC artificial leather thus obtained can be applied to automobile door panels.

[0065] table 3

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com