Intelligent constant temperature rapid milk preparing machine

A milk making machine and constant temperature technology, which is applied in beverage preparation devices, household utensils, applications, etc., can solve problems such as difficult dissolution, easy agglomeration of milk powder, and large energy loss, and achieve simple and convenient operation, high safety, and accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

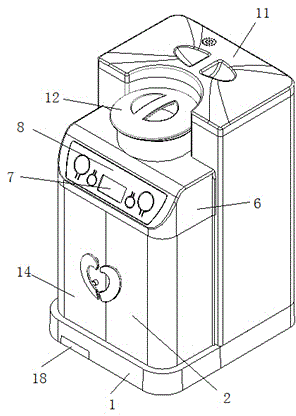

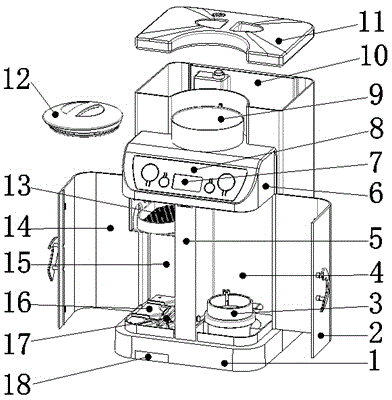

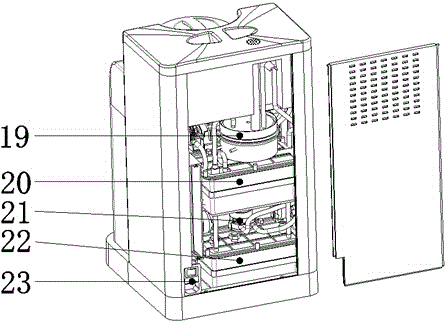

[0025] see Figure 1-9 , an intelligent constant temperature fast milk machine, comprising a base 1 and a casing 6; the casing 6 is fixedly connected to the base 1 through a bracket 5, and the bracket 5 is located in the middle of the base 1; a disinfection chamber 15 is provided on the left side of the bracket 5, and the disinfection chamber The outside of the 15 is provided with a disinfection chamber door 14; the bottom of the disinfection chamber 15 is provided with a feeding bottle support and a hot air system 16 and an ultraviolet sterilizing lamp 17; the upper end of the disinfection chamber 15 is provided with a pacifier drawer 13; The drawer 18 is located at the left end of the bottom of the base 1; the milk chamber 4 is arranged on the right side of the bracket 5, and the milk chamber door 2 is arranged on the outside of the milk chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com