Silkworm cocoon drying device for spinning

A drying device and cocoon technology, applied in the textile field, can solve problems such as poor unwinding, long drying time, increased reeling and folding, etc., and achieve good promotion and utilization value, sufficient and uniform drying, and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

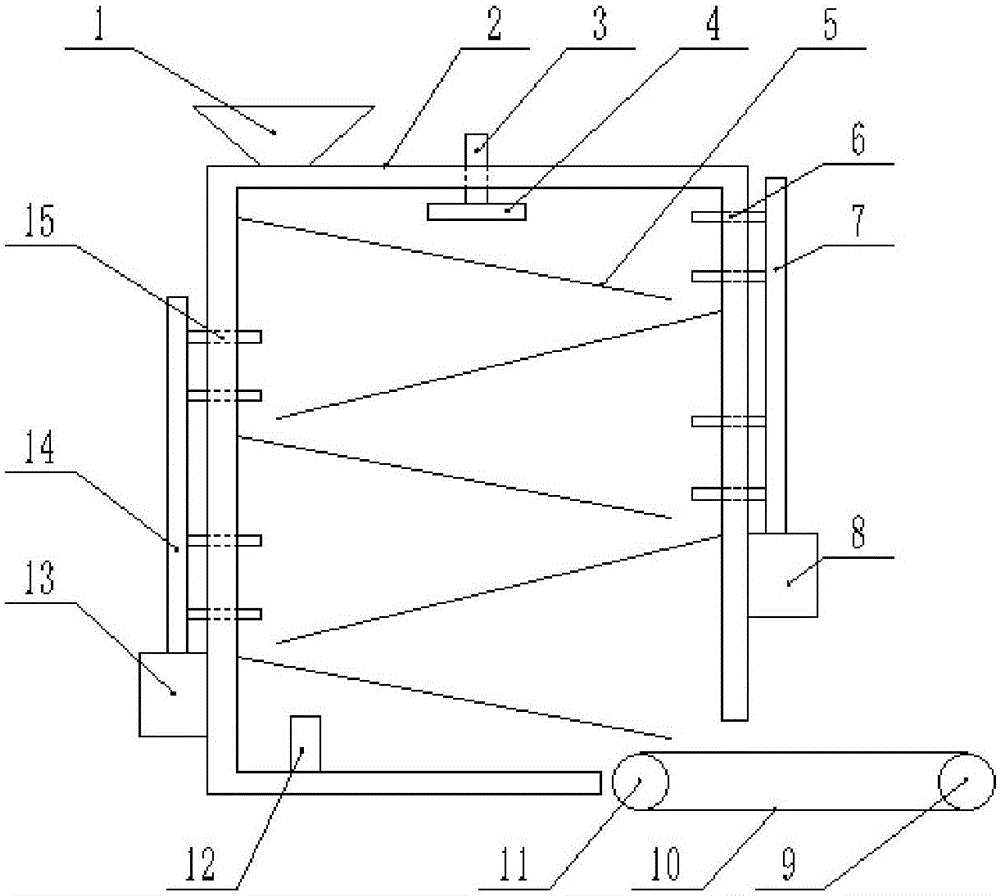

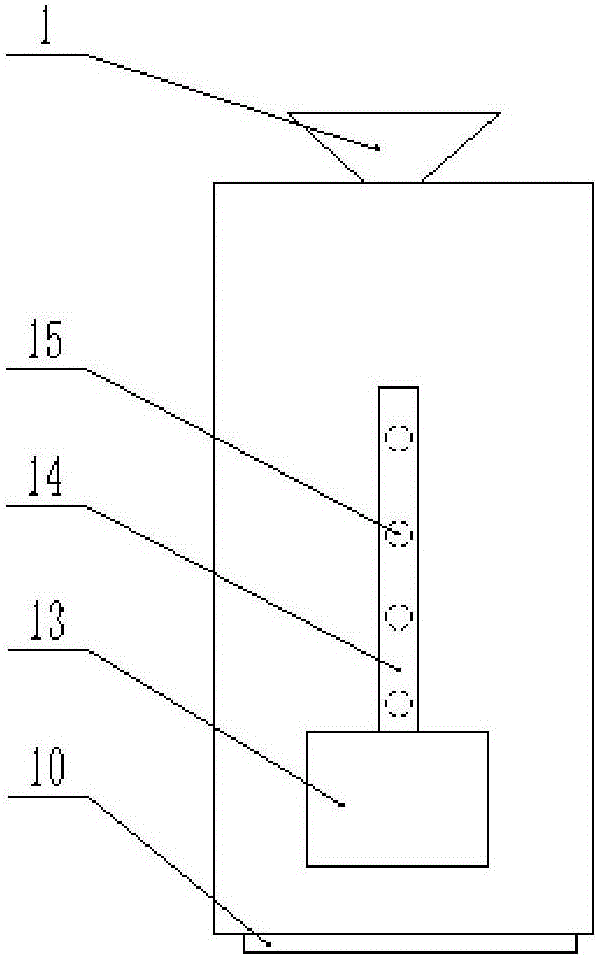

[0018] like figure 1 , figure 2 As shown, the silkworm cocoon drying device for weaving has a structure including a drying box 2, the upper end of the drying box 2 is provided with a feed port 1, and the middle of the upper end of the drying box 2 is provided with a moisture discharge hole 3, and the drying The upper end of the inside of the box 2 is provided with a dehumidifier 4, the two sides of the inside of the drying box 2 are respectively fixed with a drying plate 5, and the lower end of the inside of the drying box 2 is provided with a hygrometer 12. Therefore, during use, the dehumidifier 4 passes through the The cooperation of the moisture-discharging air holes 3 reduces the humidity in the drying box 2, the hygrometer 12 can effectively monitor the humidity in the drying box 2, and the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com