Drying device for LED aluminum substrates

A technology of LED aluminum substrate and drying device, which is applied in drying, drying machine, heating device, etc., can solve the problem of unfavorable standardized baking operation of LED aluminum substrate, reduction of production and processing quality and service life of LED lamps, and excessive baking and other issues to achieve the effect of ensuring the quality of production and processing and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

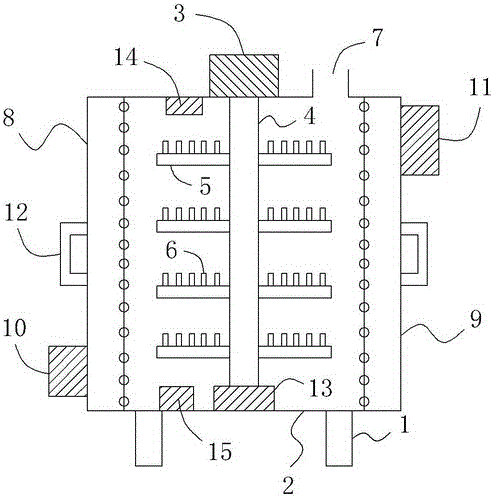

[0013] Such as figure 1 As shown, a LED aluminum substrate drying device includes a bracket 1 and a cabinet 2 arranged on the bracket 1, and a cabinet door (not shown in the figure) is also provided on the front side wall of the cabinet 2, wherein The outer top of the cabinet 2 is provided with a rotating motor 3, the output shaft of the rotating motor 3 is arranged vertically downwards and extends to the inside of the cabinet 2, and the bottom end of the output shaft of the rotating motor 3 is also connected with a vertically downward shaft. The extended rotating shaft 4 is also fixedly sleeved with a plurality of annular trays 5 on the rotating shaft 4; a plurality of tray ventilation holes are provided on the annular tray 5, and a plurality of vertical trays are evenly distributed on the top plane of the annular tray 5. The needle-shaped protrusion 6 extending upwards (and the smaller the diameter of the needle-shaped protrusion 6, the better, so that the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com