Device and method for dosed filling of containers, particularly cardboard/plastic composite packaging

A composite material and cardboard technology, which is applied in the field of cardboard/plastic composite material packaging, can solve the problems of not being able to produce a homogeneous mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

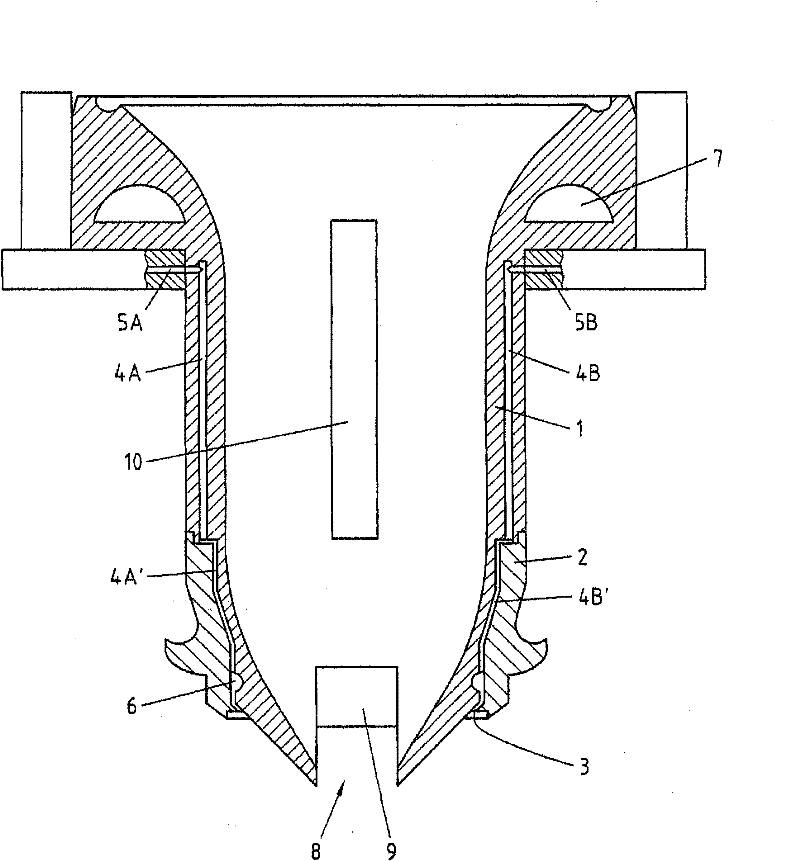

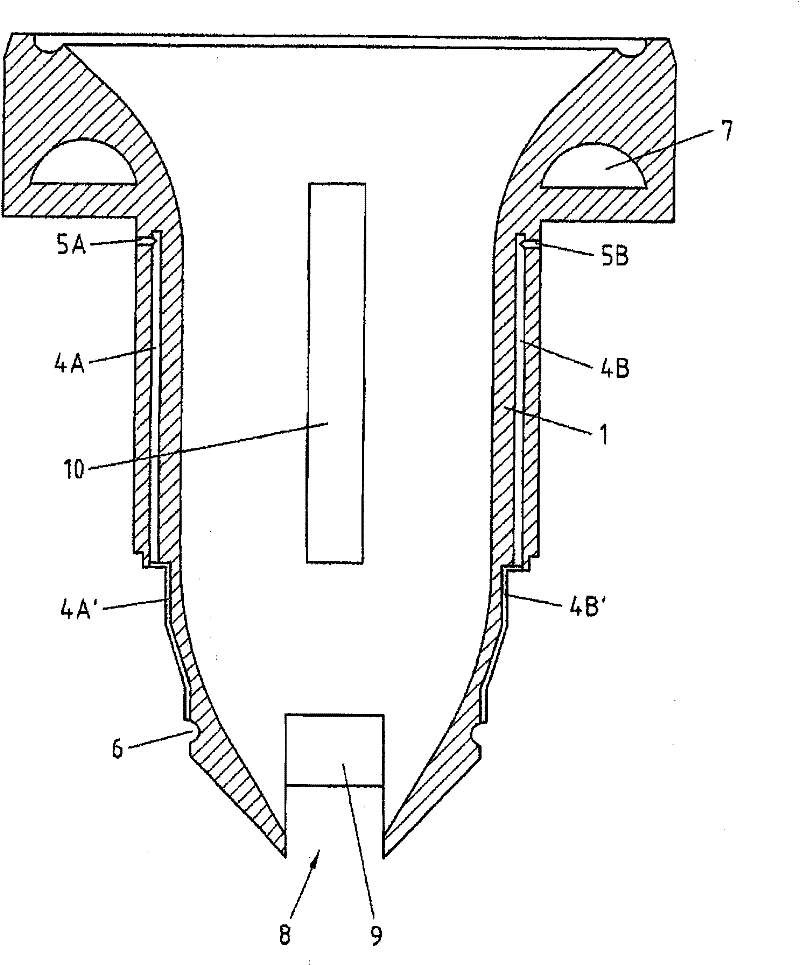

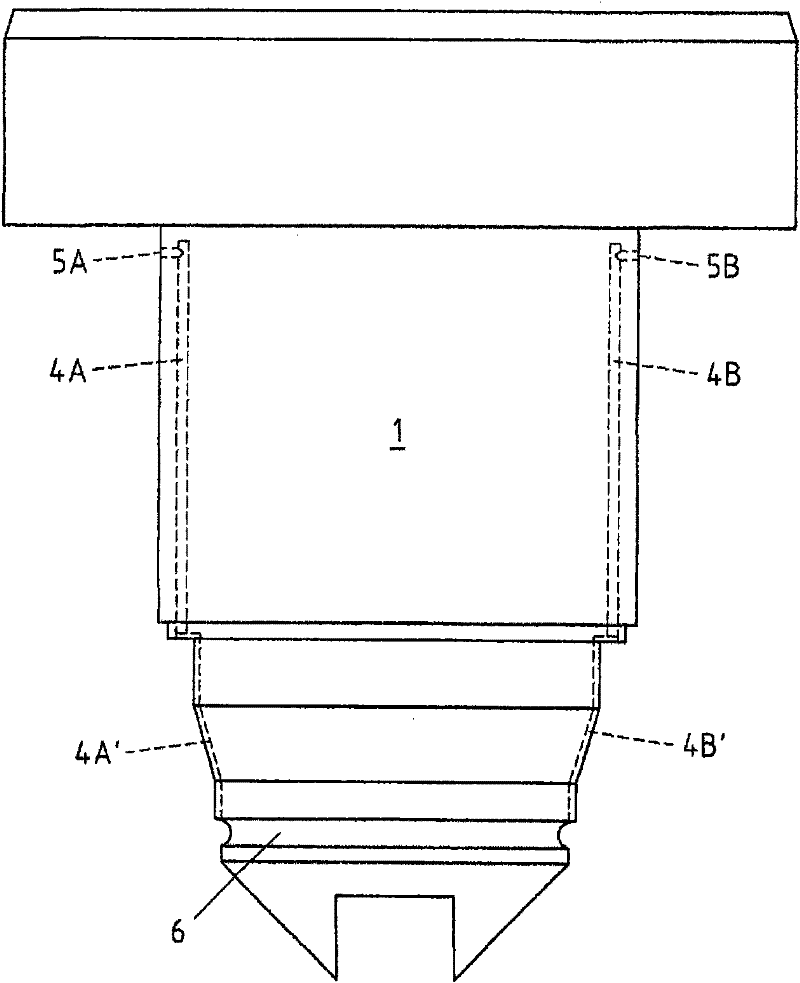

[0024] The nozzle for the device according to the invention is shown in its entirety in vertical section at figure 1 , but the plunger is not shown. Here, the internal components are indicated by 1 and the external components that can be connected are indicated by 2 . Due to the annular gap formed between the inner part 1 and the outer part 2 when the outer part 2 is placed in place in the lower region, a circumferential annular gap nozzle 3 is formed. The outer part in this case is formed in its outlet region in such a way that the product jet from the annular gap nozzle 3 impinges on the lower outer wall of the inner part 1, thus reliably preventing splashed substances, foam or the like attachment of something.

[0025] In the illustrated and preferred embodiment, channels 4A and 4B leading vertically into the side walls of the inner part 1 are provided, which channel 4A and 4B guide the product through further channels 4A' and 4B', channel 4A ' and 4B' are the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com