Patents

Literature

74results about How to "Dry evenly and fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Batch-type apparatus and method for drying and transporting electrode plate for secondary battery

InactiveCN103378350ADry evenly and fullyLess drying deviationAssembling battery machinesElectrode thermal treatmentEngineeringMechanical engineering

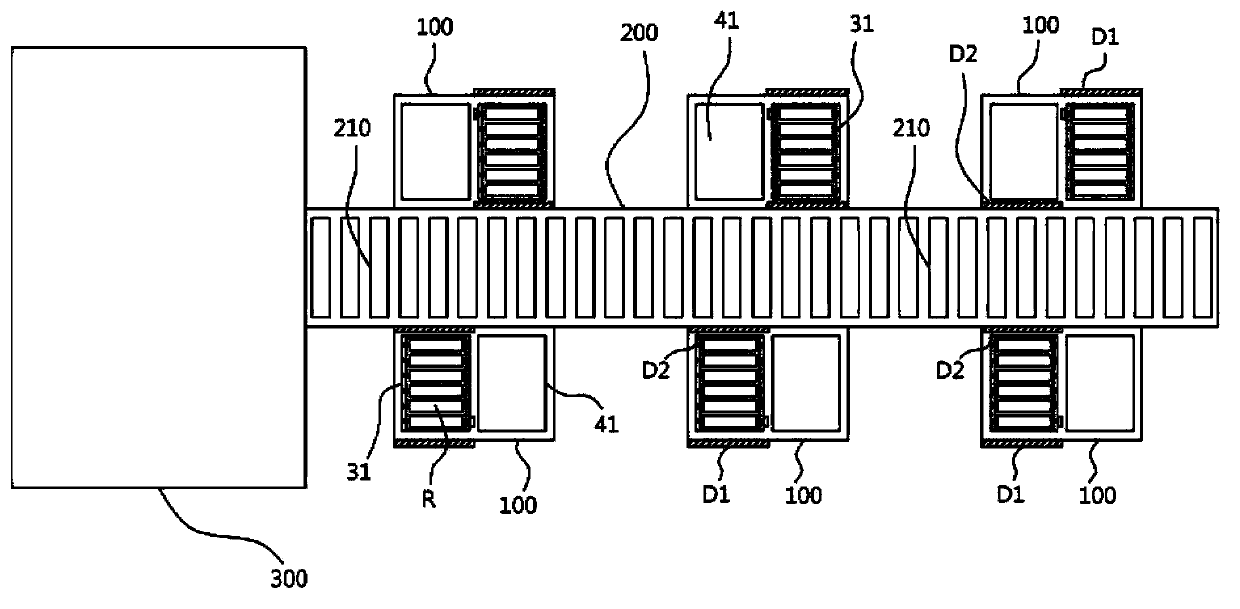

The invention relates to a batch-type apparatus and method for drying an electrode plate for a secondary battery and transporting the dried electrode plate to a process chamber, comprising: two or more electrode plate drying apparatuses (100) for drying electrode plates loaded in a group of two or more electrode plates and discharging the dried electrode plates in a loaded state to a transport pathway (200); and the transport pathway (200) which is connected to outlet doors (D2) of the electrode plate drying apparatuses (100) and includes a conveyor (210) for transporting a plurality of electrode plates (S) loaded in a vertical direction discharged through the outlet doors (D2) to a process chamber (300), wherein the transport pathway (200) is maintained in the state of being shielded from an external space, and is formed to be directly connected to the process chamber (300) via an opening / closing door (310).

Owner:莫泰克有限公司

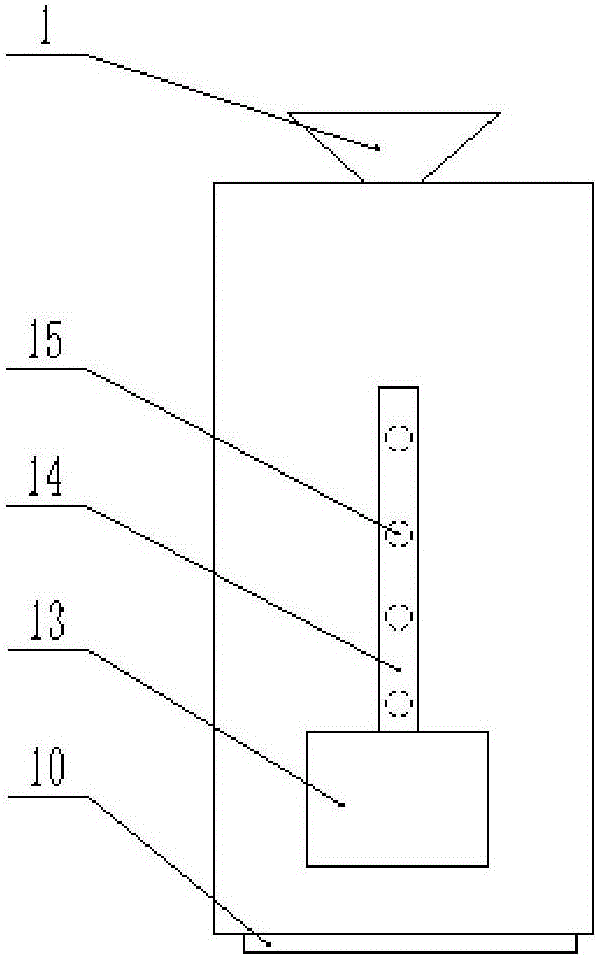

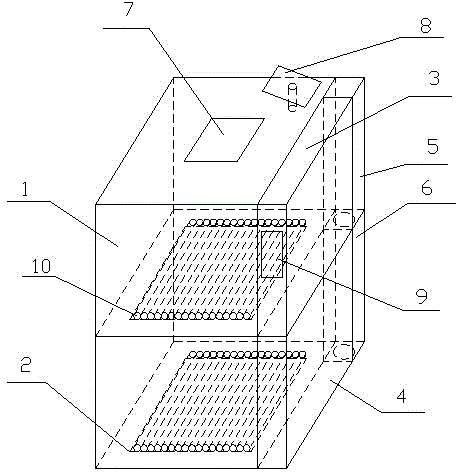

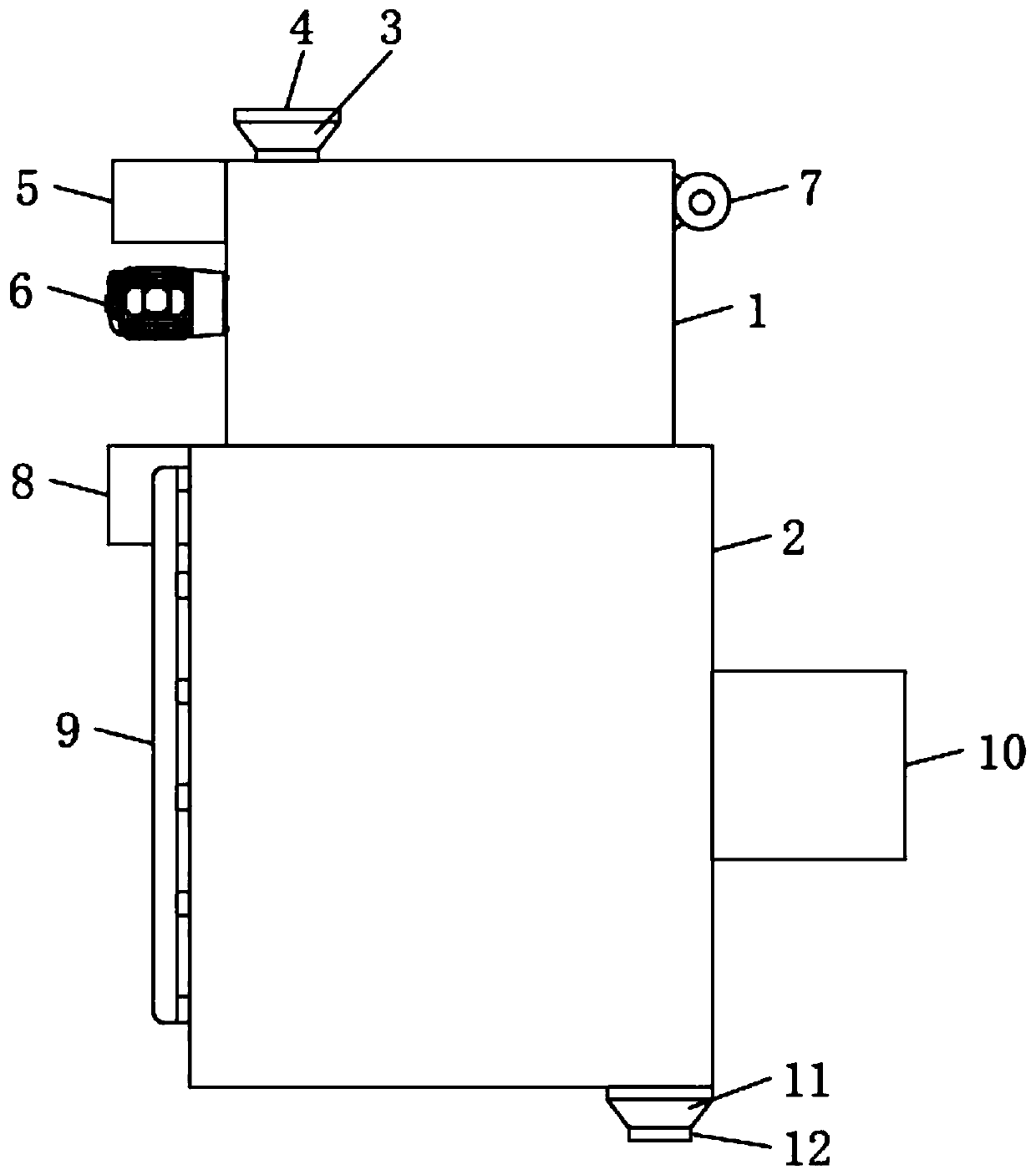

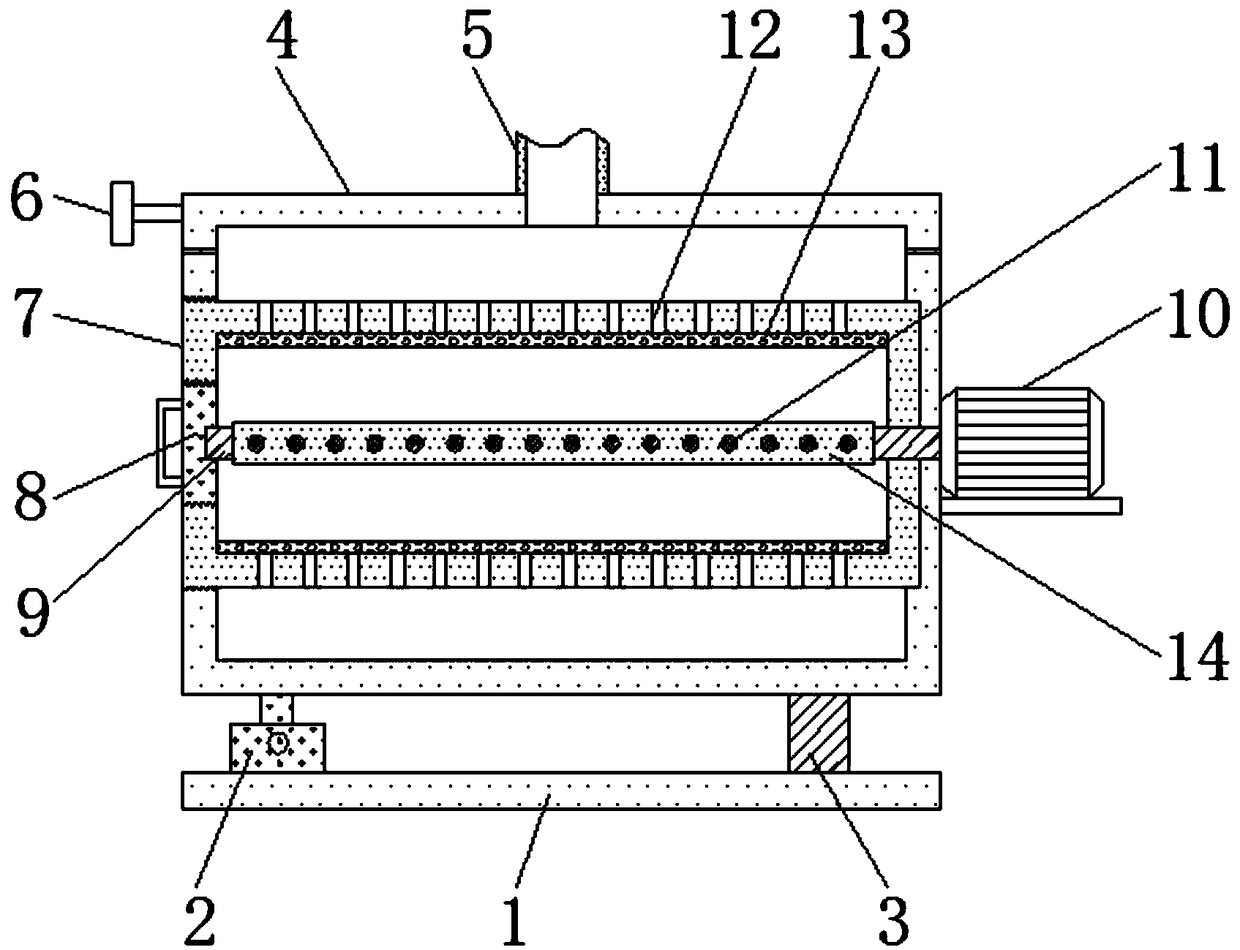

Silkworm cocoon drying device for spinning

InactiveCN105758135AReduce humidityMonitor humidityGranular material dryingDrying chambers/containersDrive wheelPulp and paper industry

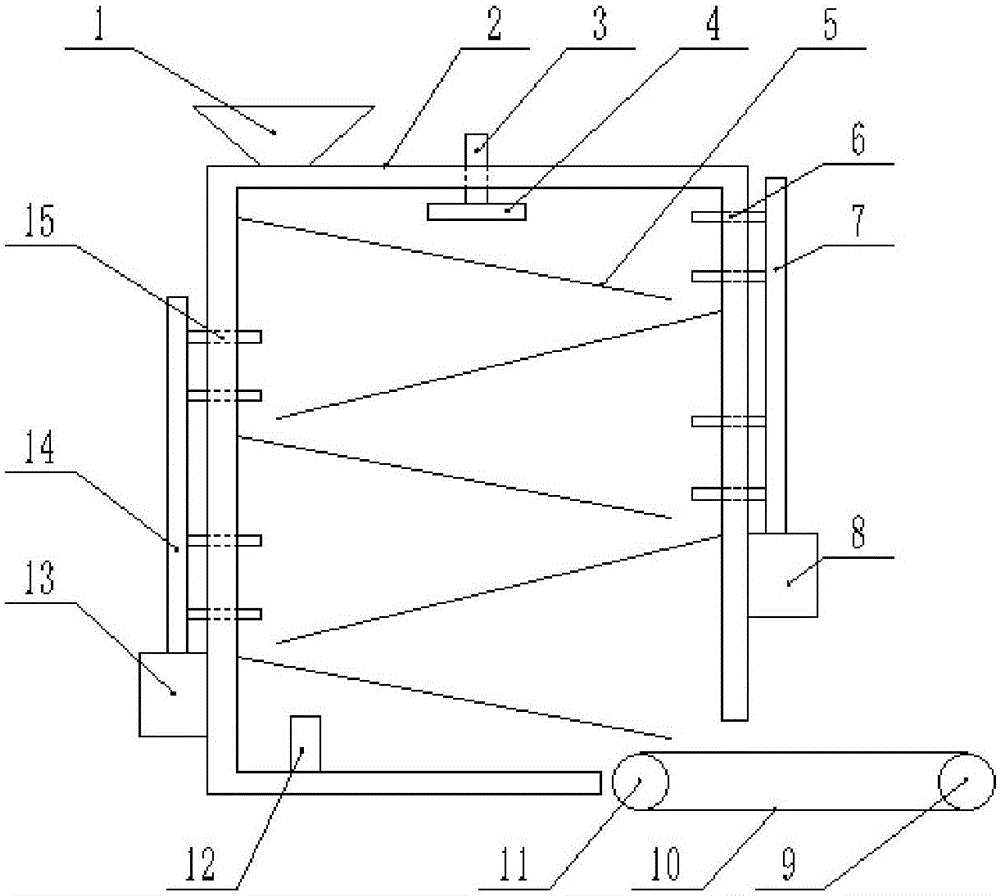

The invention relates to the field of spinning, in particular to a silkworm cocoon drying device for spinning, which can uniformly dry silkworm cocoons with high quality so that the problem that the silkworm cocoons are deteriorated in the preservation process is solved. The silkworm cocoon drying device comprises a drying box, wherein a feeding hole is formed in the upper end of the drying box; a moisture elimination hole is formed in the middle of the upper end of the drying box; a moisture eliminator is arranged at the upper end inside the drying box; drying plates are respectively fixed on two sides inside the drying box; a hygrometer is arranged at the lower end inside the drying box; a left hot air fan is arranged at the left end of the drying box; a left hot air tube is connected with the left hot air fan; four left air holes are formed in the left hot air tube; a right hot air fan is arranged at the right end of the drying box; a right hot air tube is connected with the right hot air fan; four right air holes are formed in the right hot air tube; a conveyer belt is arranged at the lower end of the drying box; a driving wheel is arranged on the right side of the conveyer belt; a driven wheel is arranged on the left side of the conveyer belt. The silkworm cocoon drying device provided by the invention is simple in structure, convenient to use and applicable to multiple places.

Owner:SUZHOU RUIRI TEXTILE SCI & TECH

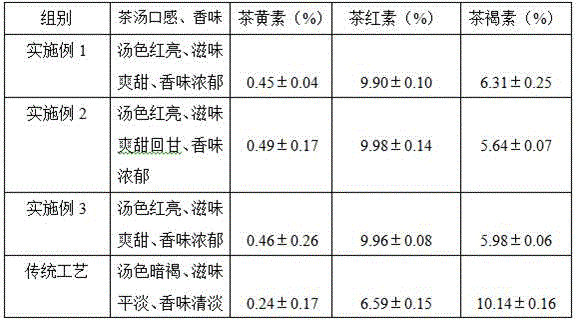

Processing technology for black tea

The invention discloses a processing technology for black tea, and belongs to the technical field of tea processing. The processing technology includes the steps of withering; four rocking, wherein the temperature in a rocking chamber is controlled to be 24 DEG C to 26 DEG C, the relative humidity is 85% to 95%, tea is standing for a period midway in each rocking, and the rocking time is gradually increased; rolling; fermenting, wherein the temperature in a fermentation chamber is controlled to be 26 DEG C to 28 DEG C, the relative humidity is 95% to 100%, the fermentation leaf temperature is 28 DEG C to 30 DEG C, the leaf spreading thickness is 8 cm to 10 cm, fermentation is carried out for 4 h to 8 h, and then fermented leaves are obtained; the fermented leaves are put into a pot at the temperature of 110 DEG C to 120 DEG C and stirred and fried for 30 min to 40 min, and then the product is put into a drying box at the temperature of 90 DEG C to 95 DEG C and dried. The color of tea soup of the black tea prepared with the technology is red brilliant and bright, the taste is refreshing, sweet and mellow, and compared with the traditional technology, the fragrance of the black tea is richer. The theaflavin and the thearubigins are relatively high, the theabrownin is low in content, and the basis is laid for the superior quality taste of the red tea and tea soup; practices verify that the processing technology of the black tea in the scheme is obviously higher than the traditional technology.

Owner:贵州琦福苑茶业有限公司

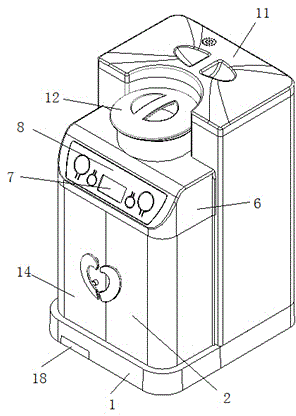

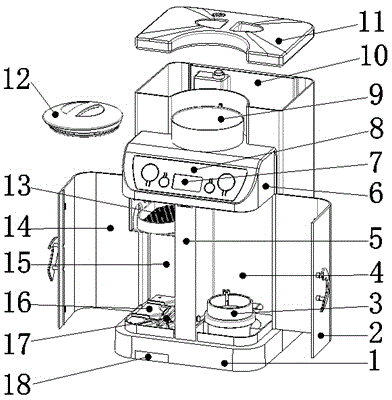

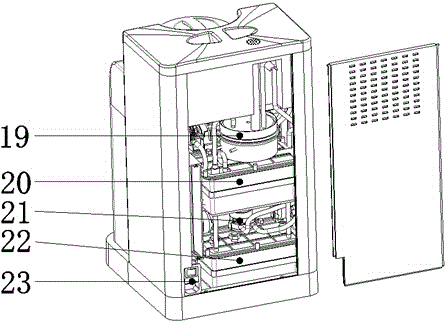

Intelligent constant temperature rapid milk preparing machine

InactiveCN105832157AAvoid reboilingShorten supply timeBeverage vesselsLiquid-crystal displayProcess engineering

The invention discloses an intelligent constant temperature rapid milk preparing machine, comprising a base and a housing. The housing is fixedly connected with the base through a support. The left side of the support is provided with a sterilizing cavity. The bottom of the sterilizing cavity is provided with a feeding-bottle support, a hot-air system, and an ultraviolet germicidal lamp. The upper end of the sterilizing cavity is provided with a nipple drawer. A filter screen drawer is arranged under the sterilizing cavity. The right side of the support is provided with a milk preparing cavity. The upper end of the housing is provided with a control panel. The middle position of the control panel is provided with a liquid crystal display. The top end of the housing is provided with a quantitative throwing mechanism. A milk powder hopper cover is arranged on the quantitative throwing mechanism. The upper end of the rear side of the housing is provided with a water tank. A water tank cover is arranged on the water tank. A water boiler is arranged under the water tank. A heat exchange cooler is arranged under the water boiler. The heat exchange cooler is communicated with a warm boiled water storage through a water pump. The housing is provided with a power switch socket. The milk preparing machine is rational in design, simple in operation, uniform in milk dissolution, and high in automation degree, and disinfects in a double manner, and is safe and sanitary.

