Substrate processing method and substrate processing apparatus

A substrate processing method and substrate technology, which are applied in cleaning methods and tools, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of expensive stripping liquid and increased cost, and achieve the purpose of suppressing increase, suppressing cost, Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

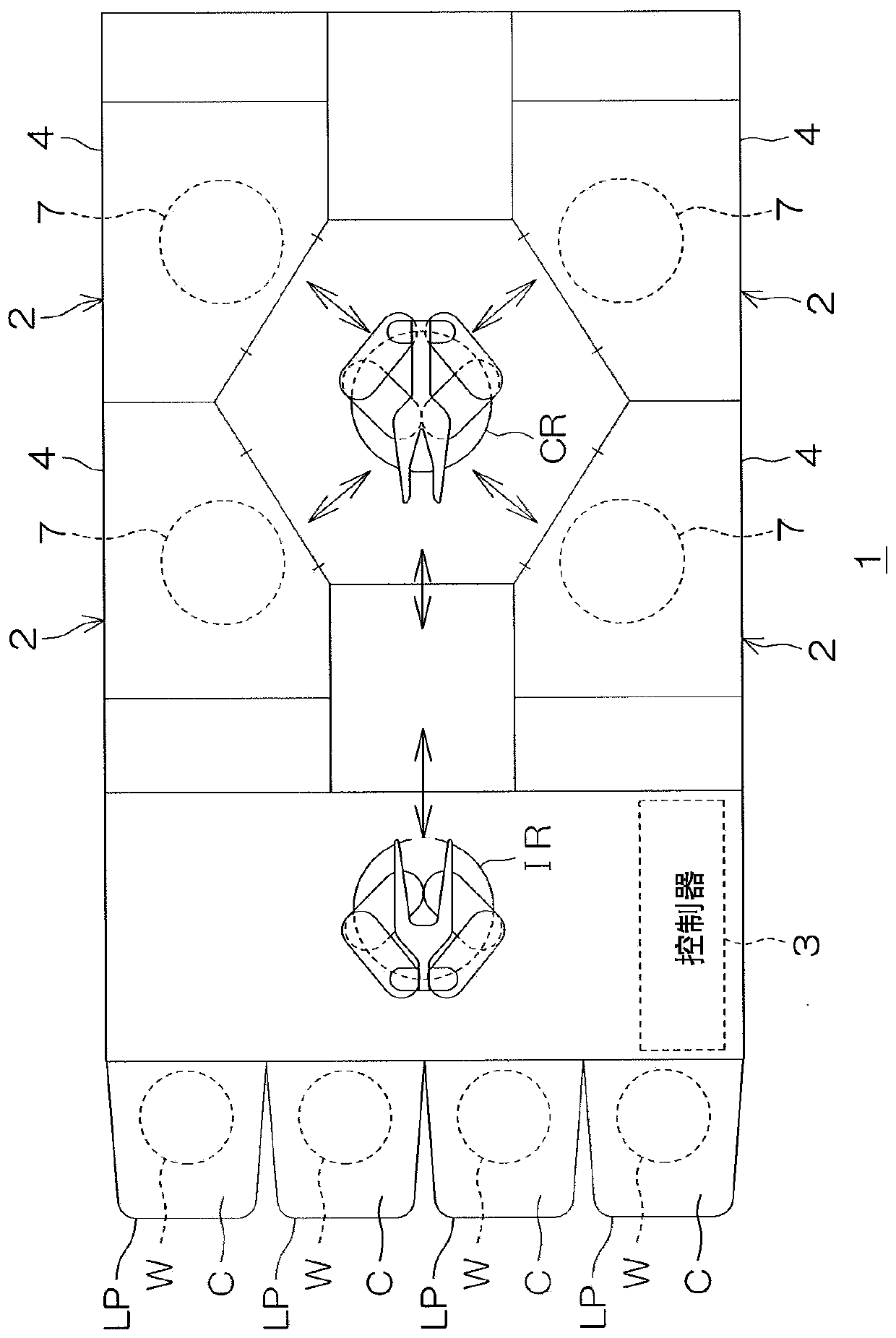

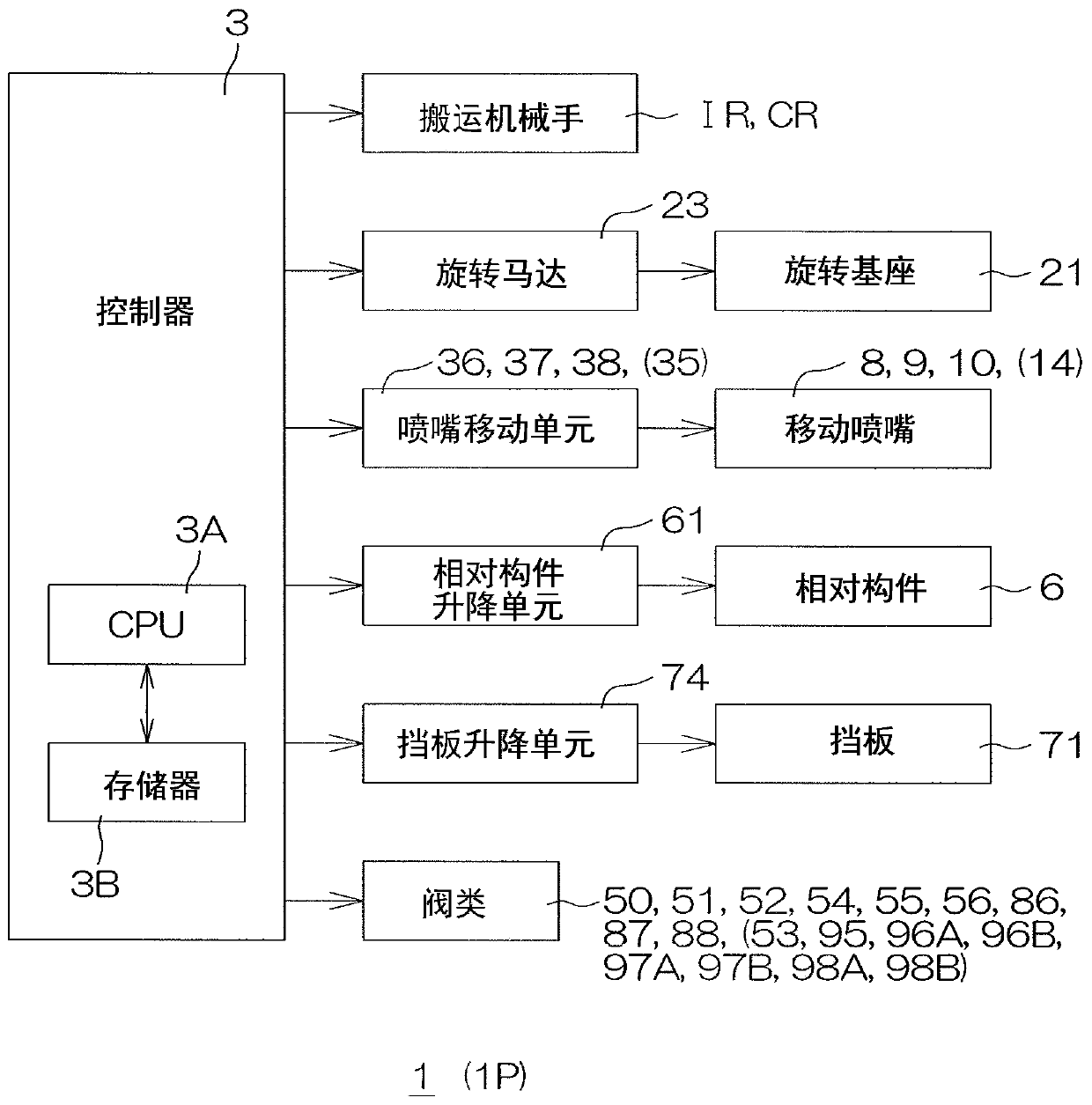

[0073] figure 1 It is a schematic plan view showing the internal configuration of the substrate processing apparatus 1 according to the first embodiment of the present invention.

[0074] The substrate processing apparatus 1 is a single type apparatus that processes substrates W such as silicon wafers one by one. In this embodiment, the substrate W is a disk-shaped substrate.

[0075] The substrate processing apparatus 1 includes: a plurality of processing units 2, which process substrates W with a fluid; a loading port LP, which is equipped with a storage rack C for accommodating a plurality of substrates W processed by the processing units 2; The substrate W is transported between the port LP and the processing unit 2 ; the controller 3 controls the substrate processing device 1 .

