Sea buckthorn fruit slag stirring and drying tank body device and stirring and drying method

The technology of sea buckthorn pomace and tank body is applied in the field of stirring and drying tank body devices, which can solve the problems of unscientific and reasonable discharging structure, low drying efficiency, etc., so as to avoid loss, fully and uniformly drying, and improve quality and speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

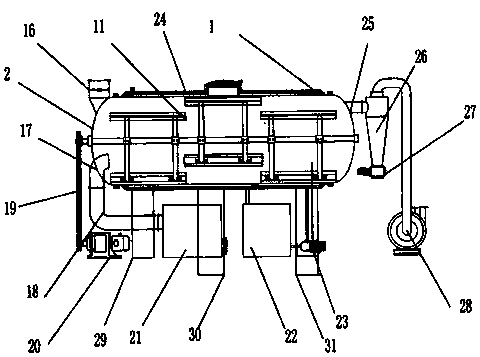

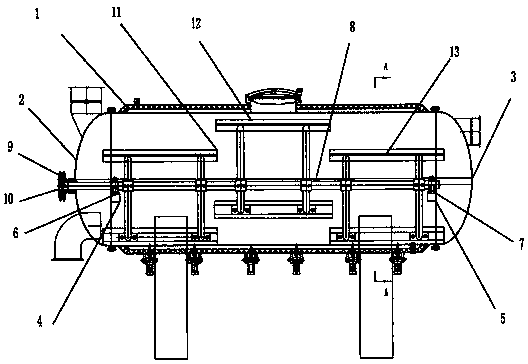

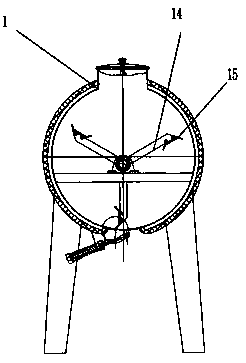

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

[0024] A seabuckthorn pomace stirring and drying tank device, comprising a cylindrical drying tank 1, a tank left end cover 2 is arranged on the left port of the cylindrical drying tank 1, and a tank left end cover 2 is arranged on the right port of the cylindrical drying tank 1. The right end cover 3 of the tank body is provided, the upper end of the left end cover 2 of the tank body is provided with a feed port 16, the lower end of the left end cover 2 of the tank body is provided with a hot air inlet 17, and the upper end of the right end cover 3 of the tank body is provided with an air outlet 25 , a cyclone unloader 26 is connected to the air outlet 25, an exhaust fan 28 is connected to the upper port of the cyclone unloader 26, and a material is provided directly below the cyclone unloader outlet 27 of the cyclone unloader 26. The conveyor belt is connected with a hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com