Owner:黄文通

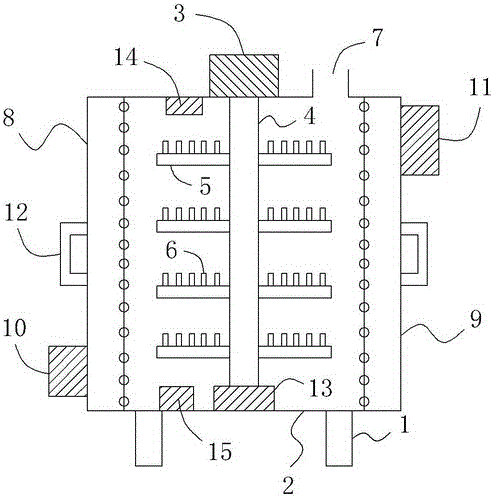

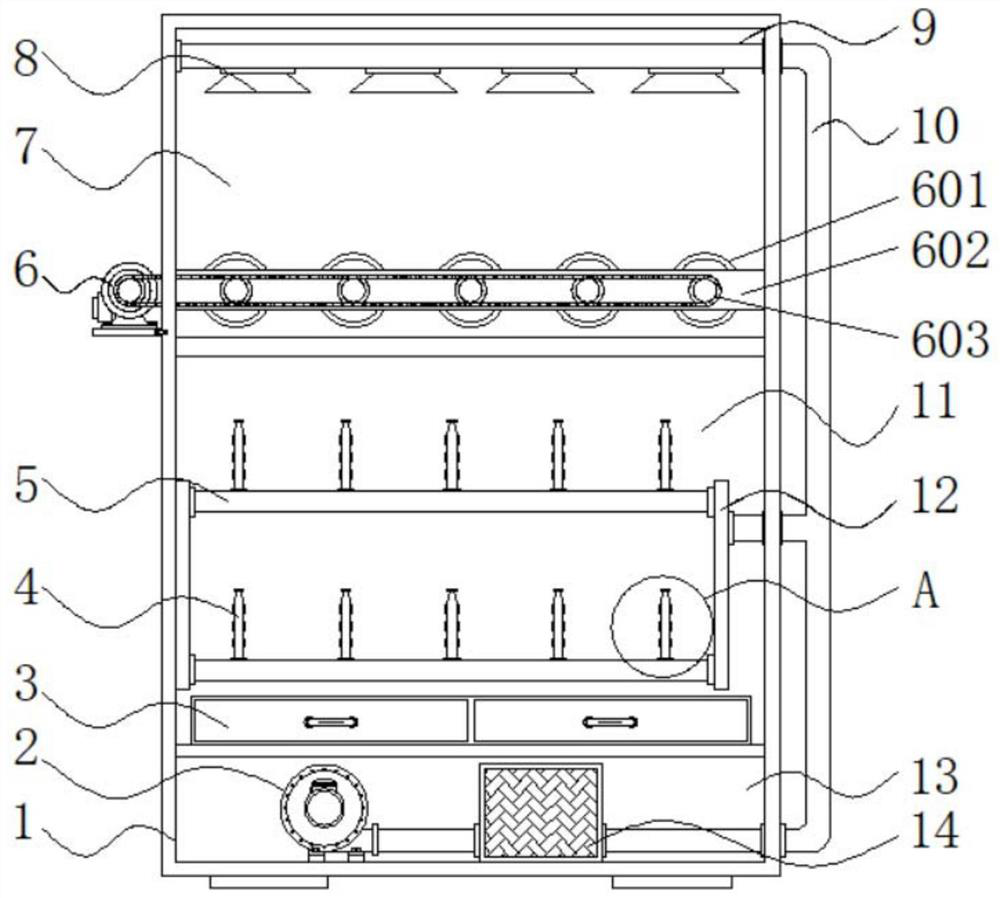

Drying device for LED aluminum substrates

InactiveCN106403552ADry evenly and fullyGuarantee the quality of production and processingDrying gas arrangementsDrying chambers/containersEngineeringAluminum substrate

The invention relates to a drying device for LED aluminum substrates. The drying device comprises a support and a cabinet body; a cabinet door is arranged on the front side wall of the cabinet body; a rotating motor is arranged at the top end of the outer part of the cabinet body; the bottom end of an output shaft of the rotating motor is connected with a rotating shaft extending vertically downwards; the rotating shaft is fixedly sleeved with circular trays; tray ventilating holes are formed in the circular trays; needle-like bulges extending vertically upwards are uniformly distributed on top planes of the circular trays; an exhaust port is formed in the top wall of the cabinet body; a left cavity and a right cavity are formed in the left side and the right side of the cabinet body respectively; multiple left ventilating holes and multiple right ventilating holes are uniformly formed in the left side wall and the right side wall of the cabinet body; a left air heater is arranged at the lower part of the left side of the left cavity; a right air heater is arranged at the upper part of the right side of the right cavity; an air outlet of the left air heater communicates with the left cavity; and an air outlet of the right air heater communicates with the right cavity. With the adoption of the structure, the aluminum substrates placed in the device can be dried sufficiently and uniformly, so that the production and machining quality and the service life of LED lamps are greatly guaranteed.

Owner:CHENGDU JUZHI IND DESIGN

Convenient-moving and good-drying-effect drying machine for shoemaking

InactiveCN107702449AEasy to moveImprove drying effectDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention discloses a convenient-moving and good-drying-effect drying machine for shoemaking. The machine comprises a drying box, wherein a blow dryer is fixedly connected to the inner bottom endof the drying box; a plurality of shoe hanging racks are fixedly connected to the side surface of the blow dryer; a first air inlet tube is fixedly connected to the upper surface of the blow dryer; one end, far away from the blow dryer, of the first air inlet tube, passes through the top part of the drying box and then is fixedly connected to a first hot-air blower; a second air inlet tube passesthrough one side of the bottom part of the drying box; a second hot-air blower is fixedly connected to one end, far away from the drying box, of the second air inlet tube. The convenient-moving and good-drying-effect drying machine for shoemaking has the advantages of being simple in structure, convenient to use, convenient to move, and capable of massively and quickly drying, so that the drying efficiency of shoemaking is improved; and the problem that the drying machine in the prior art cannot be used for massively drying and easily leads to inconsistent speeds of inner drying and outer drying of shoes, resulting in the influence on overall glue drying speed and even the influence on shoes quality, as well as the problem of inconvenient moving, can be solved.

Owner:江苏润天服饰有限公司

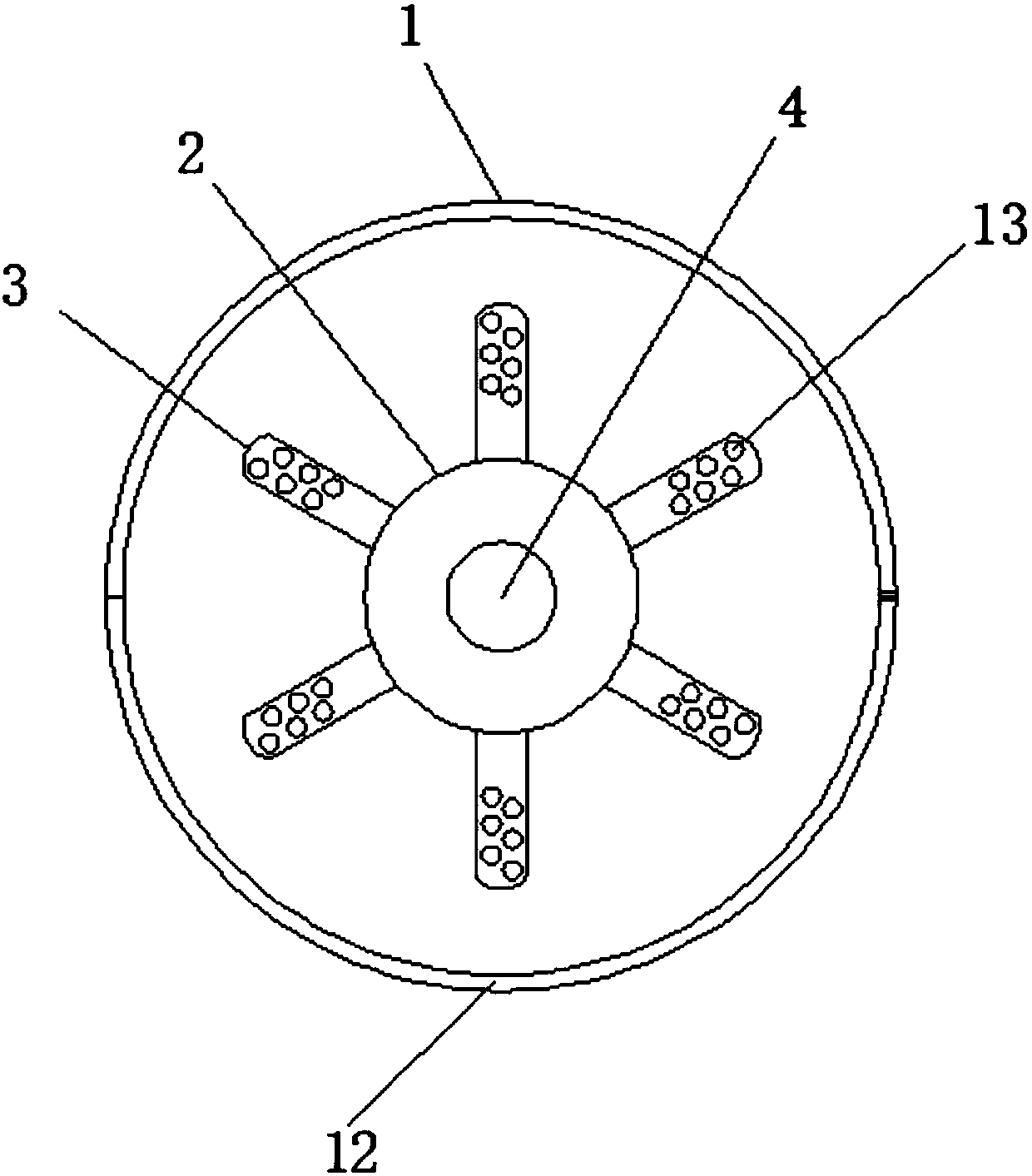

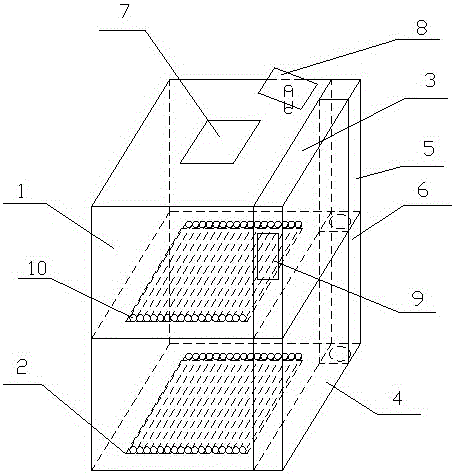

Intelligent airing and drying device

ActiveCN104930827AReduce wasteSave energyDrying machines with non-progressive movementsDrying solid materialsSUN LIGHT EXPOSUREMechanical engineering

The invention discloses an intelligent airing and drying device, which comprises a box body and control cabinets, wherein the control cabinets are arranged on the bottom or the side face of the box body; a power source module and a control module are arranged in the control cabinets; airing and drying frames are arranged inside the box body; an exhaust device is arranged on the top of the box body; a plurality of rotating shafts are closely arranged on the airing and drying frames side by side; each rotating shaft can be independently rotated; the airing and drying frames are provided with heating devices; the box body is made of a transparent material; to-be-dried materials are placed on the airing and drying frames; when sunlight irradiates the outside of the box body, the to-be-dried materials can be directly aired by utilizing the temperature of sunlight; and after the materials on the airing and drying frames are aired and dried for a period of time, the rotating shafts are controlled to rotate, and the materials are sequentially aired and dried after being overturned. The rotating shafts are arranged on the airing and drying frames, the materials are overturned by adopting the rotating shafts, and the materials can be relatively uniformly and adequately aired, so that the airing speed and efficiency are effectively improved.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Garden planting seed drying device

InactiveCN107621158ADry evenlyDry evenly and fullyDrying machine combinationsDrying gas arrangementsAgricultural engineeringPlanting seed

The invention relates to a garden planting seed drying device, which comprises a tank body. A rotating wheel is rotatably arranged in the tank body, and is located right below a feed inlet; L-shaped stirring plates are uniformly and fixedly arranged at the circumference of an edge of the rotating wheel; an air blower is arranged in the tank body; a metal screen plate is arranged in the tank body;the right end of the metal screen plate is hinged onto an inner wall of the right side of the tank body; a spring is arranged between the metal screen plate and a fixing plate; a cam is rotatably arranged at a left side wall of the tank body; a rolling wheel is rotatably arranged at the bottom part of the metal screen plate and presses against the cam; a vertical plate is vertically and fixedly arranged at the bottom part of the tank body; a slide rod is horizontally and fixedly arranged between the vertical plate and a right side wall of the tank body; a sleeve block slidably sleeves on the slide rod; and a fan is fixedly arranged at an upper side face of the sleeve block. According to the garden planting seed drying device provided by the invention, seeds are hot-air dried fully and uniformly, and dust at the surfaces of the seeds enter a dust collecting box through dust collecting through holes, so that a dust removal effect is achieved, the seeds are cleaned, and the seed quality is improved.

