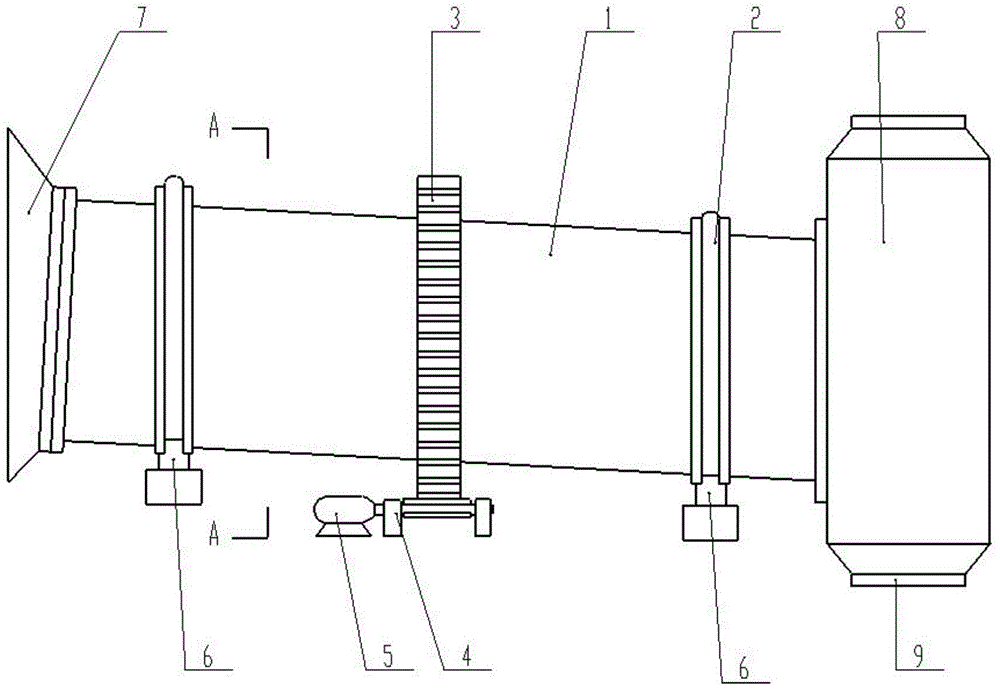

Patents

Literature

30results about How to "Avoid drying effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

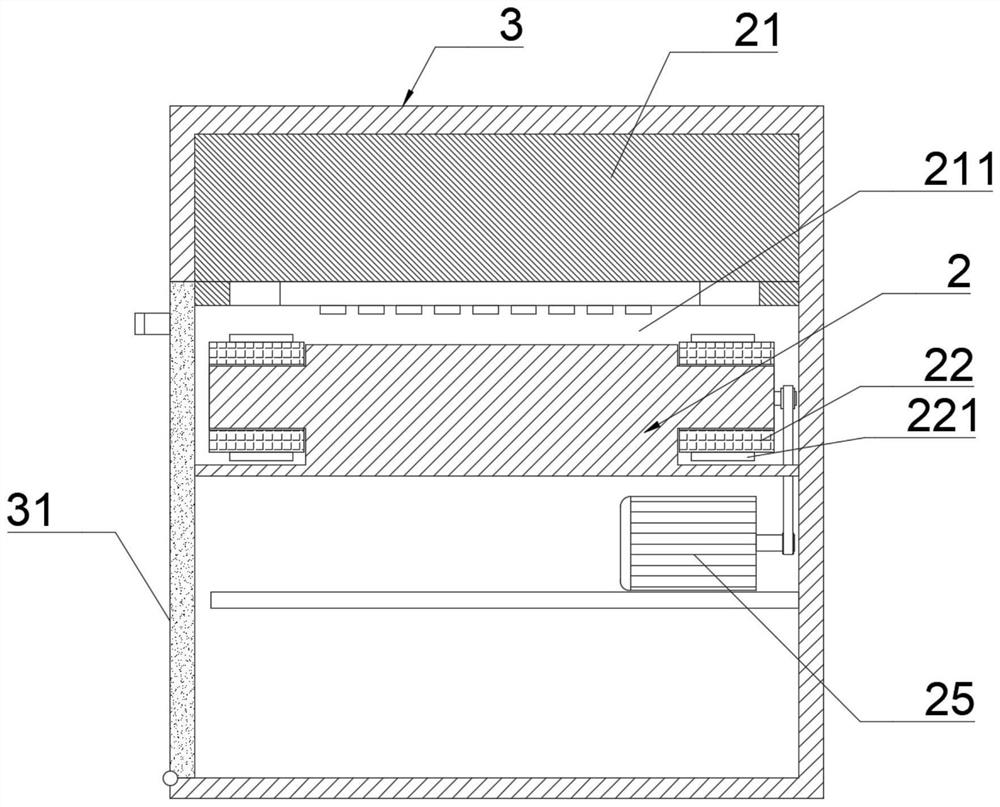

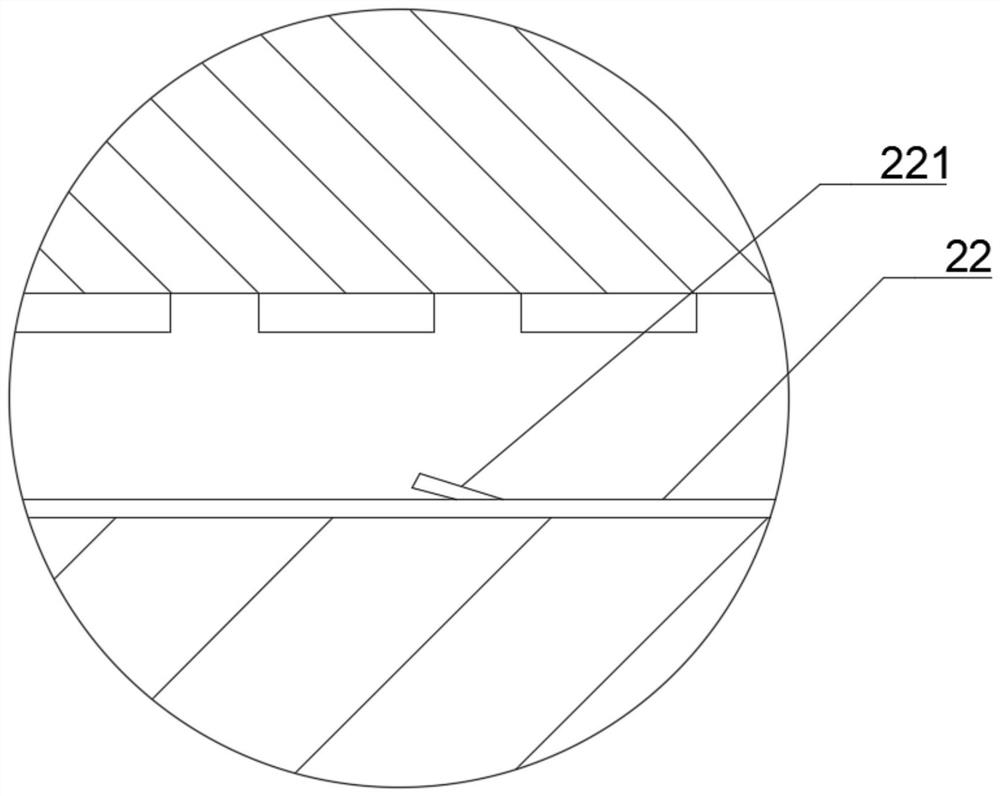

Tea leaf drying device with movable storage basket

InactiveCN108168243AEvenly heatedAvoid pollutionTea dryingDrying gas arrangementsCircular discAgricultural engineering

The invention discloses a tea leaf drying device with a movable storage basket. The tea leaf drying device comprises a base, a box body, the storage basket and a water tank. The storage basket is arranged in the box body, a hot air pipe is arranged above the storage basket, a second motor is installed at the center position of the bottom of the storage basket, an output shaft of the second motor is connected with a rotating shaft, the rotating shaft is in matching connection with a connecting rod, and a balancing weight is fixedly arranged at the other end of the connecting rod. First motors are symmetrically arranged on the left and on the right of the lower side of the box body, the first motors are mounted on the base, an output shaft of each first motor stretches into the box body andis connected with a round plate, an elastic connecting part is eccentrically and fixedly arranged on the upper end face of each round plate, the other end of each elastic connecting part is rotationally connected to the bottom of the storage basket, and the elastic connecting parts on the two sides are located on the same positions of the corresponding round plates at the same moment. By arrangingthe movable storage basket, tea leaves are shaken while being driven to conduct circular motion, the tea leaves are heated evenly, and the drying effect is guaranteed.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

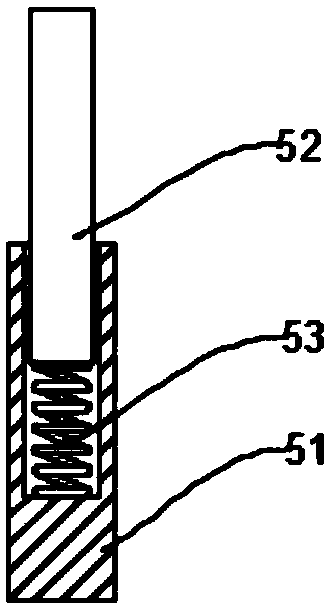

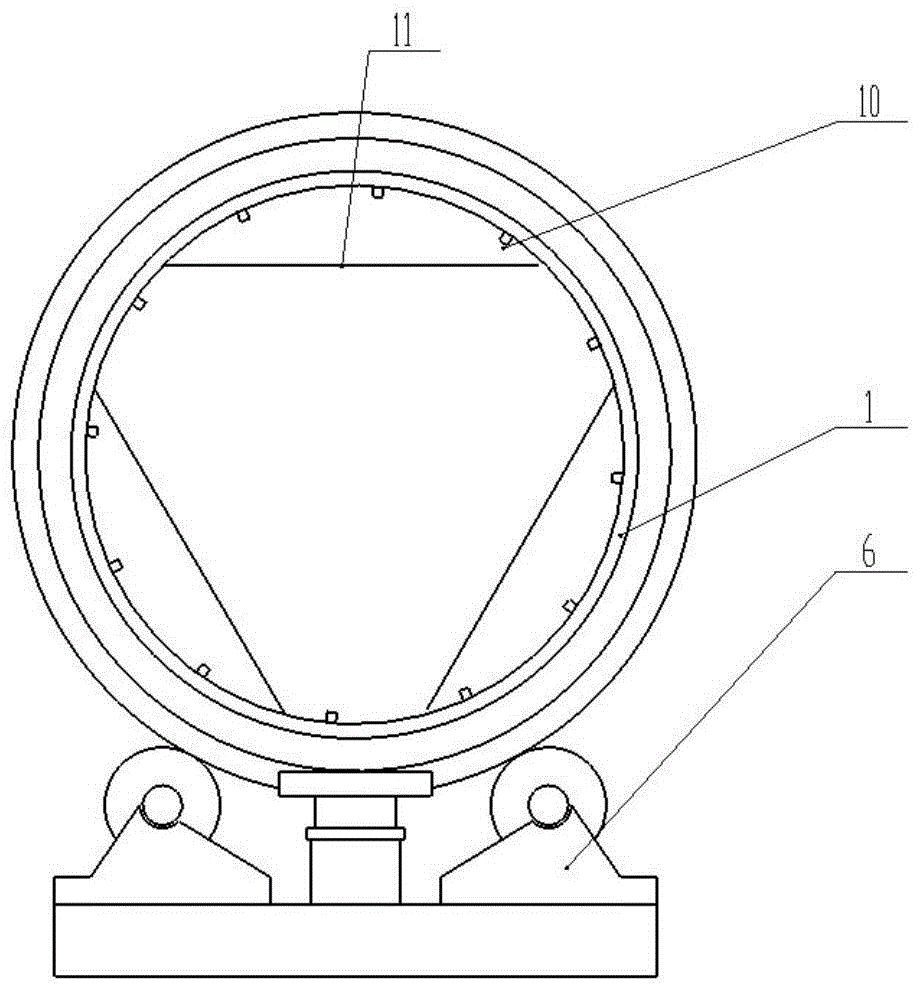

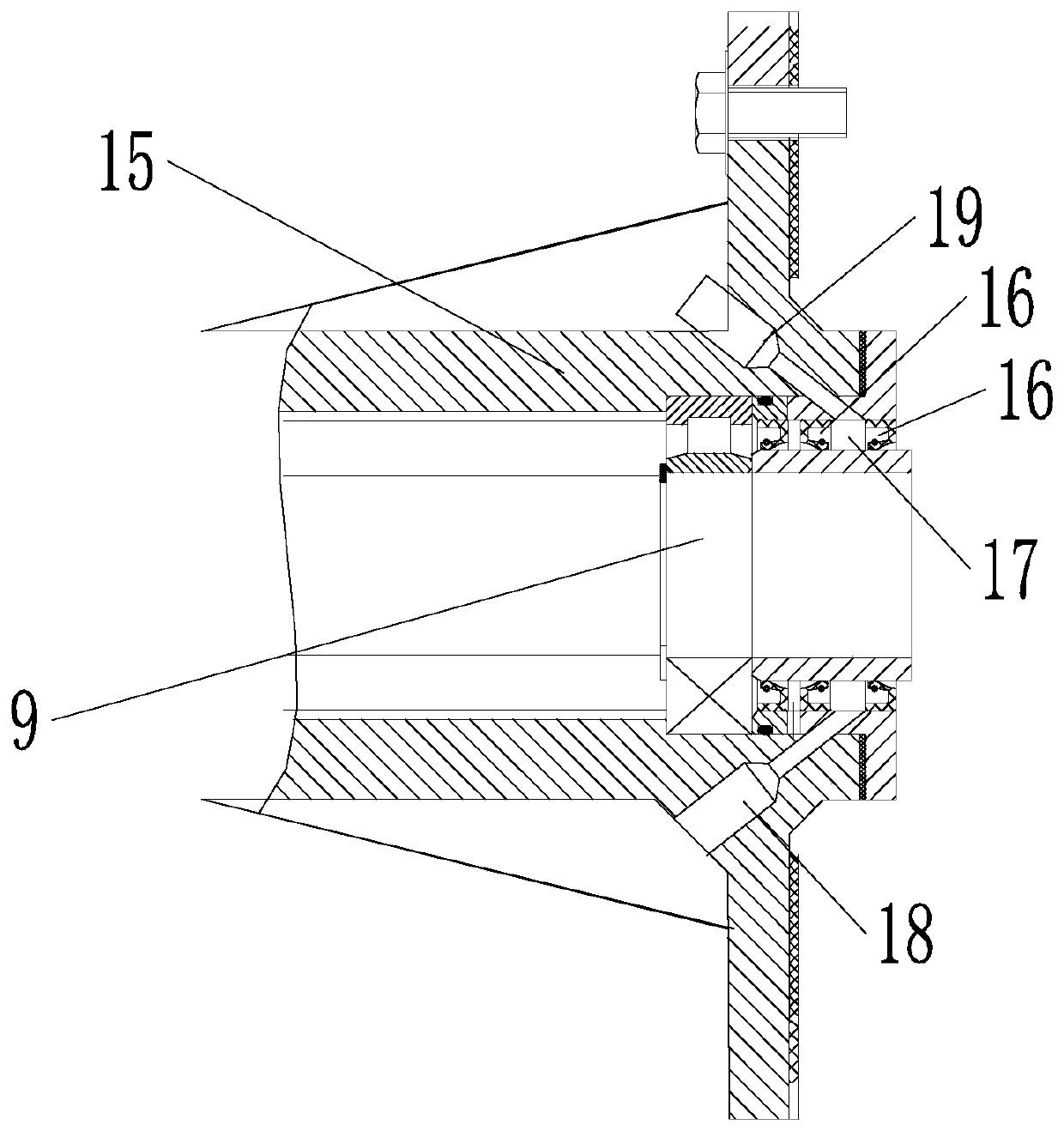

Drum drier

InactiveCN104132515AHeat and dry evenlyAvoid drying effectsDrying machines with non-progressive movementsDrying solid materialsGear driveElectric machinery

The invention relates to the technical field of drying machinery, in particular to a drum drier comprising a drum obliquely arranged. Lining strips are evenly fixed to the inner wall of the drum in the axial direction. Large rolling rings and a toothed rolling ring are fixed on the outside of the drum. Each side of the bottom of the toothed rolling ring is provided with a gear drive device and a drive motor, which drives a gear of the gear drive device to rotate. The tooted rolling rings mesh with the gears of the gear drive devices. A carrier wheel device is disposed at the bottom of each large rolling ring. A sealing device is disposed at an opening arranged in the higher end of the drum; a discharge box is fixed to an opening arranged in the other end of the drum; the lower end of the discharge box is provided with a discharge outlet. The drum drier has the advantages that the drum rotates at a uniform speed in the process of drying material, the material in the drum is evenly heated and dried, drying is effective and efficient, and the problem that dead corners resulting from accumulation of the material in the drum affects the drying effect is solved.

Owner:潘纪鸿

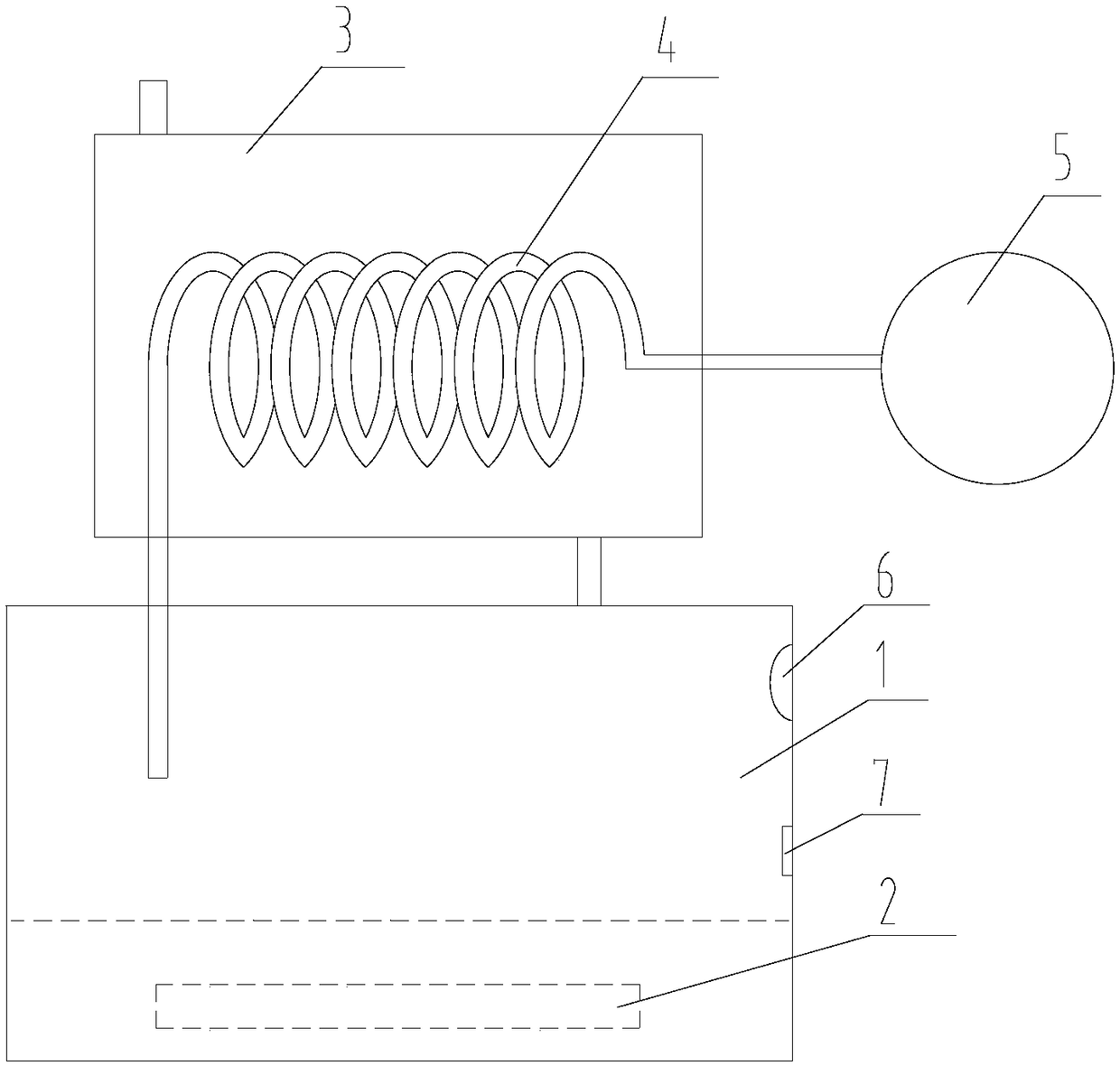

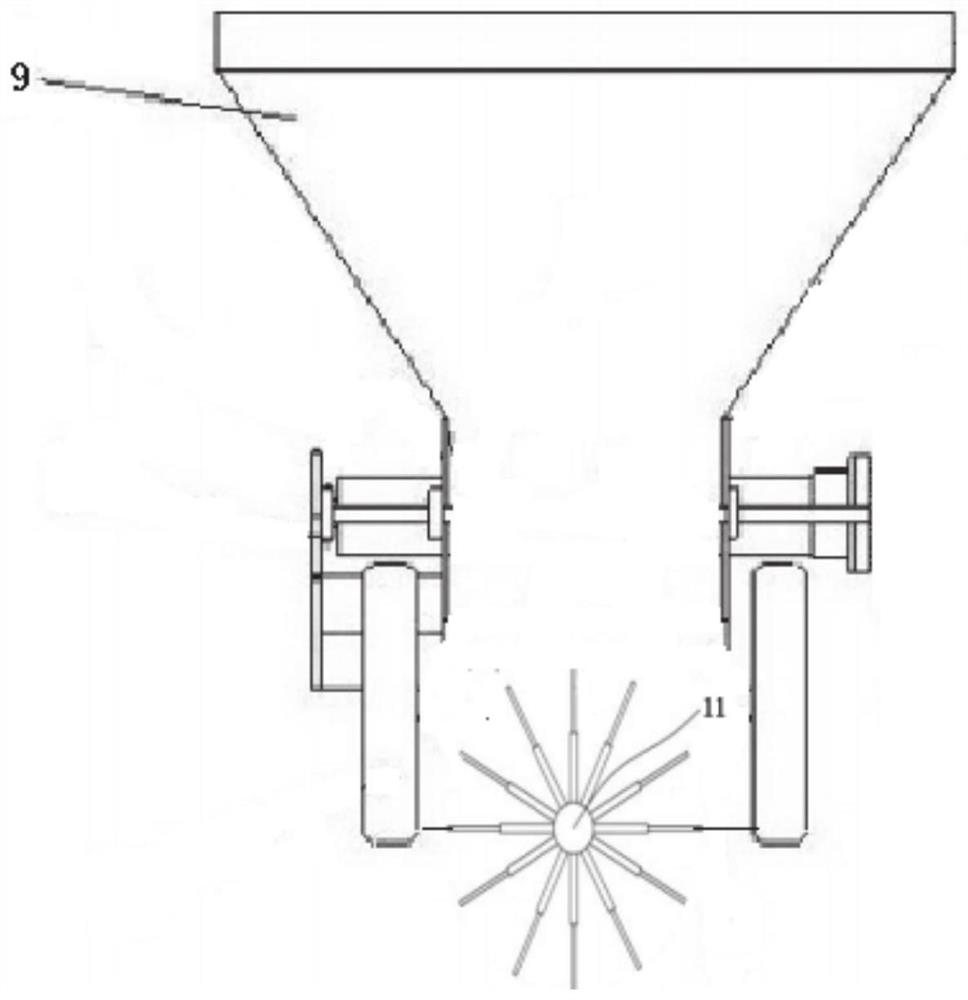

Discharging device of traditional Chinese medicine pill making machine

InactiveCN107411966AUniform temperatureImprove qualitySievingScreeningPulp and paper industryFilter effect

The invention discloses a discharge device of a traditional Chinese medicine pill making machine, which comprises a filter sieve plate, a vibrating motor, a heating block, a circulation fan and a first exhaust fan. Screening and filtering, so as to screen out the unqualified pills, improve the overall quality of the pills, use the vibration motor to vibrate and drive the vibration of the filter sieve plate to speed up the speed of pill screening, and set the heating block for the pills in the screening bin Heating and drying are carried out to prevent the high humidity of the pills from sticking to the filter sieve plate so as to affect the effect of the filter sieve on the filtration of the pills. The circulating fan is used to blow air in the screening chamber to achieve uniform temperature in the screening chamber, thus realizing For the uniform drying of the pills in the screening bin, the first exhaust fan is used to discharge the moisture generated by drying the pills in the screening bin through the dehumidification pipe, thereby speeding up the drying speed of the pills in the screening bin.

