Trimming type helical tooth-shaped triangular belt and production process thereof

A technology of toothed triangle and production process, which is applied in the field of edge-cut helical toothed V-belt and its production process, and can solve the problems of V-belts such as easy damage, poor fatigue resistance and flexural performance, and failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

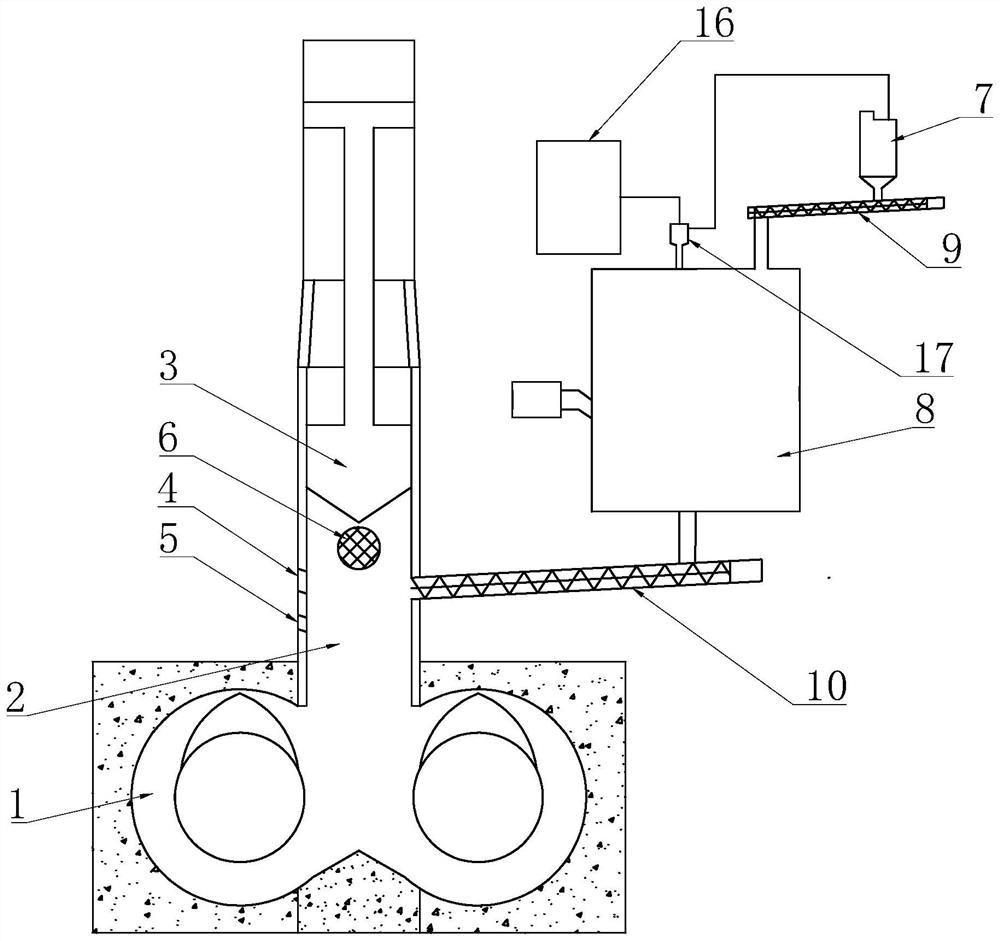

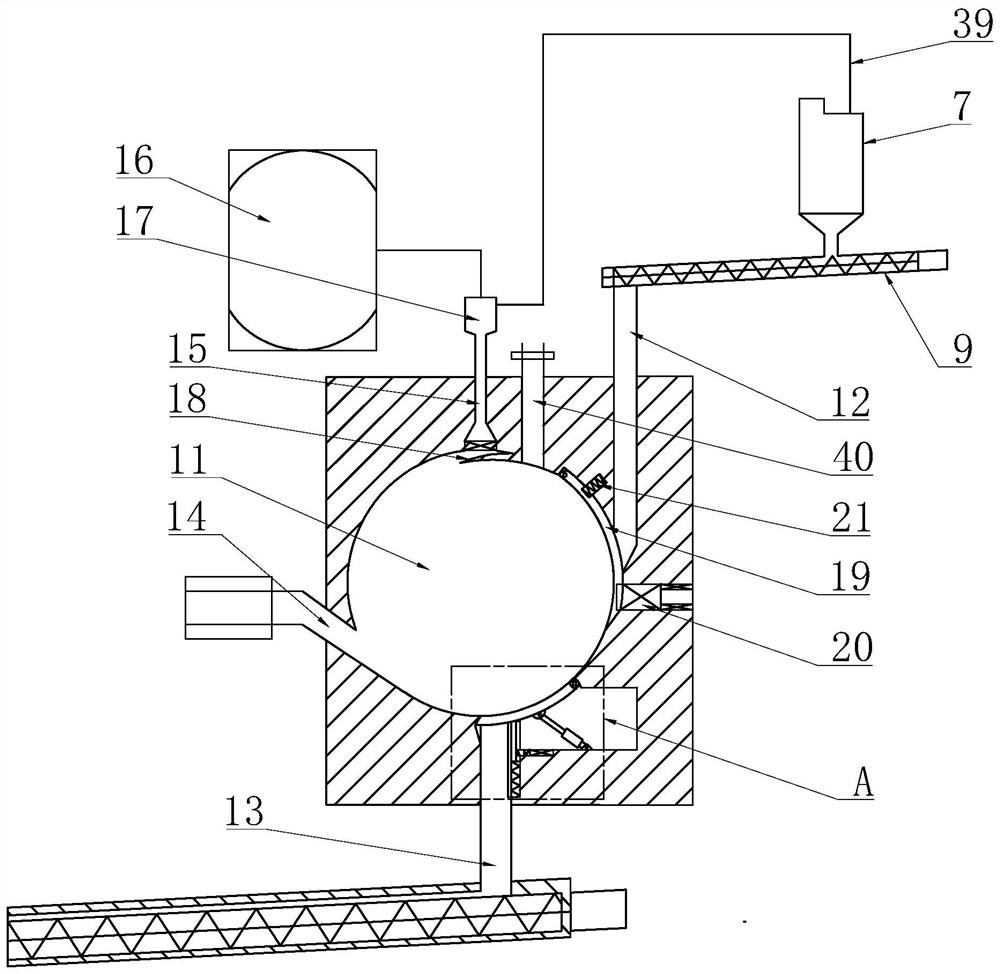

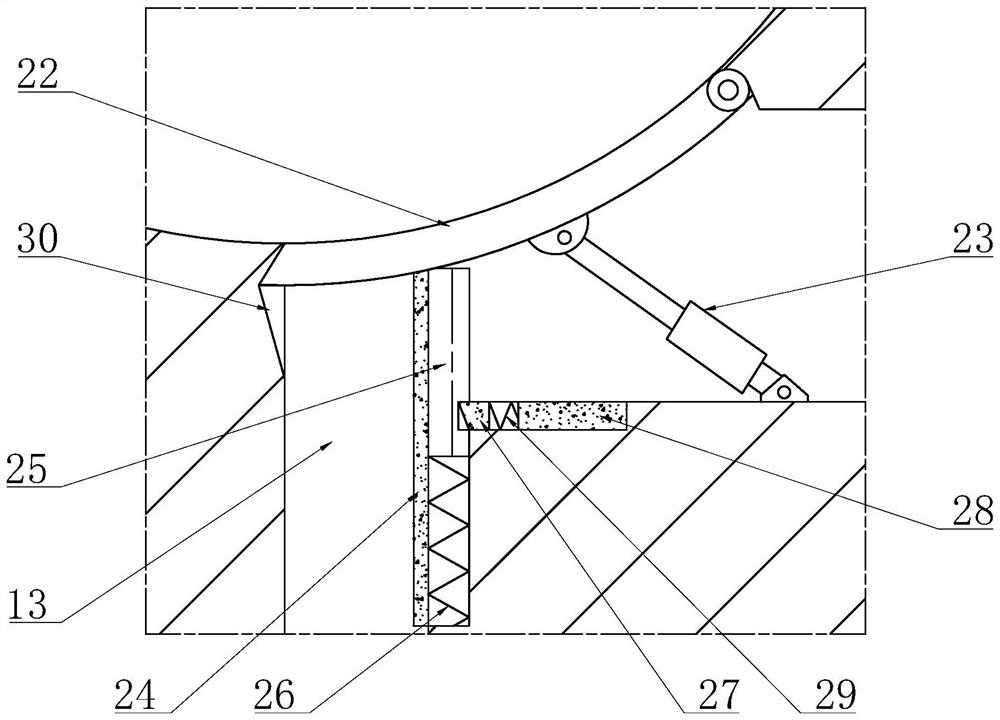

[0083] A production process for a trimmed helical-toothed V-belt, comprising the following steps:

[0084] a. Preparation: prepare the raw materials of the fiber glue layer, and prepare viscose, polyester hard rope, buffer glue and dipped canvas;

[0085] b. Mixing: separately mix the raw materials of the fiber rubber layer, the viscose and the buffer rubber;

[0086] c. Calendering: The viscose glue, viscose glue and buffer glue after mixing are calendered in a calendering machine respectively;

[0087] e. Forming: first paste the dipped canvas on the mold to form the tape layer, then paste the buffer glue to form the buffer glue layer, then paste the glue to form the glue layer, and spirally wind the outer surface of the glue layer to form the glue layer. The polyester hard cord is arranged in a longitudinal direction, and the longitudinal arrangement refers to the longitudinal arrangement of the V-belt, and finally a fiber glue layer is attached to form a belt drum;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com