Owner:何小平

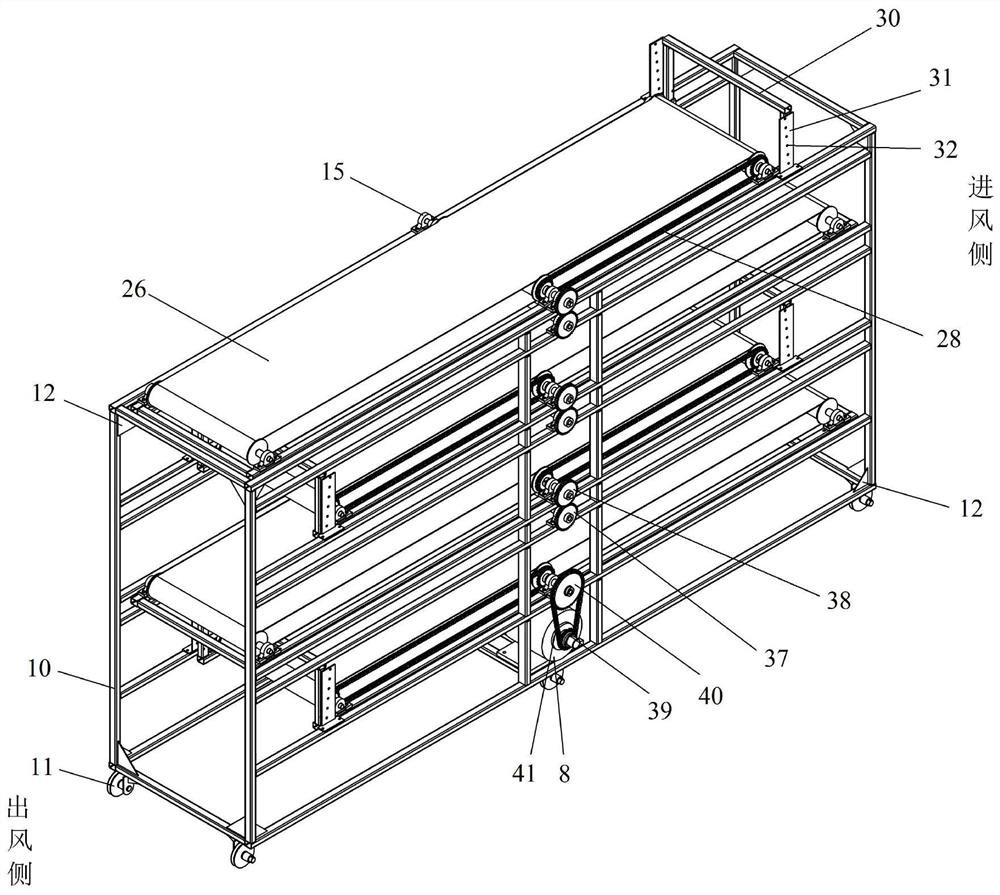

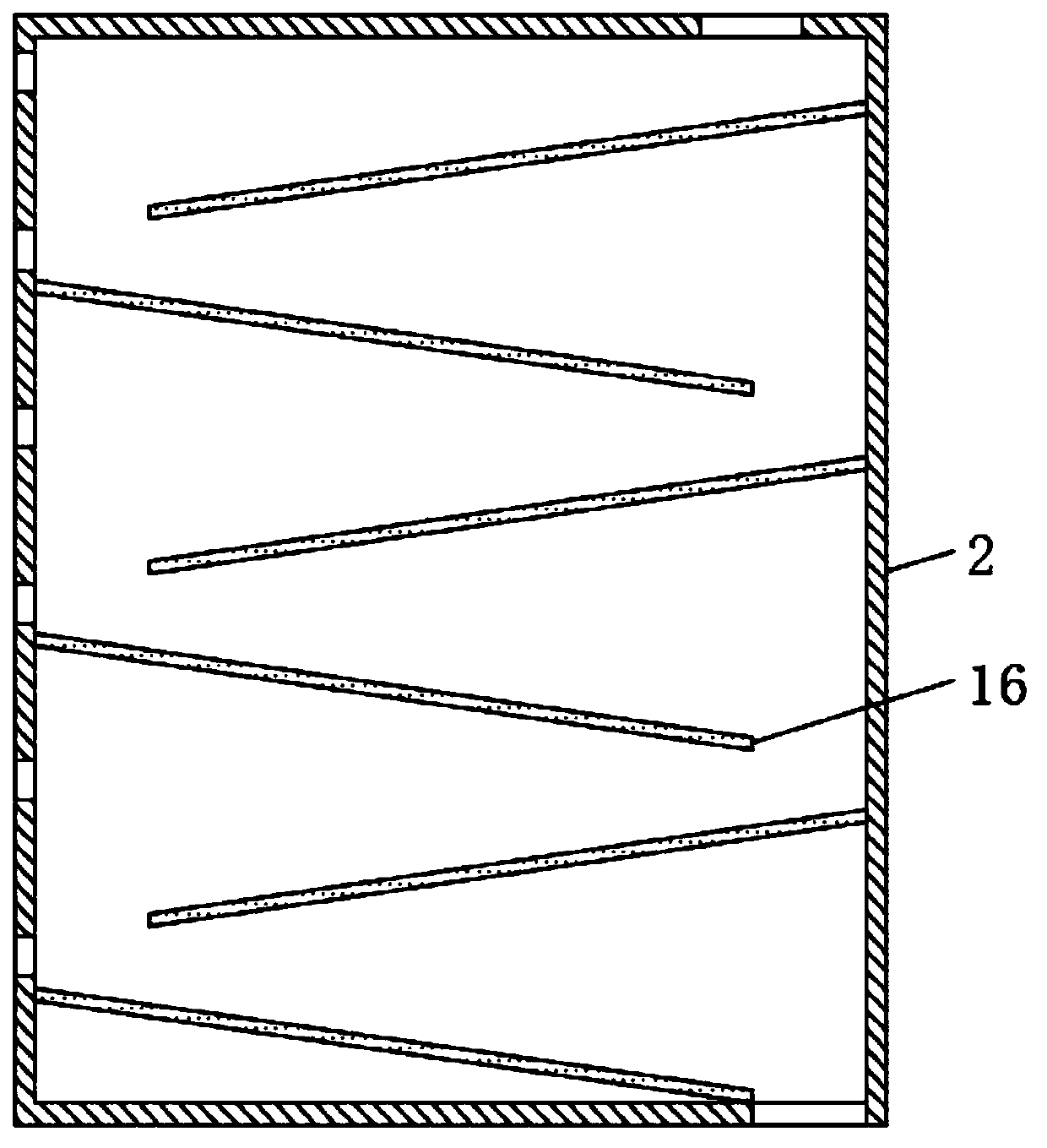

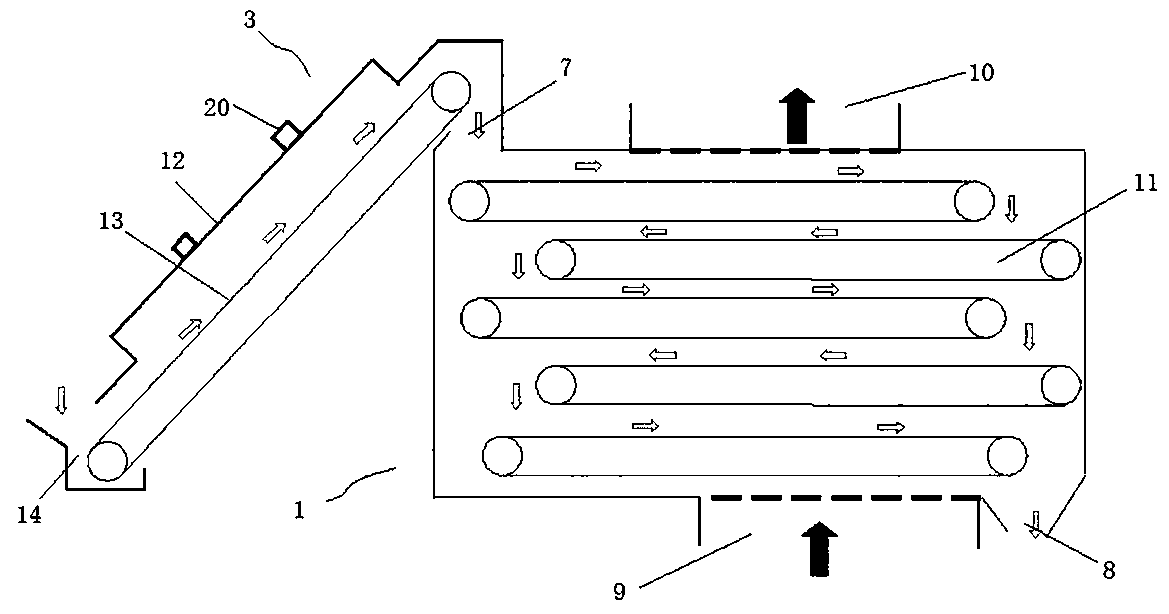

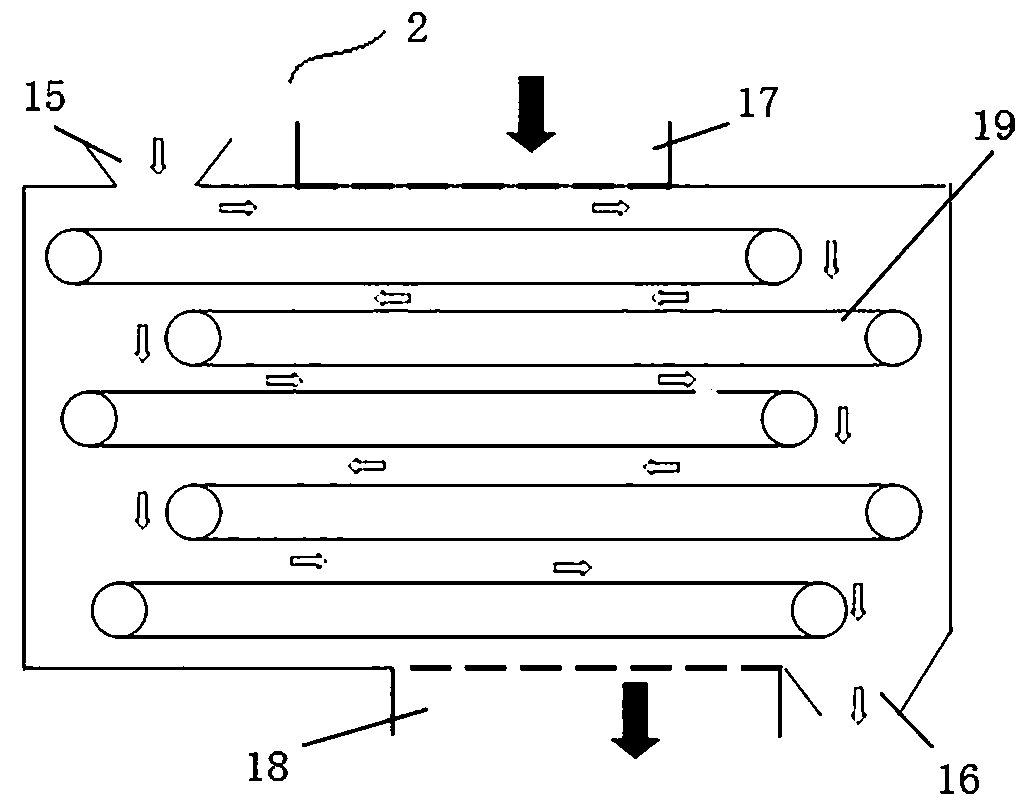

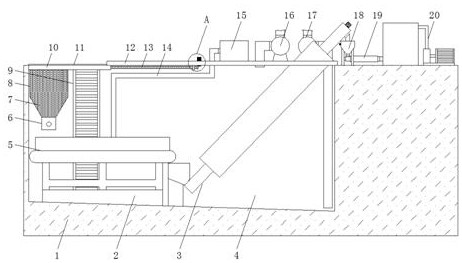

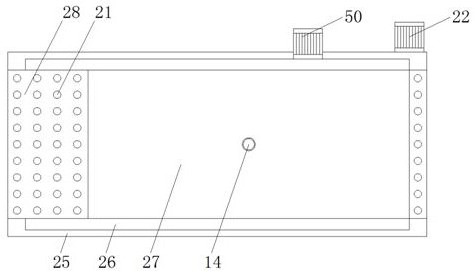

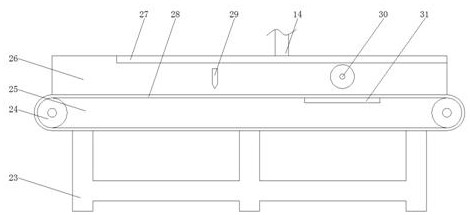

Hot air drying room

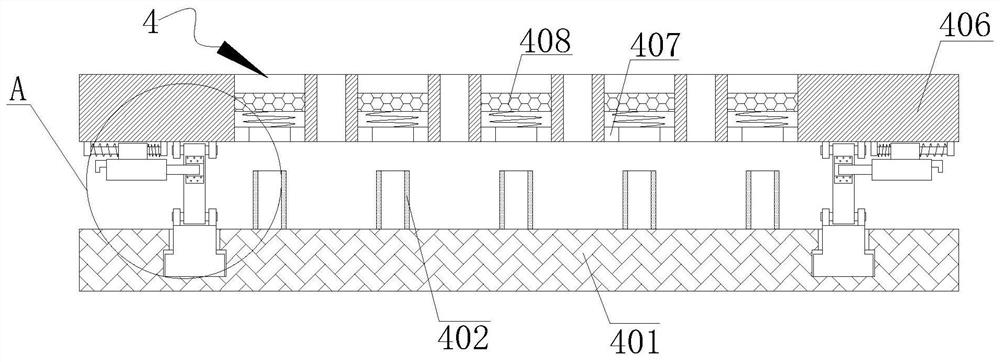

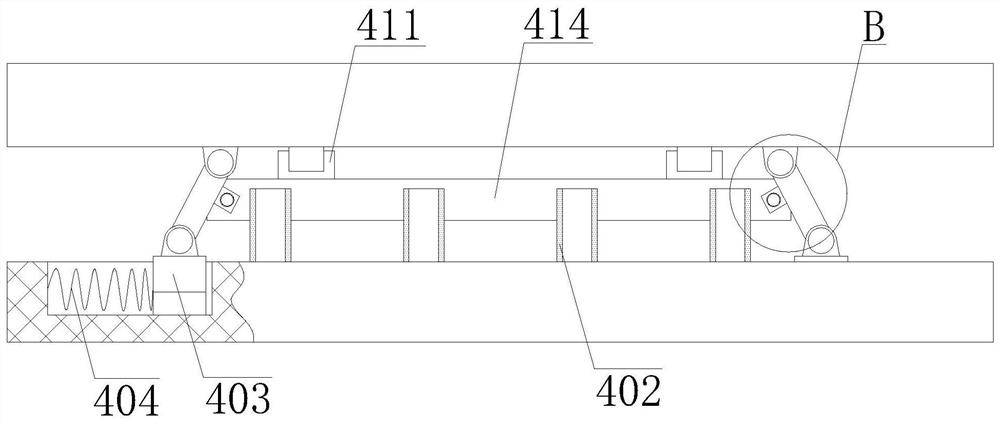

PendingCN113432406ADry evenly and fullyFully automatedDrying gas arrangementsDrying machines with progressive movementsHot blastMechanical engineering

The invention discloses a hot air drying room, and relates to the field of drying equipment. The hot air drying room comprises a box body, a guide mechanism, a dynamic conveying device and a circulating conveying device, wherein the dynamic conveying device comprises a frame body, a sliding mechanism, a driving mechanism, a plurality of material conveying mechanisms, a plurality of locking adjusting assemblies and a plurality of transmission mechanisms; and the plurality of material conveying mechanisms are sequentially installed on the frame body from top to bottom, the middle of each material conveying mechanism is rotationally installed on the frame body, one end of each material conveying mechanism is installed on the frame body through one locking adjusting assembly, every two adjacent material conveying mechanisms are connected through one transmission mechanism, the material conveying directions of every two adjacent material conveying mechanisms are opposite, and the feeding end of the lower material conveying mechanism in every two adjacent material conveying mechanisms is located at the outer side of the discharging end of the upper material conveying mechanism. According to the hot air drying room, the influence of a non-uniform flow field on material drying is reduced, the automation of material drying is realized, and the working efficiency is improved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

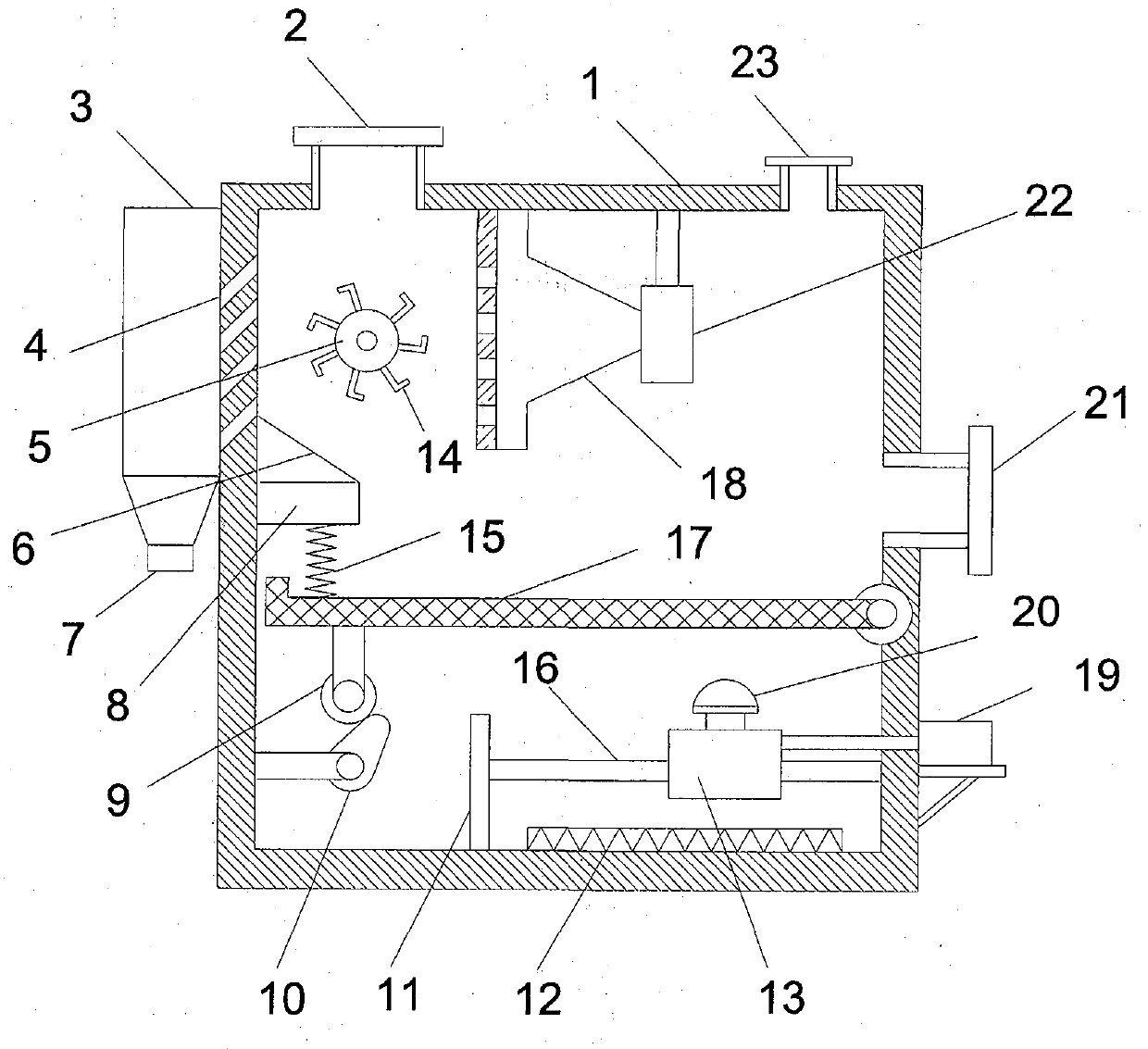

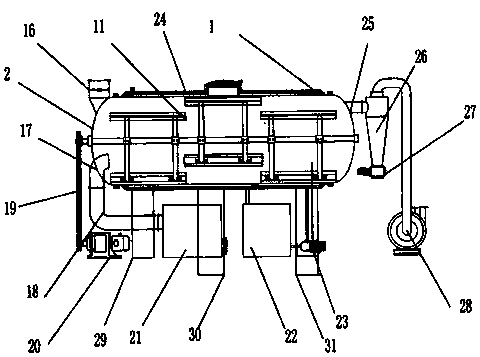

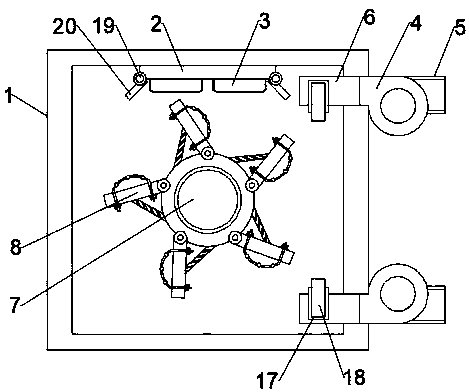

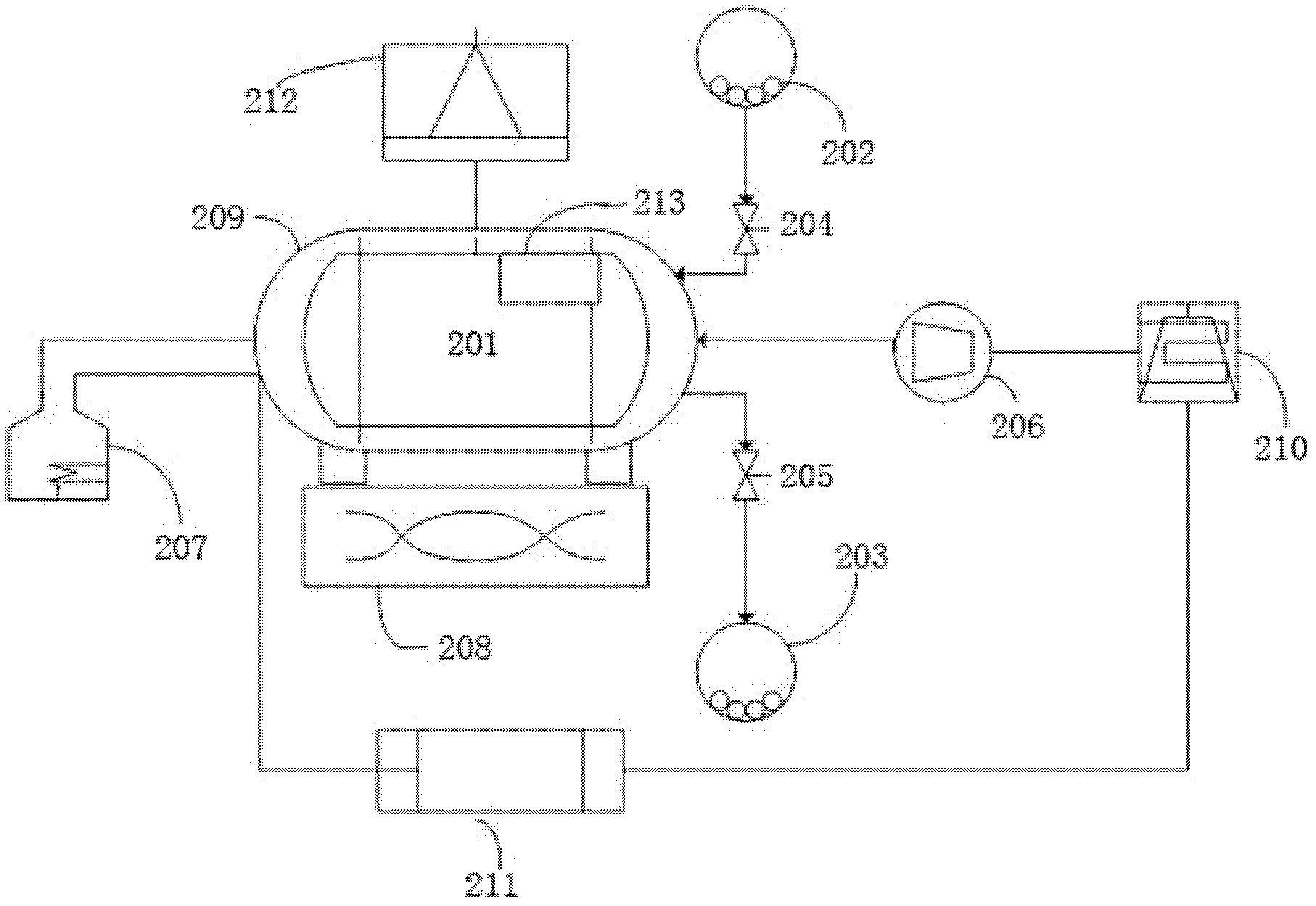

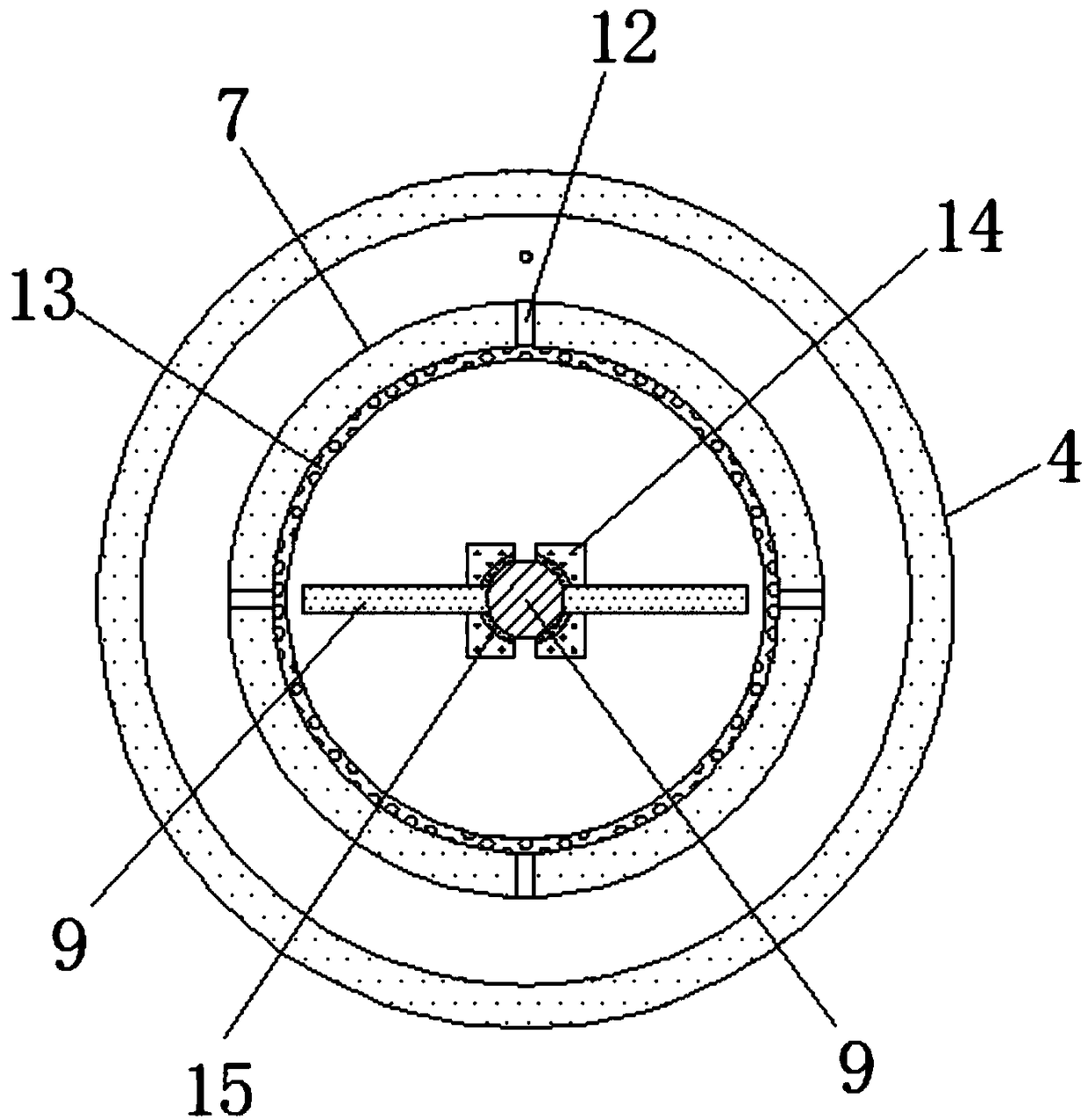

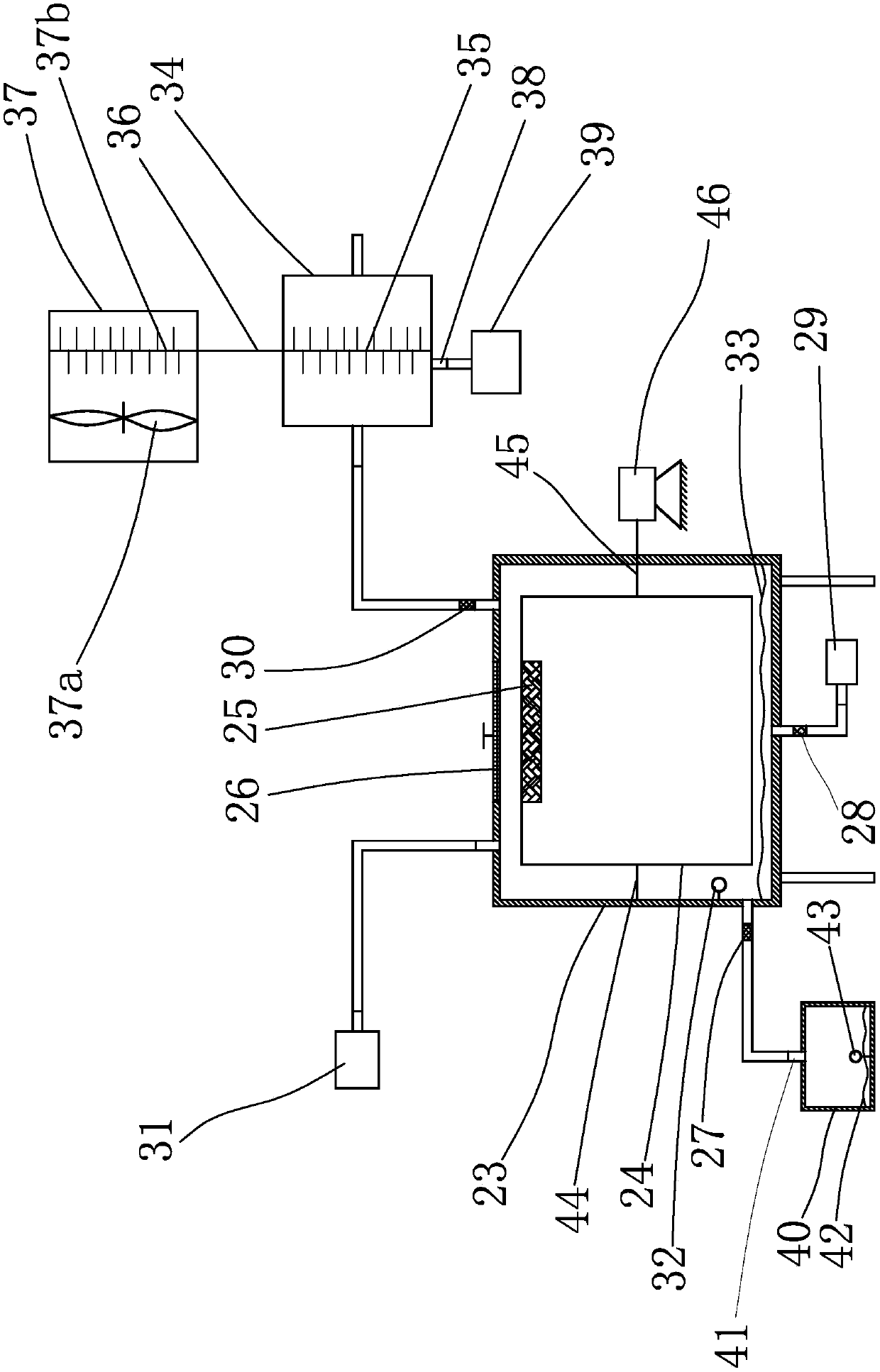

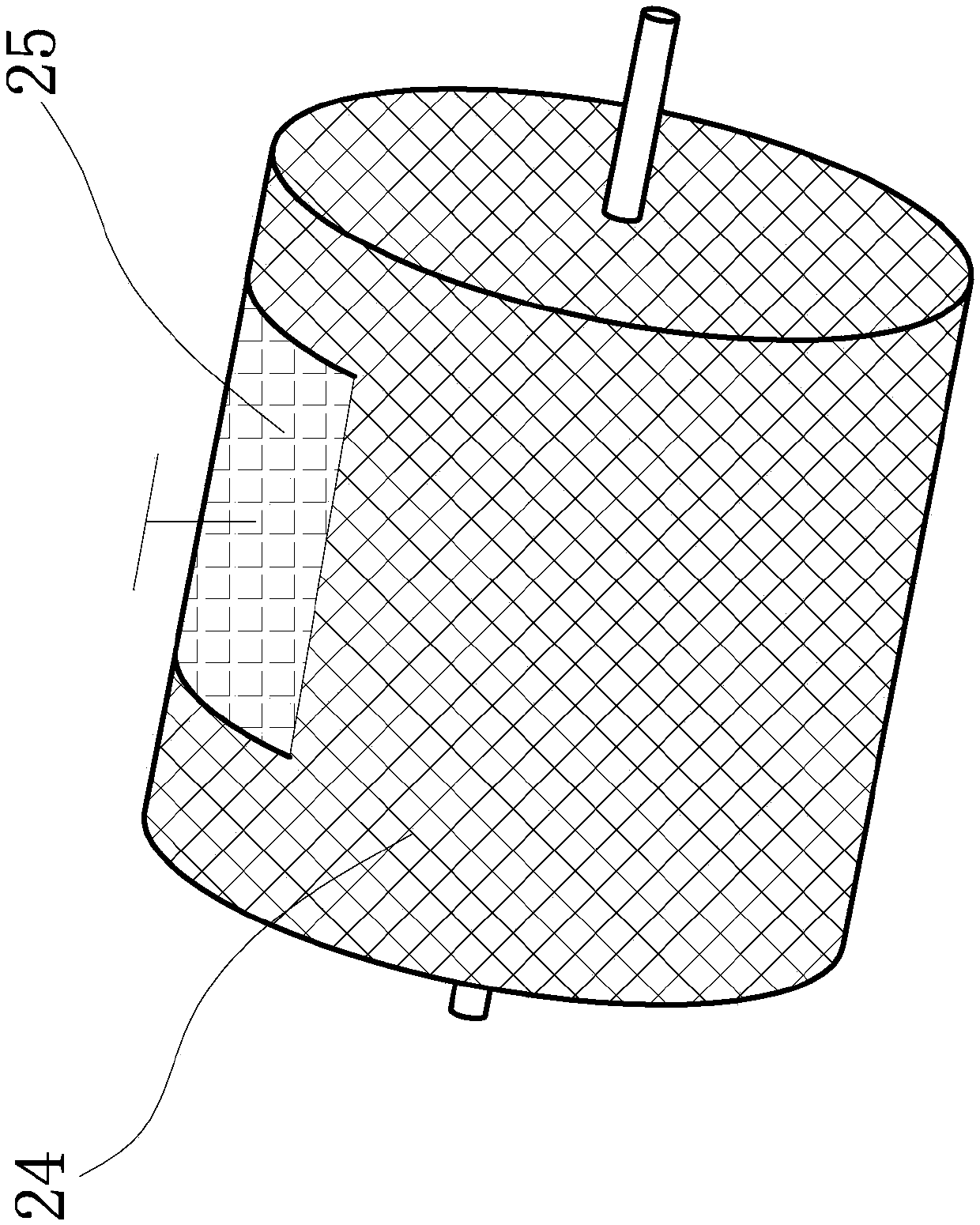

Sea buckthorn fruit slag stirring and drying tank body device and stirring and drying method

PendingCN108662876AAvoid lostMeet drying requirementsDrying gas arrangementsDrying machines with non-progressive movementsAutomatic controlSlag

The invention discloses a sea buckthorn fruit slag stirring and drying tank body device and a stirring and drying method. The problems that when existing equipment is used for drying small-particle materials of high density, the drying efficiency is low, and an exhaust structure is not scientific and reasonable are solved. The sea buckthorn fruit slag stirring and drying tank body device can be mainly divided into a stirring, throwing and scattering system, a hot-air sending and drying system, a damp air sucking system, a discharging system, a tank body heat preservation and heating system andan in-tank temperature and humidity monitoring system, and the systems can be controlled by an industrial personal computer. The tank body is internally provided with a temperature sensor and a humidity sensor. The industrial personal computer controls the in-tank temperature by collecting signals of the sensors through an automatic control program and switches between material throwing and scattering and damp air suction through the signals sent by the humidity sensor. The drying efficiency is improved, the cost is lowered, and the drying quality of the materials is improved.