Owner:SHENZHEN ZHIHUI QIANXIAN TECH CO LTD

Bamboo cane drying device

InactiveCN109028797AReduce the temperatureEnsure stabilityDrying gas arrangementsDrying solid materialsEngineeringExhaust gas

The invention provides a bamboo cane drying device which comprises a drying oven, a heater, a preheating box, an air feed pipe and an air pump, wherein the heater is arranged in the drying oven, and the air feed pipe is arranged in the preheating box; the inlet end and the outlet end of the air feed pipe extend out of the preheating box, the inlet end of the air feed pipe is connected with the airpump, and the outlet end of the air feed pipe is inserted into the drying oven; a steam inlet and a tail gas outlet are formed in the preheating box, a steam outlet is formed in the drying oven, andthe steam inlet communicates with the steam outlet; and a water outlet is formed in the bottom of the preheating box. The bamboo cane drying device realizes a bamboo drying environment with constant temperature and constant humidity. Particularly, in the bamboo cane drying device, hot air in the inner part of the drying oven ensures a certain humidity, so that a bamboo cane is dried by the hot airwith the humidity lower than the humidity of the bamboo cane; water in the bamboo cane is profitably controlled to slowly drain away, and the uniform loss of water in the bamboo cane drying process is ensured; and therefore crack is avoided, and the processing quality of the bamboo cane is guaranteed.

Owner:望江县红和木业灯饰有限公司

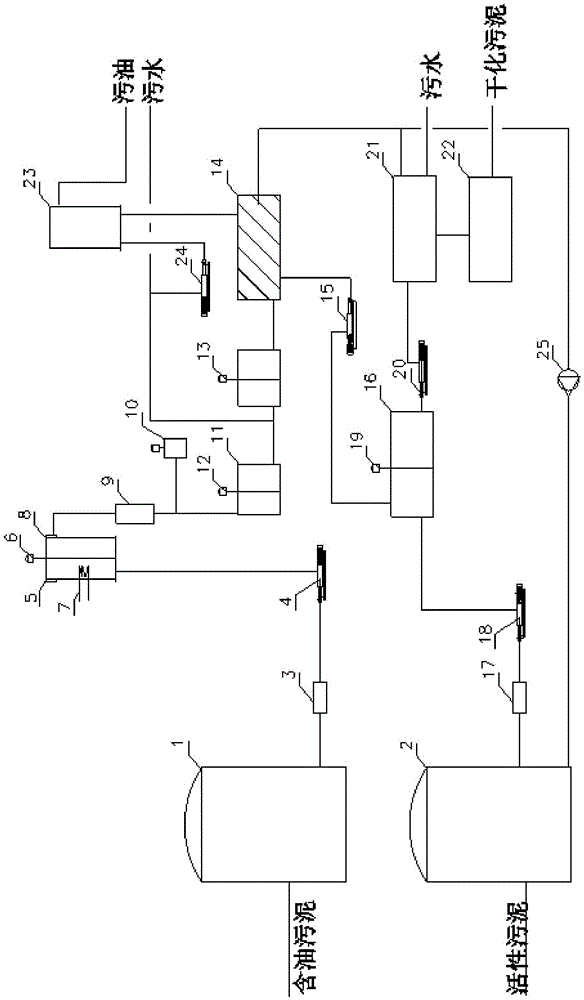

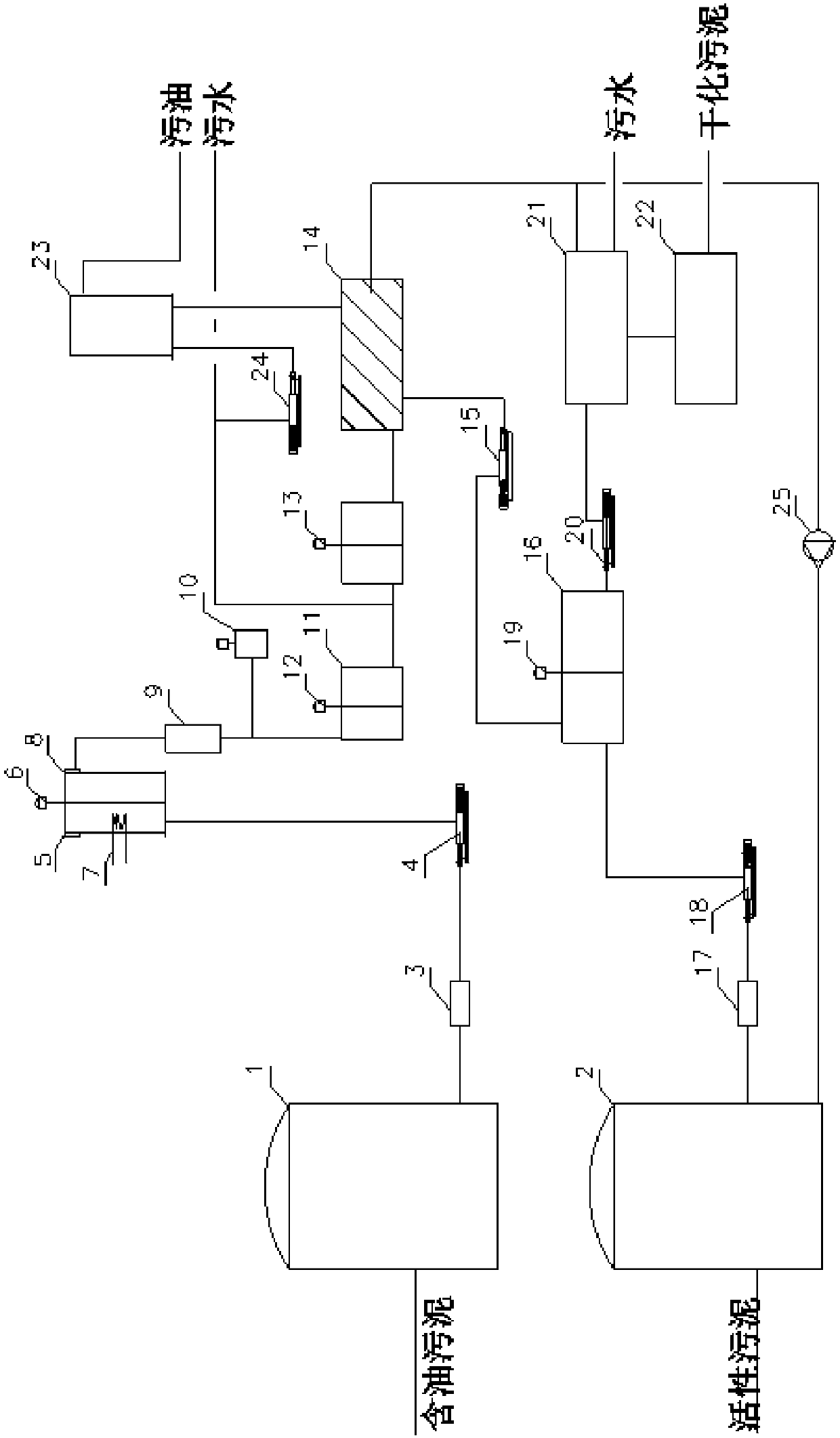

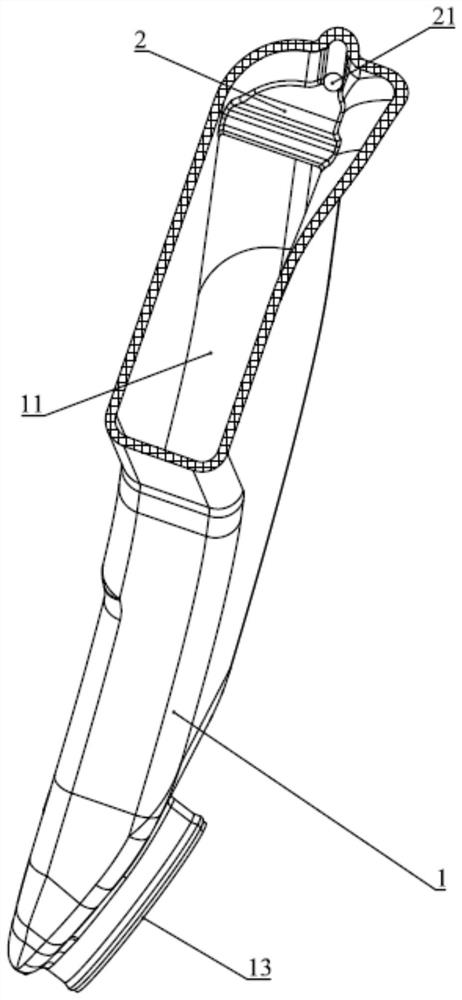

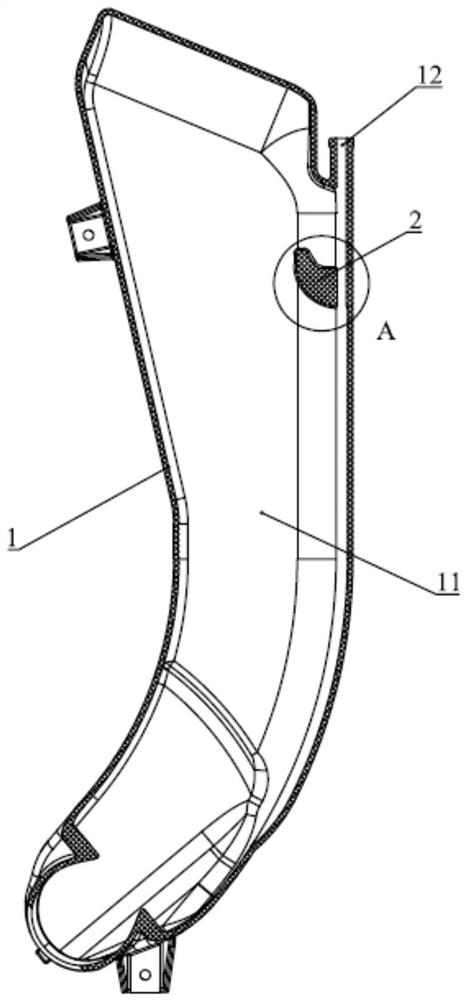

Sludge treatment device and method

ActiveCN105668961ADehydration effectsAffect dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningResource utilizationSludge

The invention provides a sludge treatment device and method.The sludge treatment device comprises an oil-containing sludge concentration tank (1), a first cutter (3), a cutting filter (5), a precise heater (9), a chemical adding device (10), an ultrasonic oscillating reactor (11), a hot water cleaning reactor (13), a gas oscillating solid-liquid separation tank (14), an oil-water separation tank (23), an active sludge concentration tank (2), a second cutter (17), a sludge mixing conditioner (16) and a sludge low-temperature thermal dehydration and desiccation all-in-one machine (21).The sludge treatment device can separate oil from oil-containing sludge, prevents the oil from affecting sludge thermal desiccation, solves the problems of sludge resource utilization and reduction, reduces the amount and the weight of the sludge, and reduces transport cost and disposal cost.

