Using method of efficient, energy-saving and environmentally-friendly type tea drying equipment

A high-efficiency, energy-saving, drying equipment technology, applied in drying, dryers, lighting and heating equipment, etc., can solve the problems of parasitic bacteria that cannot be cleaned, not economical and environmentally friendly, and imperfect functions, so as to facilitate maintenance. , The overall structure design is reasonable, and the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

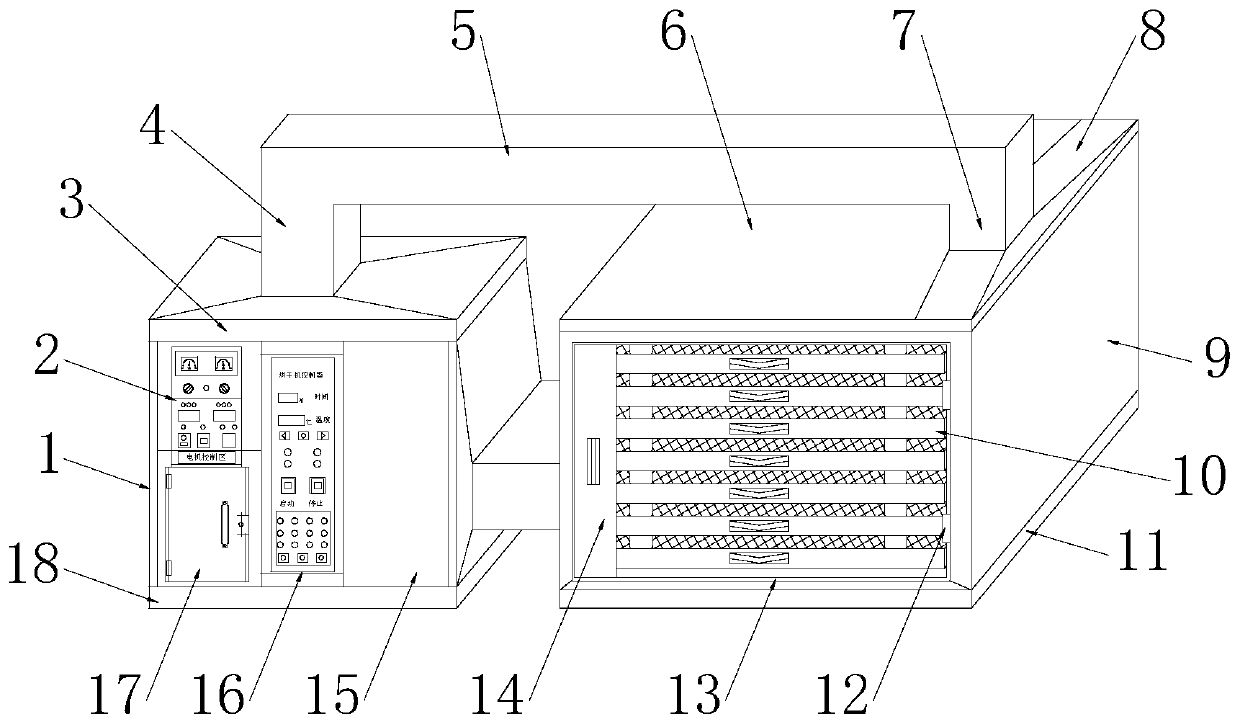