Owner:山西省林业科学研究院

Processing apparatus and method for hibiscus manihot tea

The invention discloses a processing apparatus for hibiscus manihot tea and relates to the technical field of processing the hibiscus manihot tea. The processing apparatus comprises a drying box and a cooling box, a feed pipe is fixedly connected to on end of the upper surface of the drying box, a first valve is installed at the top of the feed pipe, an air heater is fixedly connected to the top end of one side of the drying box, a stirring motor is fixedly connected to the middle of one side of the drying box, a vacuum pump is fixedly connected to the top of the other side of the drying box, an air cooler is fixedly connected to the top end of one side of the cooling box, an air pipe is vertically arranged on one side of the cooling box, a vibration box is fixedly connected to the middle of the other side of the cooling box, a discharge pipe is fixedly connected to one end of the lower surface of the cooling box, and a third valve is installed on the bottom of the discharge pipe. By the arrangement, the hibiscus manihot tea can be dried rapidly, drying efficiency is sped up, and fully uniform drying, good drying effect, compact structure, high processing efficiency and good processing quality are achieved.

Owner:金坤石家庄众创空间有限公司

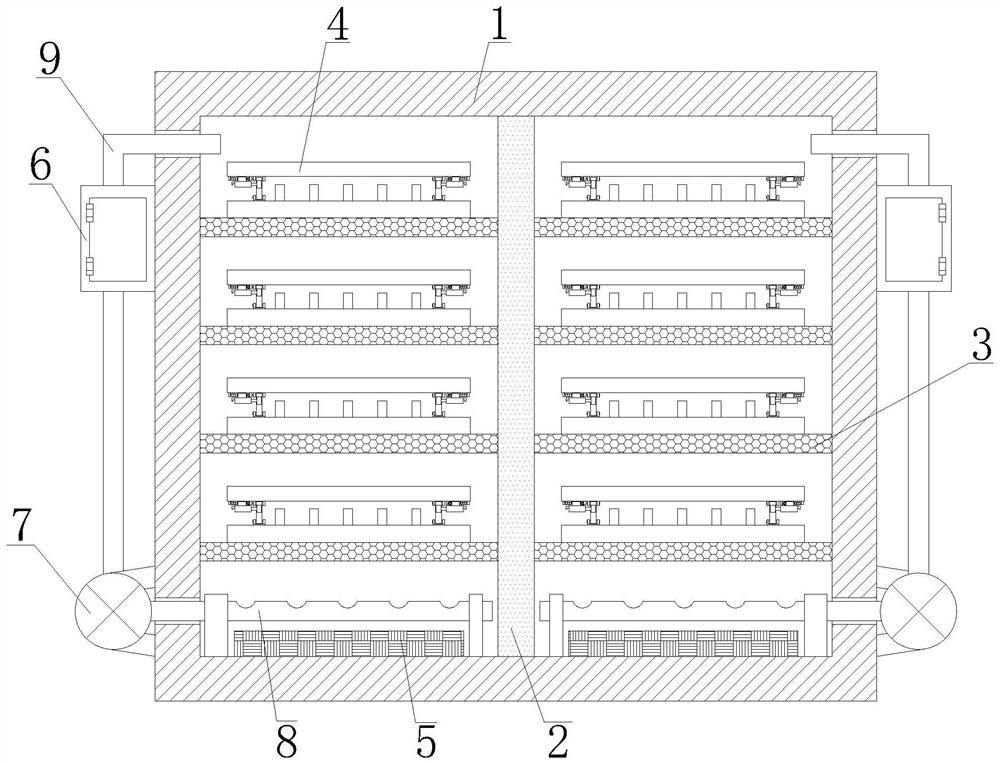

Drying device for tablet production

InactiveCN111895734AThe problem of preventing falling groundReduce wasteDrying gas arrangementsDrying chambers/containersStructural engineeringProcess engineering

The invention relates to the technical field of tablet drying and discloses a drying device for tablet production. The drying device comprises a drying box. A partition is fixedly connected between the inner top wall and the inner bottom wall of the drying box. A plurality of support plates are fixedly connected at equal intervals between the left side face of the partition and the left side innerwall of the drying box as well as between the right side face of the partition and the right side inner wall of the drying box. Tray mechanisms are placed at the top of the support plates. Two heating plates are symmetrically and fixedly installed on the inner bottom wall of the drying box. Two dehumidification boxes and two air suction fans are symmetrically and fixedly connected to the left andright side faces of the drying box. Through the drying device, the problems that in most existing tablet drying devices, a supporting plate of which the top is provided with a plurality of tablet holding cavities is adopted for holding tablets, the tablets cannot be fully dried and cannot be taken out conveniently, and thus the drying processing effect and efficiency are influenced are solved.