Owner:北京天灏柯润环境科技有限公司

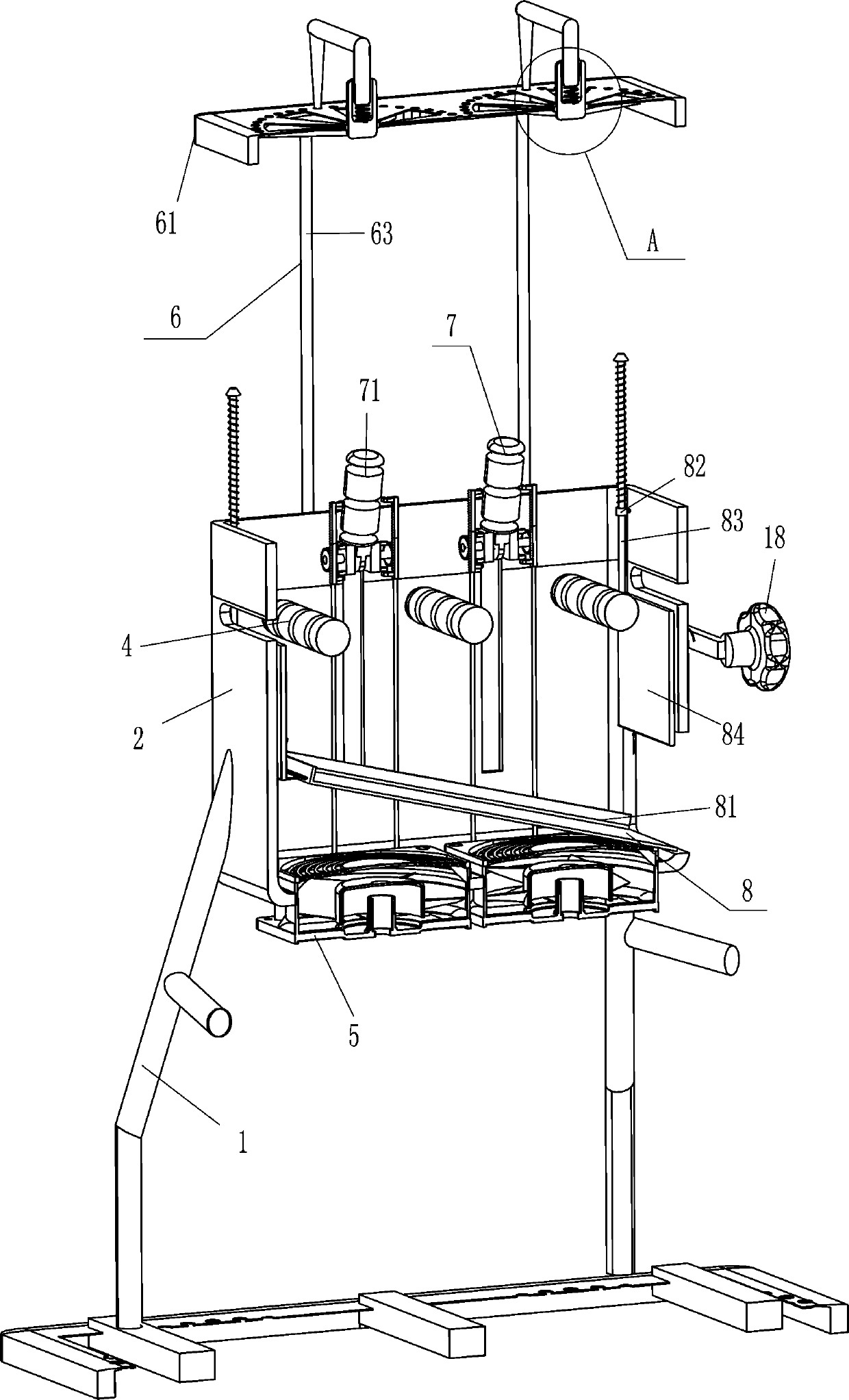

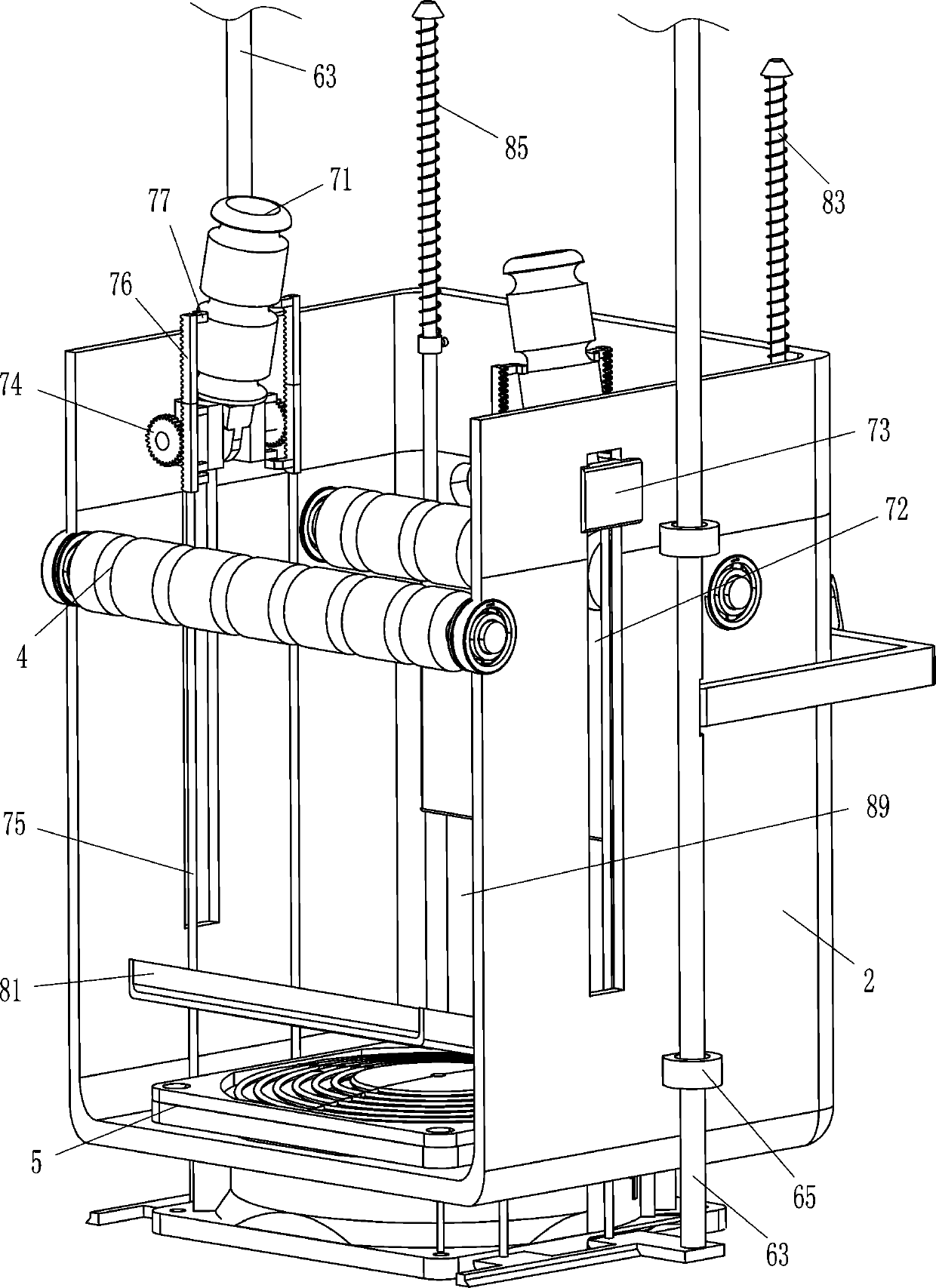

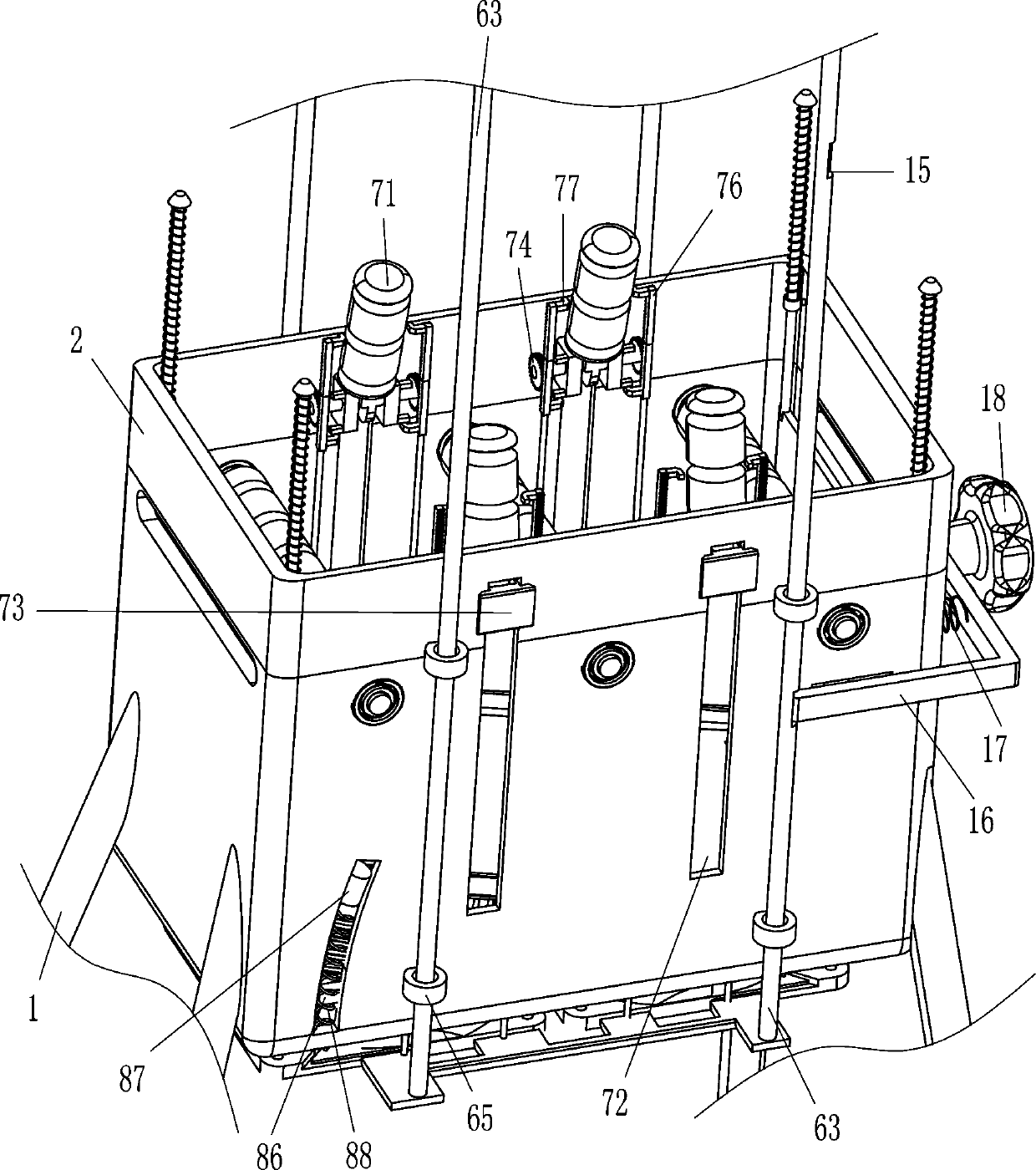

Diamond wire drying device

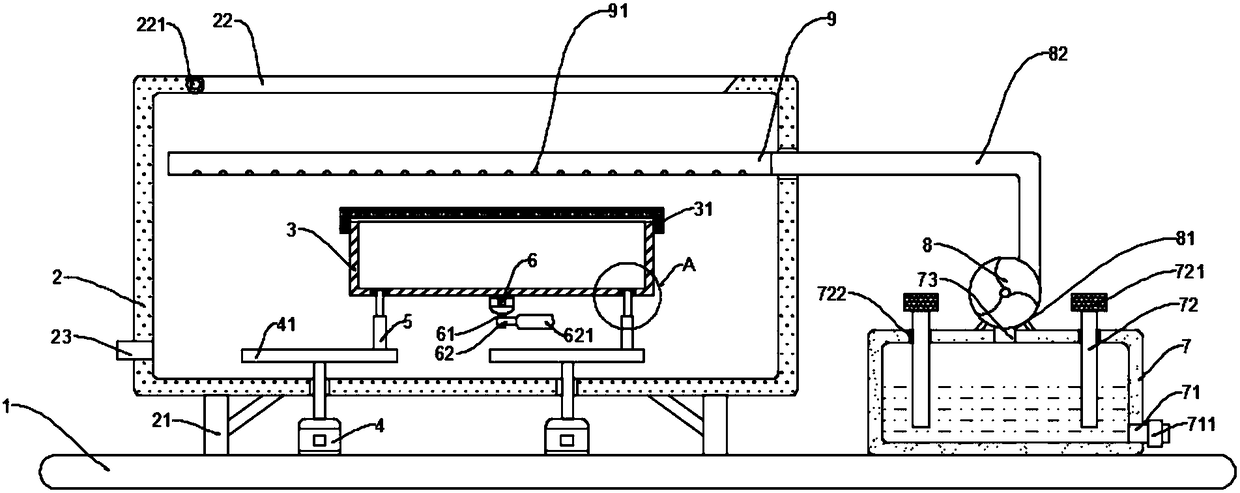

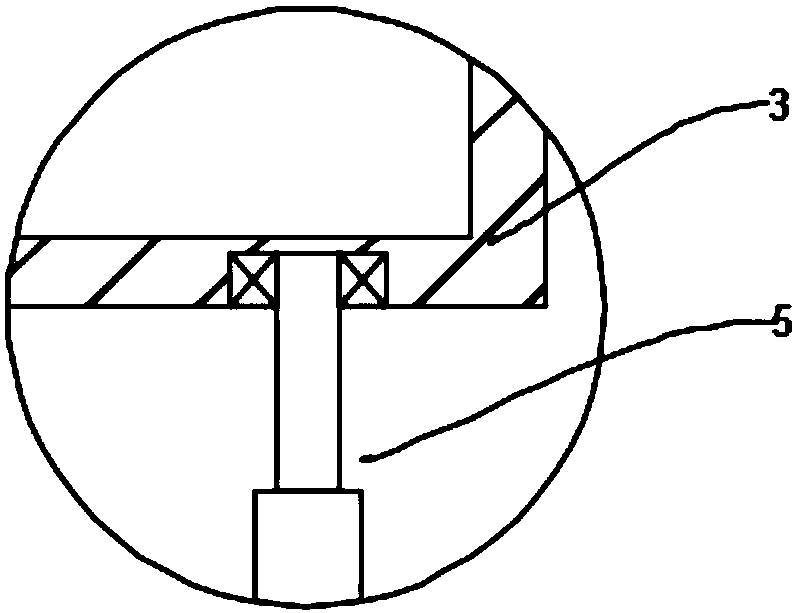

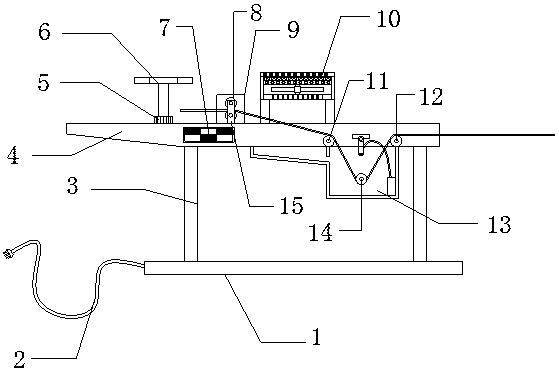

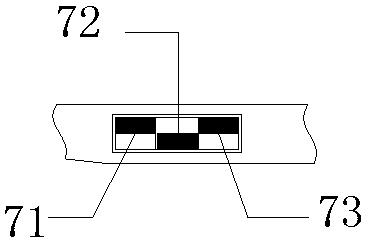

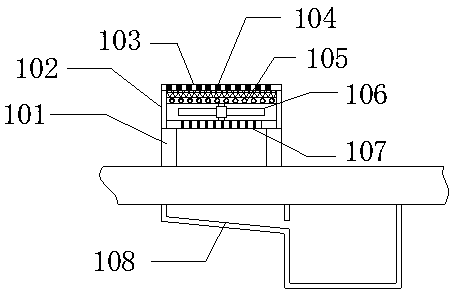

InactiveCN111121430AAvoid drying effectsAvoid affecting operationDrying gas arrangementsDrying machines with progressive movementsMaterials scienceSupport plane

The invention relates to a drying device, in particular to a diamond wire drying device. According to the diamond wire drying device, more diamond wires can be dried simultaneously, and the working efficiency is improved. The diamond wire drying device comprises a supporting frame, a frame body, hot air fans, a driving mechanism, a pushing mechanism and the like; the frame body is installed amongthe top ends of the supporting frame, the hot air fans are installed in the bottom of the frame body, the driving mechanism is arranged on the position, between the front side face and the rear side face of the frame body, outside the frame body, the pushing mechanism capable of enabling the diamond wires to move is arranged in the frame body, and the pushing mechanism is matched with the drivingmechanism. According to the diamond wire drying device, a diamond wire penetrates through openings, and a cover plate is pushed, so that guide rollers make contact with the diamond wire to enable thediamond wire to move downwards, more diamond wire is moved into the frame body, the hot air fan is started, the diamond wire can be dried, and the working efficiency is improved.

Owner:邱昌萍

Sludge treatment device and method

ActiveCN105668961BDehydration effectsReduce in quantitySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningResource utilizationSludge

The invention provides a sludge treatment device and method.The sludge treatment device comprises an oil-containing sludge concentration tank (1), a first cutter (3), a cutting filter (5), a precise heater (9), a chemical adding device (10), an ultrasonic oscillating reactor (11), a hot water cleaning reactor (13), a gas oscillating solid-liquid separation tank (14), an oil-water separation tank (23), an active sludge concentration tank (2), a second cutter (17), a sludge mixing conditioner (16) and a sludge low-temperature thermal dehydration and desiccation all-in-one machine (21).The sludge treatment device can separate oil from oil-containing sludge, prevents the oil from affecting sludge thermal desiccation, solves the problems of sludge resource utilization and reduction, reduces the amount and the weight of the sludge, and reduces transport cost and disposal cost.

Owner:北京天灏柯润环境科技有限公司

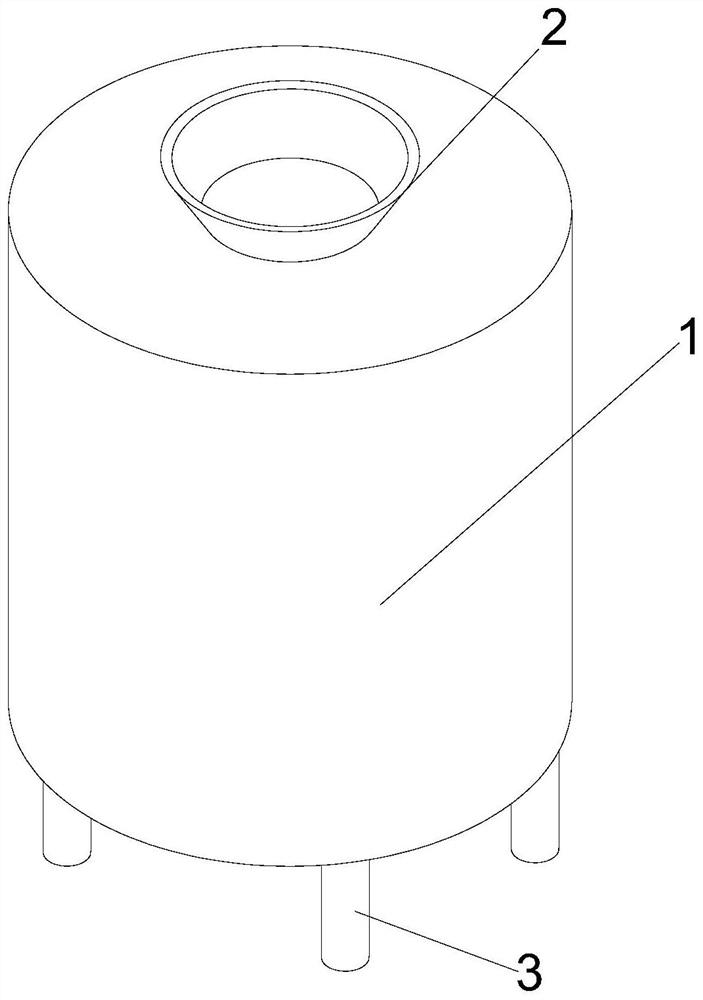

Three-stage drying device for tea leaves

InactiveCN112146403APrevent adhesionAvoid accumulationDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention relates to the technical field of tea leaves, and discloses a three-stage drying device for the tea leaves. The three-stage drying device comprises a shell, a circular truncated cone isfixedly installed on the upper wall face of the shell, three supporting legs are fixedly installed on the lower wall face of the shell, two arc-shaped openings are formed in the inner wall of the bottom of the shell, and a driving device is arranged in the shell. According to the three-stage drying device for the tea leaves, magnet blocks rotate, the magnet blocks correspond to swing blocks on triangular prisms, then when the magnet blocks sequentially pass through the swing blocks, the magnet blocks can attract the swing blocks to enable the swing blocks to swing, so that the triangular prisms are driven to swing, the situation that internal water evaporates during drying of the tea leaves, so that the tea leaves adhere to the triangular prisms is avoided, and the problems that the tea leaves easily adhere to the inner wall of a drying oven and are difficult to remove after being in a static state in the drying oven for a long time and after the internal water of the tea leaves at thebottom is dried away, and the single-time drying yield of the tea leaves is affected are avoided.

Owner:周然然

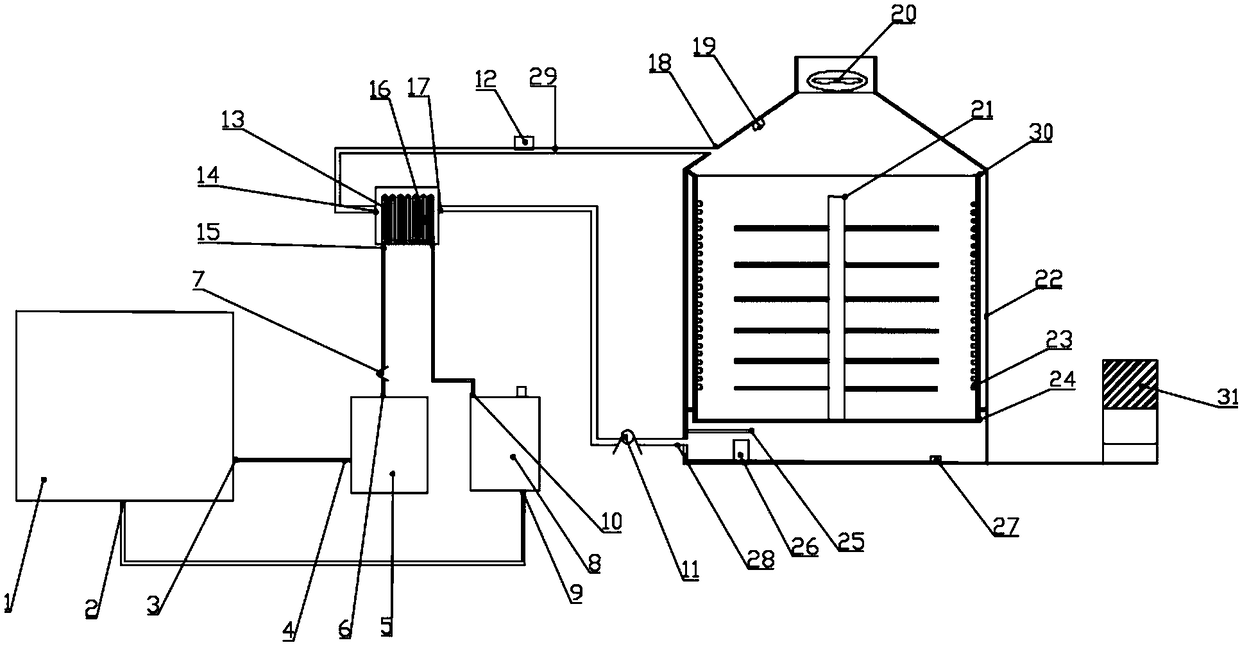

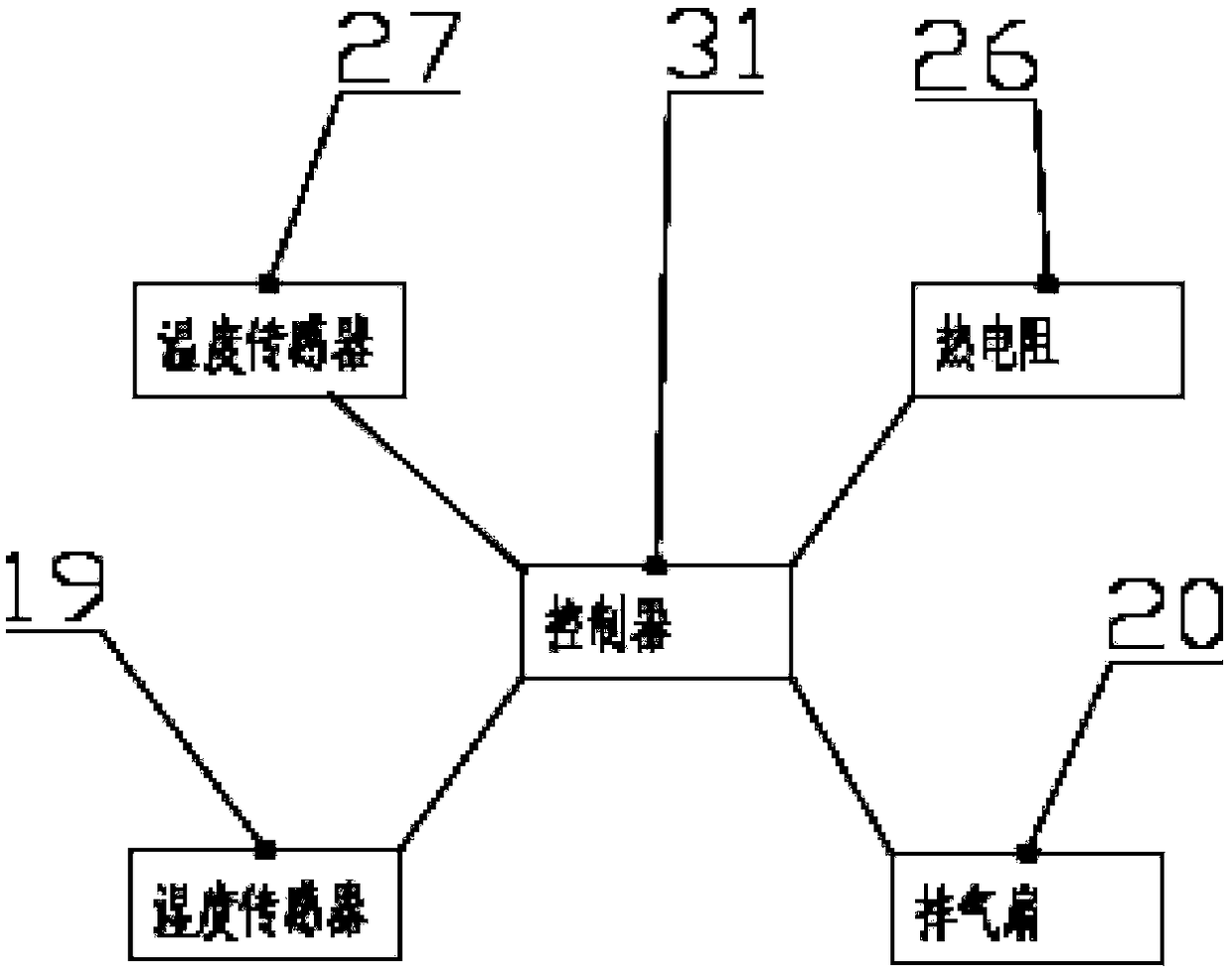

Full-automatic tobacco leaf drying room temperature adjusting system with air energy heat pump

InactiveCN108489254AImprove work efficiencyIncrease drynessDrying solid materialsHeating arrangementStable stateRoom temperature

The invention discloses a full-automatic tobacco leaf drying room temperature adjusting system with an air energy heat pump. The full-automatic tobacco leaf drying room temperature adjusting system comprises a sensor, a controller, an air door controller, a frequency converter, a power source, a fan, an air blower, the air energy heat pump, a dehumidification door, a dehumidifier, an information sending module, an information receiving module and an information acquisition host. The controller is electrically connected with the sensor. The air door controller is electrically connected with thecontroller. The power source is electrically connected with the controller through the frequency converter. The power source is electrically connected with the fan, the air blower and the air energyheat pump sequentially. The controller is electrically connected with the dehumidification door. The dehumidifier is arranged in the dehumidification door. The information sending module is electrically connected with the controller. The full-automatic tobacco leaf drying room temperature adjusting system is simple in structure, temperature and humidity of a drying room can be monitored and adjusted according to temperature and humidity conditions in the drying room, thus the temperature and humidity of the drying room are kept in a stable state, work efficiency of the tobacco leaf drying roomis improved, and the full-automatic tobacco leaf drying room temperature adjusting system has very good promotional value.

