Variable temperature vulcanization process for all-steel engineering tires

A technology for engineering tires and tires, applied in tires, household appliances, other household appliances, etc., can solve the problems of decreased rubber performance, slow heat transfer on the tire surface, and reduced heat exchange efficiency, so as to improve the tread wear performance and shorten the Supply time, the effect of overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

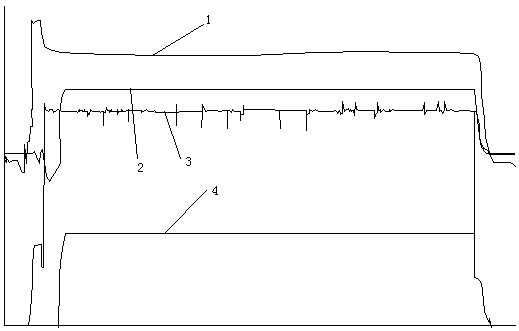

[0031] Example 1: A variable temperature vulcanization process for all-steel engineering tires. The tire is inside the mold, the bladder is inside the tire, the temperature inside the bladder is the internal temperature, and the temperature outside the mold is the external temperature. Pre-vulcanization stage, positive vulcanization stage, post-vulcanization stage, and finally complete vulcanization,

[0032] In the pre-vulcanization stage, high-temperature steam is introduced into the capsule, the temperature is between 170-180°C, the pressure is 0.05-0.14MPa, and the cycle is maintained for 5-20 minutes, so that the tire can be heated up rapidly and the start of the vulcanization and cross-linking reaction is accelerated;

[0033] In the normal vulcanization stage, the inside of the capsule and the outside of the mold are heated at the same time, saturated steam is passed through the outside of the mold, and high-temperature and high-pressure circulating water is first passed...

Embodiment 2

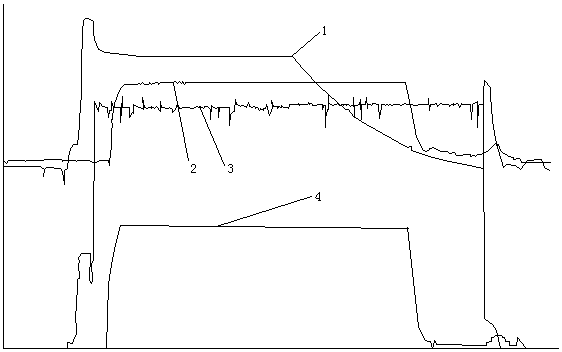

[0035] Example 2: A variable temperature vulcanization process for all-steel engineering tires. The tire is inside the mold, the capsule is inside the tire, the temperature inside the capsule is the internal temperature, and the temperature outside the mold is the external temperature. Pre-vulcanization stage, positive vulcanization stage, post-vulcanization stage, and finally complete vulcanization,

[0036] In the pre-vulcanization stage, high-temperature steam is introduced into the capsule, the temperature is between 170-180°C, the pressure is 0.05-0.14MPa, and the time is 5-20 minutes;

[0037] In the positive vulcanization stage, the internal temperature is first fed with high-temperature and high-pressure circulating water, the temperature is 155-165°C, the pressure is 2.5-2.7MPa, and then enters the pressure-holding stage, the time is 40-260 minutes, the temperature inside the capsule drops by 15-40°C; the external temperature steam pressure 0.14-0.36MPa, temperature 1...

Embodiment 3

[0039] Example 3: A variable temperature vulcanization process for all-steel engineering tires. The tire is inside the mold, the capsule is inside the tire, the temperature inside the capsule is the internal temperature, and the temperature outside the mold is the external temperature. Pre-vulcanization stage, positive vulcanization stage, post-vulcanization stage, and finally complete vulcanization,

[0040] In the pre-vulcanization stage, high-temperature steam is introduced into the capsule, the temperature is between 170-180°C, the pressure is 0.05-0.07MPa, and the time is 5-7 minutes;

[0041] In the positive vulcanization stage, the internal temperature is first passed into high-temperature and high-pressure circulating water, the temperature is 155-165 ° C, the pressure is 2.5-2.7 MPa, and then enters the pressure-holding stage, the time is 40-60 minutes, and the temperature in the capsule drops by 15-20 ° C;

[0042] The external temperature steam pressure is 0.30-0.36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com