Owner:赵鸿菓

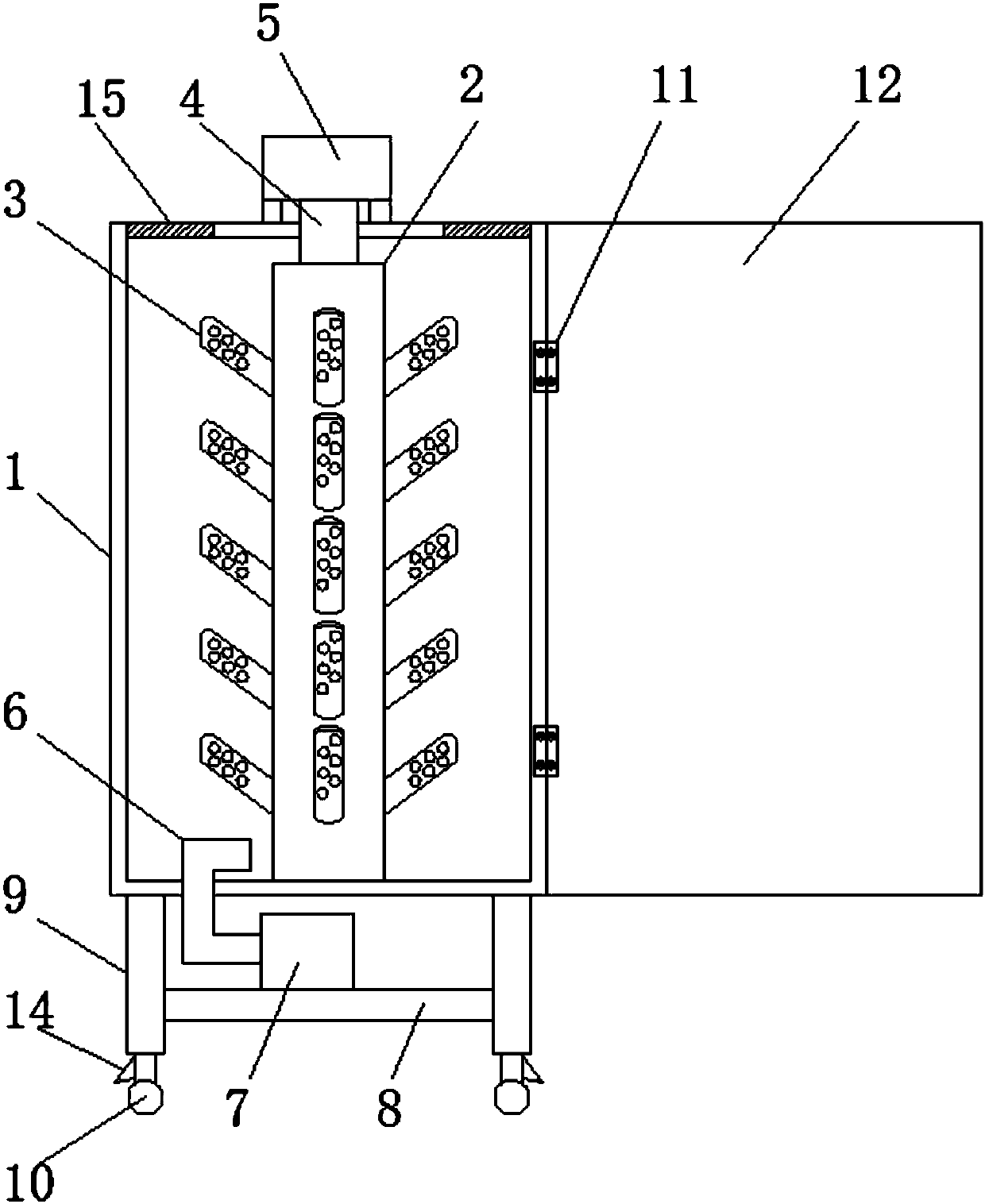

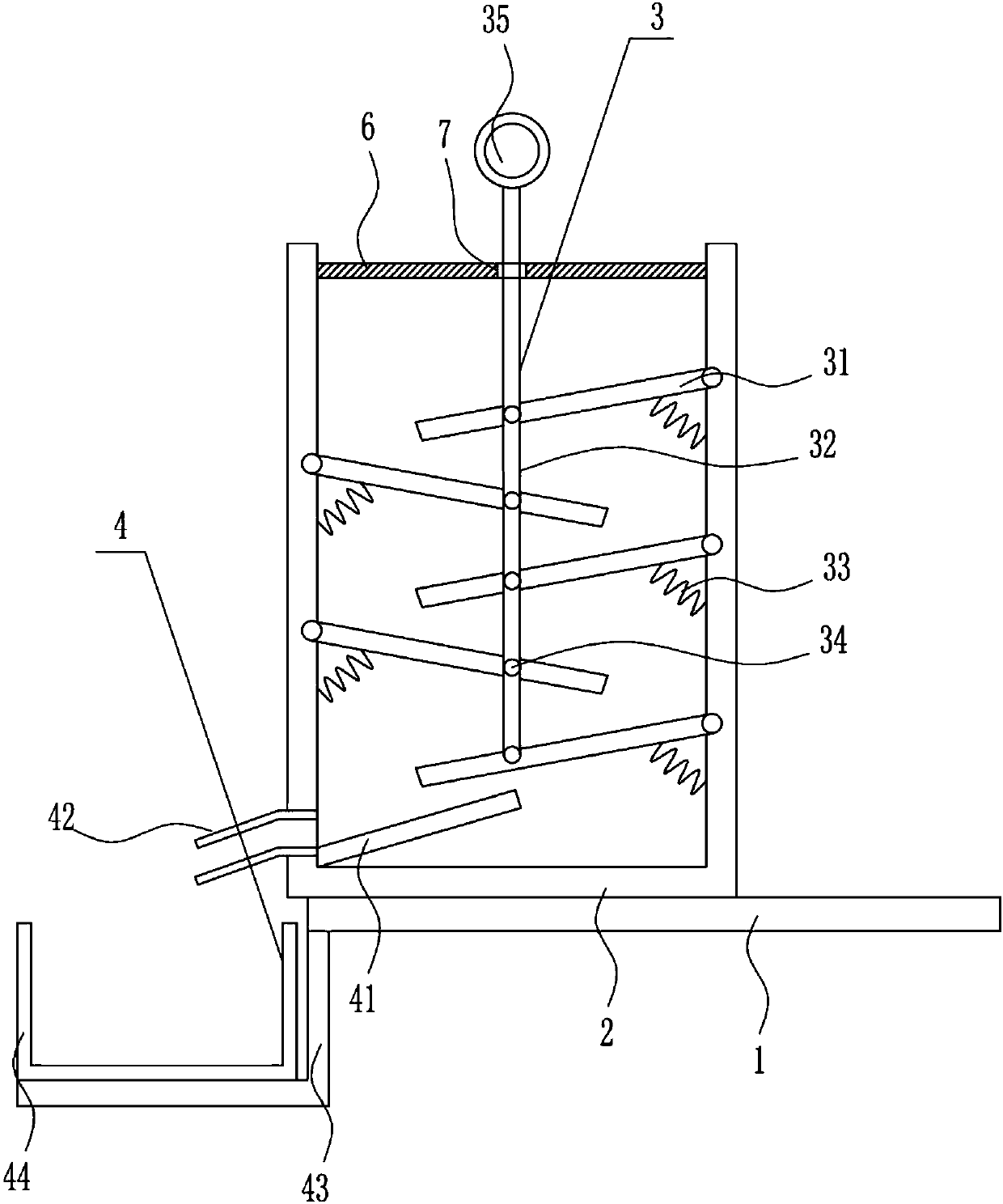

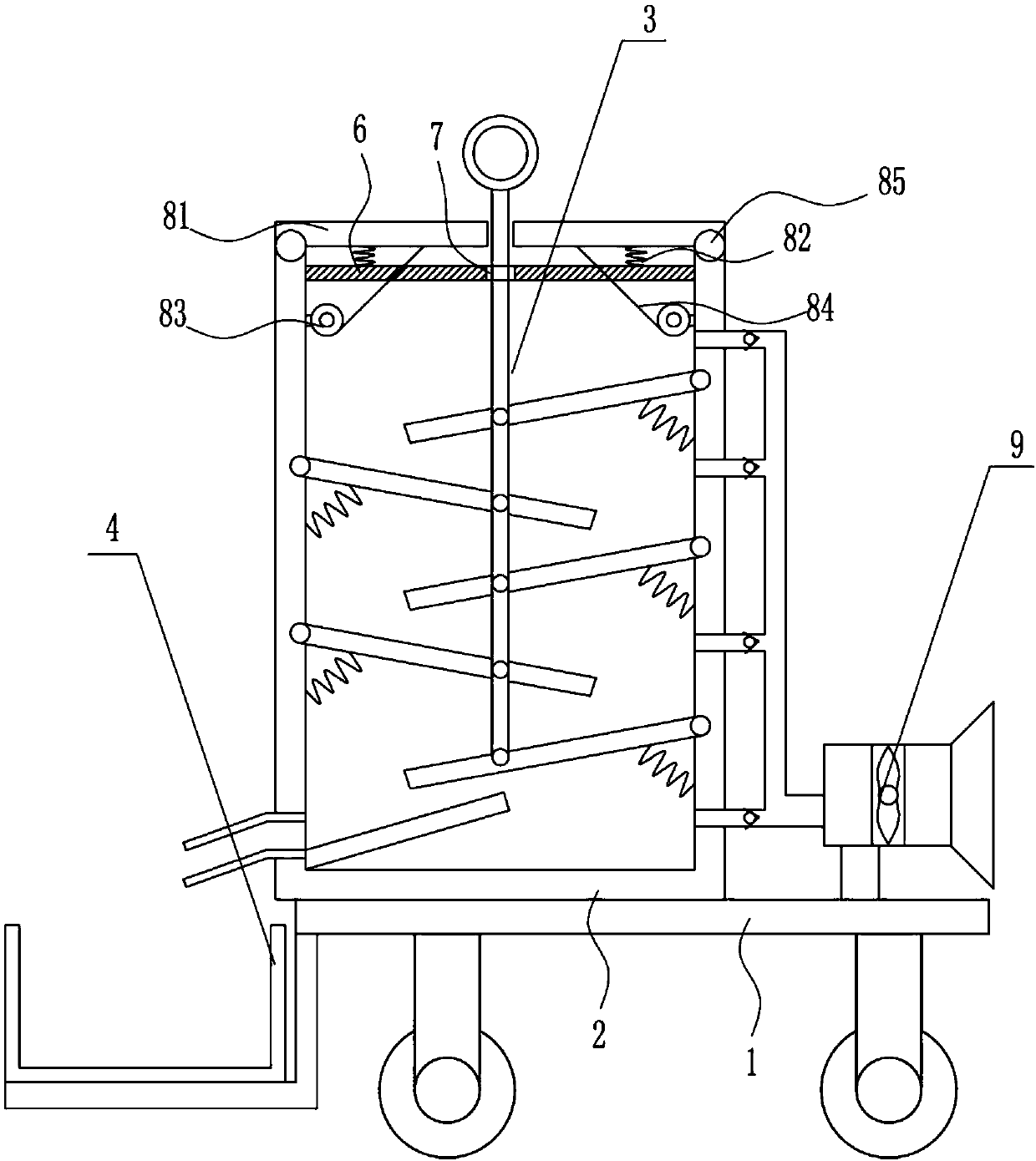

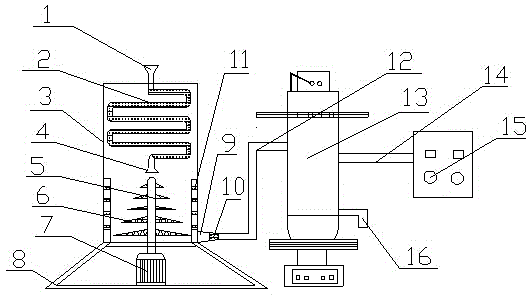

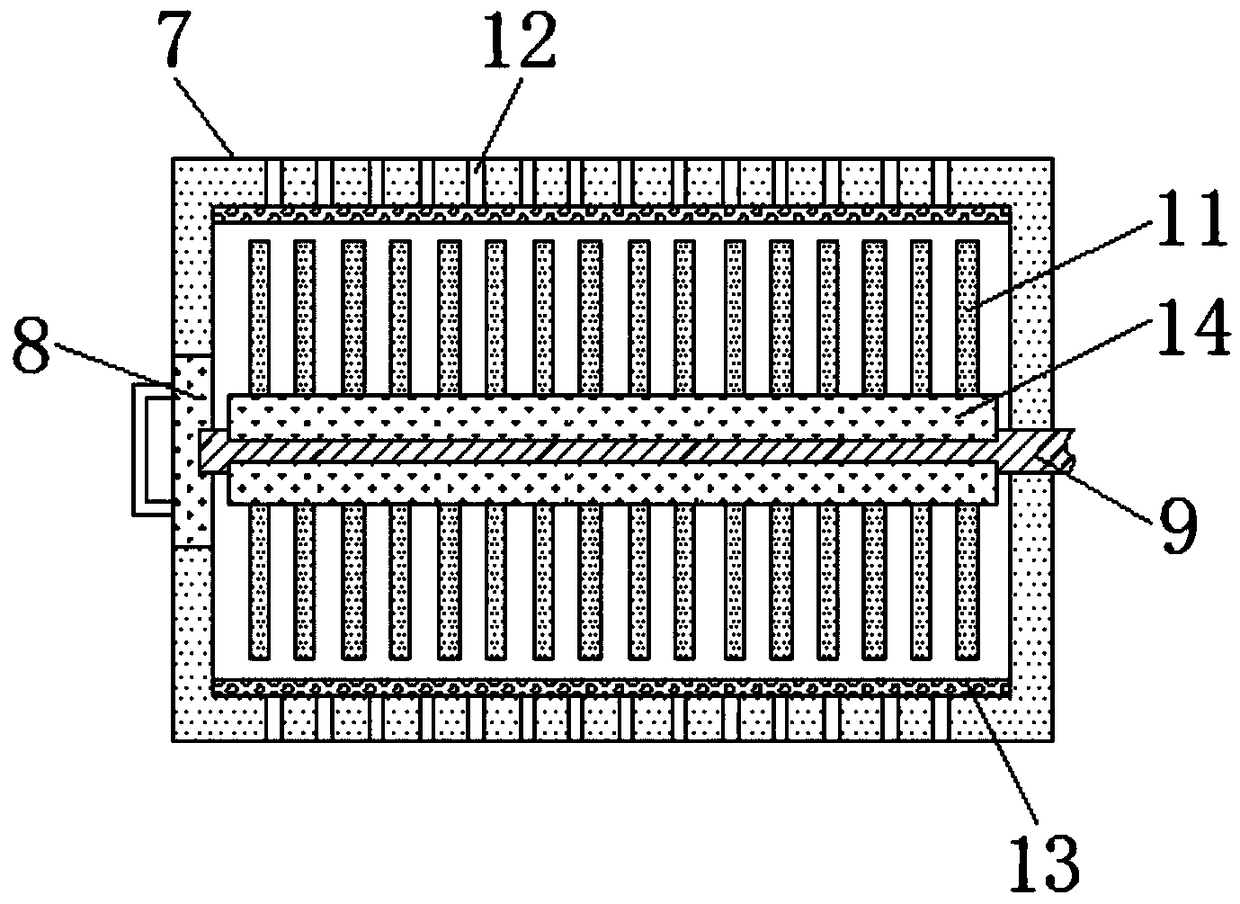

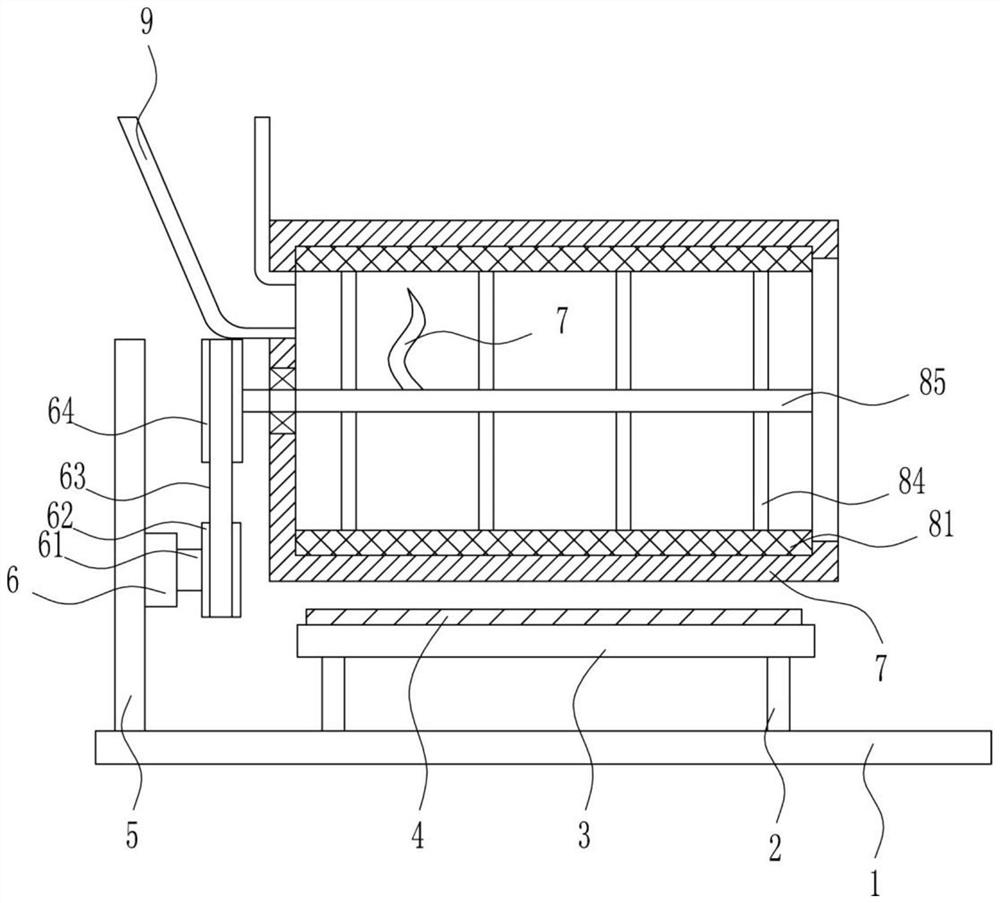

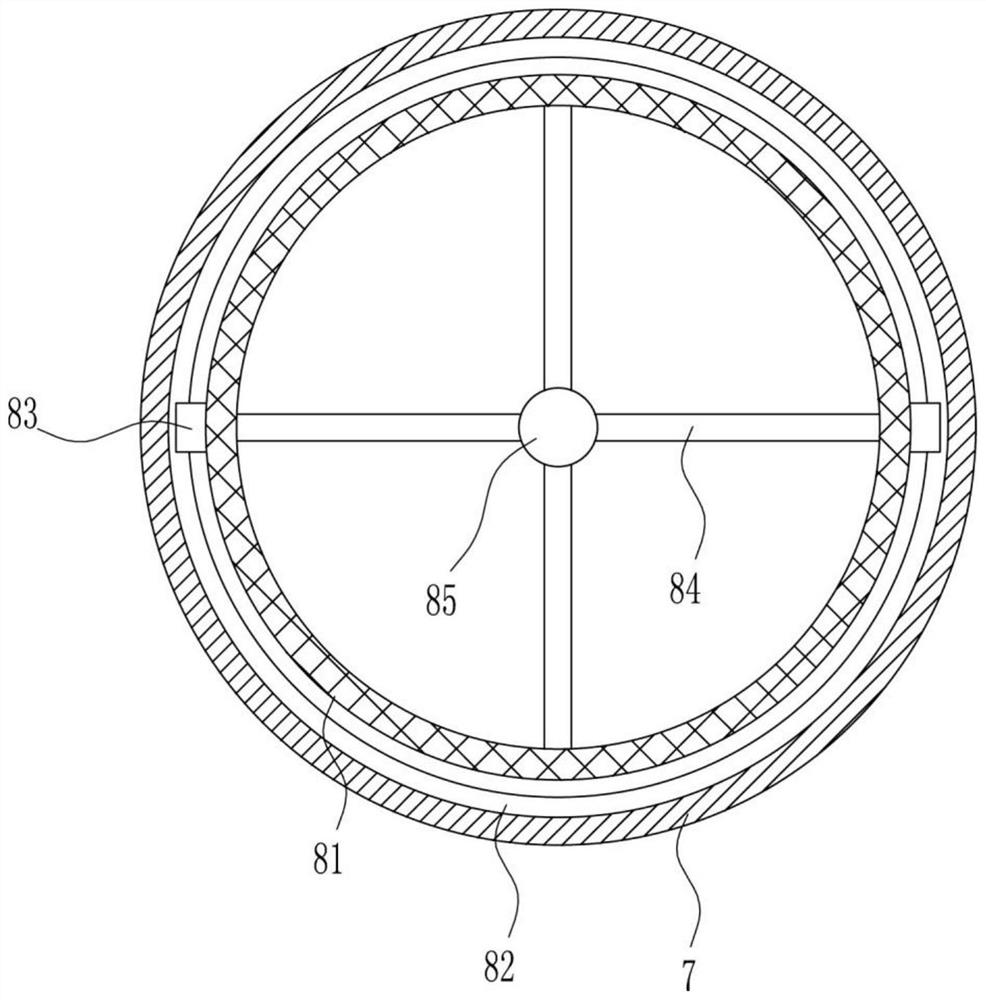

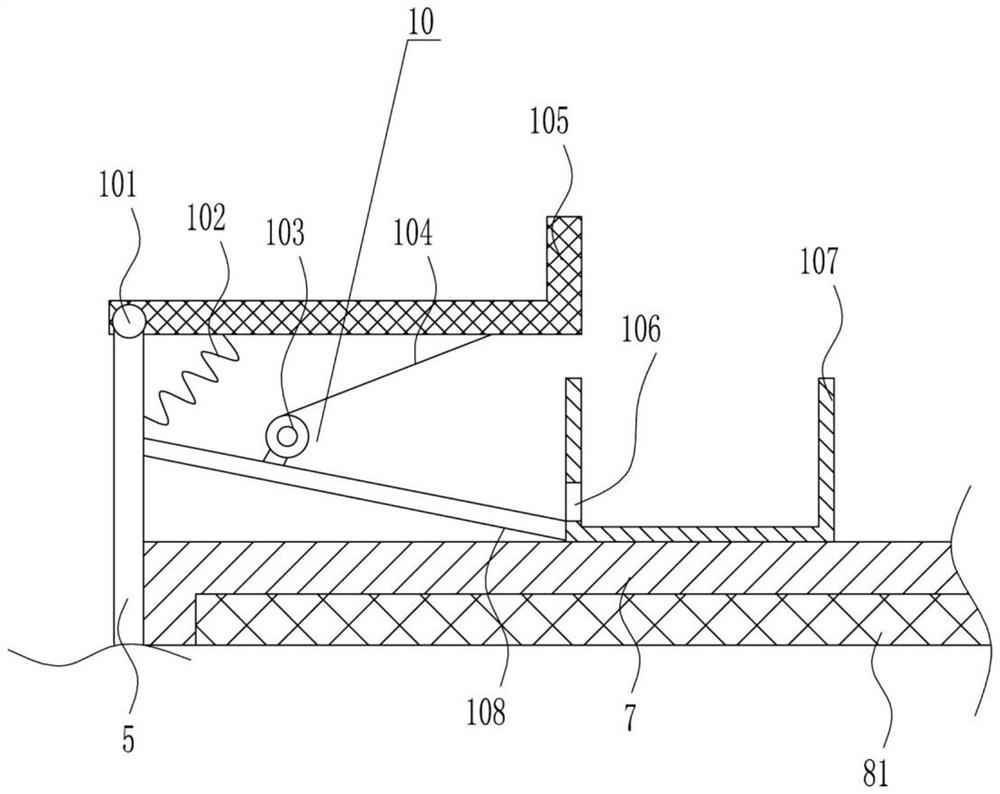

Layered drying device for wine processing raw materials

InactiveCN107806759AHigh speedImprove efficiencyDrying gas arrangementsDrying solid materialsPulp and paper industryRaw material

The invention relates to a layered drying device, in particular to a layered drying device for wine processing raw materials. According to the layered drying device for the wine processing raw materials, the wine processing raw materials are high in drying efficiency, uniform and full in drying, high in drying speed and further convenient to move. The layered drying device for the wine processingraw materials comprises a bottom plate and the like; a drying box is arranged at the top of the bottom plate, a collecting mechanism is arranged on the left side of the bottom plate, and a layered drying mechanism is arranged in the drying box; and a guiding rod is arranged at the top of the drying box, and a first through hole is formed in the middle of the guiding rod. According to the layered drying device, the effects that the wine processing raw materials are high in drying efficiency, uniform and full in drying, high in drying speed and further convenient to move are achieved, the wine processing raw materials are dried through the layered drying mechanism, and meanwhile the interior of the drying box is ventilated through a ventilation mechanism.

Owner:闫存

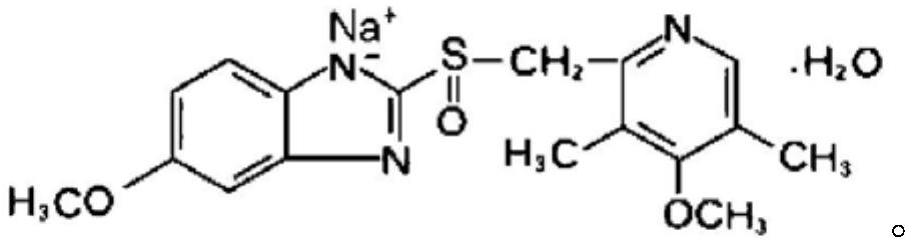

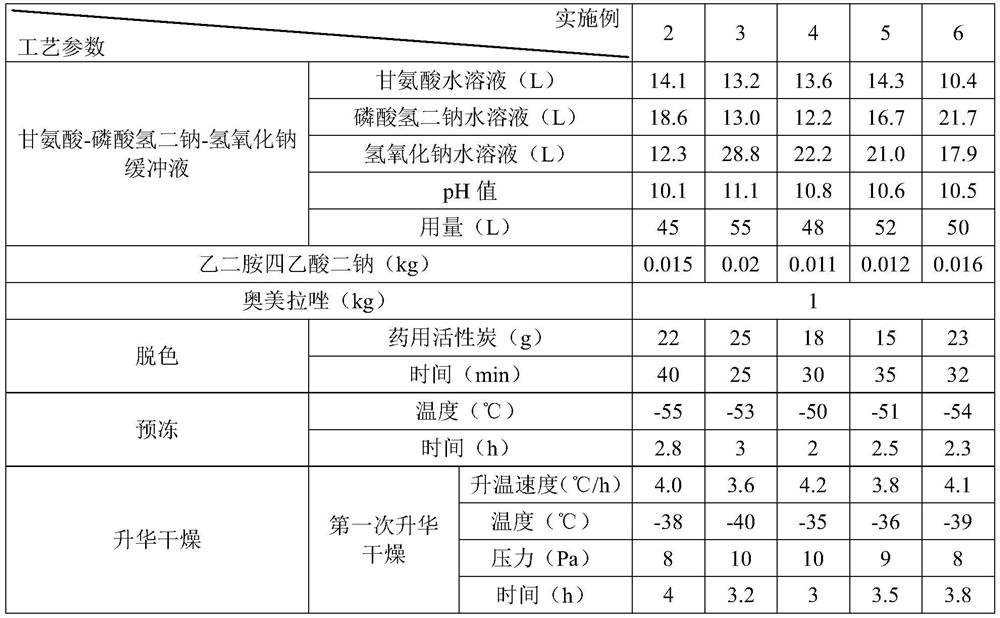

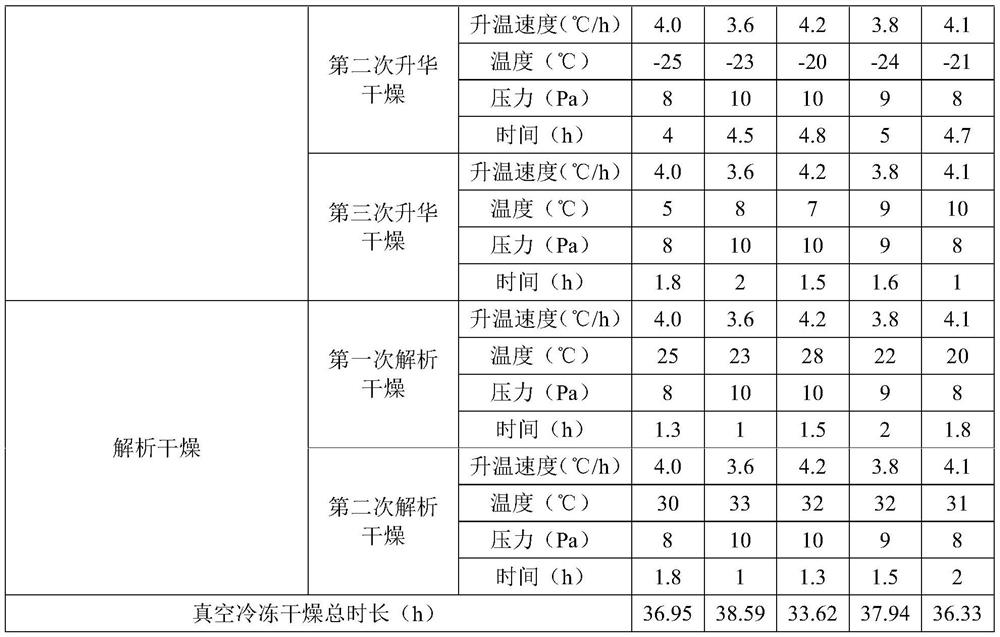

Omeprazole sodium for injection and preparation method thereof

ActiveCN114028346AAvoid PolymerizationImprove stabilityPowder deliveryOrganic active ingredientsOmeprazole SodiumGlycine

The invention provides omeprazole sodium for injection and a preparation method thereof, and belongs to the technical field of medicine preparation. The preparation method comprises the steps that 0.01-0.02 part by weight of antioxidant is taken to be dissolved in a glycine-disodium hydrogen phosphate-sodium hydroxide buffer solution with the pH value being 10.1-11.1, then 1 part by weight of omeprazole sodium is added to be dissolved, then decoloration, degerming filtration and freeze-drying are conducted to obtain the omeprazole sodium for injection. Aiming at the structural characteristics of the omeprazole sodium, the glycine-disodium hydrogen phosphate-sodium hydroxide buffer solution with a specific pH value is prepared, so that polymerization reaction of the omeprazole sodium caused by the influence of the pH value in the preparation, storage and use processes is effectively inhibited, the impurity generation of the omeprazole sodium is effectively reduced, and the stability of the omeprazole sodium for injection is improved.

Owner:HAINAN HUALON PHARM

Drying and recycling equipment for treating high-salinity wastewater concentrated mother liquor

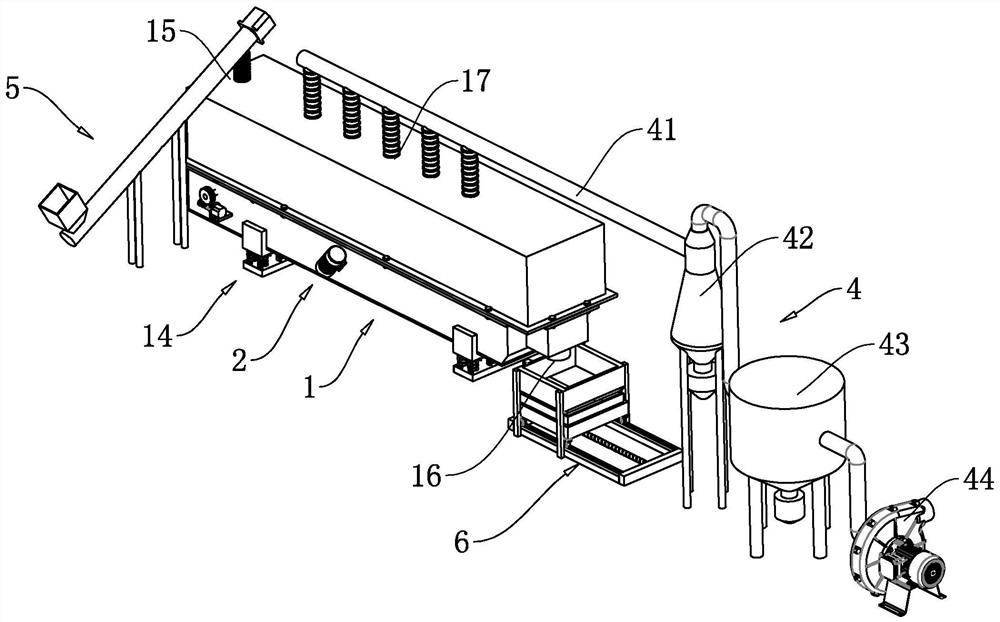

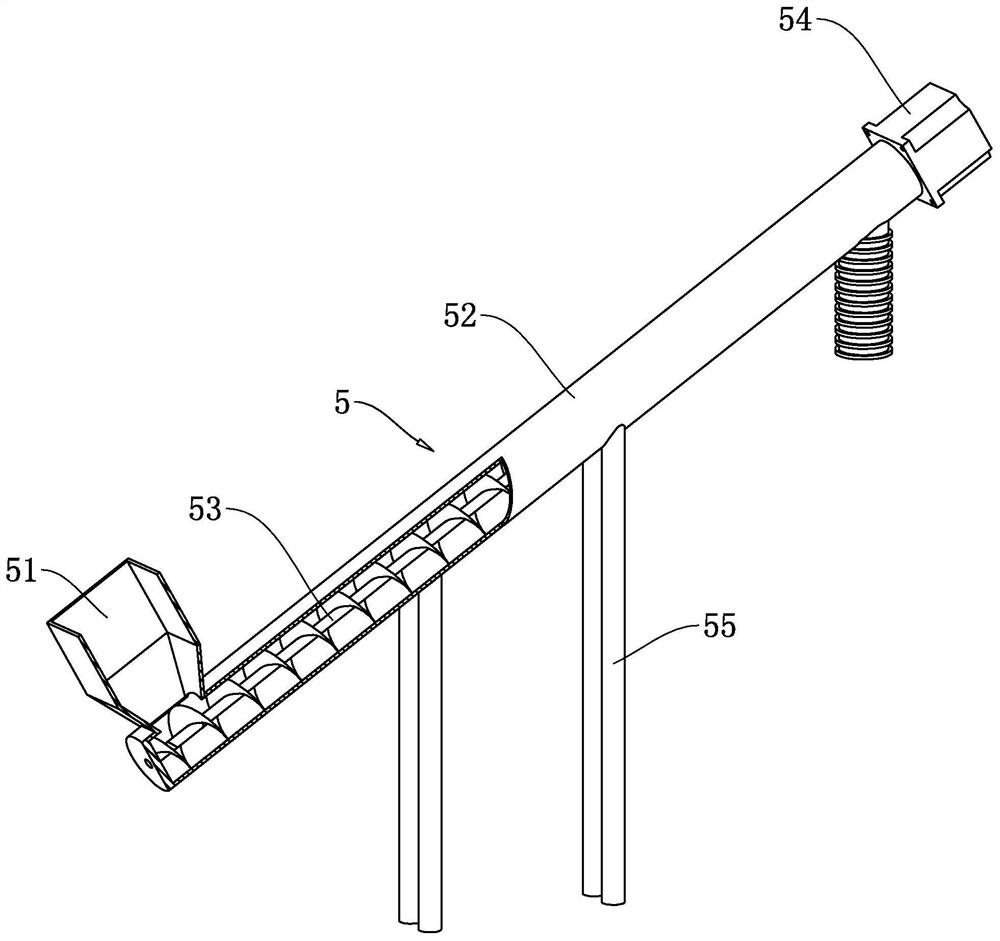

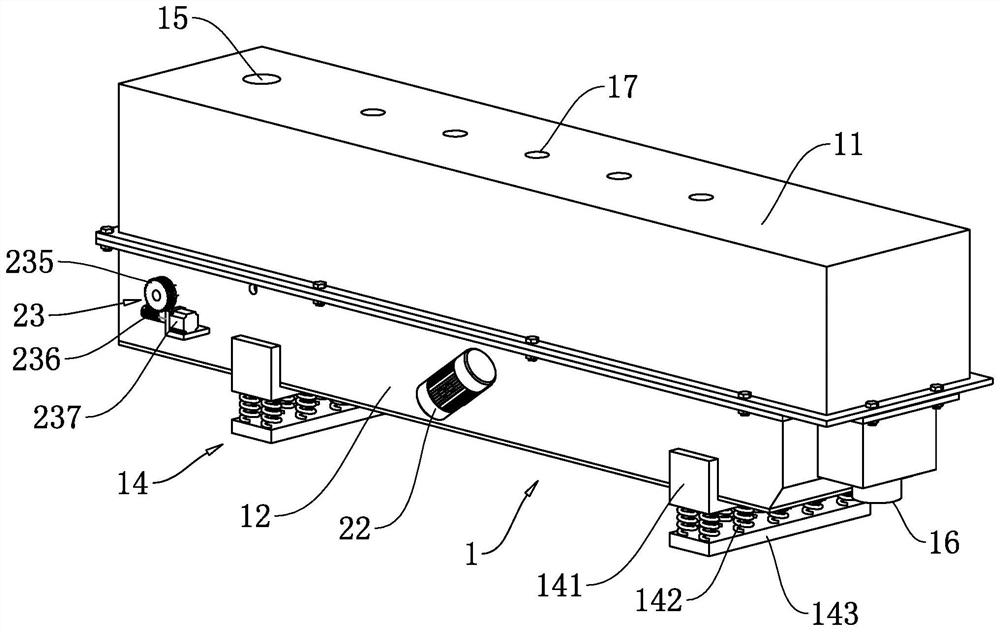

ActiveCN113087066ADry evenly and fullyNot prone to material jamsWater/sewage treatment by irradiationWater/sewage treatment by heatingElectric machineryProcess engineering

The invention relates to drying and recycling equipment for treating high-salinity wastewater concentrated mother liquor, and relates to the field of wastewater treatment. The drying and recycling equipment comprises a drying bin body, a vibration conveying device and a drying device; a feeding port and a discharging port are formed in the drying bin body, and the vibration conveying device and the drying device are both mounted on the drying bin body; and the vibration conveying device comprises a conveying plate used for conveying materials and a vibration motor used for driving the conveying plate to vibrate, and the drying device is used for heating and drying the materials on the conveying plate. The drying device has the advantages that materials are dried more evenly and fully, the drying efficiency is high, and the materials are not prone to being stuck in the material conveying process.

Owner:江苏源拓环境科技有限公司

Coal chemical industry energy-saving type drying device with stirring function

ActiveCN110260621AImprove mixing effectDry fully and evenlyChemical industryDrying machines with non-progressive movementsCoal chemical industryProcess engineering

The invention relates to a coal chemical industry energy-saving type drying device with a stirring function. The coal chemical industry energy-saving type drying device with the stirring function comprises a body, a feeding box and two support legs and further comprises a stirring mechanism and an energy-saving mechanism. The stirring mechanism comprises a fixing box, two transmission assemblies and two stirring assemblies. A drive assembly is arranged in the fixing box. The stirring assembly comprises a connection rod, two supporting shafts and two stirring plates. The energy-saving mechanism comprises an air pump, a connection pipe and a cooling pipe. The coal chemical industry energy-saving type drying device with the stirring function can stir coal materials in the body through the stirring mechanism, and the situation that the coal materials are piled, so that the drying effect is influenced is avoided; and by means of the energy saving mechanism, heat of the body can be utilized to preheat the coal materials in the feeding box, so that energy is saved.