Owner:ZHEJIANG HAILAIFU ELECTRONICS TECH CO LTD

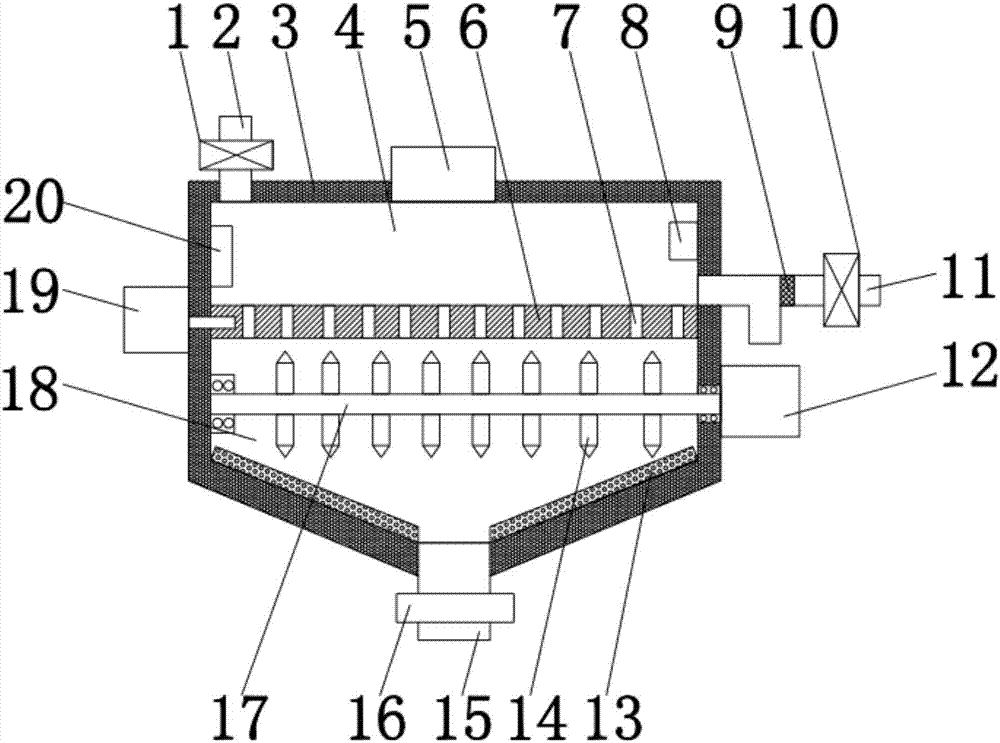

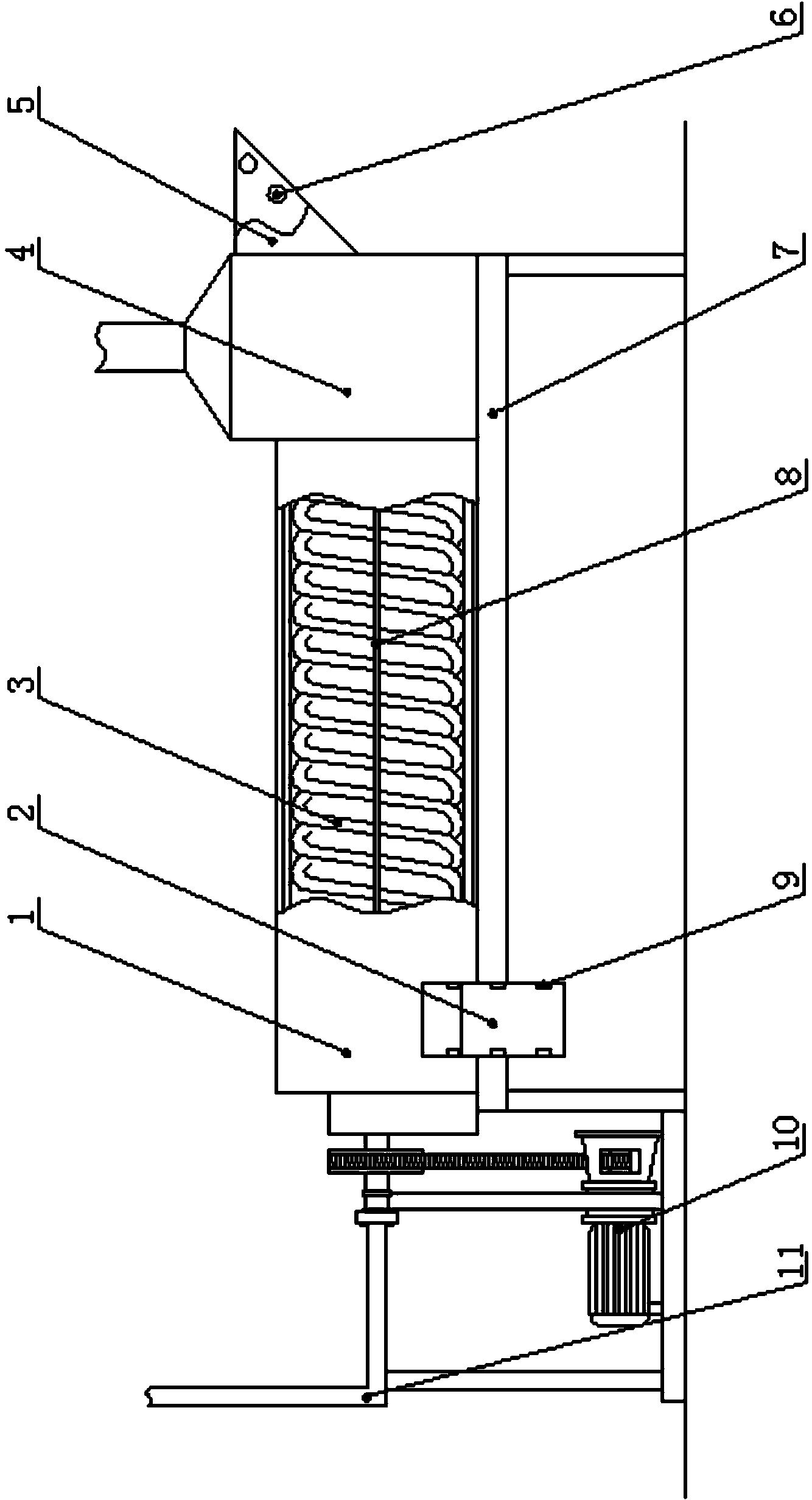

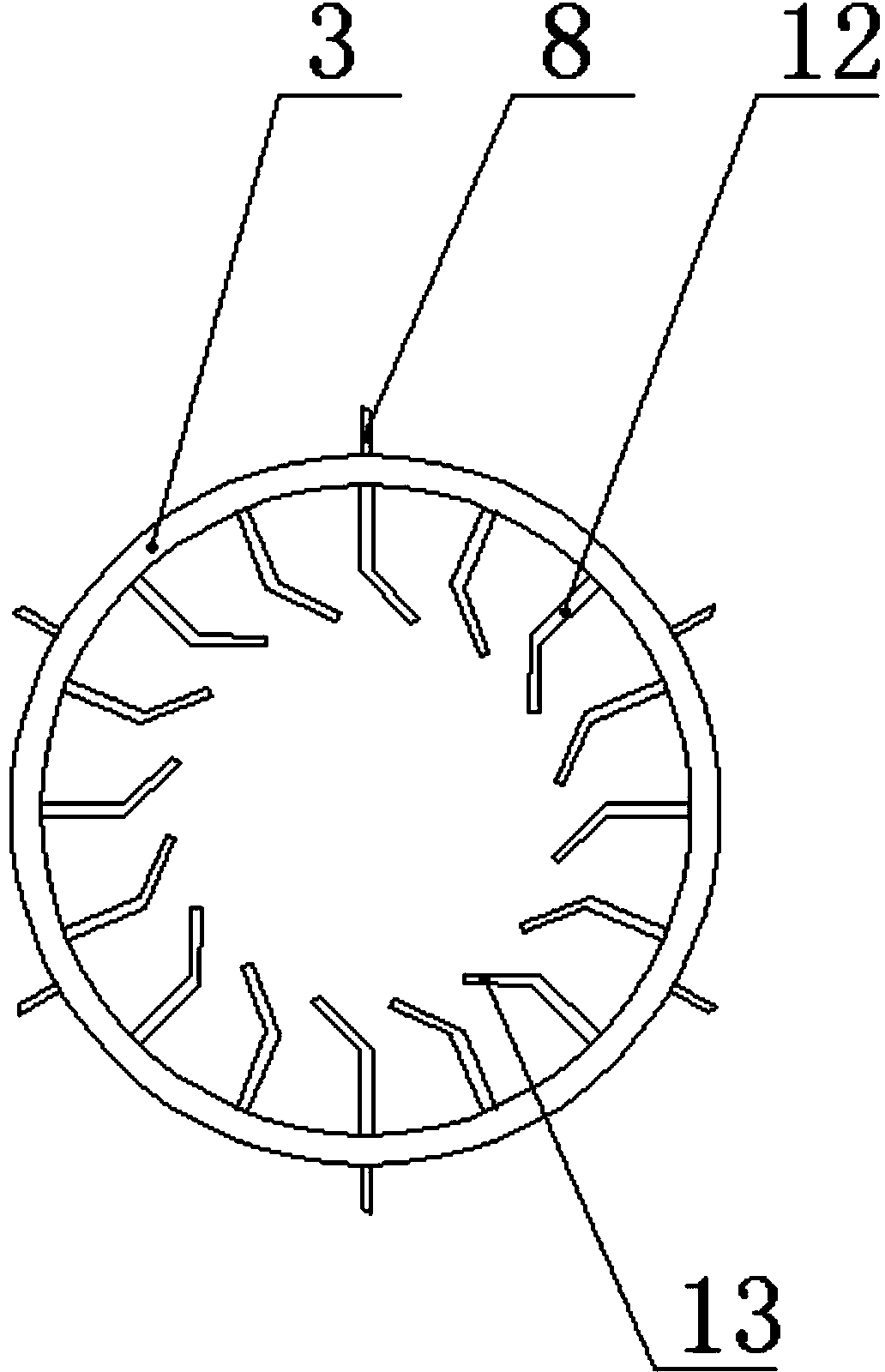

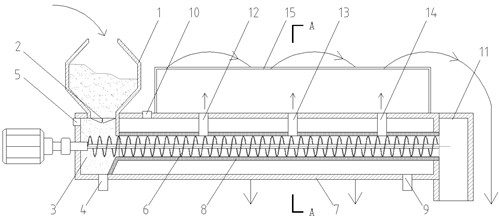

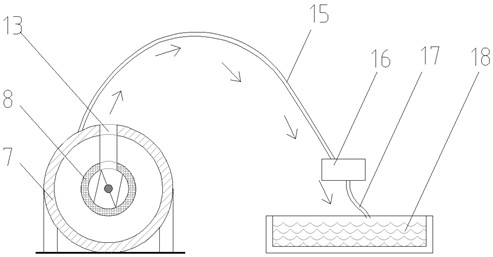

Novel spiral drying machine

InactiveCN104215053AHave the effect of flippingAffect normal useDrying machines with progressive movementsHeat conductingEngineering

The invention relates to a novel spiral drying machine, which consists of a machine frame, a feeding cabin, a drying cabin, a motor and a spiral heating tube, wherein one side of the feeding cabin is communicated with the drying cabin, the other side of the feeding cabin is provided with a feeding hopper, the back part of the drying cabin is provided with a discharging hopper, the motor is arranged under the drying cabin, a plurality of heat conducting sheets consistent with the spiral heating tube in the rotation angle are uniformly distributed and arranged on the inner wall of the spiral heating tube, and a plurality of material scraping plates transversely penetrating through the heating tube are uniformly distributed and fixedly arranged on the outer wall of the spiral heating tube. The novel spiral drying machine has the advantages that the technical problems of great occupied space and complicated regulation process of the traditional dying machine are solved, the spiral heating tube is adopted for being matched with the heat conducting sheets fixedly arranged at the inside, heat can be effectively conducted to the center of materials from the outer periphery, in addition, along with the rotation of the heating tube, the effect of turning the materials can be achieved, the heat conduction area is effectively increased, and the drying effect is improved.

Owner:TIANJIN XINYE STRAW PROD

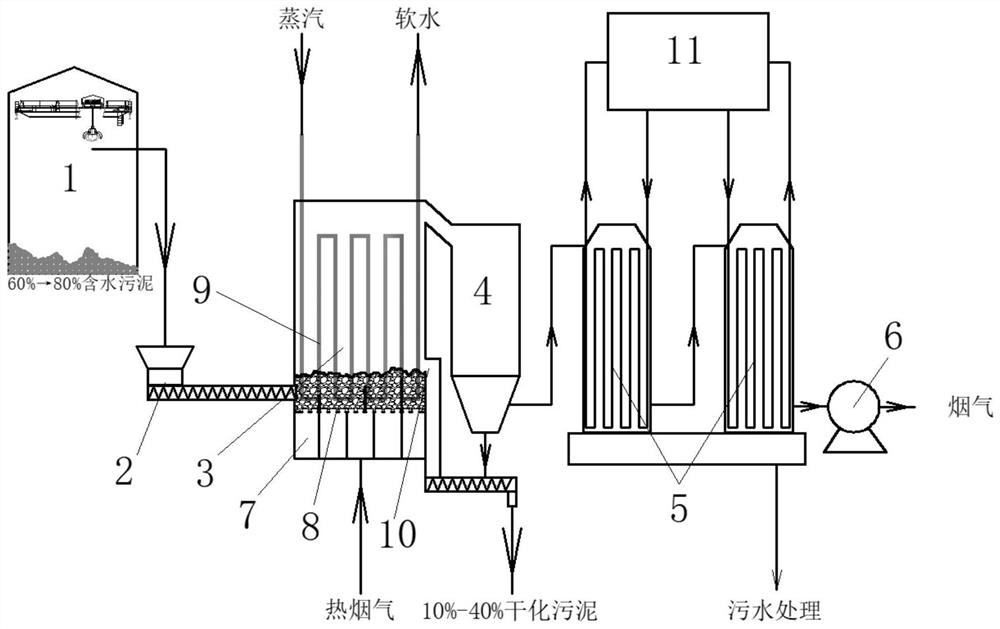

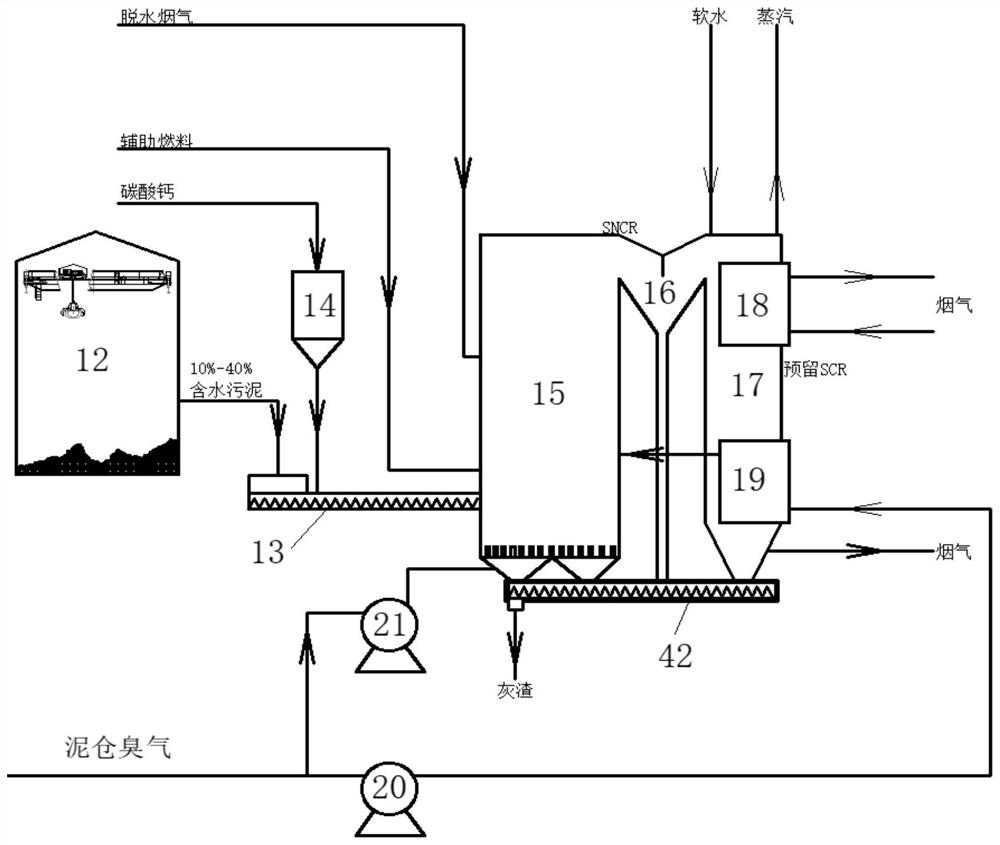

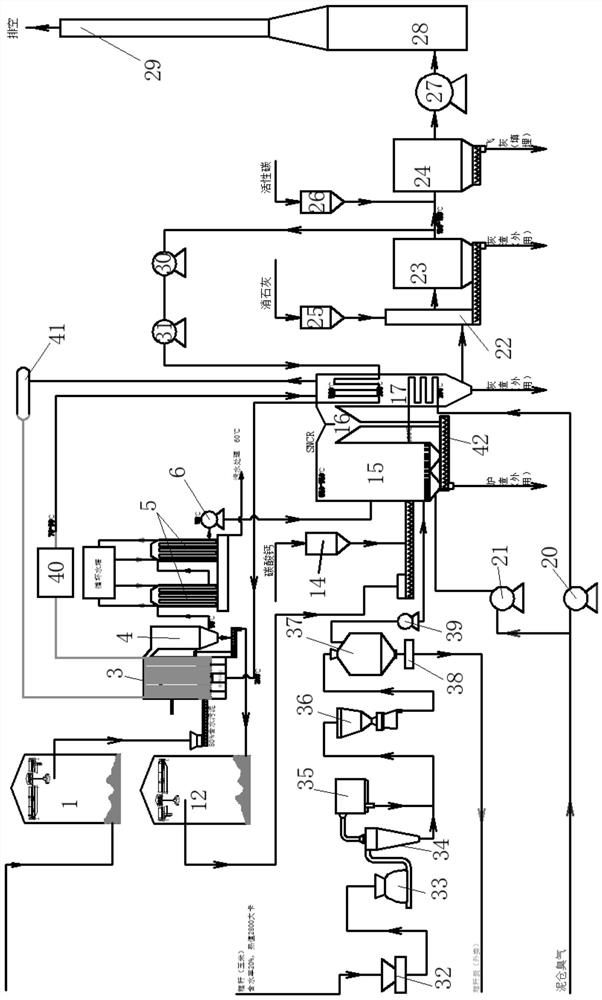

Sludge recycling treatment system

ActiveCN114735918AReduced flammability propertiesReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningEnergy inputFluidized bed dryingCyclonic spray scrubber

The invention discloses a sludge recycling treatment system which comprises a sludge drying system, a sludge incineration system, a flue gas treatment system and a straw gasification system. The sludge drying system comprises a wet sludge pit, a feeding screw conveyor, a fluidized bed dryer, a first cyclone dust collector, a secondary cooler and a first induced draft fan which are connected in sequence; the sludge incineration system comprises a dry sludge pit, a stokehole feeding system, a fluidized bed incinerator, a settling chamber and a waste heat boiler which are connected in sequence; and a calcium carbonate quantitative feeder is arranged above the stokehole feeding system in parallel. According to the sludge recycling treatment system provided by the invention, flue gas generated by sludge incineration is used as a pre-drying heat source for recycling, so that the technical problems of high operation cost, poor operation stability and non-ideal treatment effect of an existing system can be solved, and stable, harmless and resource utilization of the sludge is realized.