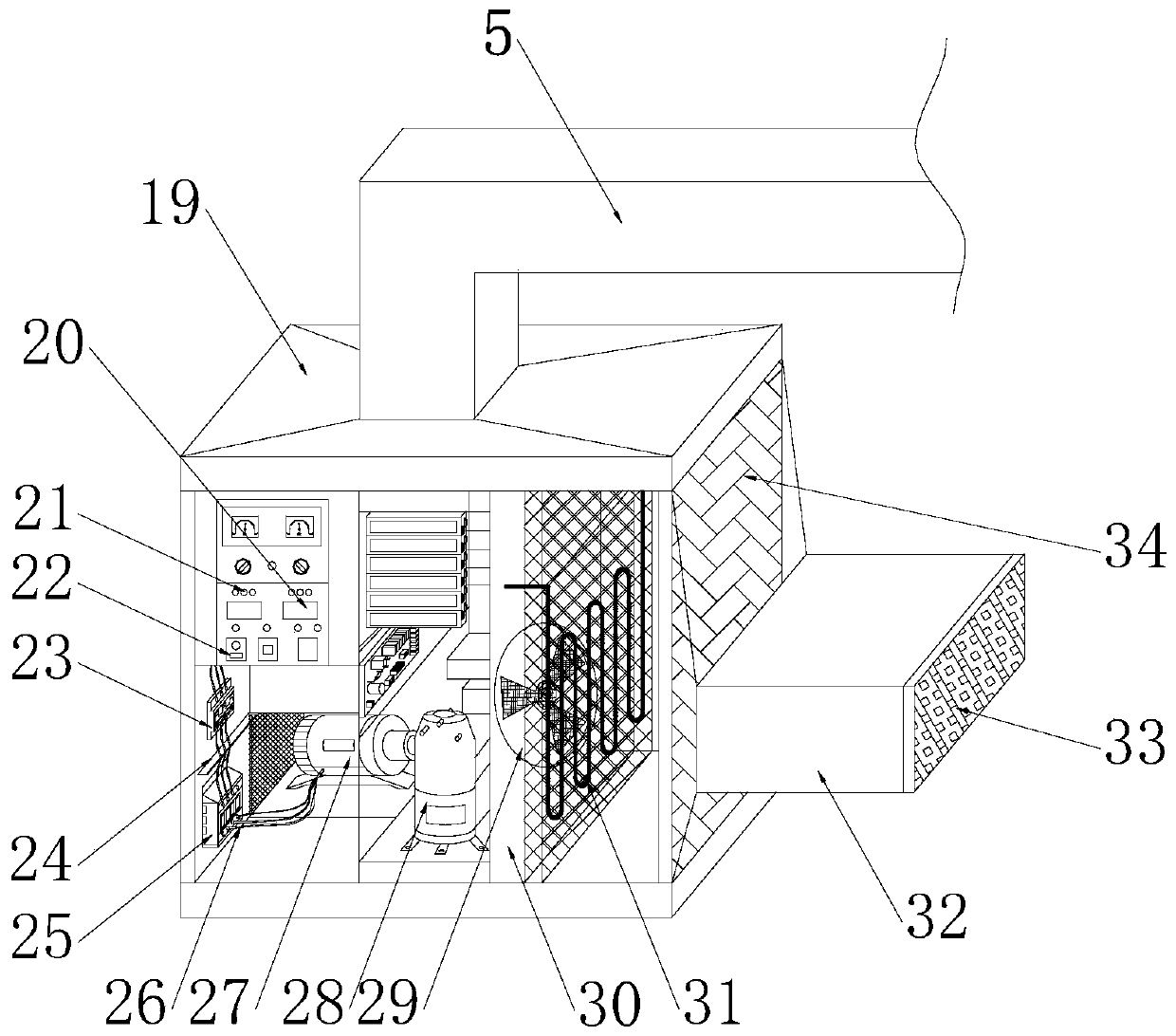

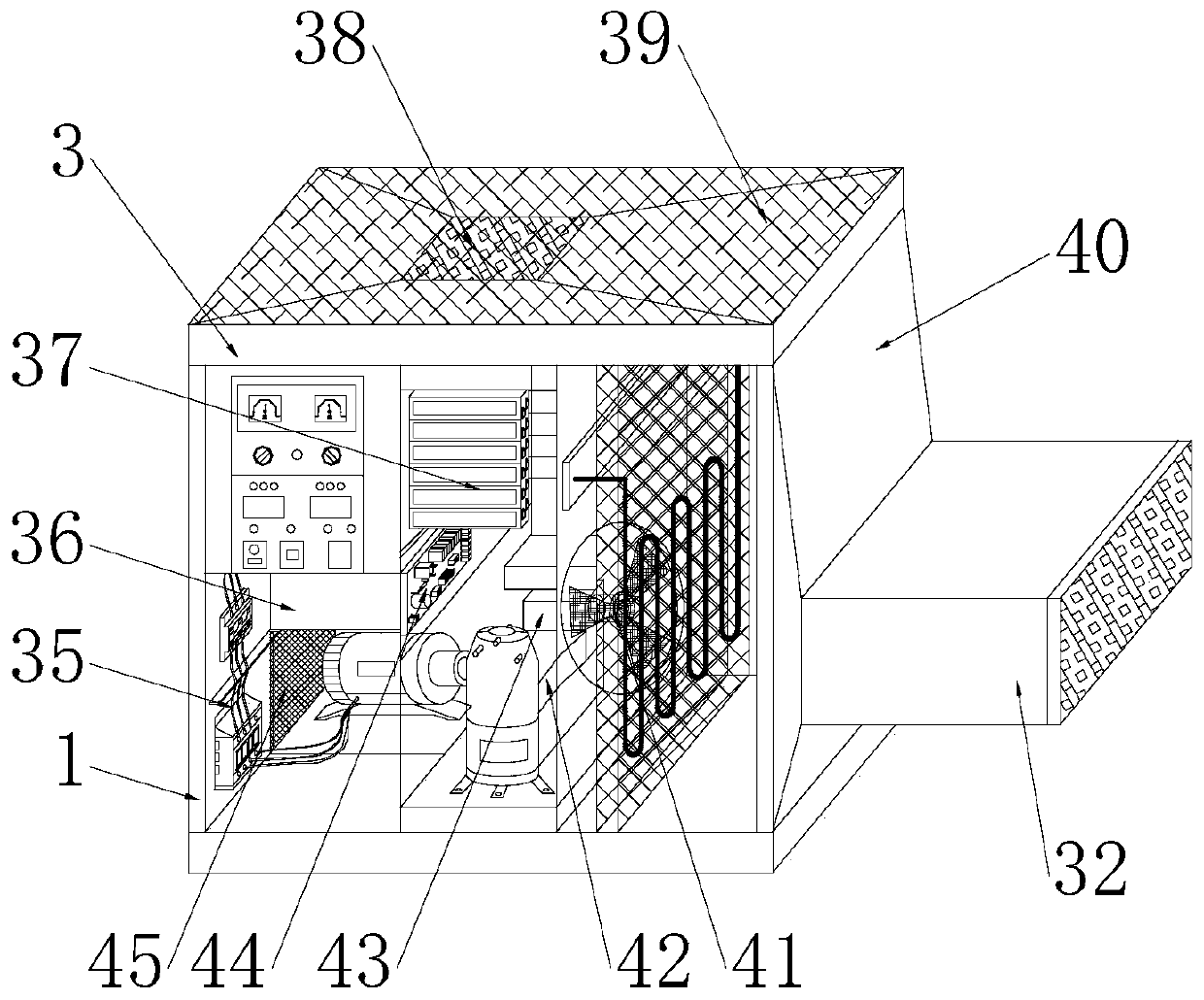

[0039] Attached below Figure 1-12 The present invention is described in detail below.

[0040] Such as Figure 1-12 As shown, the present invention includes a main control box 1, and the main control box 1 is provided with a control motor 27, a control main board 44, an expander control box 36, a thermal relay 25, a fuse 23, a barrier plate 30, an evaporator 37, Compressor 28 and condenser 71, motor cooling rear cover 62 and bearing seat 68 are arranged on control motor 27, bearing 67 is arranged on bearing seat 68, control shaft seat 66 is arranged on bearing 67, motor wire is arranged at the bottom of control motor 27 box 64, the motor wire box 64 is provided with a junction tube 63, the motor connection line 26 is arranged in the junction pipe 63, the motor support seat 65 is arranged at the bottom of the motor wire box 64, and the main control box body top plate is arranged on the main control box body 1 3. There is a roof partition 39 inside the top plate 3 of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com