Owner:ANHUI HAOYUAN CHEM IND GRP

An intelligent drying device

ActiveCN104930827BReduce wasteSave energyDrying machines with non-progressive movementsDrying solid materialsMechanical engineeringSunlight

The invention discloses an intelligent airing and drying device, which comprises a box body and control cabinets, wherein the control cabinets are arranged on the bottom or the side face of the box body; a power source module and a control module are arranged in the control cabinets; airing and drying frames are arranged inside the box body; an exhaust device is arranged on the top of the box body; a plurality of rotating shafts are closely arranged on the airing and drying frames side by side; each rotating shaft can be independently rotated; the airing and drying frames are provided with heating devices; the box body is made of a transparent material; to-be-dried materials are placed on the airing and drying frames; when sunlight irradiates the outside of the box body, the to-be-dried materials can be directly aired by utilizing the temperature of sunlight; and after the materials on the airing and drying frames are aired and dried for a period of time, the rotating shafts are controlled to rotate, and the materials are sequentially aired and dried after being overturned. The rotating shafts are arranged on the airing and drying frames, the materials are overturned by adopting the rotating shafts, and the materials can be relatively uniformly and adequately aired, so that the airing speed and efficiency are effectively improved.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

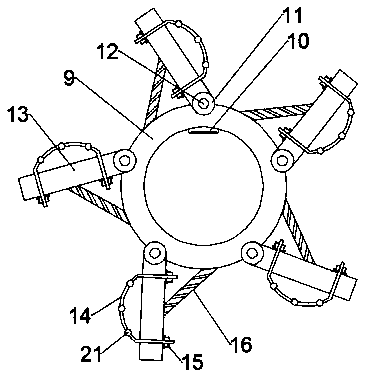

Combined type high-applicability pin drying device

PendingCN108613520AUniform receptionDry evenly and fullyDrying gas arrangementsDrying chambers/containersPulp and paper industryHeating furnace

The invention discloses a combined type high-applicability pin drying device. The combined type high-applicability pin drying device comprises a drying kettle, wherein a lamp support is arranged inside the drying kettle; drying lamps are mounted on the lamp support; the outer side of the drying kettle is equipped with two hot air fans; the hot air fans are connected with heat furnace interfaces; the other ends of the hot air fans are connected with air inlet tubes; the air inlet tubes are inserted into the drying kettle; a drive rotary shaft is arranged inside the drying kettle; the outer sideof the drive rotary shaft is connected with a drying bracket; the two hot air fans are used for blowing hot air to the inner part, and are matched with the drying lamps for drying pins on the rotating drying bracket, so that the pins inside uniformly receive heat for being dried more uniformly and sufficiently; and the pins are fixed by the drying bracket, so that different angles can be kept atdifferent rotation speeds, the drying effects are different as long as spacing between the pins and heat sources is different, different pins can be dried, and therefore, the combined type high-applicability pin drying device is worthy of being popularized.

Owner:天津卓帛科技发展有限公司

Polyester postaddition melt modifying system

The invention discloses a polyester postaddition melt modifying system, which belongs to the field of a polyester production technology. The polyester postaddition melt modifying system comprises a melt main pipe, a blending screw, a melt filter, a fluid converter and multiple melt pumps. In addition, the polyester postaddition melt modifying system further comprises a vacuum drying apparatus and / or a vacuum suction device. According to the polyester postaddition melt modifying system provided by the invention, as the vacuum drying device is arranged, an additive can be completely and uniformly dried before entering the modifying system, and further, the moisture brought into the modifying system through the additive can be reduced as much as possible; and as the vacuum suction device is arranged in the modifying system to suck the moisture removed from the additive after the additive and a melt are mixed, the moisture in the modifying system is further reduced, and further, the influence on the intrinsic viscosity of the melt, due to the addition of the additive, is finally reduced.

Owner:江苏桐昆恒欣新材料有限公司

Pymetrozine powder drying machine

InactiveCN105318699AReduce lossHigh purityDrying gas arrangementsDrying solid materialsImpellerPulp and paper industry

The invention discloses a pymetrozine powder drying machine which comprises a drying machine body, a feeding hopper, a discharging port and a motor. The drying machine body is supported on a base, stirring vane wheels are arranged on a stirring shaft arranged on the motor, airflow holes are formed in the two ends of the drying machine body, the feeding hopper is arranged at the top end of the drying machine body, one end of the feeding hopper is connected to an electric heater, a spray head is arranged at the tail end of the electric heater, a connector is arranged at the lower end of the drying machine body, the other end of the connector is connected to a vacuum feeding machine through a conveying pipe, the discharging port is formed in the bottom end of the vacuum feeding machine, and the vacuum feeding machine is connected to an electric control device through a power line. The pymetrozine powder drying machine is sufficient and uniform in drying, short in time and high in efficiency, purity of products is ensured, meanwhile, materials are automatically collected, and hand labor is reduced.

Owner:ANHUI YANGZI CHEM

Glue blending granulation process for preparing hard alloy

InactiveCN110202126ADry evenly and fullyQuality assuranceTransportation and packagingMetal-working apparatusWaxQuality assurance

The invention provides a glue blending granulation process for preparing a hard alloy. The glue blending granulation process for preparing the hard alloy comprises the steps of drying, cooling, sieving and glue (wax) blending granulation on a mixed wet abrasive. The technical control contents in the various steps are illustrated in detail, the glue blending granulation process provides quality assurance for subsequent pressing and sintering of the hard alloy, the rejection rate is reduced, and meanwhile, the glue blending granulation process is also beneficial to obtaining a hard alloy body with stable mechanical properties.

Owner:四川铭泰顺硬质合金有限公司

Quick drying device for tea processing

InactiveCN108759400ADry evenlyImprove practicalityPre-extraction tea treatmentTea dryingEngineeringMagnet

The invention discloses a quick drying device for tea processing. The quick drying device comprises a baseplate and a second shell; a first shell is arranged above the baseplate, and the left side ofthe lower end of the first shell is connected to the left side of the upper end of the baseplate through a hinge; the right side of the lower end of the first shell is provided with a support column,and the middle position of the upper end of the first shell is provided with an air inlet; the left upper end of the first shell is provided with a pull rod, and the second shell is located in the first shell; and a sleeve plate is arranged on a connecting rod, and a magnet is arranged between the sleeve plate and a rotating shaft. According to the quick drying device for tea processing, hot air is delivered into device through external equipment, and tea can be quickly dried through cooperation of stir-fry; and in the stir-fry process, small stones or some fragments mixed in the tea can be filtered out, and the practicability is improved.

Owner:福州众点网络技术开发有限公司

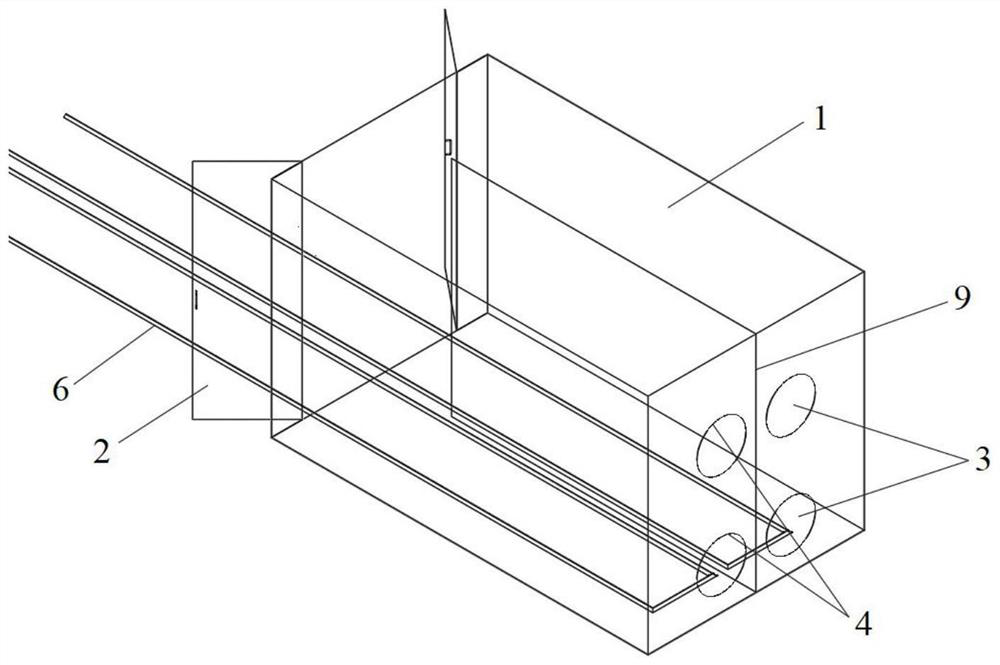

Material drying unit

InactiveCN111023778AAvoid breakingGuaranteed qualityDrying solid materials with heatDrying gas arrangementsEngineeringAtmospheric sciences

The invention relates to a material drying unit, which comprises a hot air drying region and a cold air drying region. The hot air drying region is used for drying the materials by means of hot air; the cold air drying region is used for drying the materials by means of cold air; and a tempering region is arranged between the hot air drying region and the cold air drying region, and is used for buffering the temperature change from the hot air drying region to the cold air drying region or from the cold air drying region to the hot air drying region. Through setting the hot air drying region and the cold air drying region for drying materials by means of hot air and cold air correspondingly, and setting the tempering region between the hot air drying region and the cold air drying region,the materials pass through the tempering region firstly and then enter the hot air drying region after coming out of the cold air drying region, the temperature of the materials can be buffered in thetempering region to adapt to temperature changes, the materials are prevented from being overheated in the hot air drying region, and the quality of agricultural products is guaranteed.