Owner:JIANGSU QUANNENG ELECTROMECHANICAL EQUIP ENG LTD BY SHARE LTD

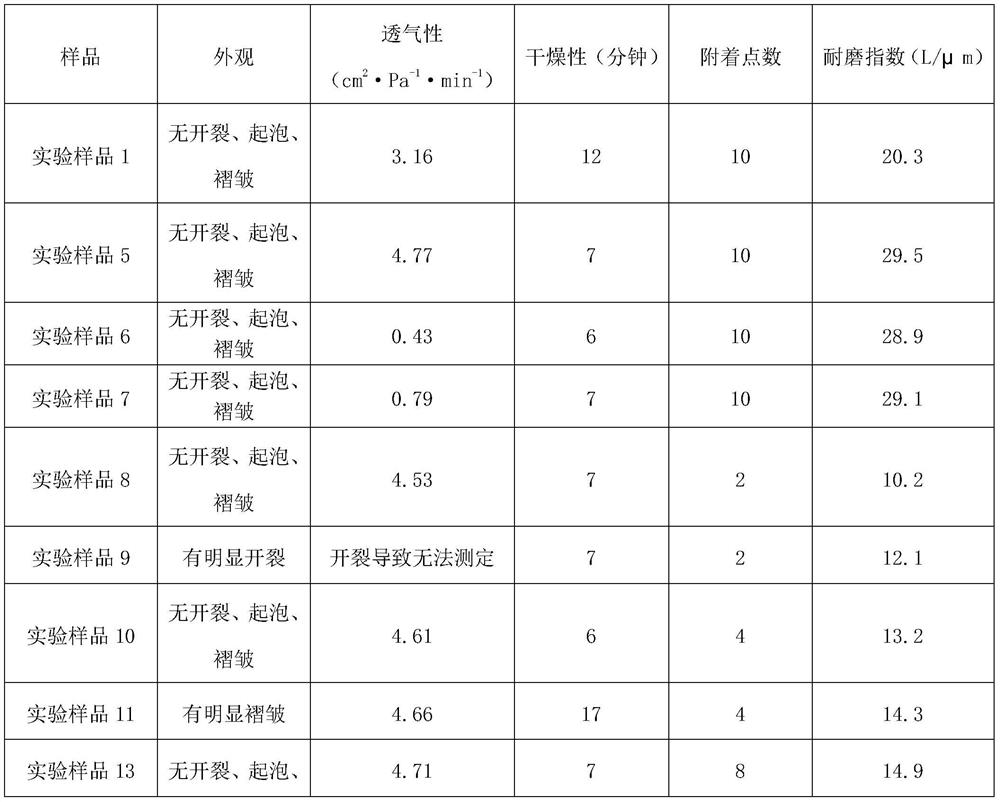

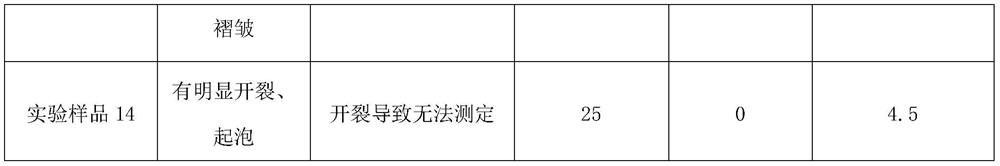

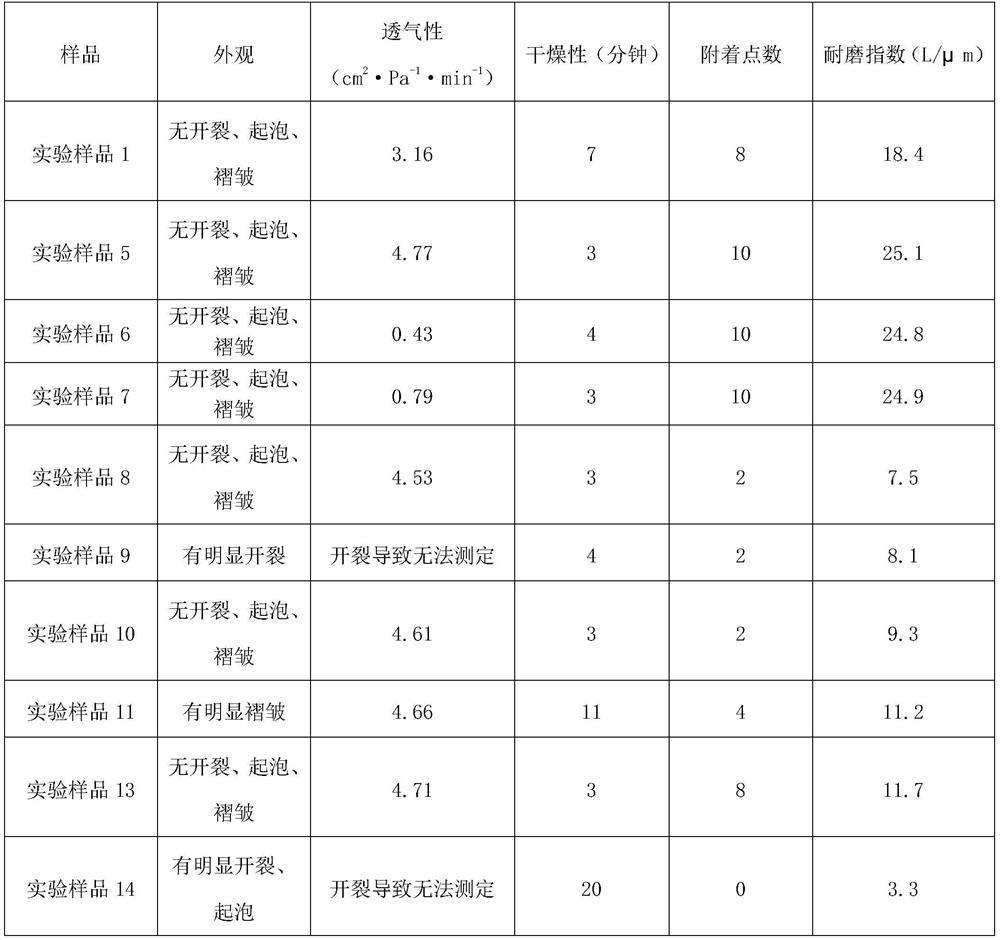

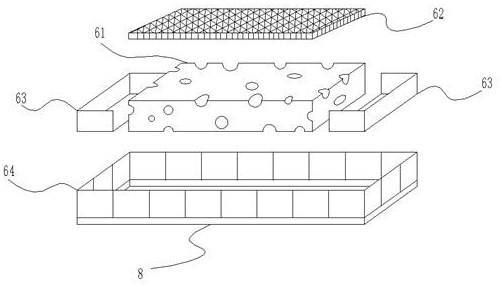

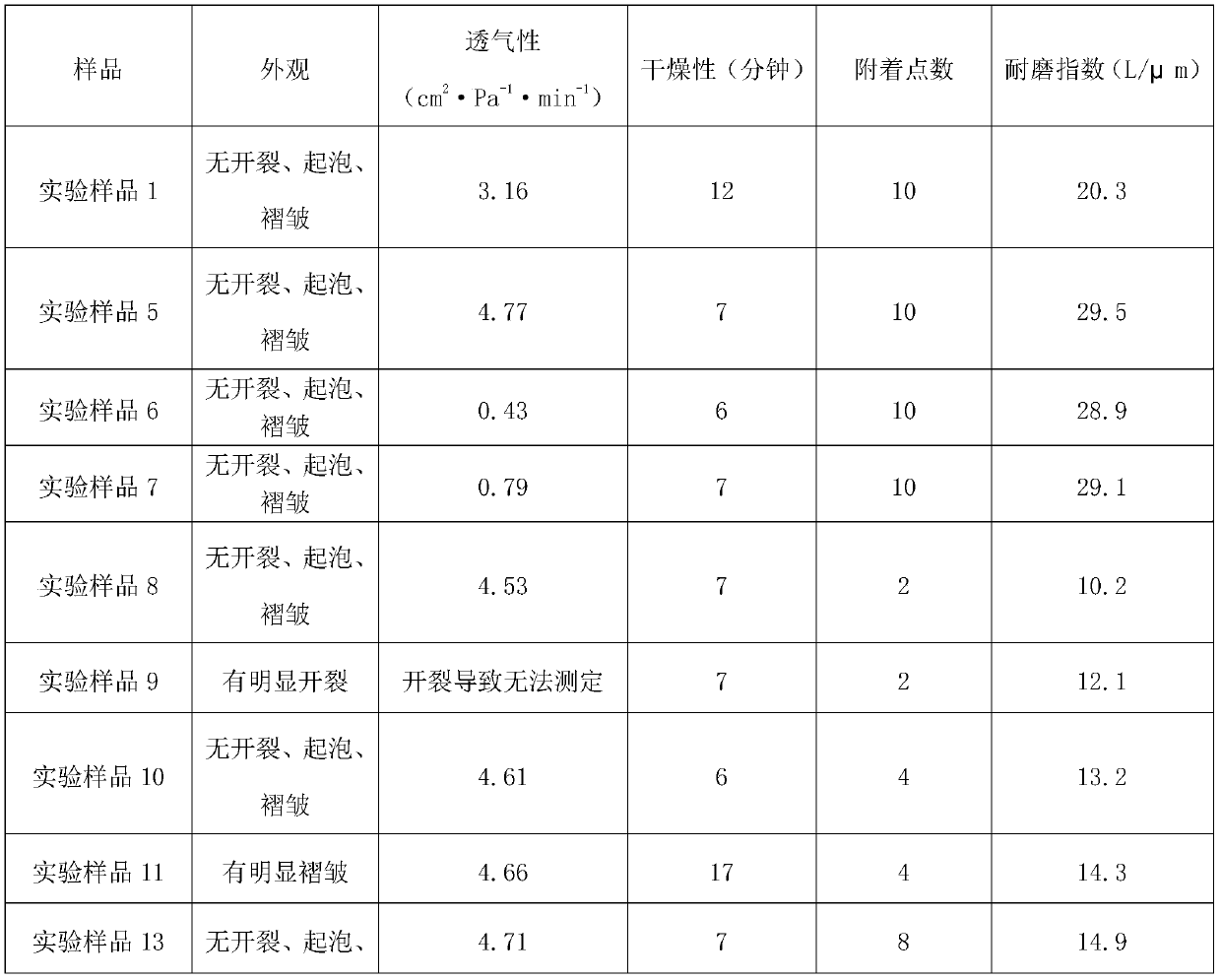

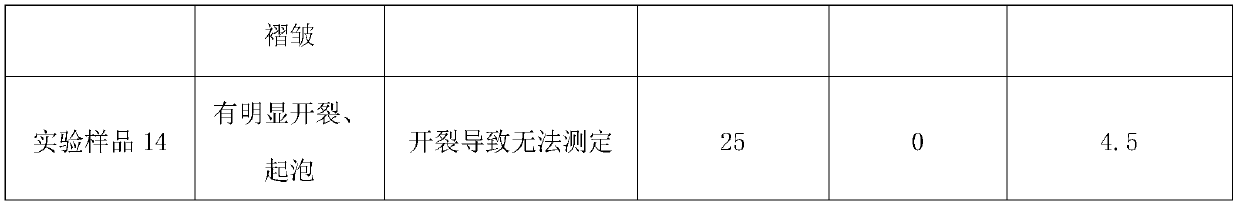

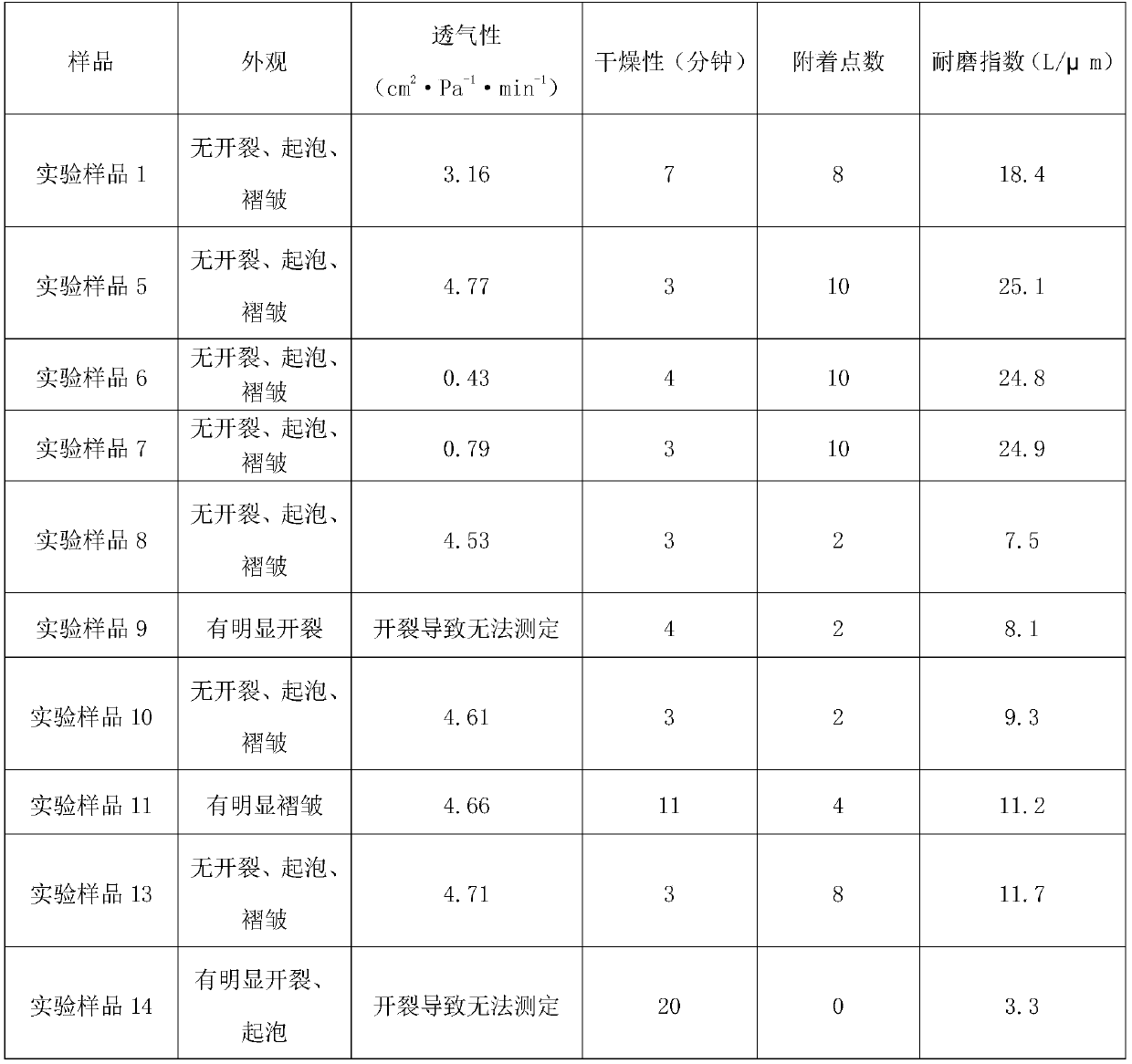

A kind of multifunctional coating for casting and preparation method thereof

ActiveCN110625061BPrevent sticky sandPrevent shrinkageFoundry mouldsFoundry coresPolystyreneLost-foam casting

The invention provides a multifunctional coating for casting and a preparation method thereof and particularly relates to the technical field of casting coatings. The method comprises the steps that firstly, a polystyrene fused solution is adopted for firing a compound, quartz sand powder and bentonite wrap the compound in batch in sequence, a wrapping compound is prepared, then powder of plasterof paris, sweet wormwood herb wax, trehalose and zinc oxide crystal whiskers are added to the wrapping compound, and the multifunctional coating for casting is prepared. The coating can be simultaneously used for two processes of lost foam casting and V-method casting, after coating is completed, cracks, bubbles and wrinkles do not exist, and the multifunctional coating for casting has the advantages of being resistant to wear, high in drying speed, adhesive force and air permeability and the like. The sand burning, shrinkage porosity and pore defects of a casting can also effectively prevented. The other aim of the invention is to provide the preparation method of the multifunctional coating for casting. The method is easy to operate, stable in process and suitable for large-scale production, and parameters can be controlled.

Owner:柳州市一乐科技有限公司

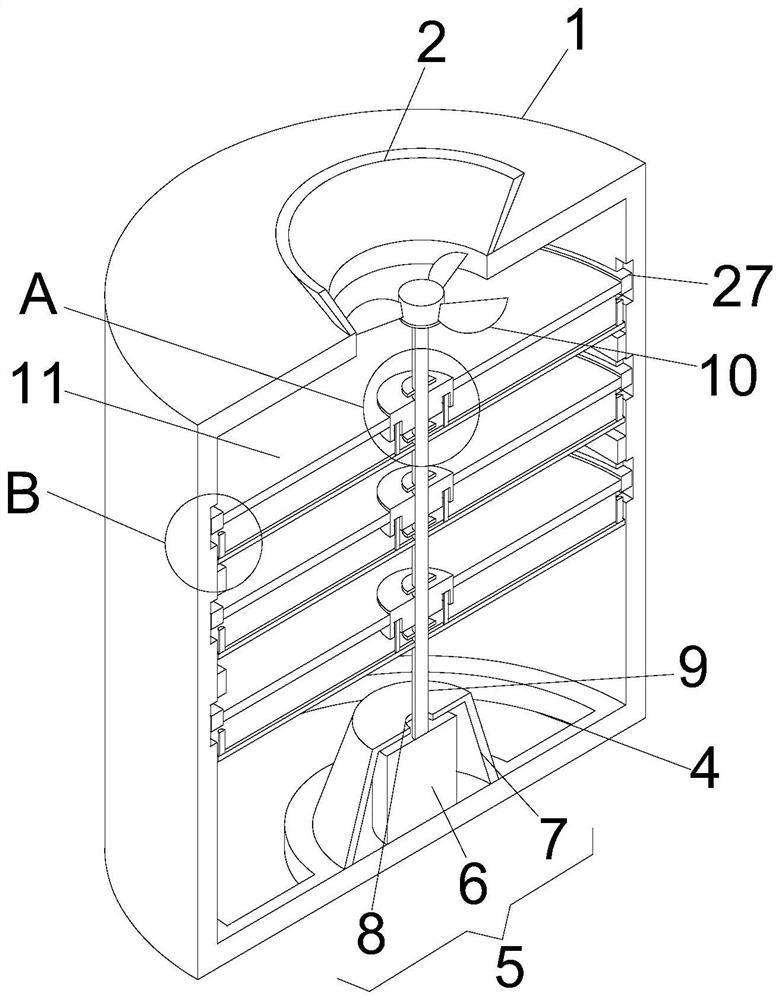

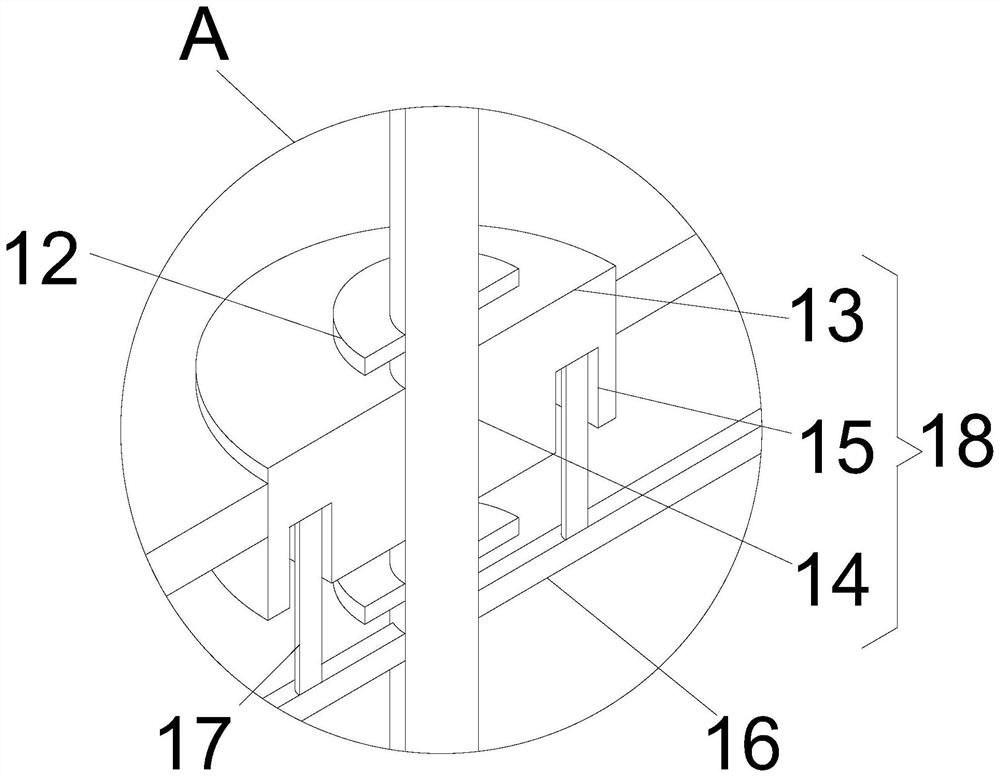

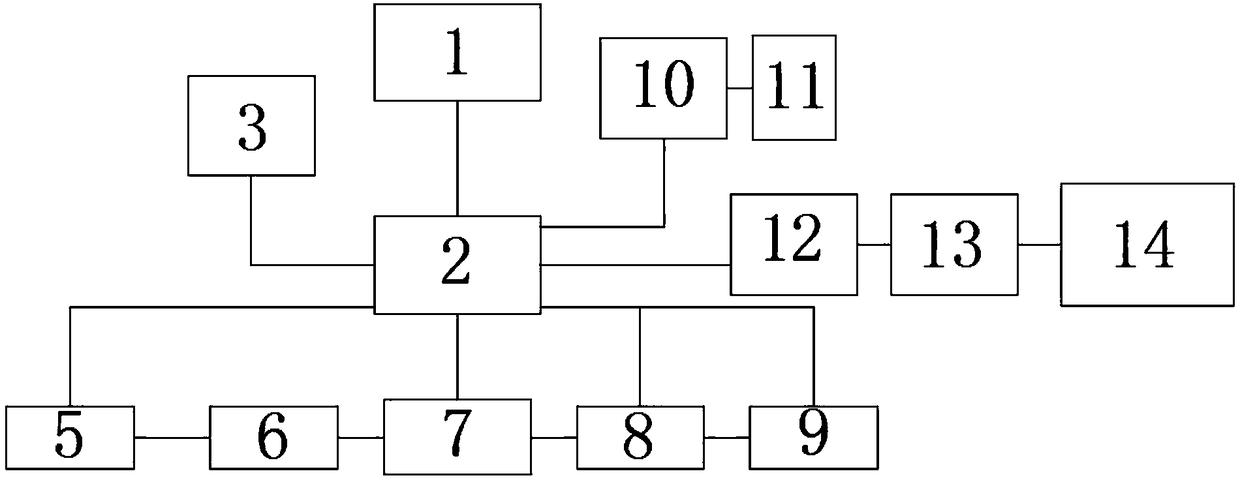

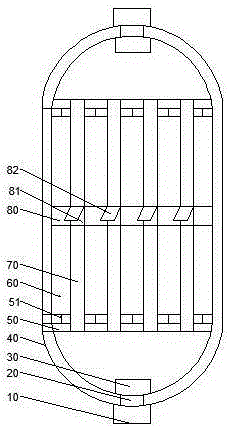

Automatic recovery type air dryer

InactiveCN105214454AAvoid drying effectsDispersed particle separationPulp and paper industryMoisture sensor

The invention discloses an automatic recovery type air dryer. The scheme is as follows: the automatic recovery type air dryer comprises a barrel, wherein an air outlet I and a draught fan I connected with the air outlet I are formed in and arranged at the upper end of the barrel; an air outlet II and a draught fan II connected with the air outlet II are formed in and arranged at the lower end of the barrel; an air inlet is formed in the middle of the barrel; the barrel is internally provided with an upper pipe plate, a middle pipe plate and a lower pipe plate; vertical drying layers are arranged between the upper pipe plate and the middle pipe plate, and between the middle pipe plate and the lower pipe plate; the air inlet is communicated with the drying layers through the middle pipe plate; each drying layer contains a drying agent; the drying layers are uniformly arranged on the barrel in the horizontal direction; heating layers are arranged between the drying layers; humidity sensors are arranged in the air outlet I and the air outlet II; the humidity sensors are connected with a controller; the controller is connected with the draught fan I, the draught fan II and the heating layers. The automatic recovery type air dryer aims at solving the problems in the prior art that the drying agent is recovered after the drying of the air is stopped, and the air cannot be continuously dried.

Owner:CHONGQING UNION MACHINE MFG

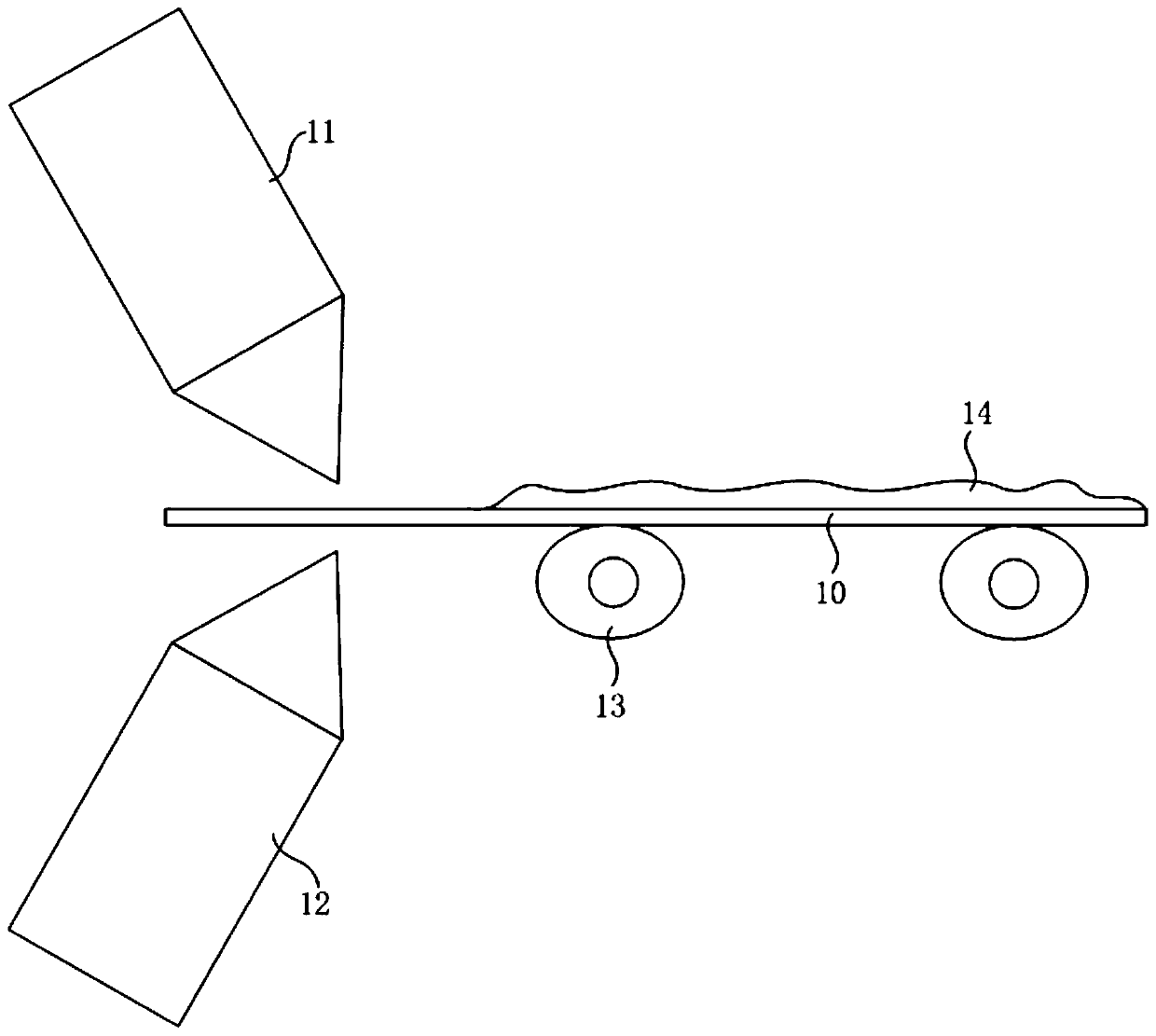

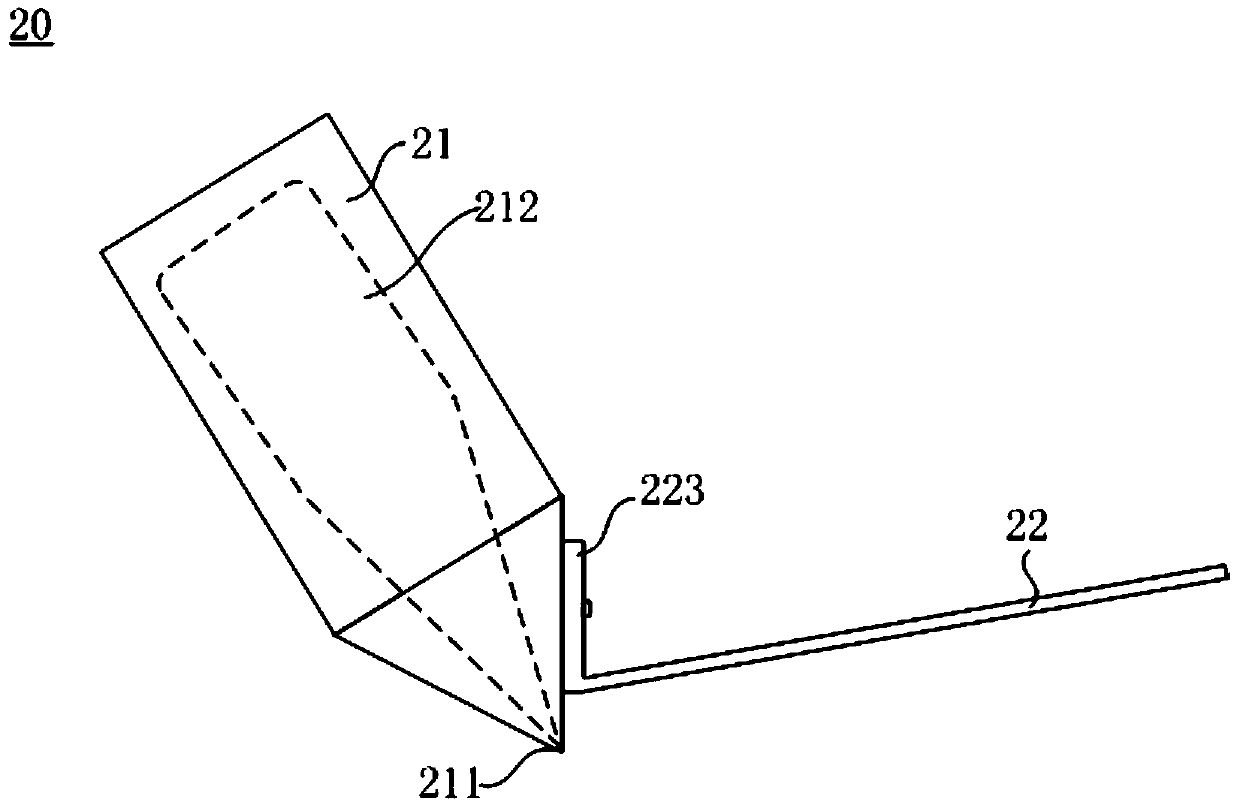

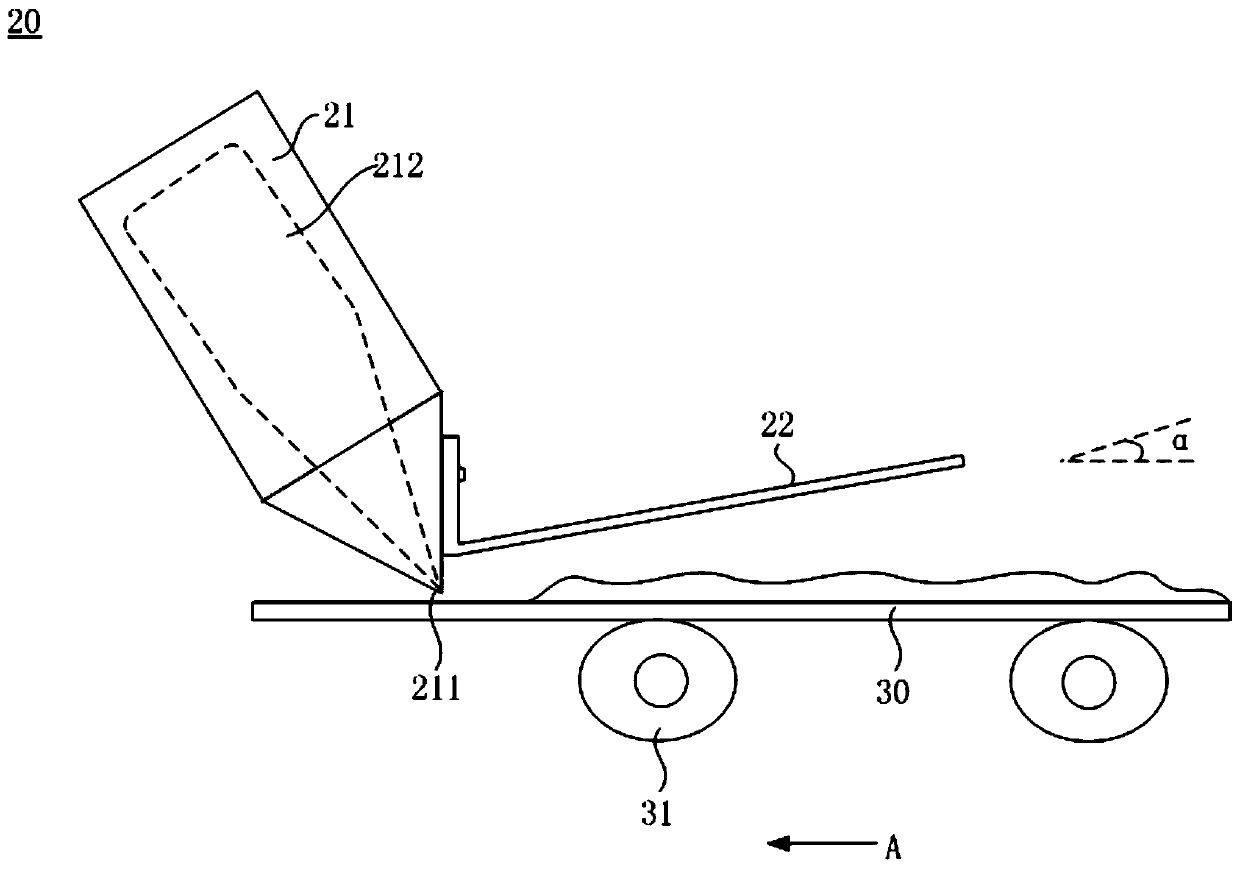

Air knife and drying device using the air knife

ActiveCN109373743BExtended horizontal travelExtend the time of wind actionDrying gas arrangementsAir knifeMechanics

