Slit nozzle and treating liquid supplying device with such nozzle

A slit nozzle and supply device technology, which is applied to spray devices, spray devices, and devices for coating liquids on surfaces, etc., can solve the problems of high price, long time and labor, and capillary infiltration, etc., to shorten the supply time and shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] [Invention embodiment]

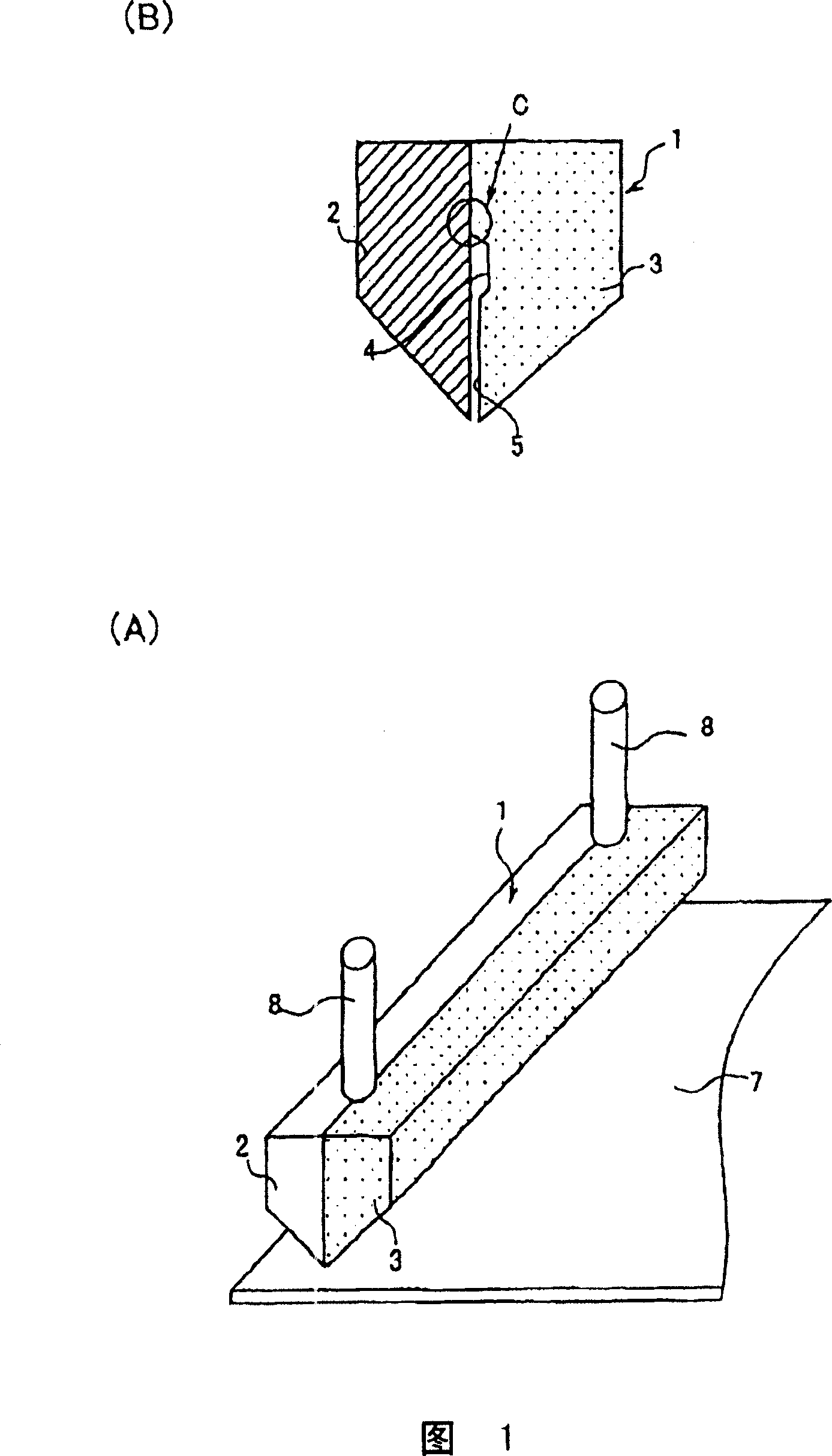

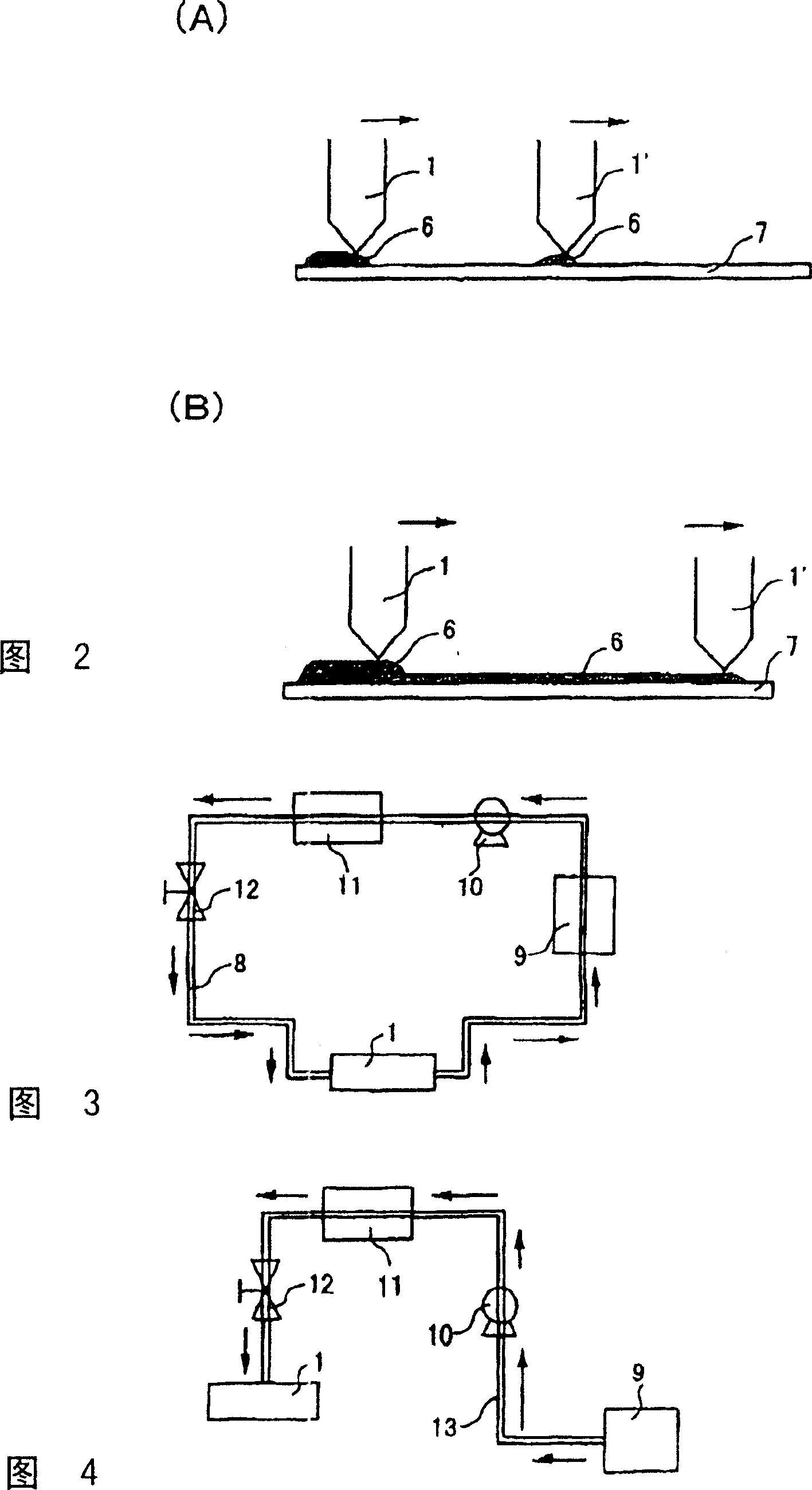