[0076] The transfer robot IR transfers the substrate W between the storage rack C and the transfer robot CR. The transfer robot CR transfers the substrate W between the transfer robot IR and t...

no. 2 approach >

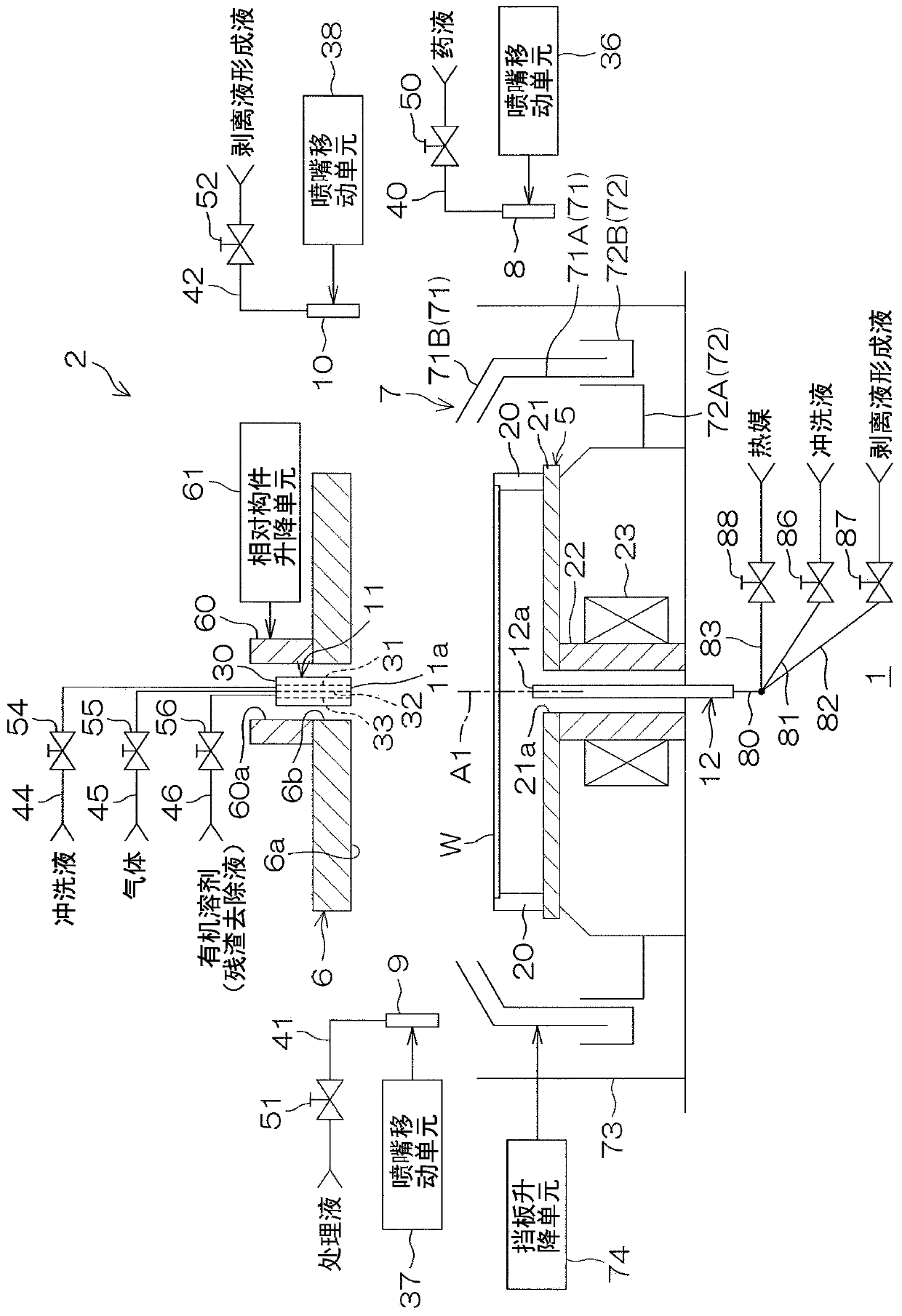

[0207] Figure 7 It is a schematic partial cross-sectional view showing a schematic configuration of a processing unit 2P included in the substrate processing apparatus 1P of the second embodiment. refer to Figure 7 , the processing unit 2P of the second embodiment is the same as the processing unit 2 of the first embodiment (refer to figure 2 ) is mainly different in that the processing unit 2P of the second embodiment includes a fourth moving nozzle 14 instead of the opposing member 6 and the central nozzle 11 .

[0208] The fourth moving nozzle 14 is an example of an organic solvent supply unit that supplies an organic solvent to the upper surface of the substrate W. As shown in FIG. In addition, the fourth moving nozzle 14 may be an example of a gas supply unit that supplies gas such as nitrogen gas to the upper surface of the substrate W. As shown in FIG.

[0209] The fourth moving nozzle 14 is moved horizontally and vertically by the fourth nozzle moving unit 35 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com