An air knife (20) and a drying apparatus (100) using said air knife (20). A deflector (22) is provided on a side wall of a main air knife (21), the deflector (22) having an obstructing effect on a drying gas, extending a horizontal path of the drying gas, thereby extending the length of time of wind action of the drying gas, improving a drying effect thereof. The deflector (22) is also capable of having an obstructing effect on water droplets spraying up from a surface of a substrate to be dried (30) in response to high pressure, thus avoiding the occurrence of secondary contamination and the impact thereof on the drying effect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

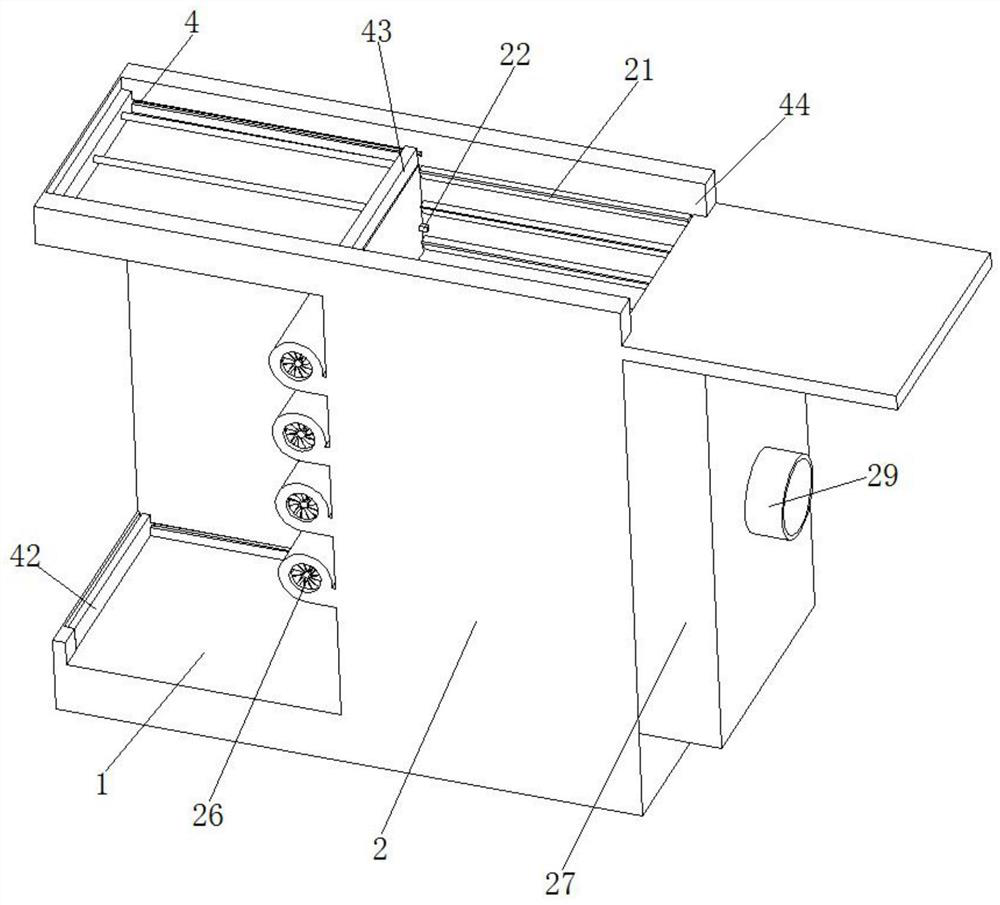

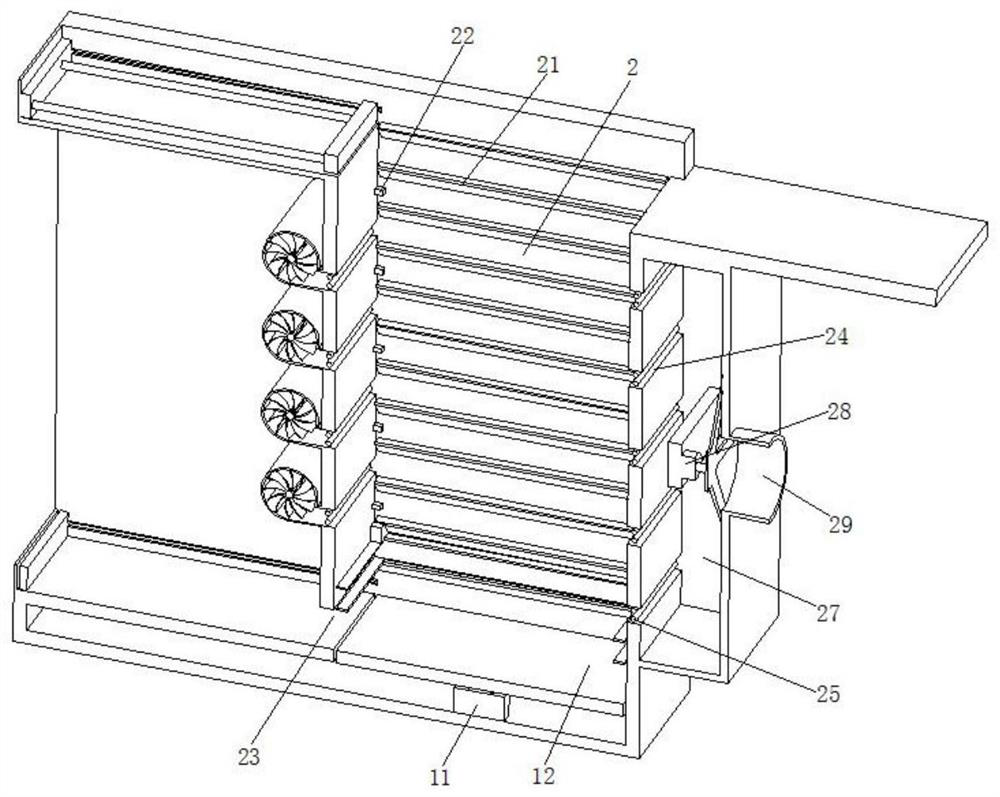

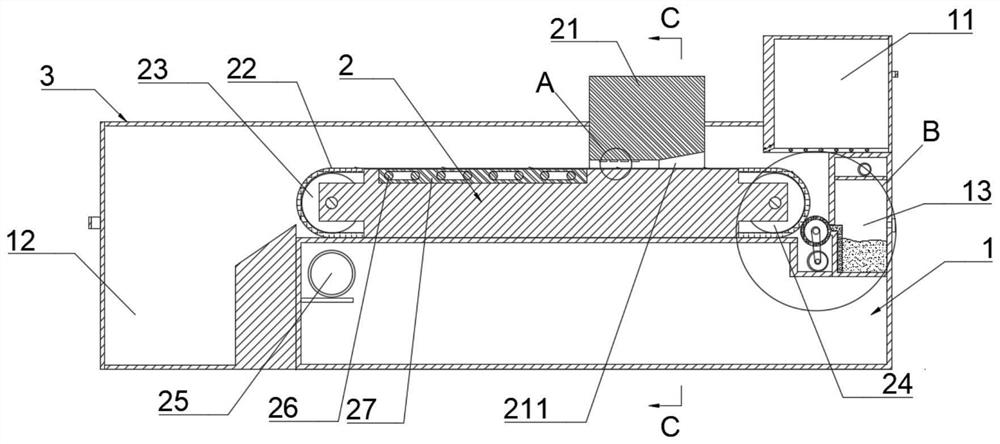

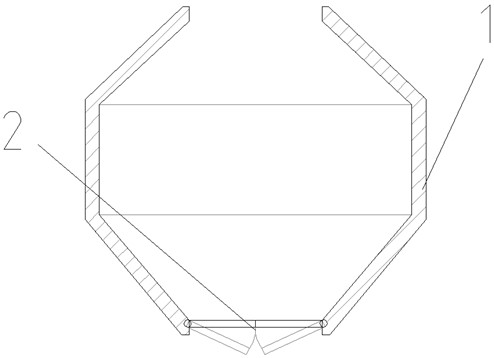

Anti-corrosion and anti-moth shaving board manufacturing process

InactiveCN112873473AImprove drying results and qualityImprove manufacturing efficiencyWood working apparatusDomestic articlesStructural engineeringManufacturing engineering

The invention relates to the field of plate processing, in particular to an anti-corrosion and anti-moth shaving board manufacturing process which uses a shaving board manufacturing device. The shaving board manufacturing device comprises a machine body, a drying groove and a plurality of fixing frames, wherein the fixing frames are respectively arranged corresponding to a discharging hopper of a feeding port. The fixing frames are inserted into the drying groove through the feeding port, each fixing frame is formed by connecting two supporting plates and two connecting frames, the supporting plates are symmetrically arranged, and the two ends of the connecting frames are fixedly installed at the two ends of the supporting plates correspondingly. A shaving board can be dried in all directions, the influence of clamping and bearing areas on the shaving board on drying is avoided, and the shaving board manufacturing device is suitable for popularization.

Owner:朱建林

Intelligent manufacturing printing equipment

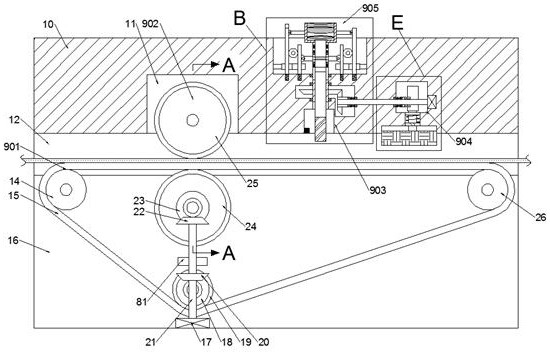

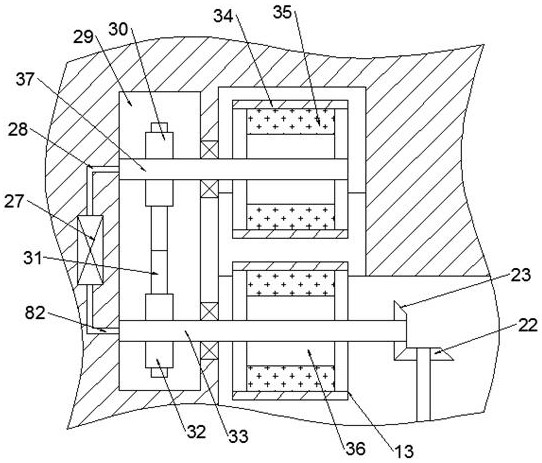

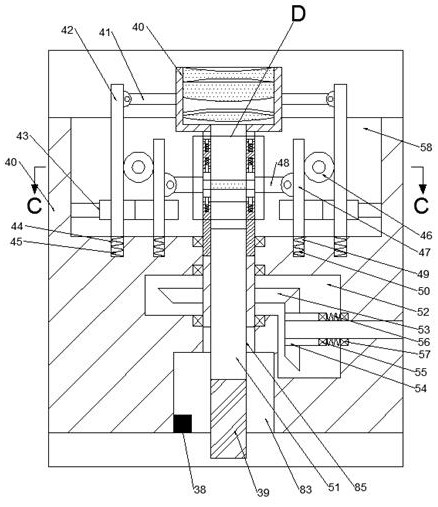

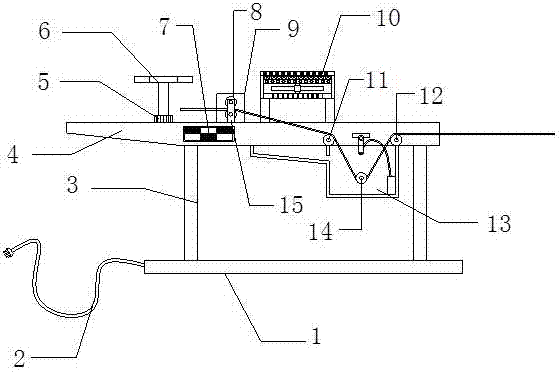

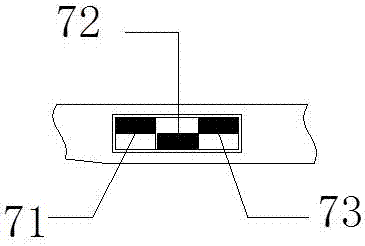

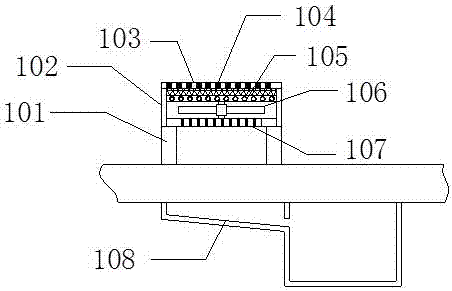

InactiveCN113103748AImprove uniformityAvoid drying effectsRotary pressesPrinting press partsElectric machineryEngineering

The invention discloses intelligent manufacturing printing equipment which comprises an equipment body. A material putting box is arranged at the upper end of the equipment body, a conveying platform is arranged at the lower end of the material putting box, a conveying belt is arranged on the two sides of the conveying platform, a driving roller and a driven roller are arranged at the two ends of the conveying belt, and a first motor is arranged at the lower end of the driving roller. The first motor is in transmission connection with the driving roller through a synchronous belt and a synchronous wheel. A printing machine is arranged at the upper end of the conveying platform, an electric heating wire is arranged in the conveying platform, a material receiving box is arranged at the side end of the equipment body, a cleaning roller is arranged at the front end of the conveying platform, a second motor is arranged at the lower end of the cleaning roller, the cleaning roller is rotationally connected with the equipment body, and a cleaning agent storage box is arranged at the front end of the cleaning roller. According to the intelligent manufacturing printing equipment, the drying effect of residual ink marks on paper is greatly improved, and the cleaning effect of the equipment is greatly improved by arranging the cleaning agent storage box and continuously supplying a cleaning agent to the cleaning roller through a material guide plate.

Owner:张帆

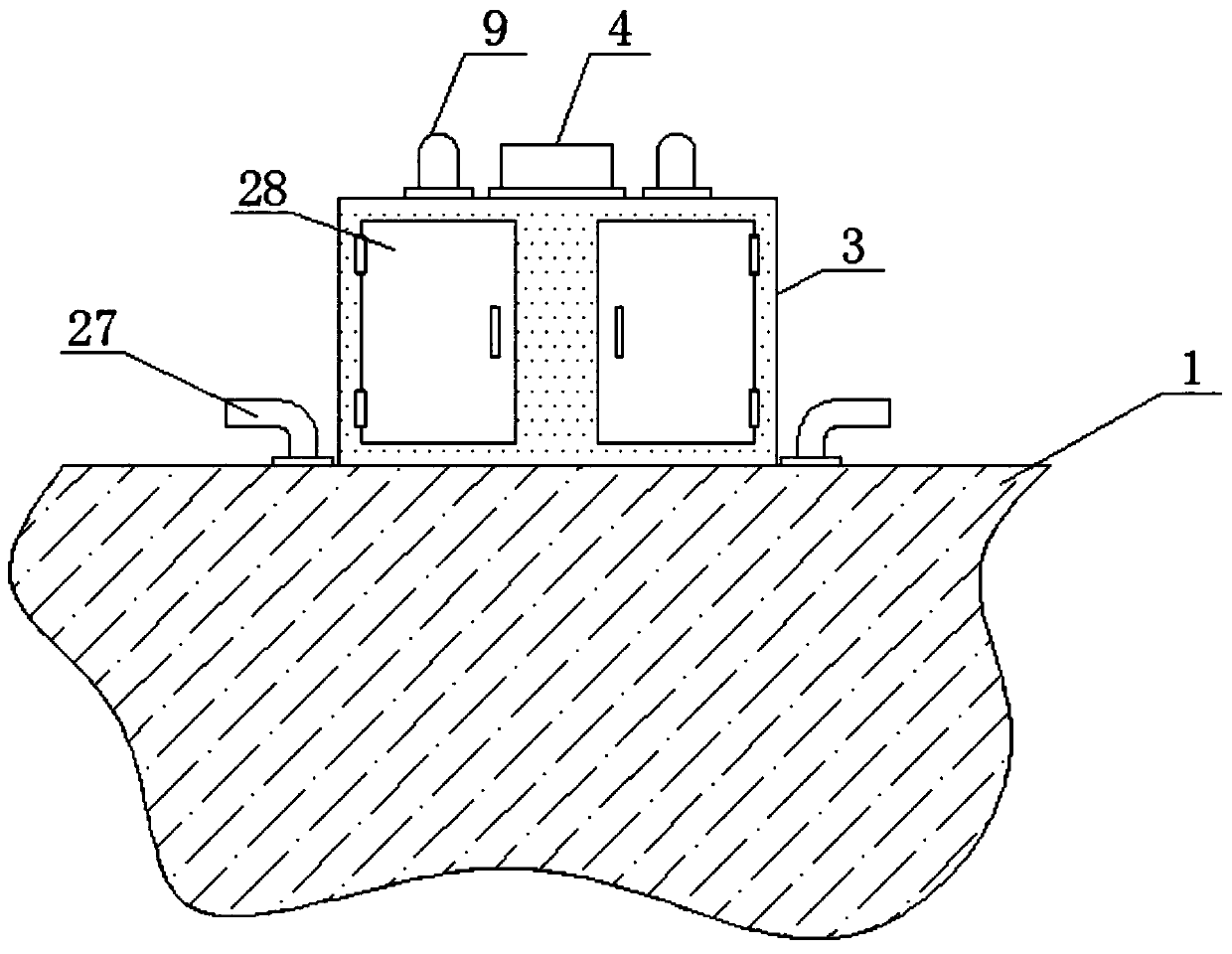

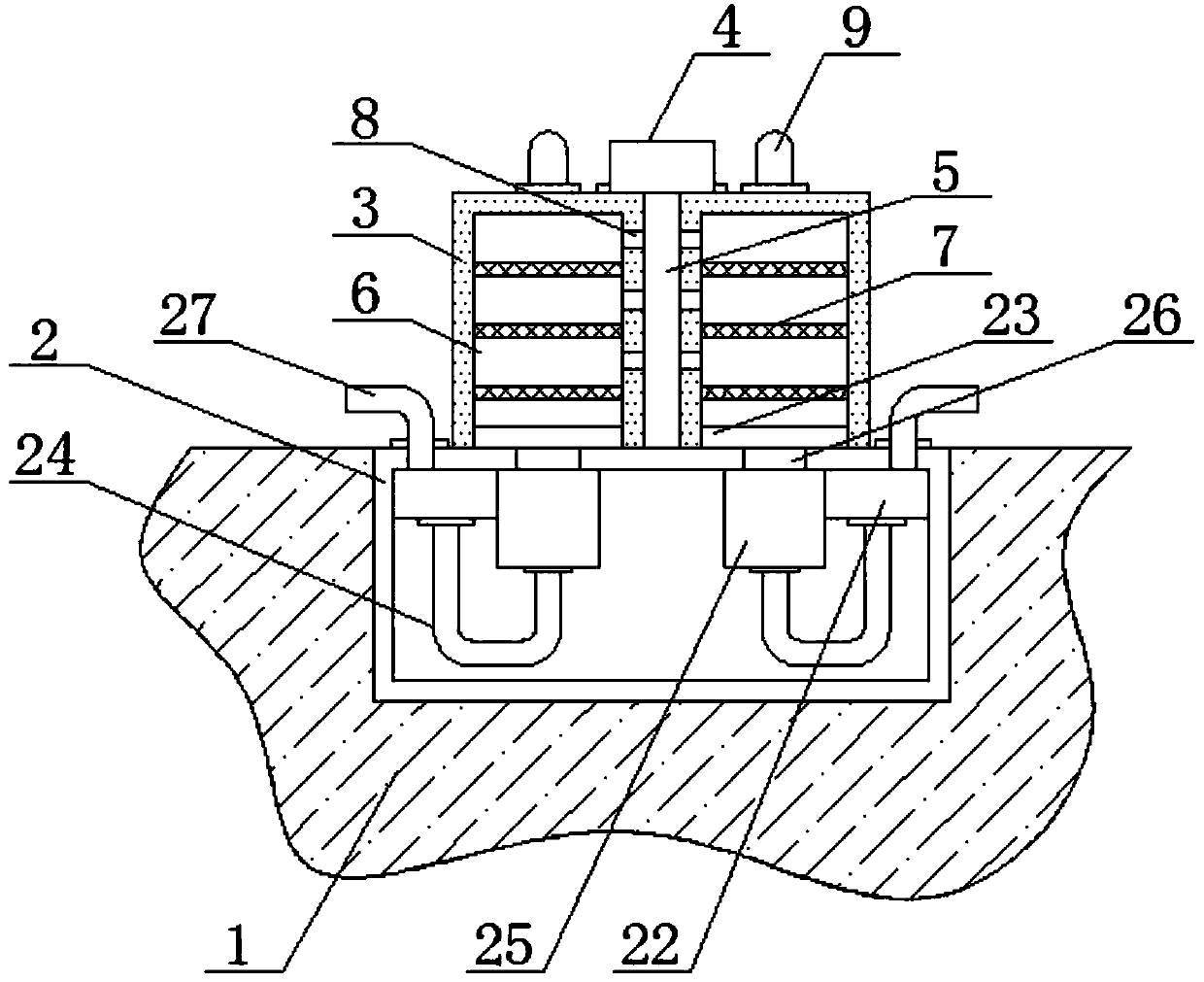

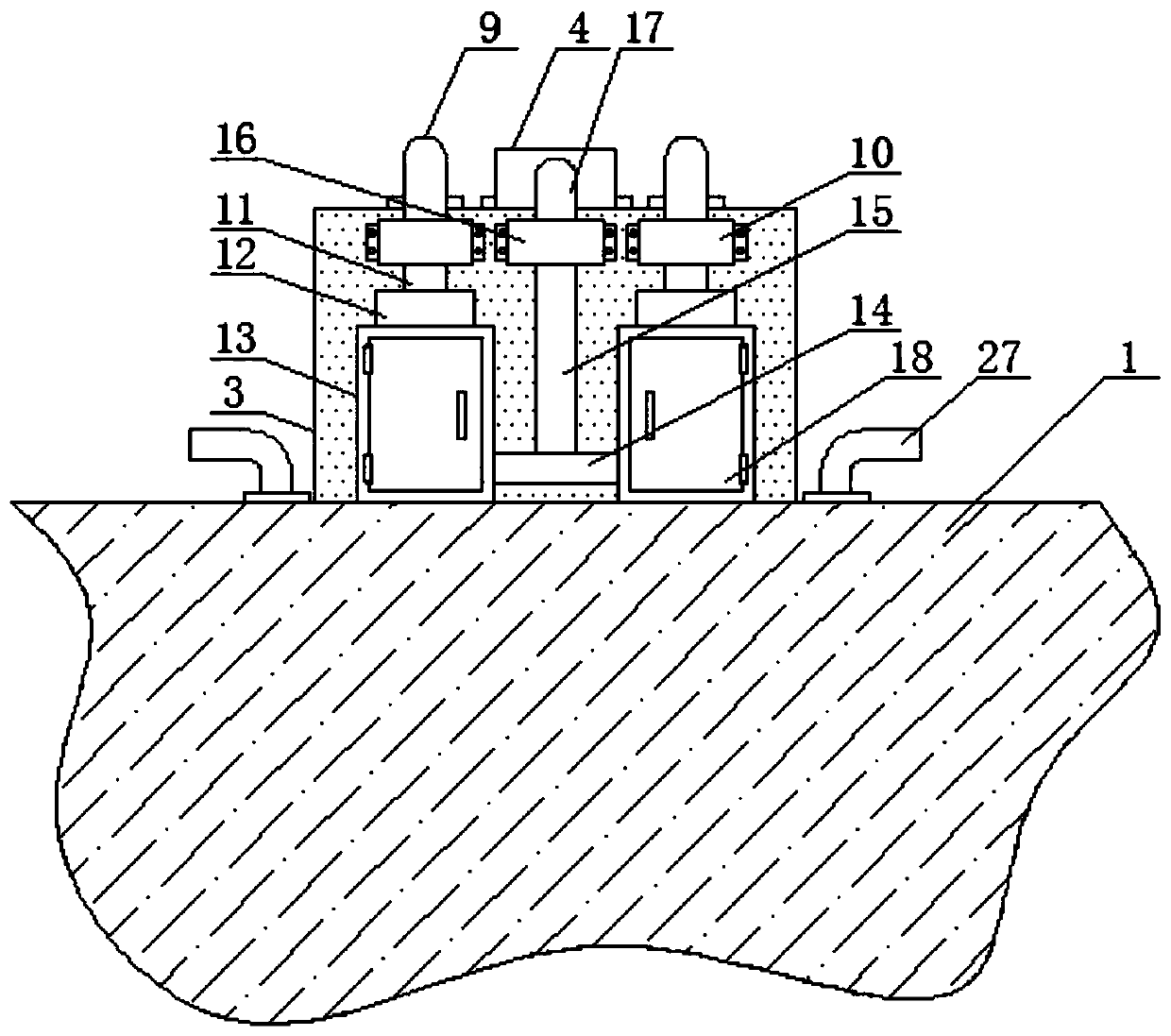

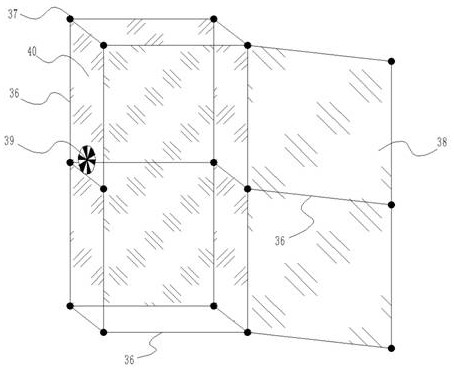

Pit-type magnetic tile drying room structure

InactiveCN110864504AAchieve recyclingAvoid wastingDrying gas arrangementsDrying chambers/containersAir pumpEngineering

