Multi-layer uniformizing device of fiber particle rotary drum dryer

A drum drying and particle technology, which is applied to the drying of granular materials, drying gas arrangement, non-progressive dryers, etc., can solve the problems of affecting processing quality, uneven drying, insufficient drying, etc., to ensure processing quality and design Reasonable, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

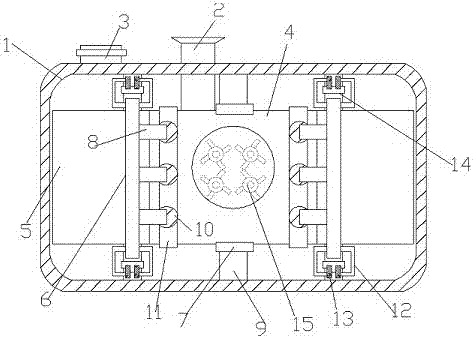

[0012] Such as figure 1 Shown: a multi-layer uniform device of a fiber particle drum dryer in this embodiment, comprising a drum drying cylinder 1, wherein the drum drying cylinder 1 is provided with a feed port 2 and a steam valve 3; The drum drying cylinder 1 is connected and fixed to the drying material cylinder 4 through reinforcing ribs 9; a collar block 7 is set on the reinforcing ribs 9.

[0013] Wherein the left and right ends of the drying barrel 4 are rotated to connect the movable cylinder 5; the movable cylinder 5 is covered with a fastening ring 6, and the fastening ring 6 extends the connecting arm 8 in turn; the end of the connecting arm 8 The part is slidably fixed in the chute 11 of the drying barrel 4 through the universal bearing 10; wherein the fastening ring 6 is respectively connected with several hangers 12, and each of the hangers 12 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com