Owner:河南省农业科学院农副产品加工研究中心

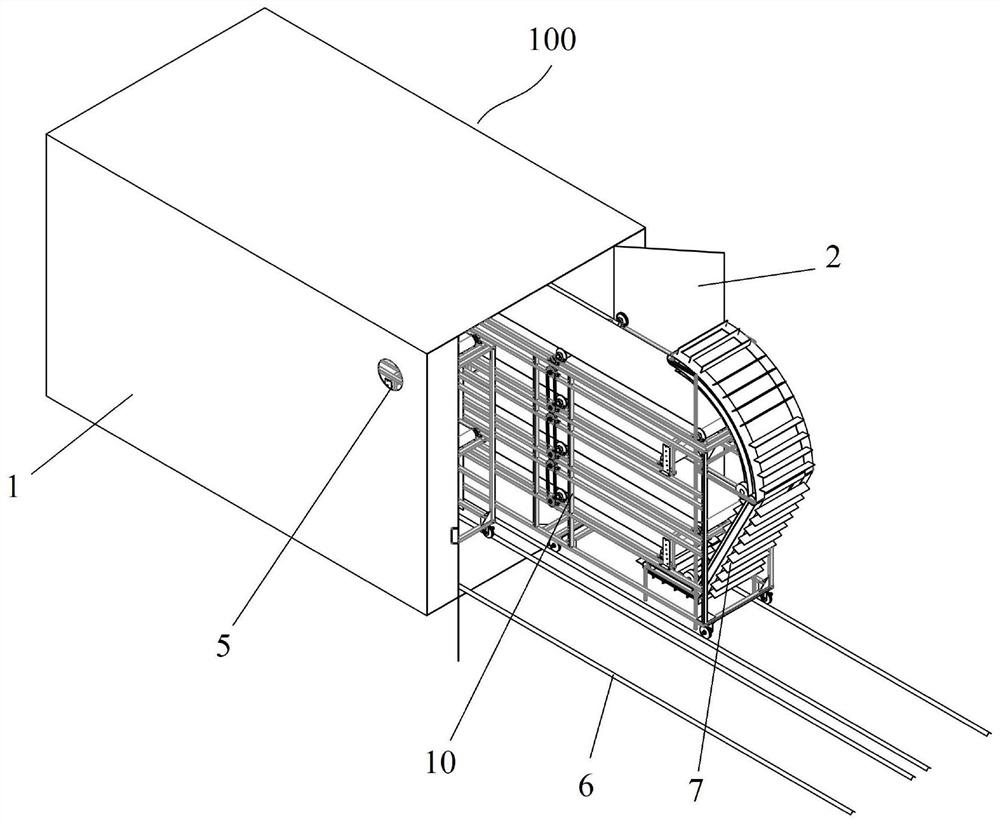

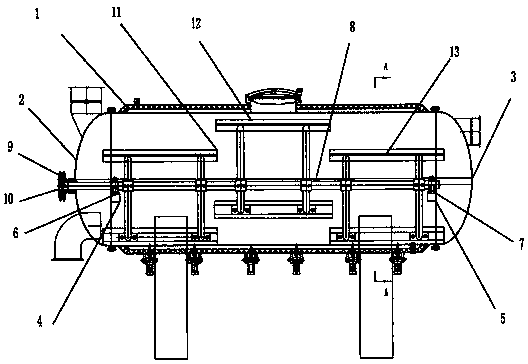

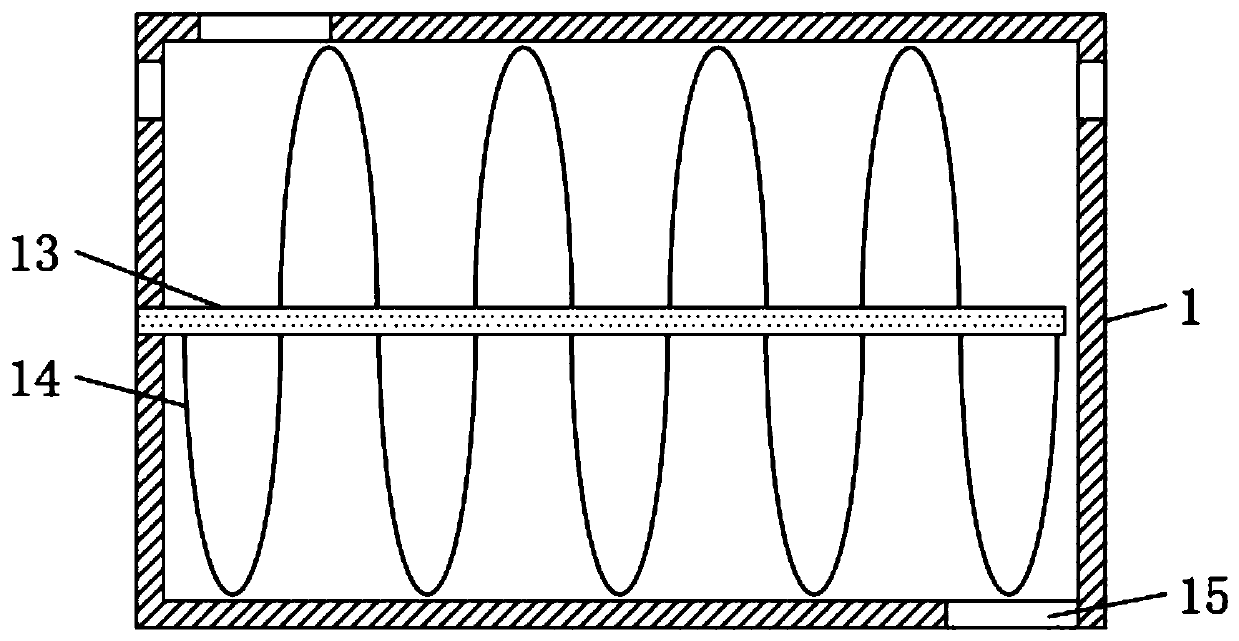

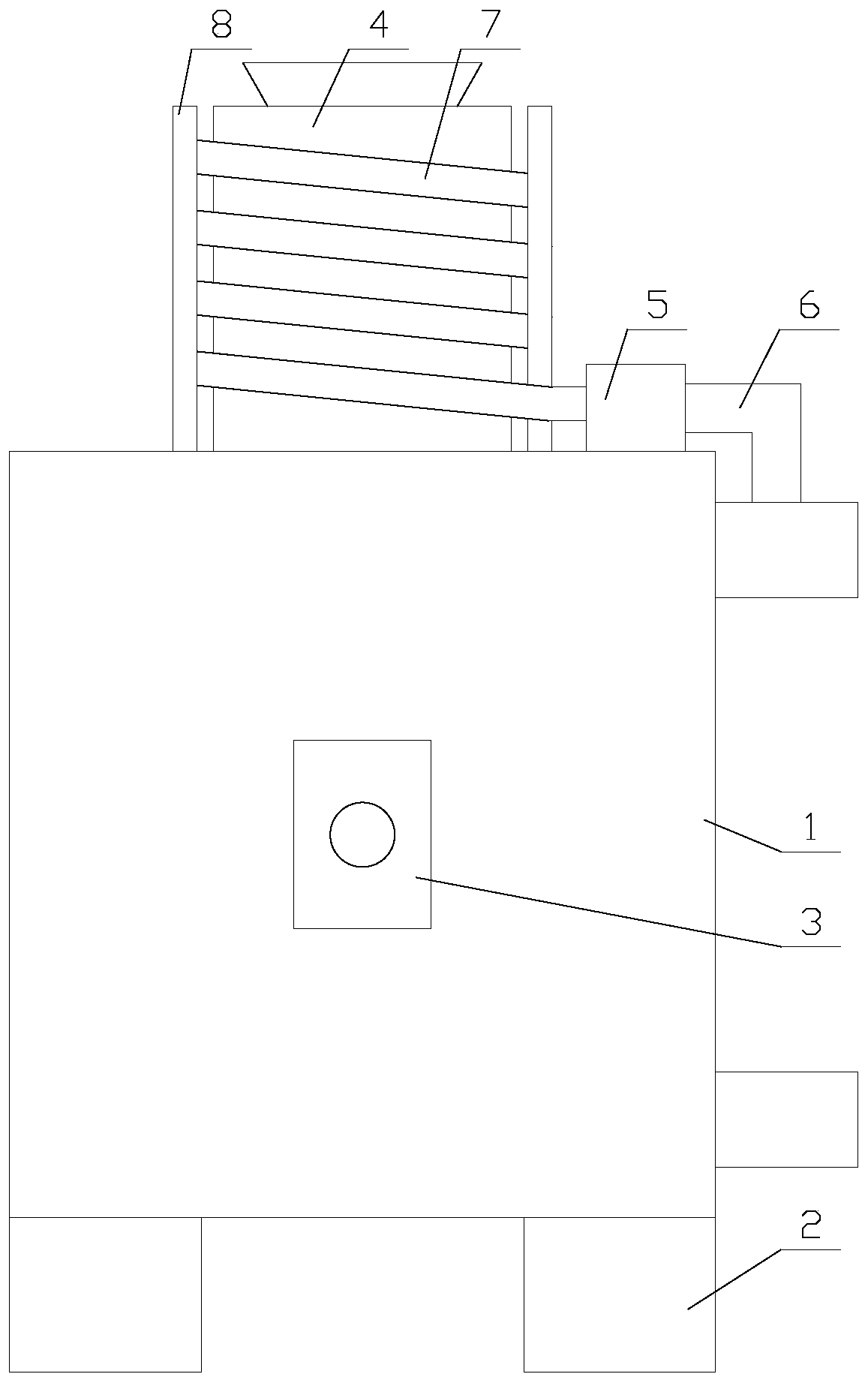

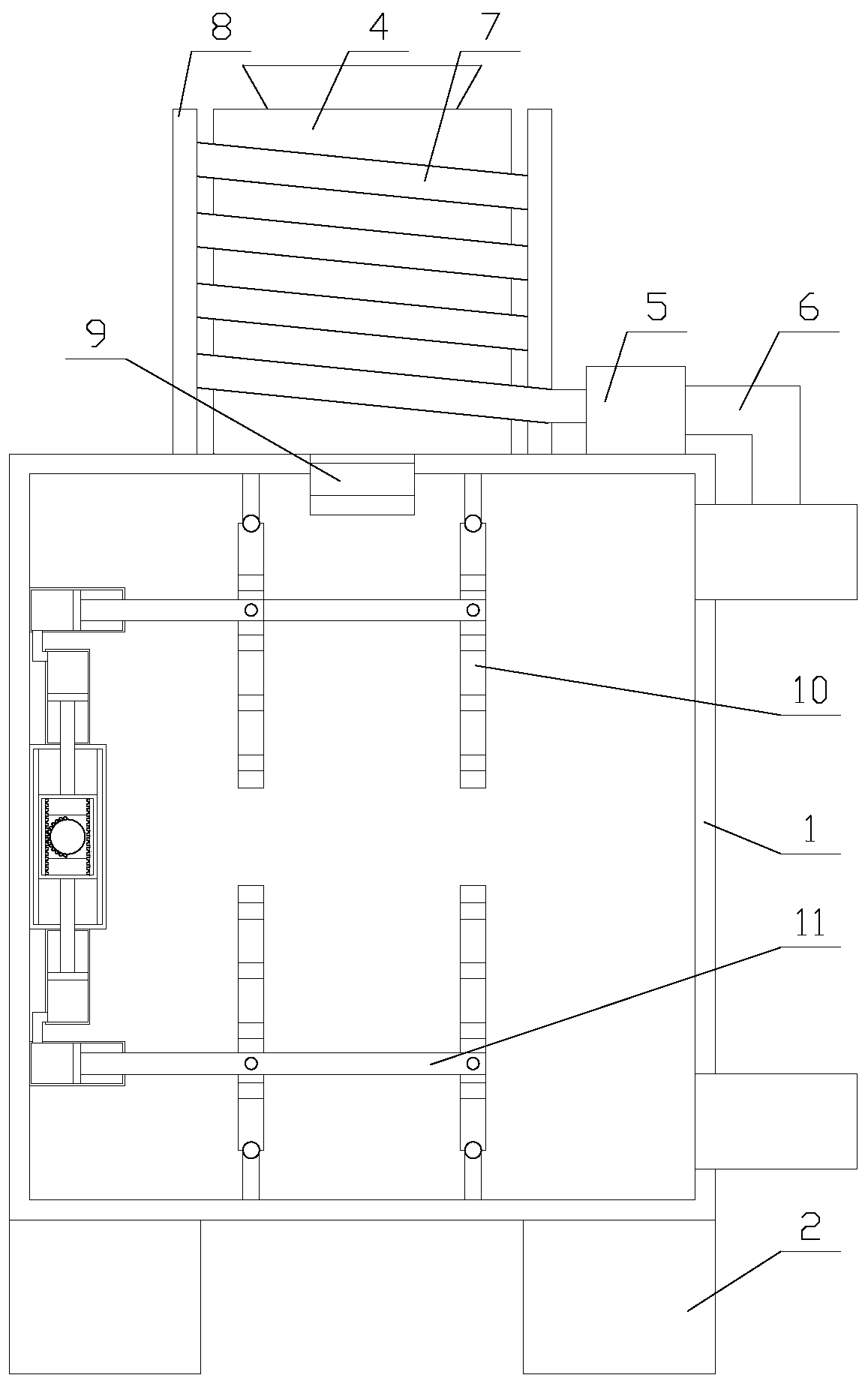

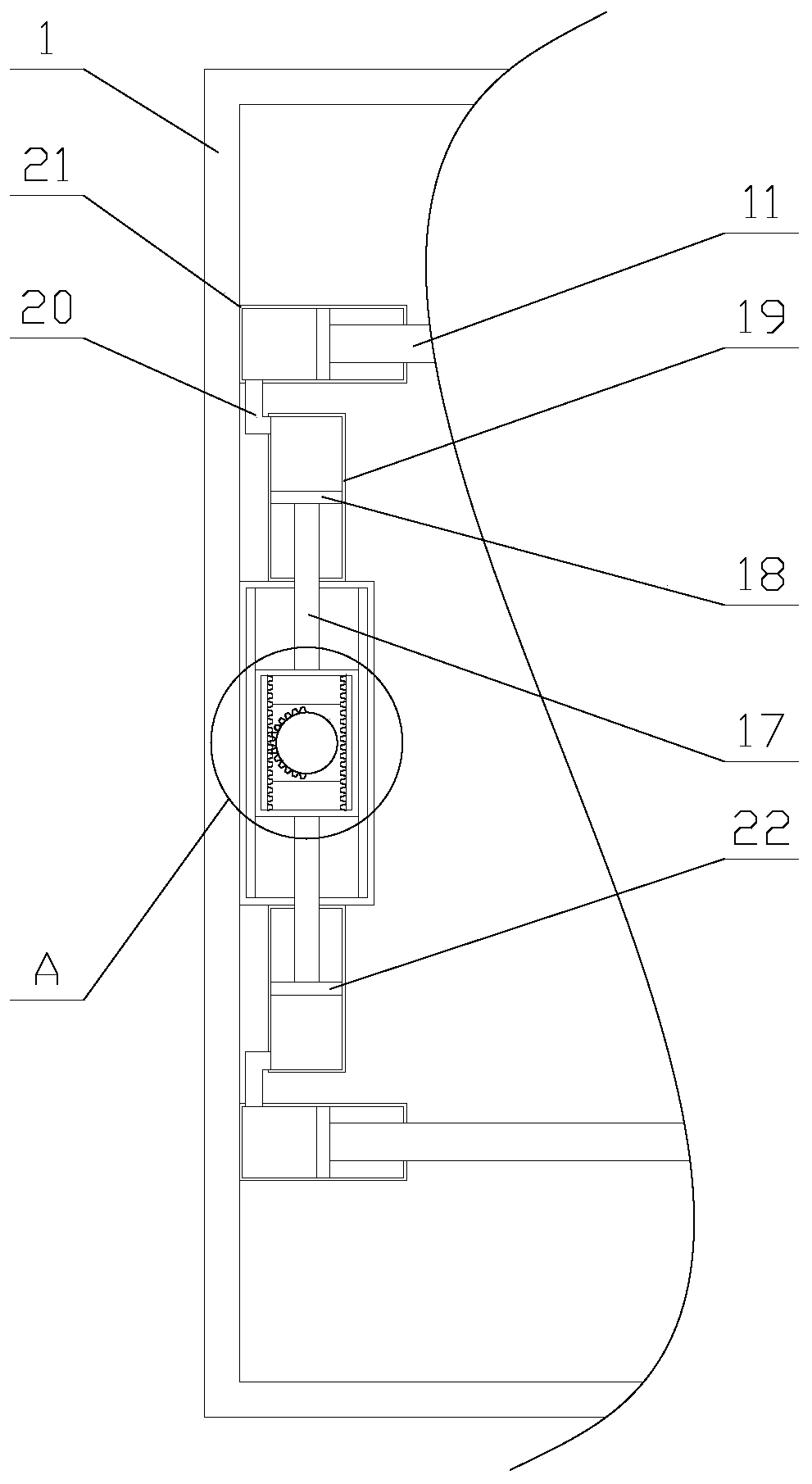

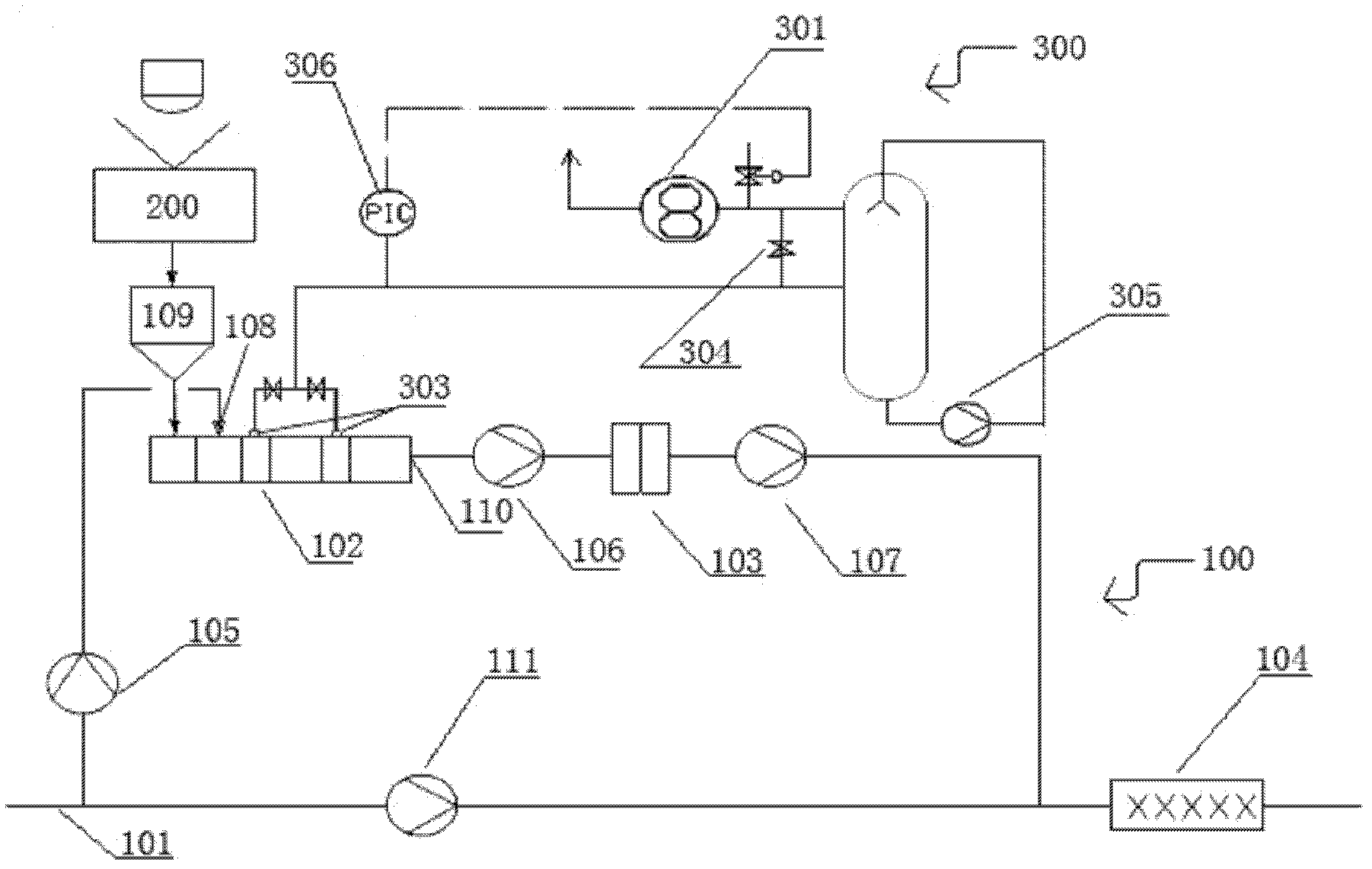

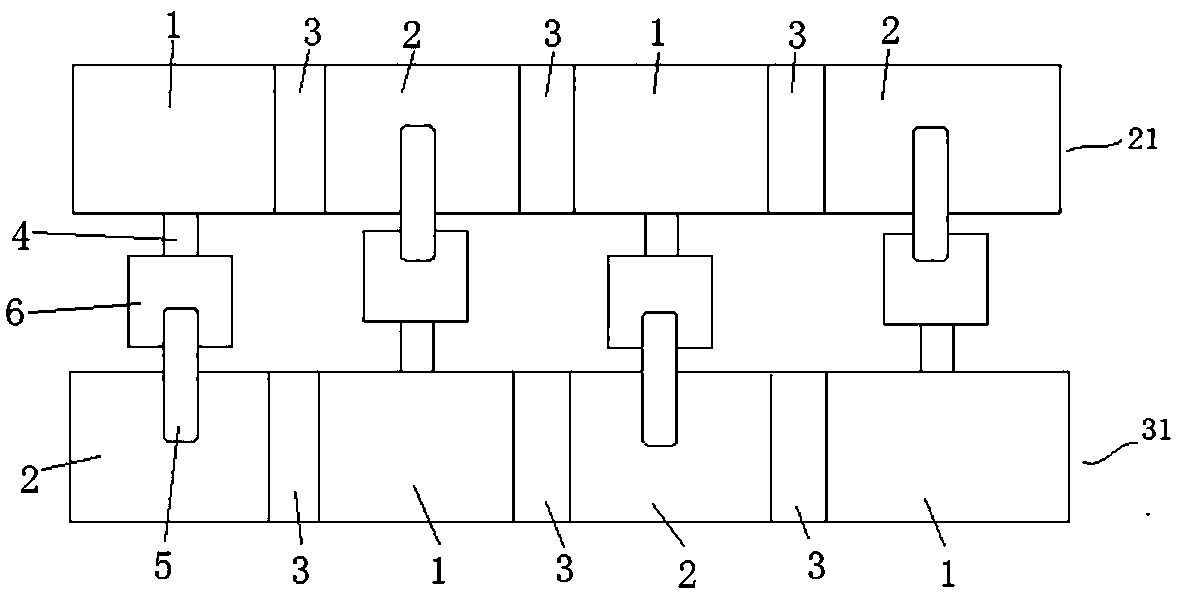

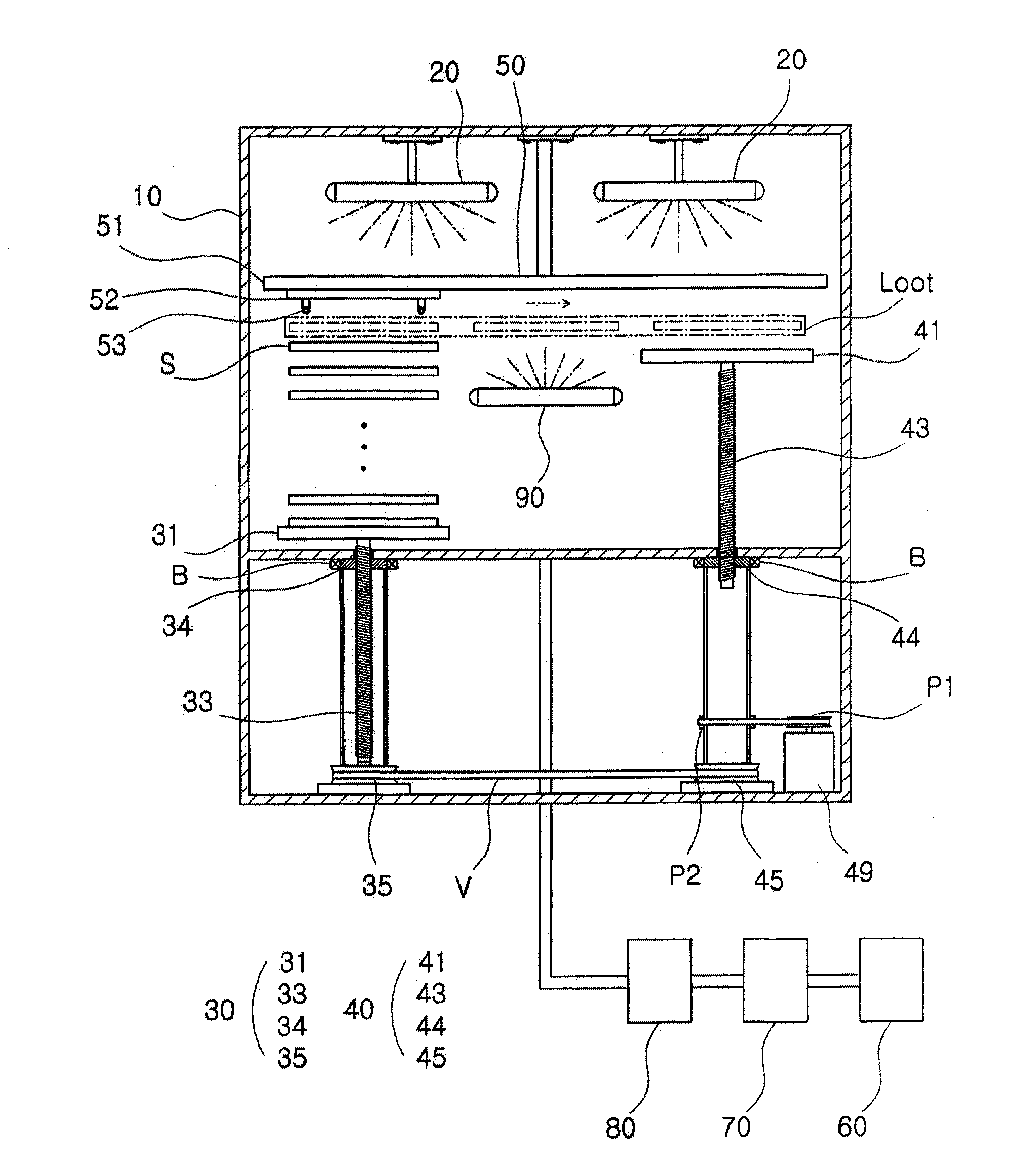

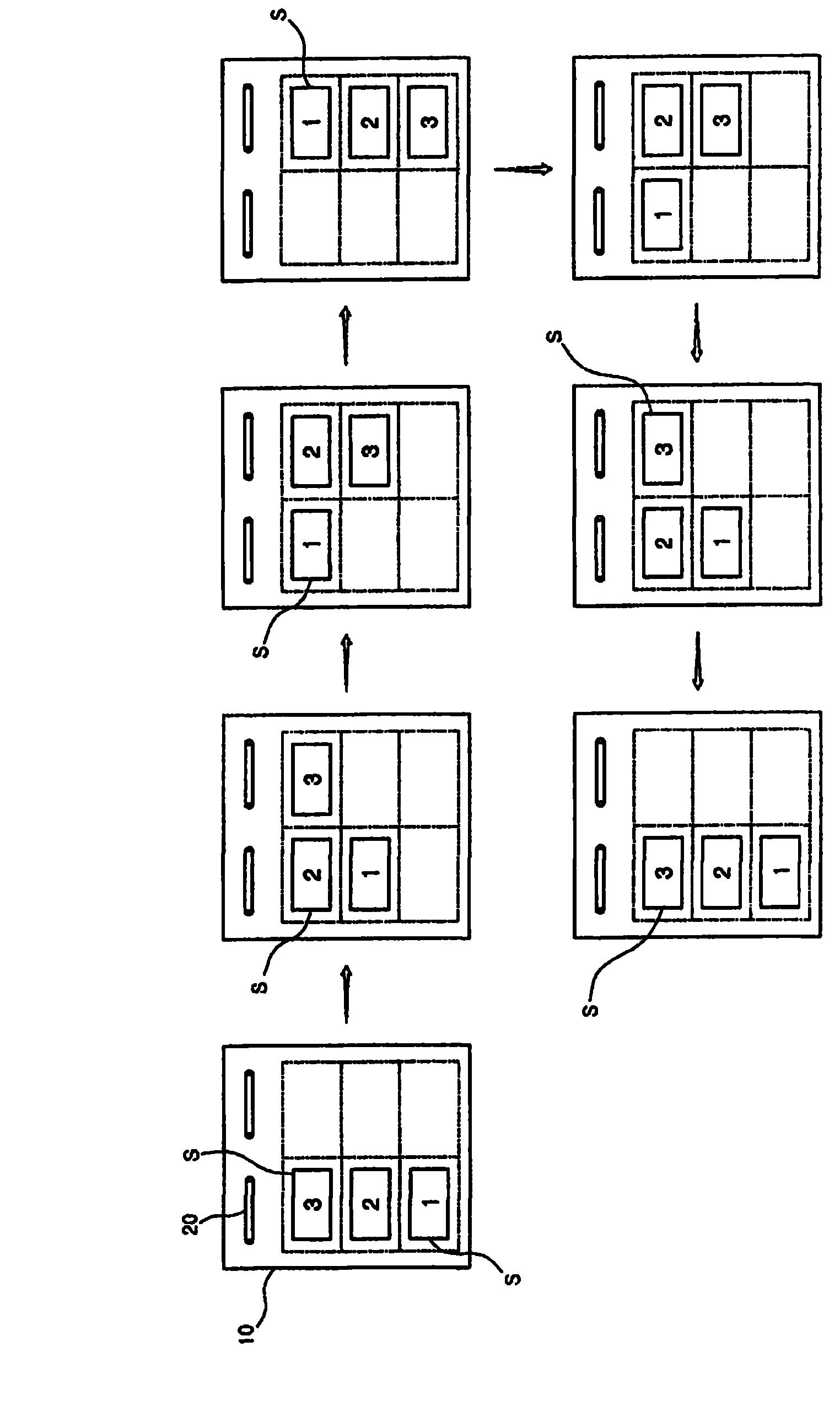

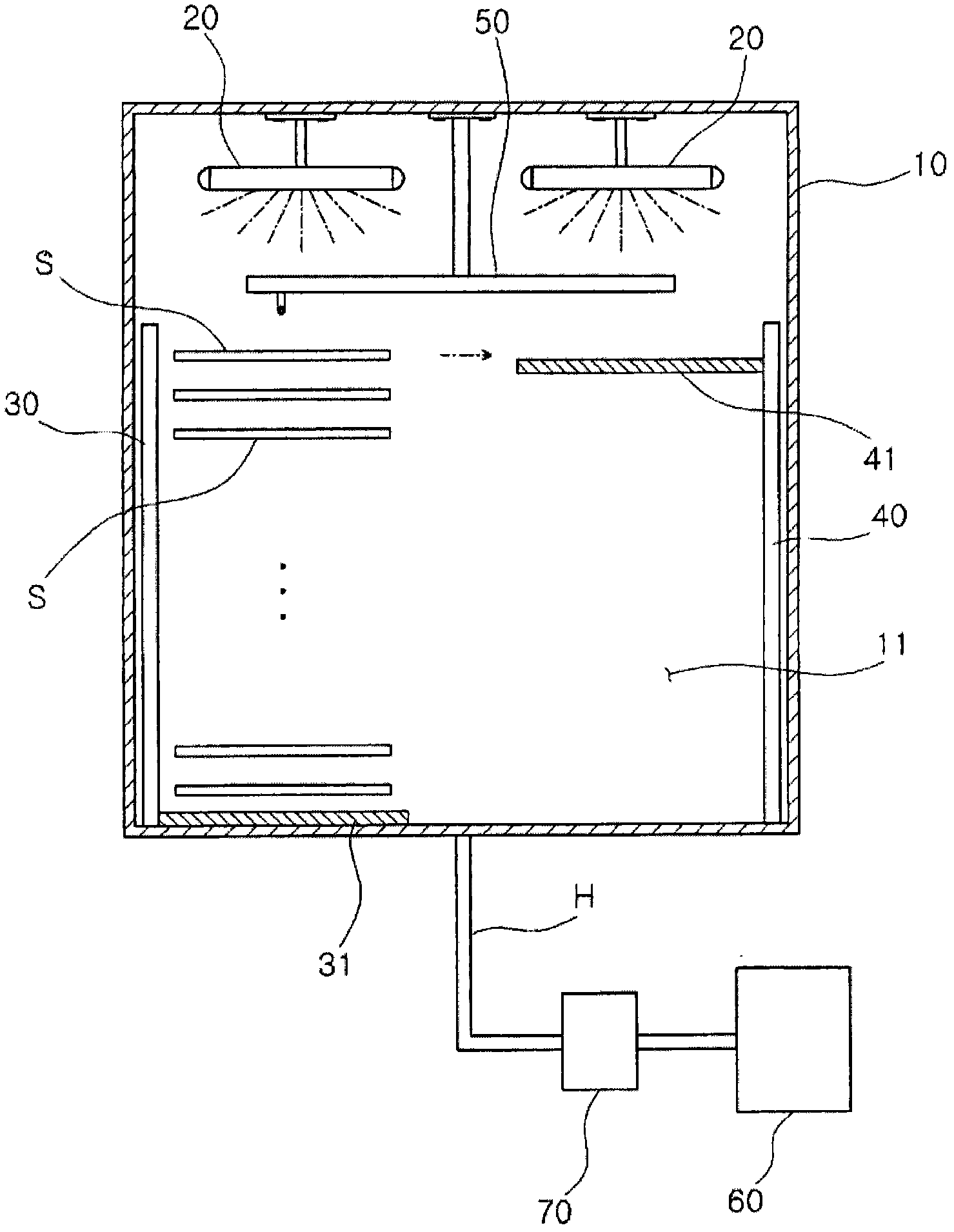

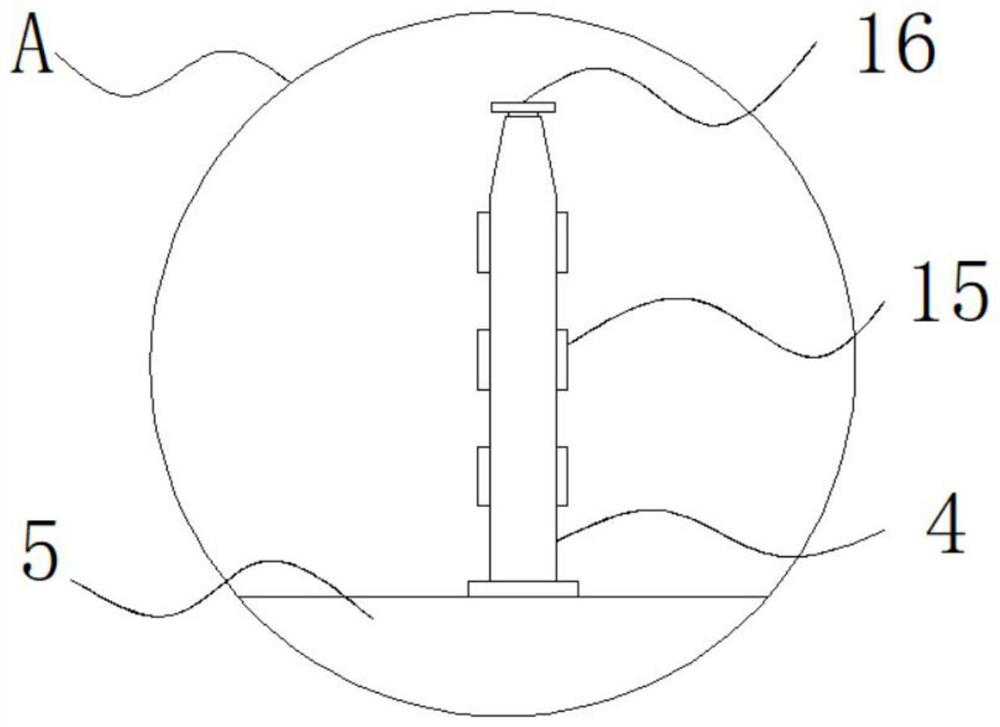

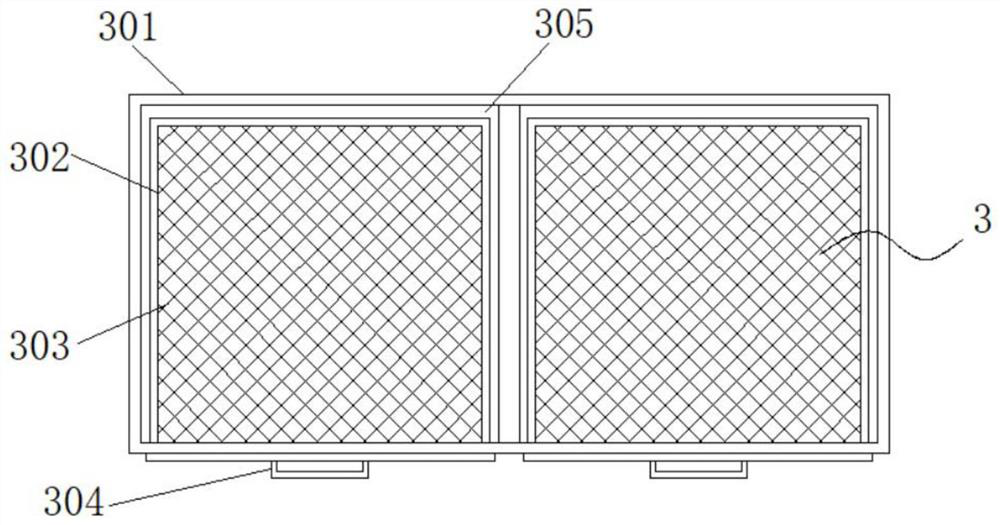

Vacuum drying apparatus of electrode plate for secondary battery and drying method therefor