The invention relates to the technical field of magnetic tile drying devices, and discloses a pit-type magnetic tile drying room structure. The pit-type magnetic tile drying room structure comprises aground; a drying room is arranged in the top end of the ground; a top box is fixedly mounted at the top of the drying room; a first air pump is fixedly mounted in the middle of the top end of the topbox; and a vertical pipe fixedly communicates with the bottom of the first air pump. The pit-type magnetic tile drying room structure is provided with the first air pump, the vertical pipe, exhaust ports, a transverse pipe and a long pipe, when the first air pump operates, hot air flow in two drying boxes is extracted through the transverse pipe and the long pipe, and is exhausted from the exhaust ports through the vertical pipe, so that the hot air flow is recycled, and the energy waste is avoided; and the exhaust ports are vertically distributed, so that magnetic tiles above first mesh plates are more uniformly heated when being dried, and the practicability of the drying room structure is improved.

Owner:湖南瑞磁新材料有限公司

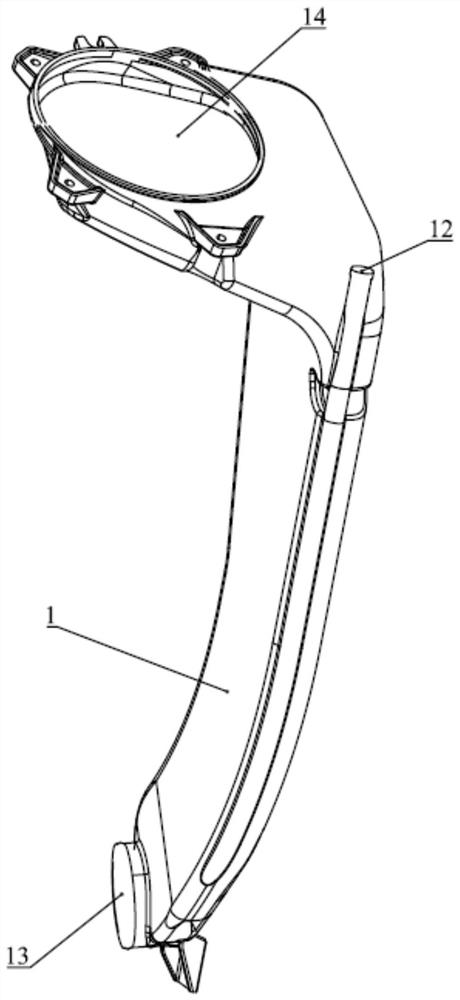

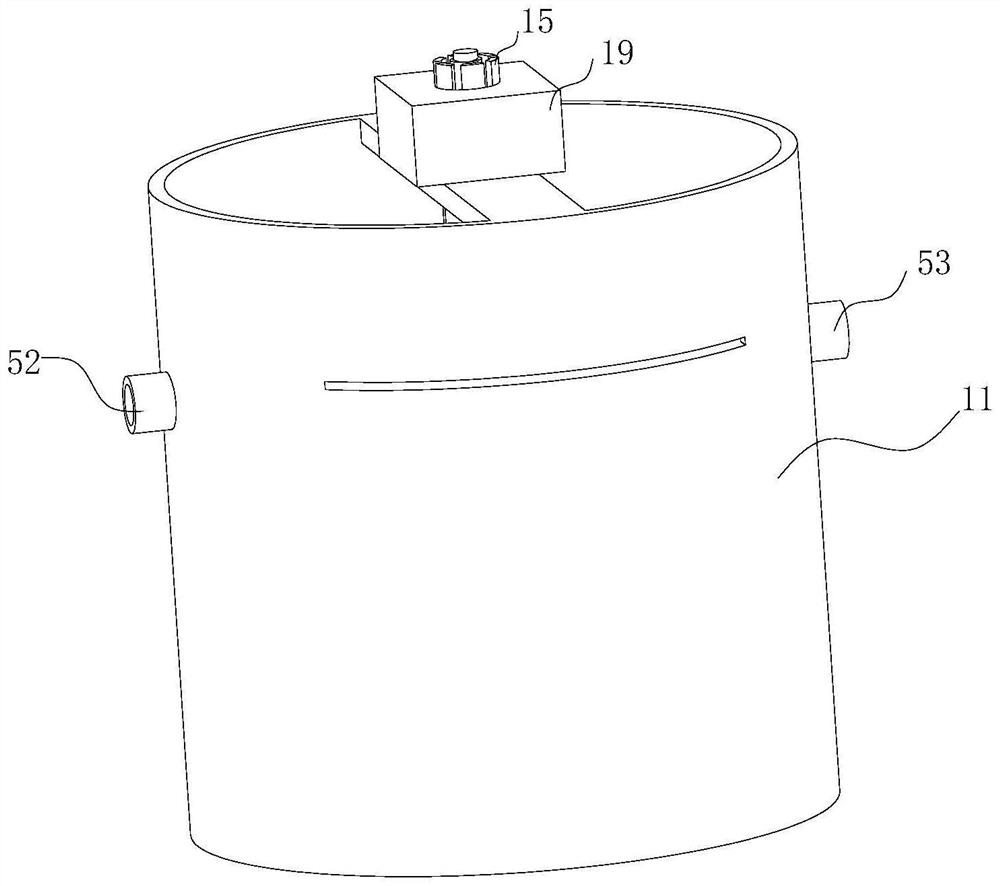

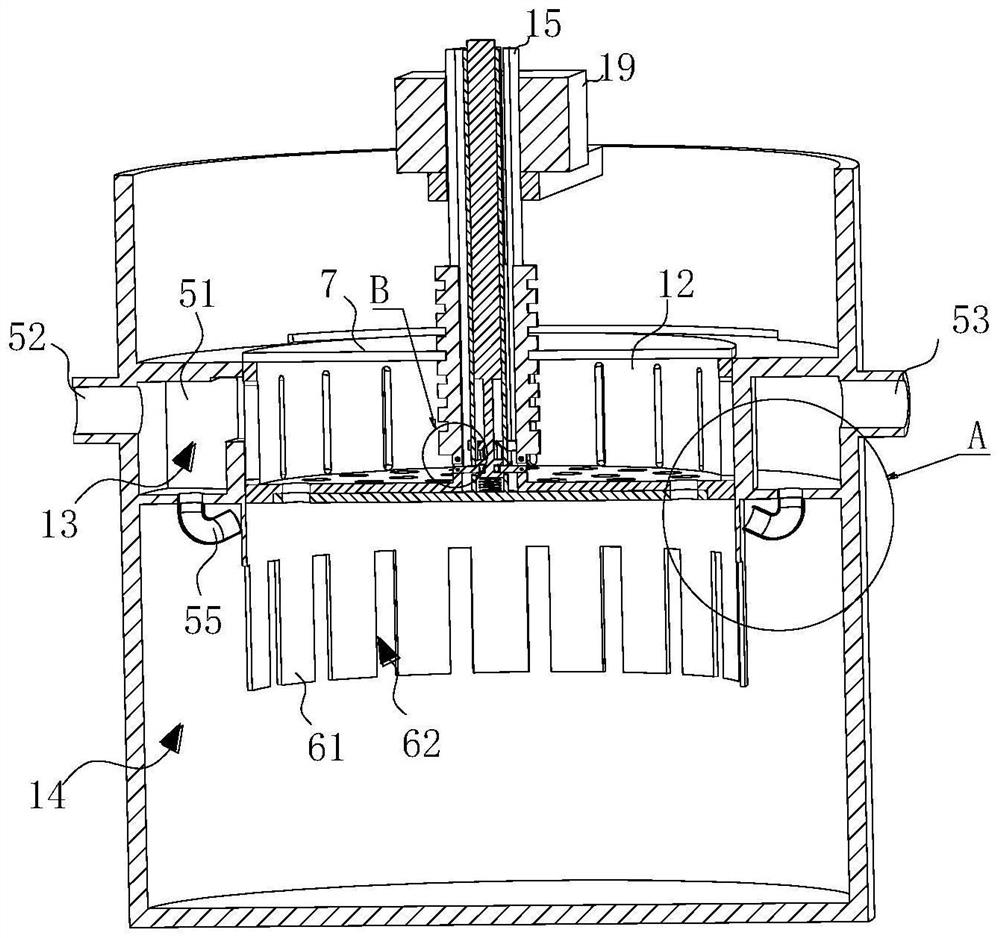

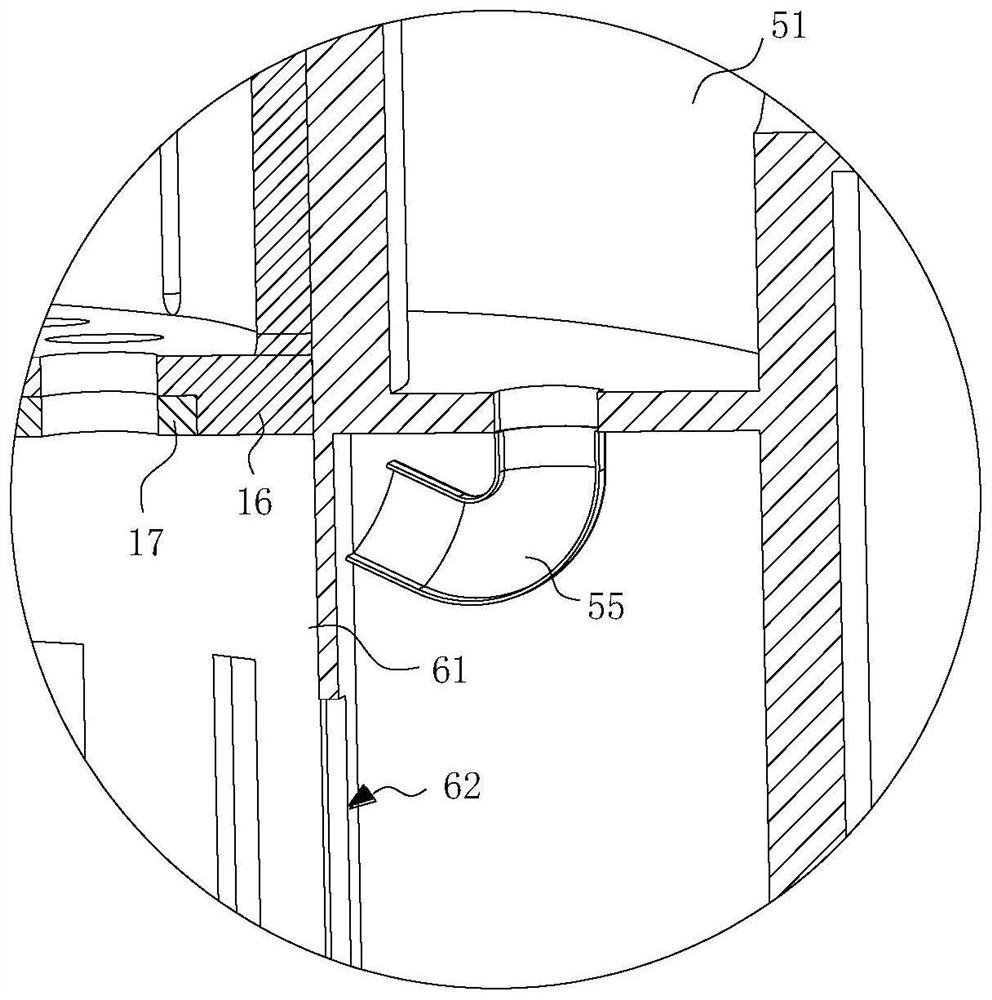

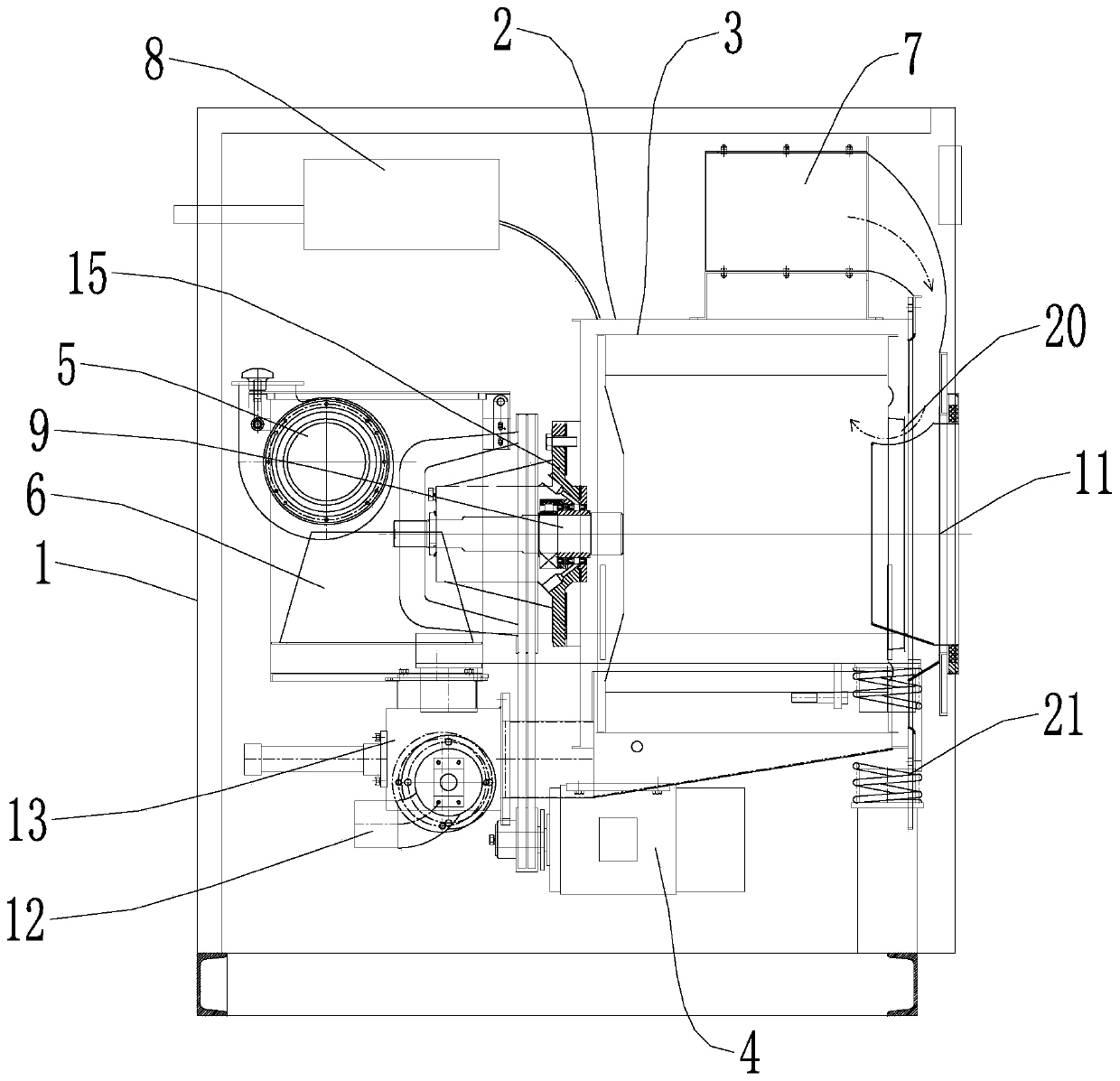

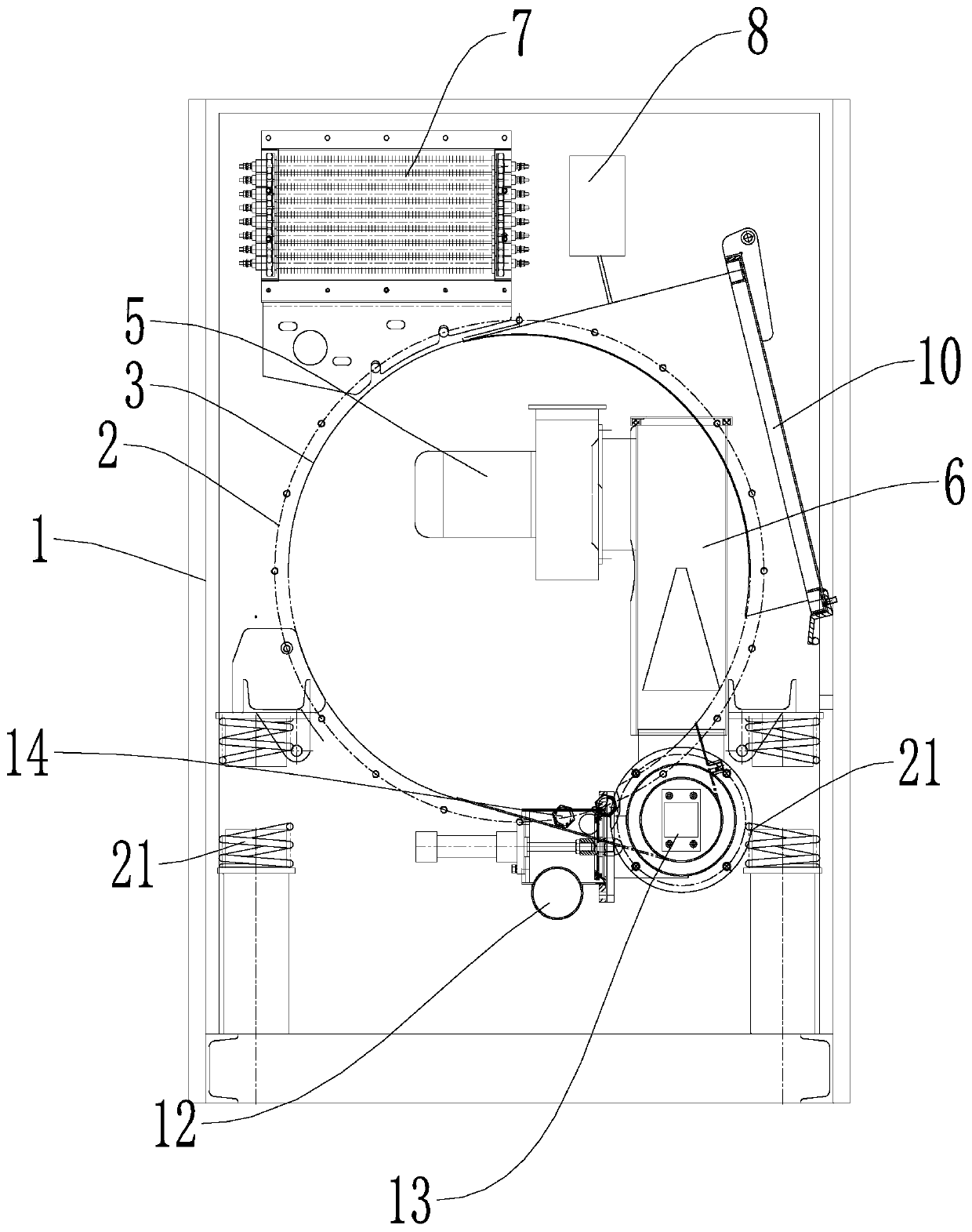

A water-cooled condenser and an integrated washing and drying machine

ActiveCN109518440BGuaranteed circulating air volumeAvoid drying effectsWashing machine with receptaclesTextiles and paperAir volumeRinse water

The invention discloses a water-cooled condenser and an integrated washing and drying machine. The water-cooled condenser includes a condenser body and a boss. The interior of the condenser body is hollow to form a chamber. The upper end of the condenser body is provided with a water inlet, which communicates with the chamber; the boss is arranged on the inner wall of the chamber, and the boss is arranged There are boss holes; when flushing water is passed into the water inlet, due to the large flow of flushing water, the collision between the flushing water and the boss will be broken up into water splashes, which will be raised and splashed around to flush the condenser body. The inner wall has a large flushing area, washing away impurities such as lint attached to the inner wall of the condenser body, ensuring the circulating air volume inside the condenser body, reducing wind resistance, and improving the drying effect; when the water inlet is passed into condensed water, Due to the small flow of condensed water, the condensed water will flow out through the hole of the boss, so as to avoid changing the flow path of condensed water and affecting the condensation effect after the condensed water is raised along the boss.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

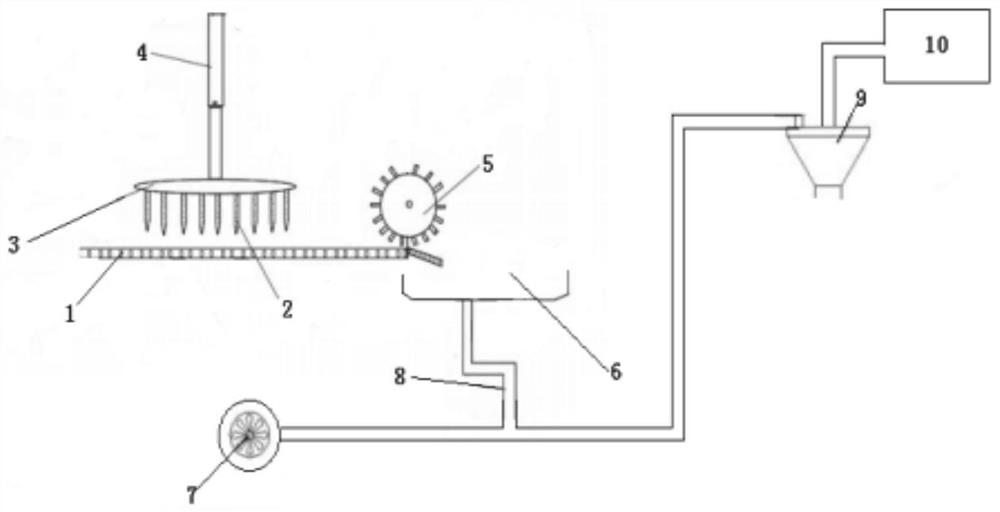

Automatic equipment used for fabric sunlight drying and printing

InactiveCN111750649AImprove drying efficiencyAvoid drying effectsDrying solid materials with heatDrying machines with progressive movementsEngineeringTextile printer

The invention discloses automatic equipment used for fabric sunlight drying and printing. The automatic equipment used for fabric sunlight drying and printing comprises a machine body; a transportingcavity is formed in the machine body; a belt wheel cavity I is formed in the lower side of the transporting cavity; and a transporting device used for transporting is arranged in the belt wheel cavityI. According to the automatic equipment used for fabric sunlight drying and printing, by arranging a roller drying device, a fabric can be dried through cooperation between a rolling housing and a heating block which are arranged on the external side of a roller; and then by using a connecting block, the steam on the rear side of drying is enabled to enter into a steam box through the rolling housing to be collected so as to prevent the steam from affecting drying; and therefore, the drying efficiency is enhanced. According to the automatic equipment used for fabric sunlight drying and printing, by arranging a solar drying device, sunlight can be enabled to always vertically enter into a solar drier through a solar lens box and lens adjusting and can be scattered to the fabric on the upper side of a transporting belt through the solar drier to perform solar drying on the fabric.

