Tea dryer facilitating full use of heat

A tea dryer and heat energy technology, which is applied in dryers, tea drying, drying and other directions, can solve the problems of inconsistent tiling thickness, uneven tiling thickness, and uneven drying effect of tea leaves in different batches. , to maintain the temperature, promote full utilization, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

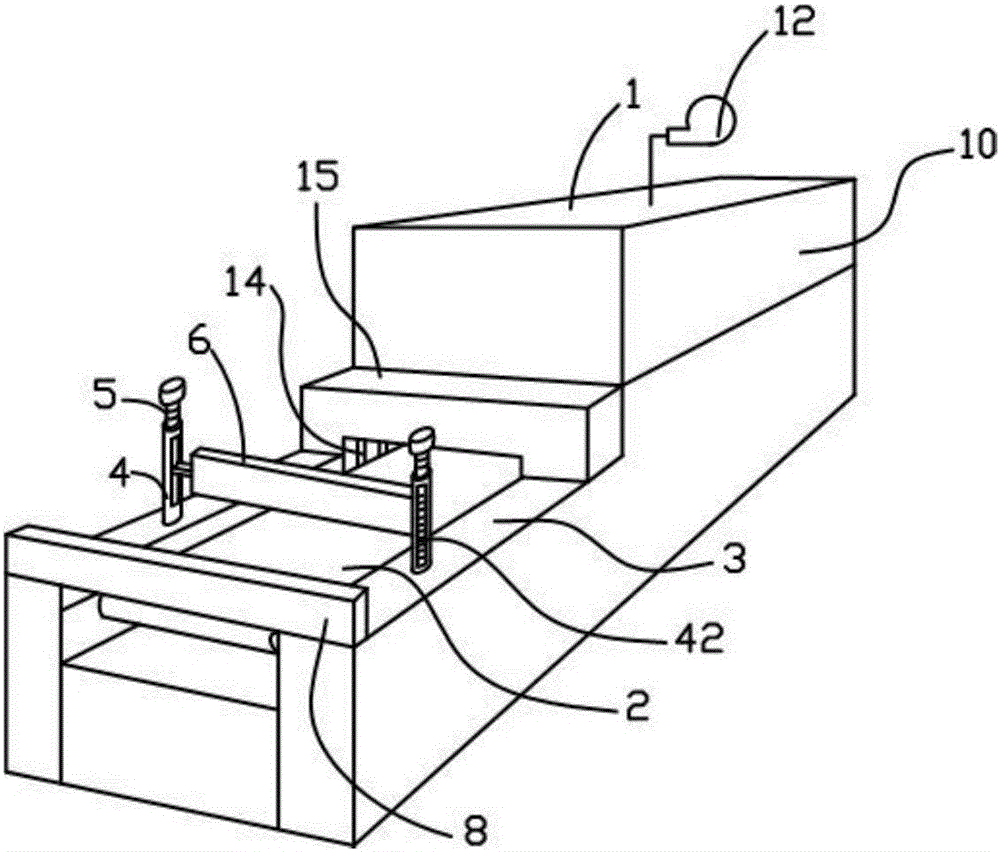

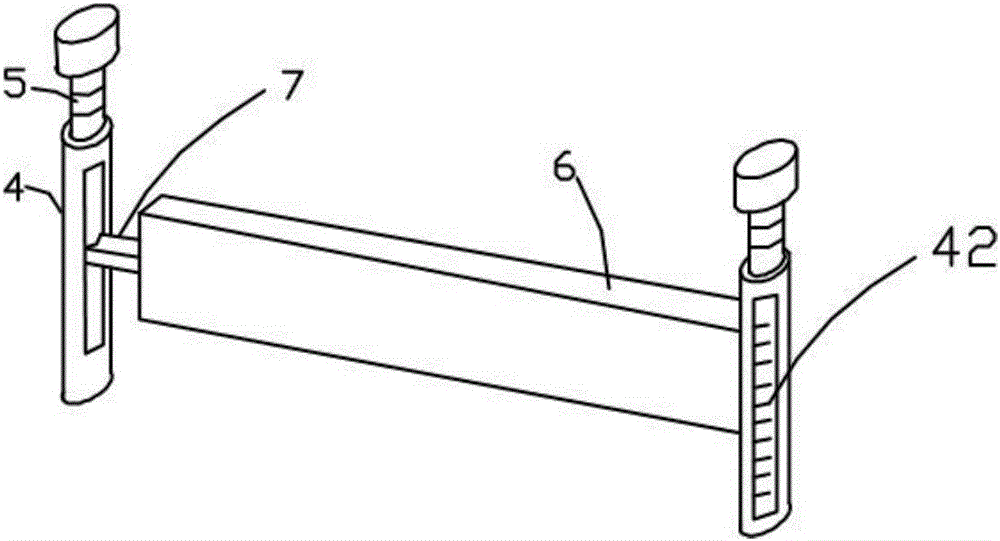

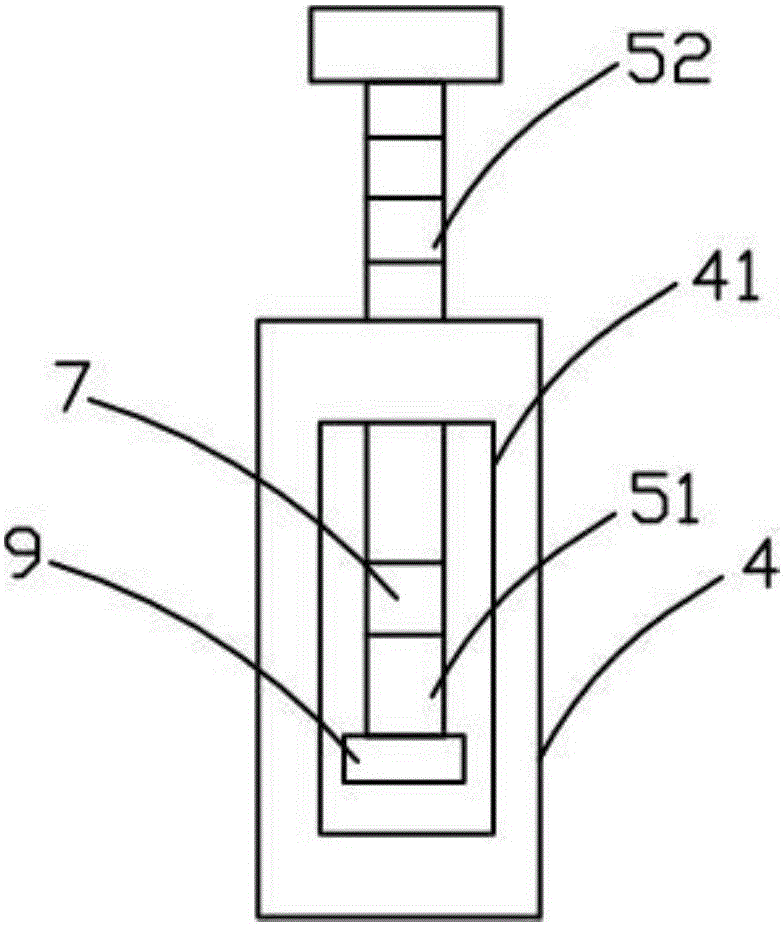

[0041] Such as Figure 1~4 As shown, the present invention is a kind of tea dryer that is easy to make full use of heat energy, including a drying box 1, a transmission mesh belt 2 is arranged inside the drying box 1, and a stand 3 is arranged at the entrance end of the drying box 1 , the transmission mesh belt 2 extends from the inlet end of the drying box 1 to the stand 3. Also includes a baffle mechanism, the baffle mechanism includes two identical fixed sleeves 4, two identical adjustment rods 5 and a rectangular parallelepiped movable baffle 6; the two fixed sleeves 4 are correspondingly arranged on the platform 3, and They are respectively located at both ends of the transmission mesh belt 2; the free end of the fixed sleeve 4 is inserted into the adjustment rod 5, the adjustment rod 5 includes a fixed column 51 and a bolt 52, the axis lines of the fixed column 51 and the bolt 52 coincide and are fixedly connected in a straight line , the fixed column 51 can be movably ...

Embodiment 2

[0044] Further improvement on the basis of Embodiment 1 is a tea dryer that is easy to make full use of heat energy, and a scale 42 is arranged on the outer wall of the fixed sleeve 4 along the axial direction.

Embodiment 3

[0046] Further improvement on the basis of Embodiment 2 is a tea dryer that is easy to make full use of heat energy, and a magnet block is installed at the connection end between the fixed sleeve 4 and the stand 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com