InactiveCN102884656ALess drying deviationDry evenly and fullyDrying solid materials with heatElectrode thermal treatmentElectrical batteryEngineering

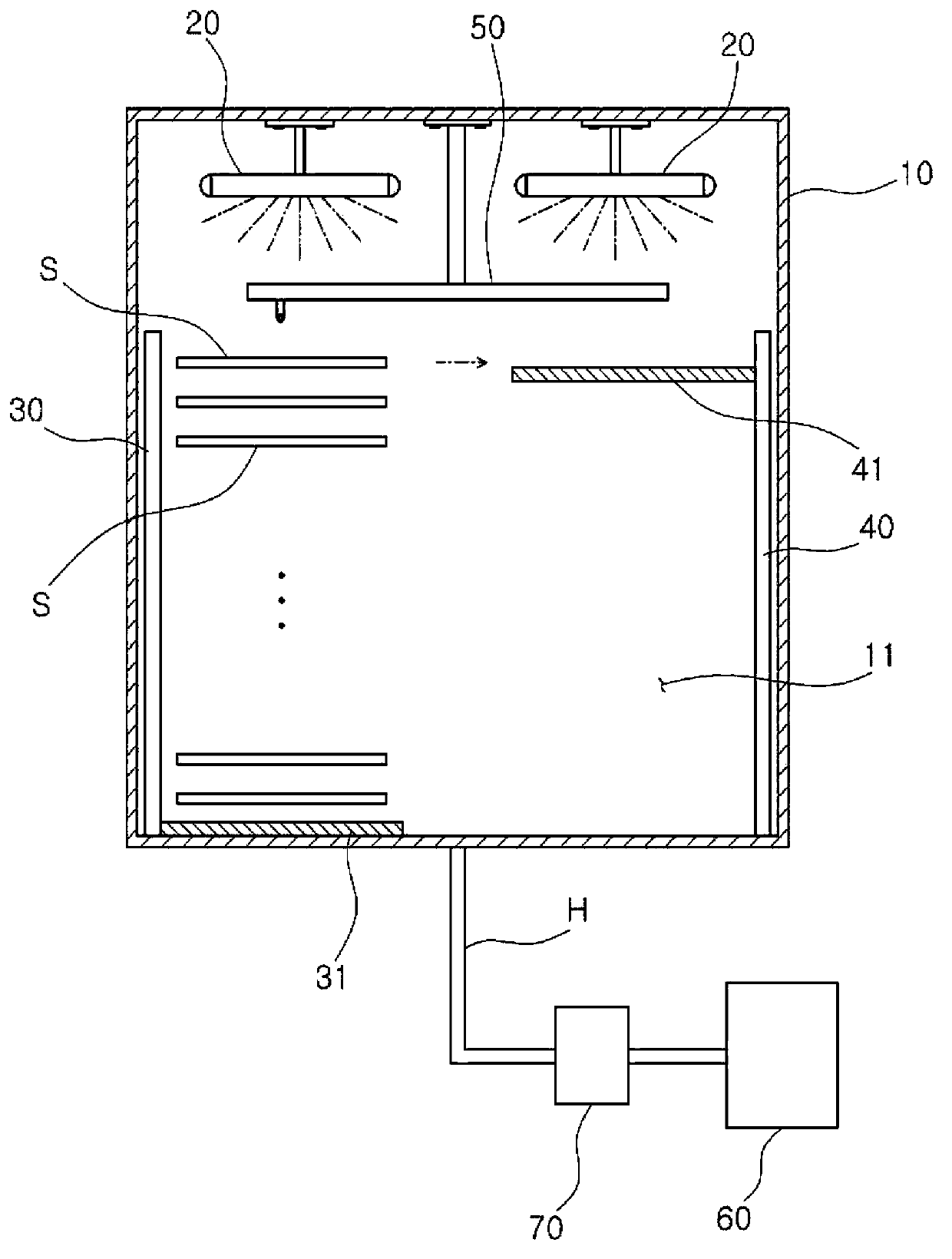

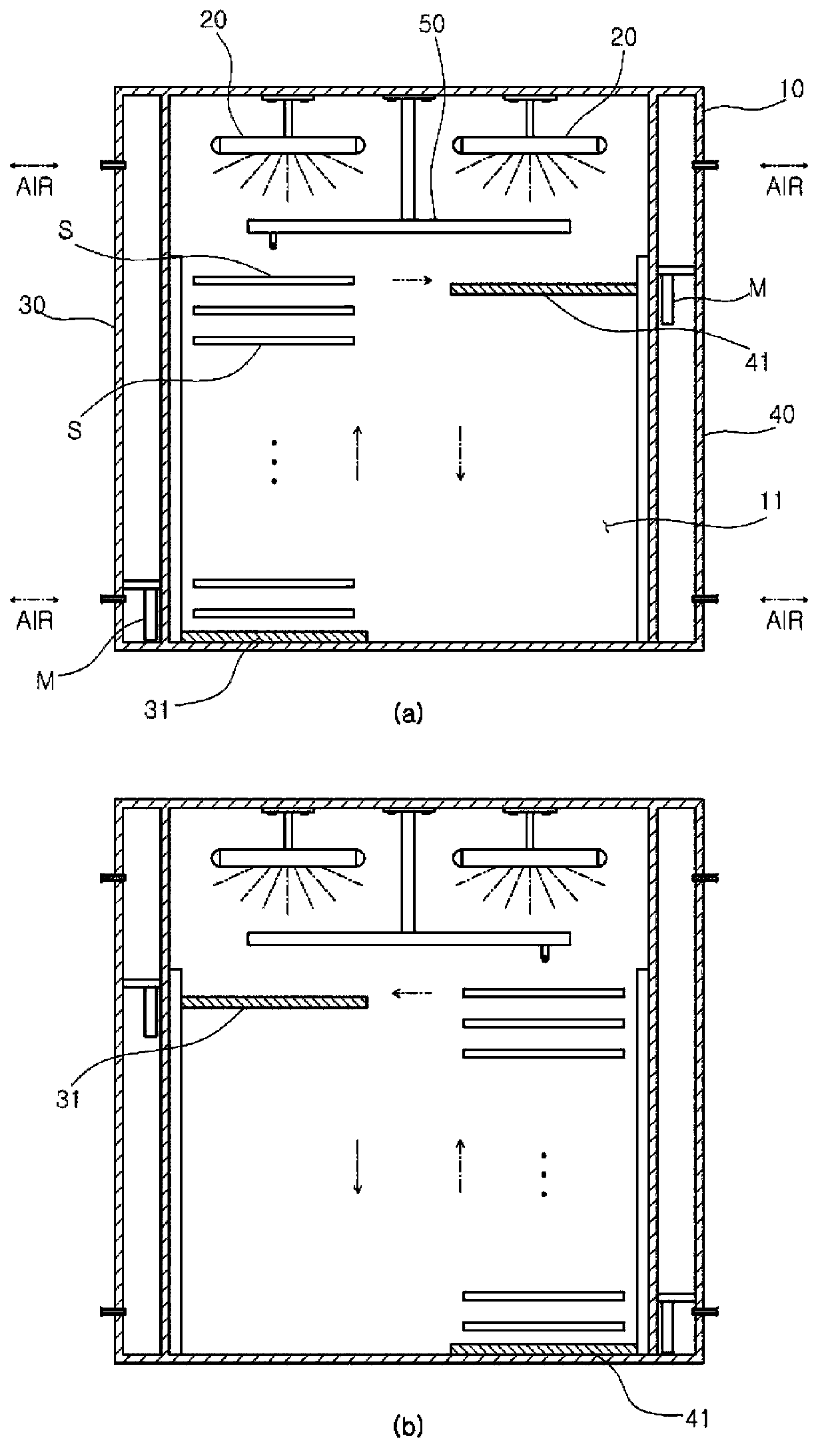

The present invention relates to a drying apparatus of an electrode plate for a secondary battery, and more specifically, to a drying apparatus of an electrode plate for a secondary battery which includes: a door for inserting and removing an electrode plate; a housing unit(10) wherein a drying chamber(11), which is shielded from the outside by an upper wall unit, a side wall unit, and a lower wall unit, is formed; a heating means(20) formed on the top of the drying chamber(11); a first elevator(30) for lifting the electrode plate (S) laminated on a first loading plate(31) to a predetermined height; a transfer means(50) for transferring the highest electrode plate(S) among electrode plates loaded on the first elevator to a second elevator(40); and a second elevator(40) lowering a second loading plate(41) to a predetermined height while loading the electrode plate(S) supplied from the first elevator(30) to a second loading plate(41) by the transfer means(50).

Owner:莫泰克有限公司

Waste tea drying and flavoring integrated machine

InactiveCN107917602ADry evenly and fullyEvenly and fully flavoredPre-extraction tea treatmentDrying gas arrangementsSolenoid valvePulp and paper industry

The invention provides a waste tea drying and flavoring integrated machine. Waste tea is dried and flavored to improve the recycling value of the waste tea. The waste tea drying and flavoring integrated machine comprises a drying box, and a tubular rotating cage is rotatably arranged in the drying box and connected with a power mechanism capable of enabling the rotating cage to rotate. An air inlet nozzle is fixed to the side wall of the drying box and connected with the output end of an air inlet solenoid valve, and the input end of the air inlet solenoid valve is connected with a flavoring device. A wind inlet nozzle is fixed to the bottom of the drying box and connected with the output end of a wind inlet solenoid valve, and the input end of the wind inlet solenoid valve is connected with a warm air blower. An air outlet nozzle is fixed to the top of the drying box and connected with the input end of an air outlet solenoid valve. A wind delivering nozzle is fixed to the top of the drying box and connected with an air compressor. The waste tea drying and flavoring integrated machine has the advantage that the waste tea is evenly and fully fluffed, dried and flavored.

Owner:叶剑

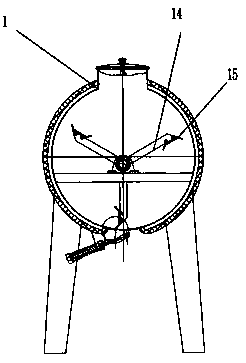

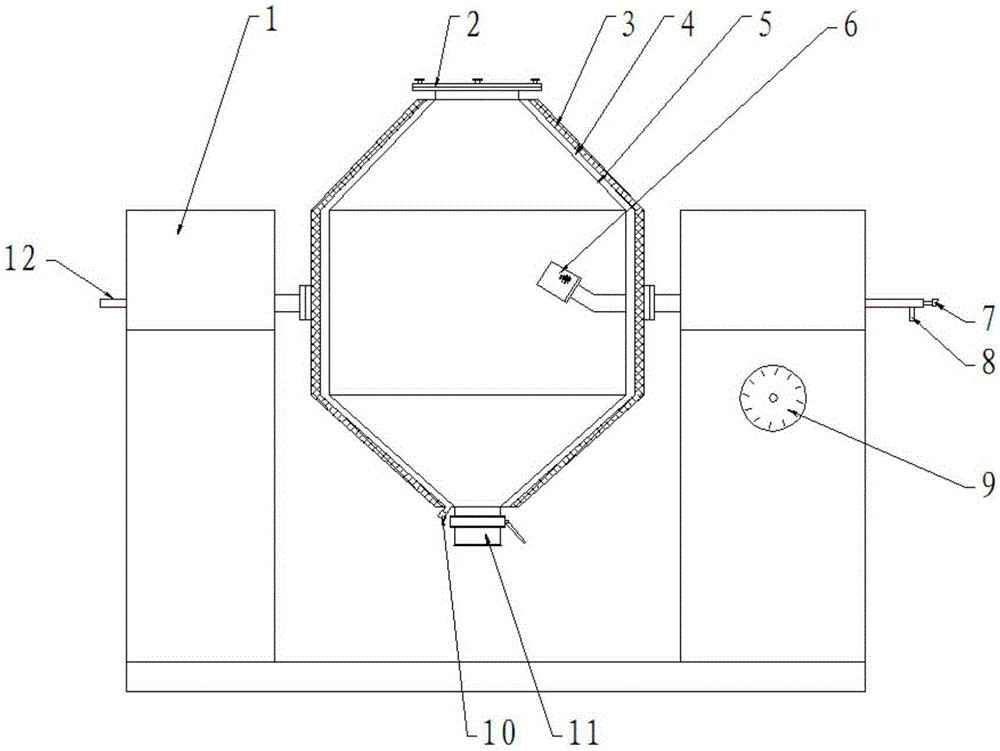

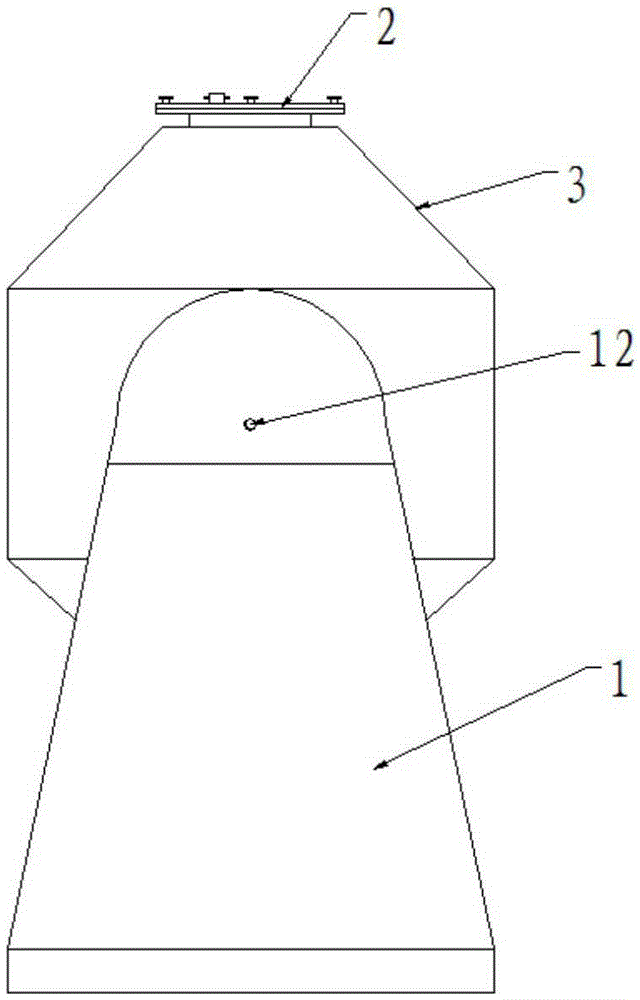

Rotary vacuum dryer

InactiveCN106643048ADry evenly and fullyReduce labor intensityDrying using combination processesDrying machines with non-progressive movementsMechanical engineeringVacuum drying

The invention discloses a rotary vacuum dryer comprising a fixed frame and a bipyramid rotary cylinder. The bipyramid rotary cylinder is mounted on the fixed frame. The fixed frame comprises two symmetrically-arranged mounting plates. The bipyramid rotary cylinder comprises two cone end portions and a cylindrical middle portion. A material adding opening is formed in one of the cone end portions, and a sealing opening is formed in the other cone end portion. Rotary shafts are symmetrically arranged on the two sides of the cylindrical middle portion. The rotary shafts are mounted on the mounting plates correspondingly. A liner is arranged in the bipyramid rotary cylinder, a clamping sleeve layer is arranged between the liner and the bipyramid rotary cylinder, and a condensed water outlet is formed in the position, on the edge of the sealing opening, of the clamping sleeve layer. The design is scientific and reasonable, the structure is simple, and the rotary vacuum dryer is applied to vacuum drying and mixing of powdery materials and granular materials in the industries of medicine, food, chemical engineering and the like.

Owner:南京物创建材有限公司

Drying device for tea production

InactiveCN107726778BHigh speedDry evenly and fullyPre-extraction tea treatmentTea dryingProcess engineeringMechanical engineering

Owner:杭州永宏茶业有限公司

Garbage incineration power generation system for harmless treatment of garbage

InactiveCN112032729ARealize water filtration operationAvoid dropping large batches at onceMachines/enginesIncinerator apparatusElectric machineryProcess engineering

The invention discloses a garbage incineration power generation system for harmless treatment of garbage. The garbage incineration power generation system comprises a cement floor and a mounting groove formed in the cement floor, wherein a garbage can is fixedly connected to one side of the interior of the mounting groove. According to the garbage incineration power generation system for harmlesstreatment of garbage, through cooperative use of a crushing structure, a second feeding mechanism, a driving motor IV, crushing rollers and a crushing box, garbage entering the crushing box is crushed, small pieces of garbage are dried again through the second feeding mechanism, and large pieces of garbage are crushed into small pieces one by one, so that the contact area between the garbage and heat is further increased, and the garbage drying uniformity is further improved. Multiple drying measures are adopted for heating and drying the garbage, so that the garbage is dried more sufficientlyand thoroughly, and the garbage drying effect is good. The sufficiently-dried small pieces of garbage can be sufficiently combusted, so that smoke generated during garbage combustion can be reduced,and the garbage incineration power generation system is relatively environment-friendly.

Owner:(LONGYAN XINDONGYANG) SHENZHEN ENERGY ENVIRONMENT PURIFICATION CO LTD

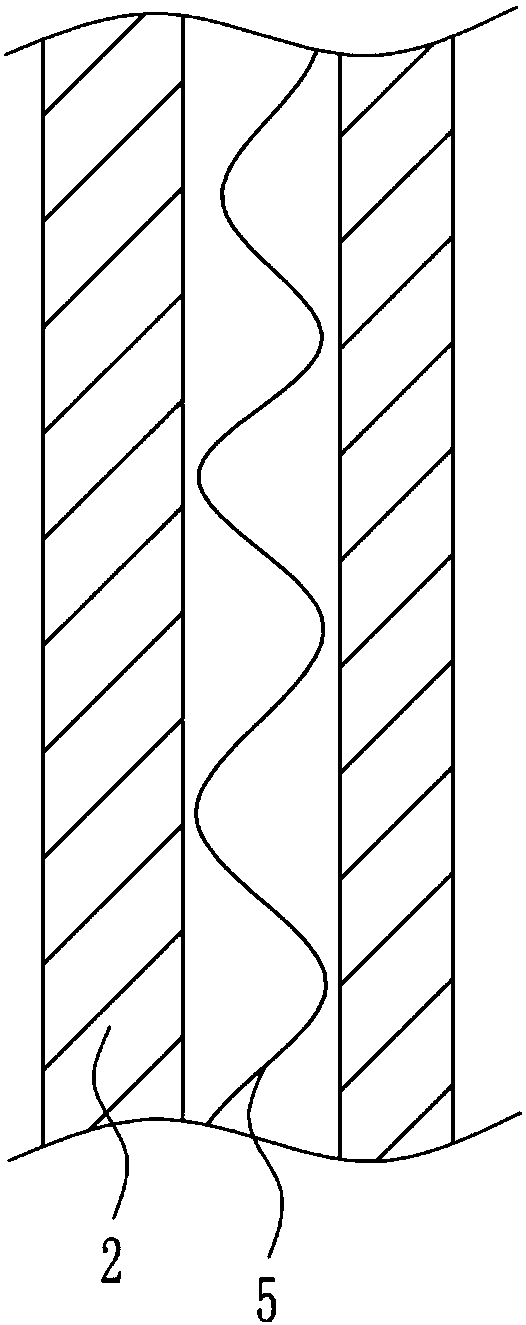

Energy-saving drying device for inner wall of pipeline

PendingCN112815682ACan be dried coarseRealize the collectionDrying gas arrangementsDrying chambers/containersThermodynamicsEngineering

The invention discloses an energy-saving drying device for the inner wall of a pipeline, and particularly relates to the technical field of pipeline drying. The energy-saving drying device comprises a machine body and a first cavity, wherein the first cavity, a second cavity and a third cavity are formed in the machine body, the bottom end in the third cavity is fixedly connected with a fan, and the output end of the fan is fixedly connected with a heater. According to the energy-saving drying device, drying pipes, air conveying pipes, a second exhaust pipe, air outlets and silica gel sheets are arranged, the inner walls of some pipelines with small pipe orifice diameters are difficult to dry, the drying pipes are arranged in several sets on the to-be-dried drying pipeline, the drying pipes are sleeved with the pipeline firstly, then the fan and the heater convey hot air into the conveying pipes, and the hot air in the conveying pipes is conveyed into the drying pipes through the second exhaust pipe and then is discharged from the air outlets of the drying pipes to dry the inner wall of the pipeline. According to the structure, the inner wall of the pipeline is directly dried, and the situation that the inner wall of the pipeline is insufficiently dried is avoided.

Owner:住重福惠动力机械有限公司

Processing and preparation process of indigo powder

InactiveCN112126245AThe processing and preparation process steps are simpleImprove processing efficiencyNatural dyesPulp and paper industryEnvironmental engineering

The invention discloses a processing and preparation process of indigo powder. The processing and preparation process comprises the following steps of: airing indigo leaves for later use; putting theair-dried indigo leaves into a cloth bag to knead the air-dried indigo leaves; adding purified water, lime and sodium chloride into an indigo pool, and performing uniform stirring; putting the indigoleaf raw material into an indigo pool, and covering the indigo leaves with glutinous rice straw; introducing pressurized hot gas into the indigo pool; fishing out the indigo leaves and the glutinous rice straw, removing impurities in indigo liquid, and putting the indigo liquid into a prepared liquid material barrel; sending a precipitate subjected to standing precipitation into a vacuum filter tofilter out moisture; adding calcium chloride and quintozene into prepared indigo mud, performing uniform stirring, and drying to remove moisture; then putting an indigo block mold to prepare indigo blocks; crushing the indigo blocks in a crusher to obtain indigo powder, and further drying the indigo powder; sterilizing and inspecting the prepared indigo powder, and then vacuumizing and packagingthe indigo powder. The indigo powder processing and preparing technology well ensures the indigo liquid yield, and improves indigo powder processing benefits.

Owner:贵州靛山沟蓝靛产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com