Owner:ZHUJI PANDA TEXTILE TECH CO LTD

A sludge drying and feeding device and feeding method

ActiveCN112094027BIncrease moisture contentHigh viscositySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

Owner:山东达源环保工程有限公司

Municipal solid waste drying device

InactiveCN112880379AImprove drying effectReduce water vaporDrying gas arrangementsDrying solid materialsHot blastEnvironmental geology

The invention relates to a municipal solid waste drying device which is composed of a feeding port, a throttling baffle, a heating cavity, a drying chamber outer wall, a drying chamber inner wall, a water vapor discharging port, an arc-shaped flow guide plate, a filter and a liquid collecting box. Municipal solid waste enters the heating cavity through the feeding port, is subjected to primary hot air drying in the heating cavity, enters the drying chamber inner wall under the pushing action of a screw feeder, and is subjected to secondary drying with hot air on the outer side of the drying chamber inner wall. The dried municipal solid waste falls into a material collecting barrel. The water vapor discharging port is formed in the upper portion of the drying chamber inner wall, water vapor after drying is condensed and then falls into the filter through the arc-shaped guide plate, and filtered municipal solid waste water finally flows into the liquid collecting box. The municipal solid waste drying device can improve the drying effect, reduce water vapor discharged into the air effectively, recycle water in the municipal solid waste, and avoid the situation that the water vapor is directly discharged into the air to affect the drying effect. The municipal solid waste drying device has certain prospects in the future industry.

Owner:HARBIN UNIV OF SCI & TECH

Cleaning device for garment production

ActiveCN107503054ASolve incomplete cleaningSolve the problem of not being able to dryTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsPulp and paper industryAir blower

The invention provides a cleaning device for garment production. The cleaning device for the garment production comprises electric heating tubes, a fan, air outlets, a water tank, a water pump and a combined spraying head; the electric heating tubes are mounted in an air blower main body; the fan is mounted in the lower end of the air blower main body; the air outlets are mounted at the lower end of the air blower main body; the water tank is mounted on the lower end surface of an operating platform; the water pump is mounted in the water tank; the upper end of the combined spraying head is mounted at the lower end of a connecting rod. According to the cleaning device for the garment production, washed fabric can be quickly dried in time, garment production is prevented from being influenced by wet fabric, and the production efficiency is improved; the fabric used for the garment production is washed with water through the water tank, and then is sprayed, so that the cleanness of the fabric is ensured, and the decontamination capacity is improved.

Owner:JIANGSU SUNSHINE

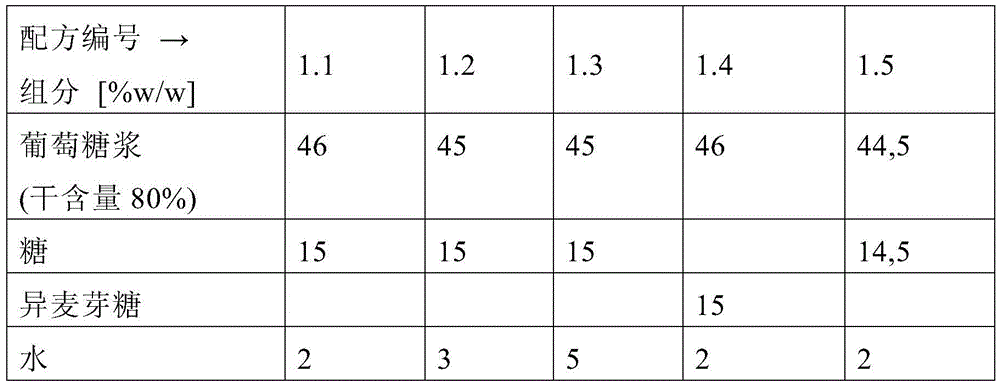

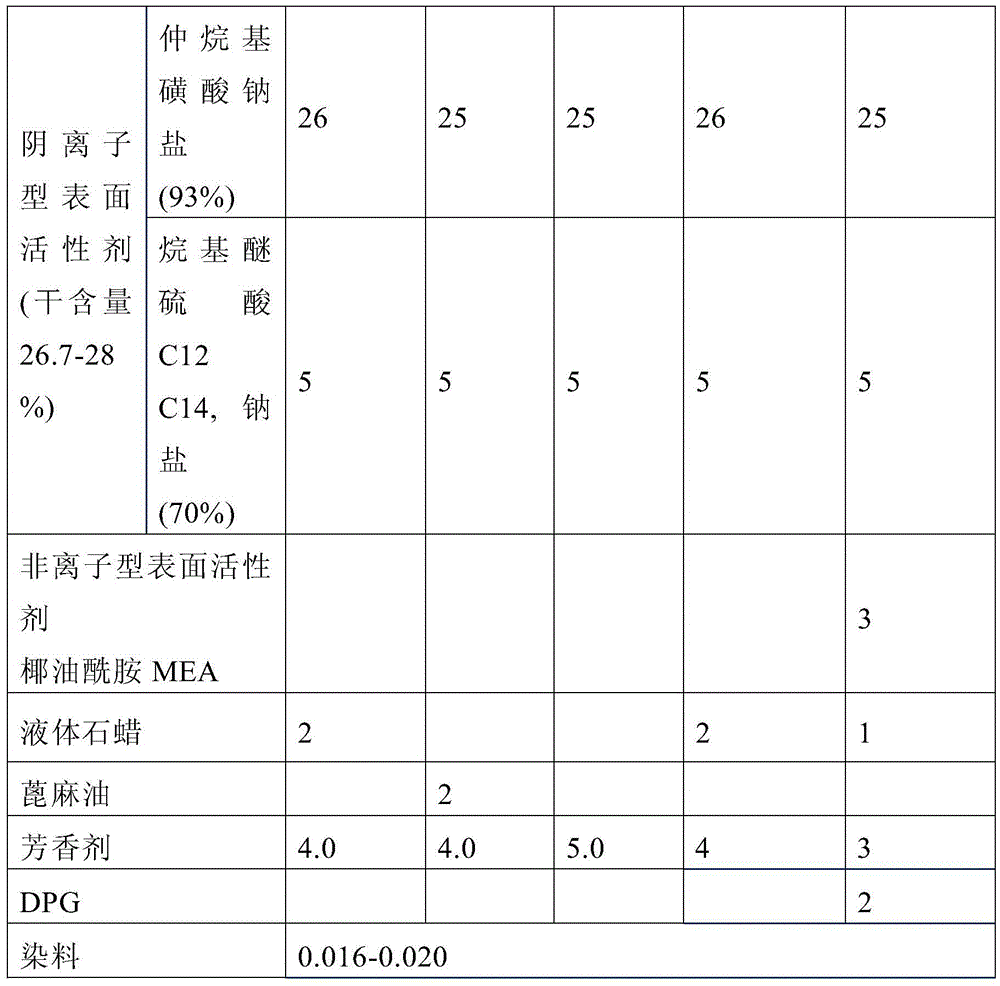

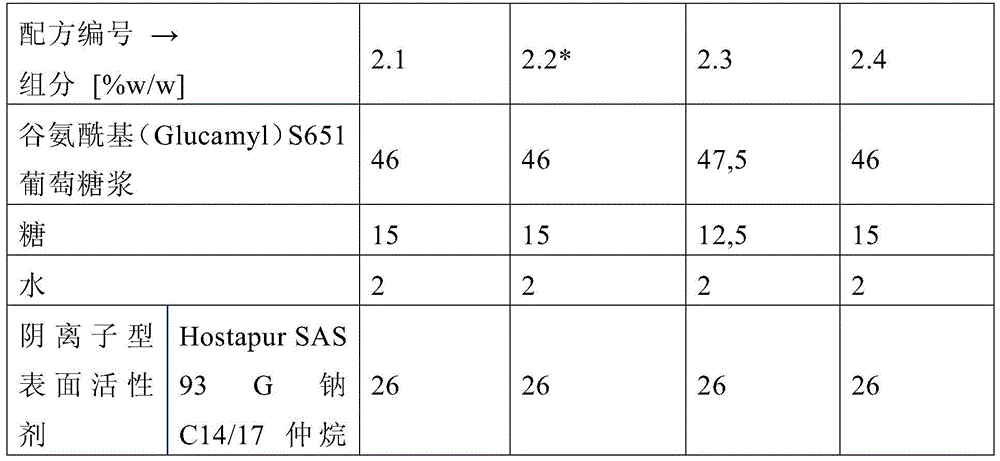

New sanitary composition

InactiveCN105555939AAvoid joiningAvoid drying effectsBiocideSurface-active detergent compositionsSURFACTANT BLENDDisaccharide

The invention is directed to a self-adhesive sanitary composition for cleaning and / or disinfecting and / or deodorizing comprising an adhesion promoter comprising a mono, di, or oligosaccharide, preferably a monosaccharide or disaccharide and a surfactant, both in a high amount.

Owner:尤洛维斯特公司

Energy-saving water pipe drying device

InactiveCN108077969AGuaranteed Humidity RequirementsAvoid drying effectsFood processingFood treatmentSolar waterAir pump

The invention discloses an energy-saving water pipe drying device. The device comprises a heating device and a drying main body; the heating device comprises a solar water heater, a hot water tank, acold water tank, a water pump, an air pump and a heat exchanger; and the drying main body is provided with a ventilation opening, a humidity sensor, a ventilation fan, a fruit holder, spray heads, a hot gas baffle, a division plate, a thermal resistor, a temperature sensor, an air inlet, a pipeline, a sealing plate and a controller. The device of the invention adopts a solar heating mode to dry fruits, is energy-saving and environmentally friendly, and simultaneously designs circulating use of dry air and hot water so as to further save energy. According to the invention, the humidity sensor exactly ensures the humidity requirement of a drying environment in real time, and avoids manual judgment mistake which affects drying. Meanwhile, the temperature sensor and the thermal resistor are arranged to further ensure drying temperature.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

A cleaning device for garment production

ActiveCN107503054BSolve incomplete cleaningSolve the problem of not being able to dryTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsPulp and paper industryAir blower

The invention provides a cleaning device for garment production. The cleaning device for the garment production comprises electric heating tubes, a fan, air outlets, a water tank, a water pump and a combined spraying head; the electric heating tubes are mounted in an air blower main body; the fan is mounted in the lower end of the air blower main body; the air outlets are mounted at the lower end of the air blower main body; the water tank is mounted on the lower end surface of an operating platform; the water pump is mounted in the water tank; the upper end of the combined spraying head is mounted at the lower end of a connecting rod. According to the cleaning device for the garment production, washed fabric can be quickly dried in time, garment production is prevented from being influenced by wet fabric, and the production efficiency is improved; the fabric used for the garment production is washed with water through the water tank, and then is sprayed, so that the cleanness of the fabric is ensured, and the decontamination capacity is improved.

Owner:JIANGSU SUNSHINE

Production device and method for preparing urea oxidation catalyst by taking egg shell membrane as raw material

ActiveCN114471740AAvoid drying effectsAvoid breakingDrying solid materials without heatDrying gas arrangementsBiotechnologyPtru catalyst

The production device comprises a working barrel and a working box, the working barrel comprises a drying area with the upper end externally connected with an air source and a dissolving area with hydrochloric acid at the lower end, and a driving rod connected with an external power source is arranged on the working box; and the driving rod drives the working box to vertically move and rotate. The bottom surface of the working box comprises an upper filter plate and a lower filter plate which are mutually stacked, and the lower filter plate is rotationally connected with the upper filter plate. The egg shell membrane can be immediately transferred into the drying area after the egg shell is immersed in hydrochloric acid to be dissolved into the membrane, and the egg shell membrane is dried after the residual hydrochloric acid is recovered through centrifugal spin-drying. The drying area and the dissolving area can be automatically isolated during drying, and the situation that volatilization of hydrochloric acid in the dissolving area is accelerated by drying gas, and the drying effect of egg shell membranes is affected is avoided.

Owner:LULIANG UNIV

Isolation type washing and drying integrated machine

PendingCN110328187AReliable disinfection effectShorten heating timeDrying gas arrangementsOther washing machinesAir filtrationExhaust valve

The invention discloses an isolation type washing and drying integrated machine. An outer cylinder, a driving motor, a drying fan, an air filtering device, an air heater and an instant heater of the isolation type washing and drying integrated machine are all installed in a frame; an inner cylinder is rotatably arranged in the outer cylinder through a rotating shaft; the upper part of the outer cylinder is provided with a water inlet and an air inlet, and the bottom of the outer cylinder is provided with a water outlet and an air outlet; a water inlet pipe is sequentially connected with the instant heater and the water inlet of the outer cylinder; an air outlet of the air heater is connected with the air inlet of the outer cylinder; an exhaust valve is sequentially connected with the air filtering device and the drying fan through a pipeline; and the bottom of the outer cylinder is provided with a water heater for heating water in the outer cylinder. The isolation type washing and drying integrated machine has the beneficial effects that the moist heat disinfection can be realized, the A0 value is monitored in real time, and it is ensured that the disinfection effect is more reliable than manual disinfection effect; the heating time is shortened, the temperature difference and the abrasion are reduced, and the efficiency is improved; the rotating shaft is provided with a watercooling structure, so that a sealing structure is prevented from being influenced by high temperature and drying; and air enters a drying air duct from a front door opening of the inner cylinder, so that the heat efficiency is high.

Owner:SHANDONG DACHENG WASHING MACHINERY CO LTD

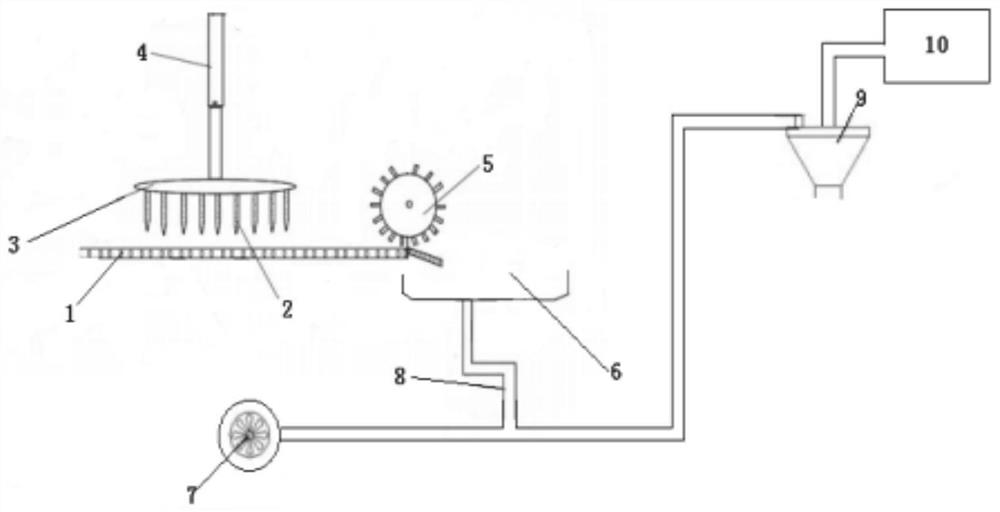

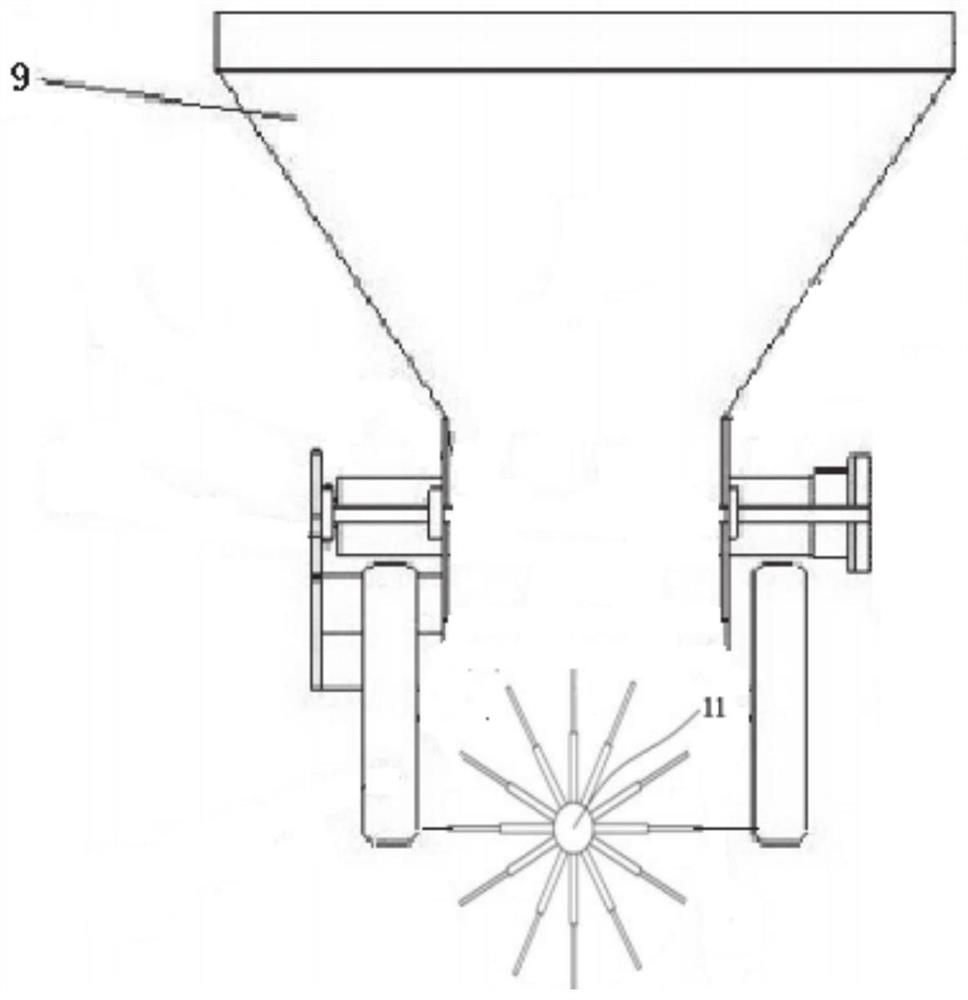

Sludge drying and feeding device and feeding method

ActiveCN112094027AIncrease moisture contentHigh viscositySludge treatment by de-watering/drying/thickeningSludge cakeProcess engineering

The invention relates to the field of sludge treatment, and particularly provides a sludge drying and feeding device and a feeding method. The sludge drying and feeding device comprises a dewatered sludge cake conveying belt and a discharging hopper located at the tail end of the dewatered sludge cake conveying belt, an outlet of the discharging hopper is connected with a dilute phase conveying pipe at a certain angle, a fan is arranged at an inlet of the dilute phase conveying pipe, a gas-material separation device is arranged at an outlet of the dilute phase conveying pipe, and a gas outletof the gas-material separation device is connected with a gas suction device. And a windmill is arranged at a sludge outlet of the gas-material separation device. The problems that dehydrated mud cakes are high in water content, the conveying pipe is easily blocked, and the dehydrated mud cakes are difficult to uniformly distribute in a sludge drying device are solved.

Owner:山东达源环保工程有限公司

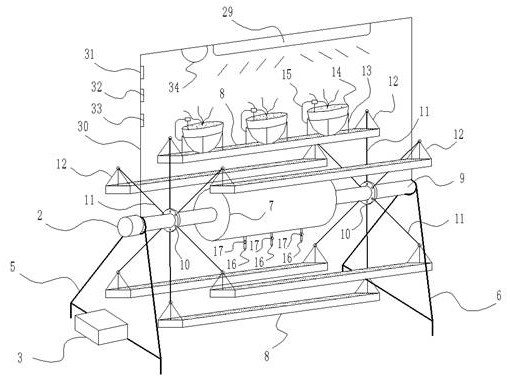

An intelligent monitoring winter household potted plant maintenance device and control method

ActiveCN107211850BPrevent overflowAvoid pollutionSelf-acting watering devicesClimate change adaptationAgricultural scienceIlluminance

The invention discloses an intelligent monitoring type winter domestic pot culture device and a control method. The device comprises a rotary flower stand, an actuator, a master controller, a light supplementing device, a water supply tank, supporting plates and a greenhouse. The water supply tank is connected at the horizontal axis center position of the rotary flower stand through a rotating shaft. Nitrogen, phosphorus and potassium fertilizer liquid boxes and spraying pipes are arranged above and below the water supply tank respectively. The actuator is connected to the right end of the rotating shaft, the master controller is connected below the actuator, the supporting plates are connected to left and right ends of the rotating shaft respectively, and soil humidity monitoring probes are arranged on the supporting plates. The light supplementing device is arranged above the rotary flower stand and connected with the master controller, a light supplementing lamp, a 360-degree camera and illuminance, air humidity and environment temperature sensors are arranged on the light supplementing device, and the greenhouse is positioned around the rotary flower stand. The intelligent monitoring type winter domestic pot culture device and the control method have advantages of high practicality, convenience in operation and the like.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Multifunctional coating for casting and preparation method thereof

The invention provides a multifunctional coating for casting and a preparation method thereof and particularly relates to the technical field of casting coatings. The method comprises the steps that firstly, a polystyrene fused solution is adopted for firing a compound, quartz sand powder and bentonite wrap the compound in batch in sequence, a wrapping compound is prepared, then powder of plasterof paris, sweet wormwood herb wax, trehalose and zinc oxide crystal whiskers are added to the wrapping compound, and the multifunctional coating for casting is prepared. The coating can be simultaneously used for two processes of lost foam casting and V-method casting, after coating is completed, cracks, bubbles and wrinkles do not exist, and the multifunctional coating for casting has the advantages of being resistant to wear, high in drying speed, adhesive force and air permeability and the like. The sand burning, shrinkage porosity and pore defects of a casting can also effectively prevented. The other aim of the invention is to provide the preparation method of the multifunctional coating for casting. The method is easy to operate, stable in process and suitable for large-scale production, and parameters can be controlled.

Owner:柳州市一乐科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com