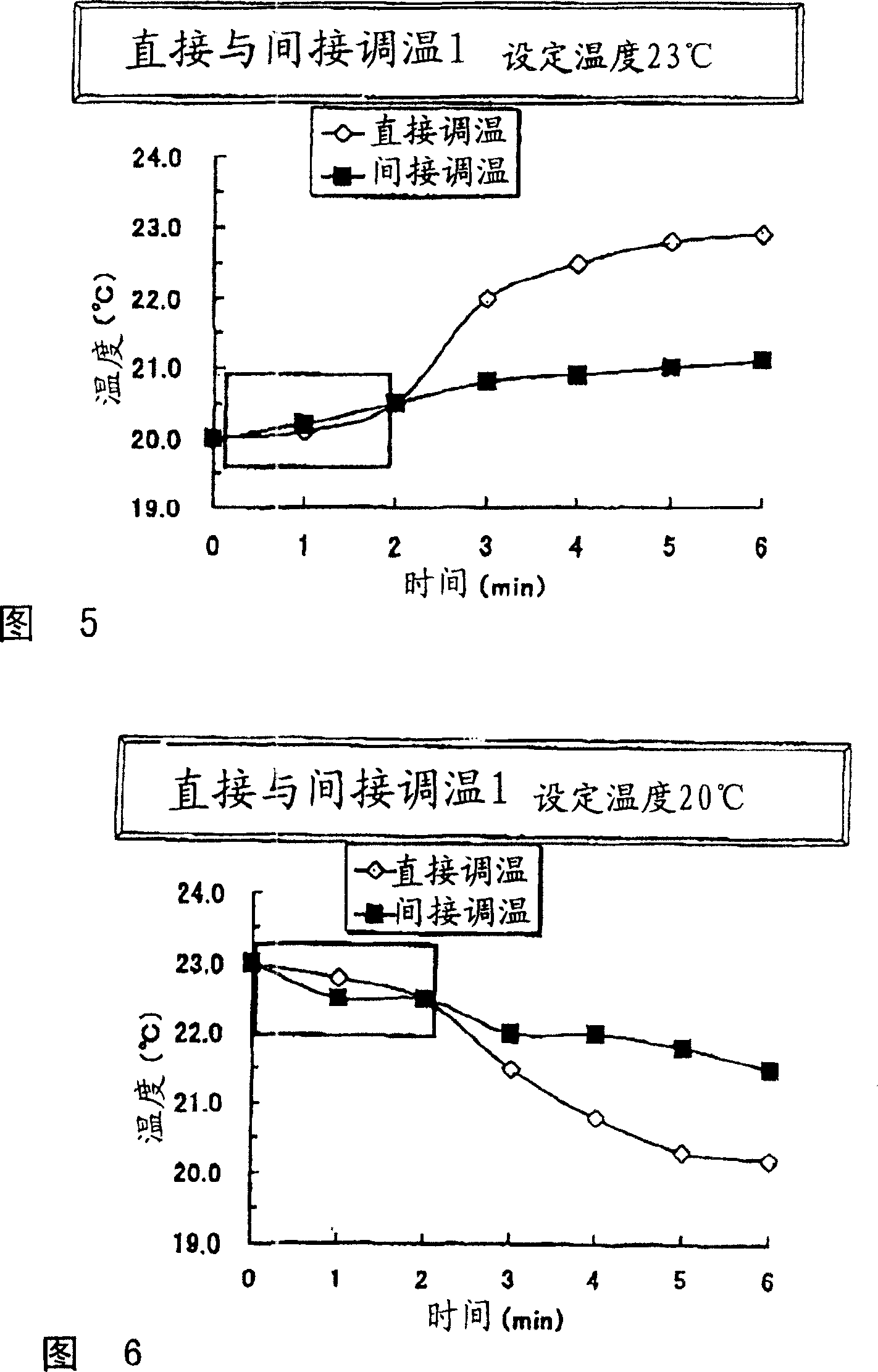

[0030] Embodiments of the present invention will be described below with reference to the drawings. Here, Fig. 1 (A), (B) is a side view and an enlarged sectional view of a slit nozzle of the present invention, and Fig. 2 (A), (B) is a process of supplying a treatment liquid using a plurality of slit nozzles of the present invention. Schematic diagram, Fig. 3 is a schematic diagram of direct temperature regulation with a slit nozzle and a temperature regulator of the present invention. Fig. 4 is a schematic diagram of indirect temperature regulation of a conventional device.

[0031] As shown in Figure 1, the slit nozzle 1 is composed of a left half body 2 made of titanium and a right half body 3 made of PPS (polyphenylene sulfide). channel) and a flat surface 5 forming a longitudinal flow path shallower than the bottom surface of the recess 4. Furthermore, the left half body 2 may also be made of stainless steel.

[0032] In this way, by ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com