Air knife and drying device using the air knife

An air-knife and drying-based technology, applied in the field of drying devices and air-knives, can solve the problems of affecting the drying effect, water droplets gathering and dripping on the air-knife device, secondary pollution, etc., so as to prolong the action time of wind and avoid secondary pollution. , the effect of extending the horizontal stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

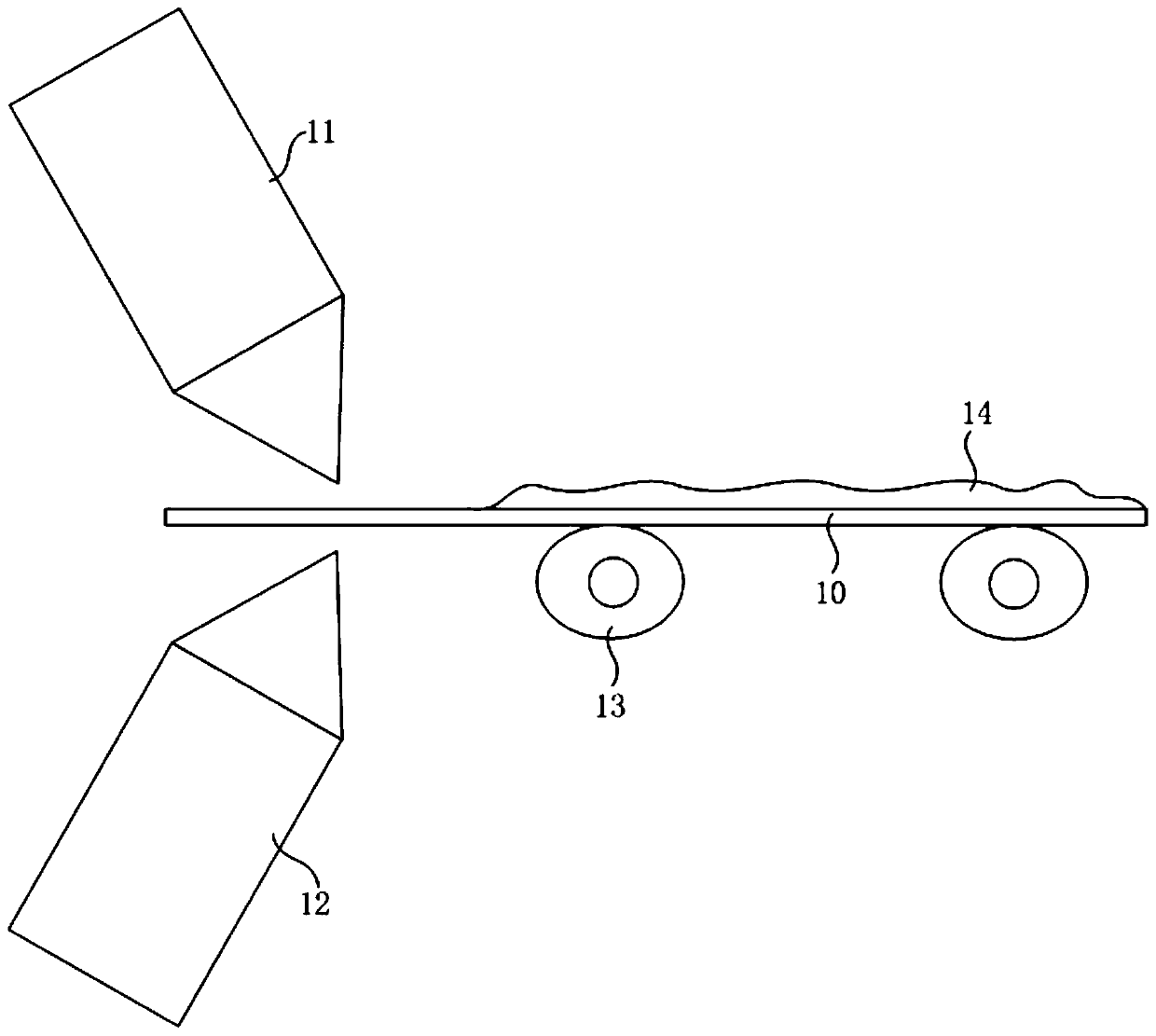

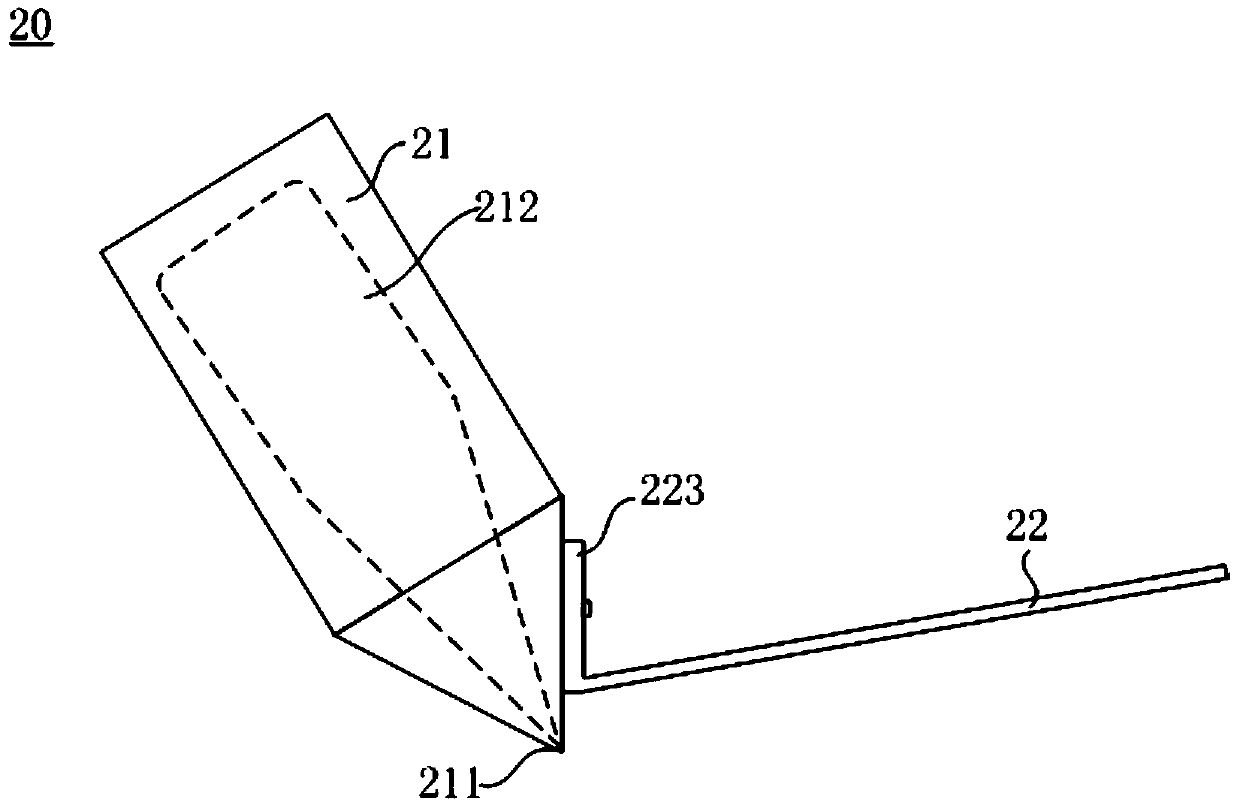

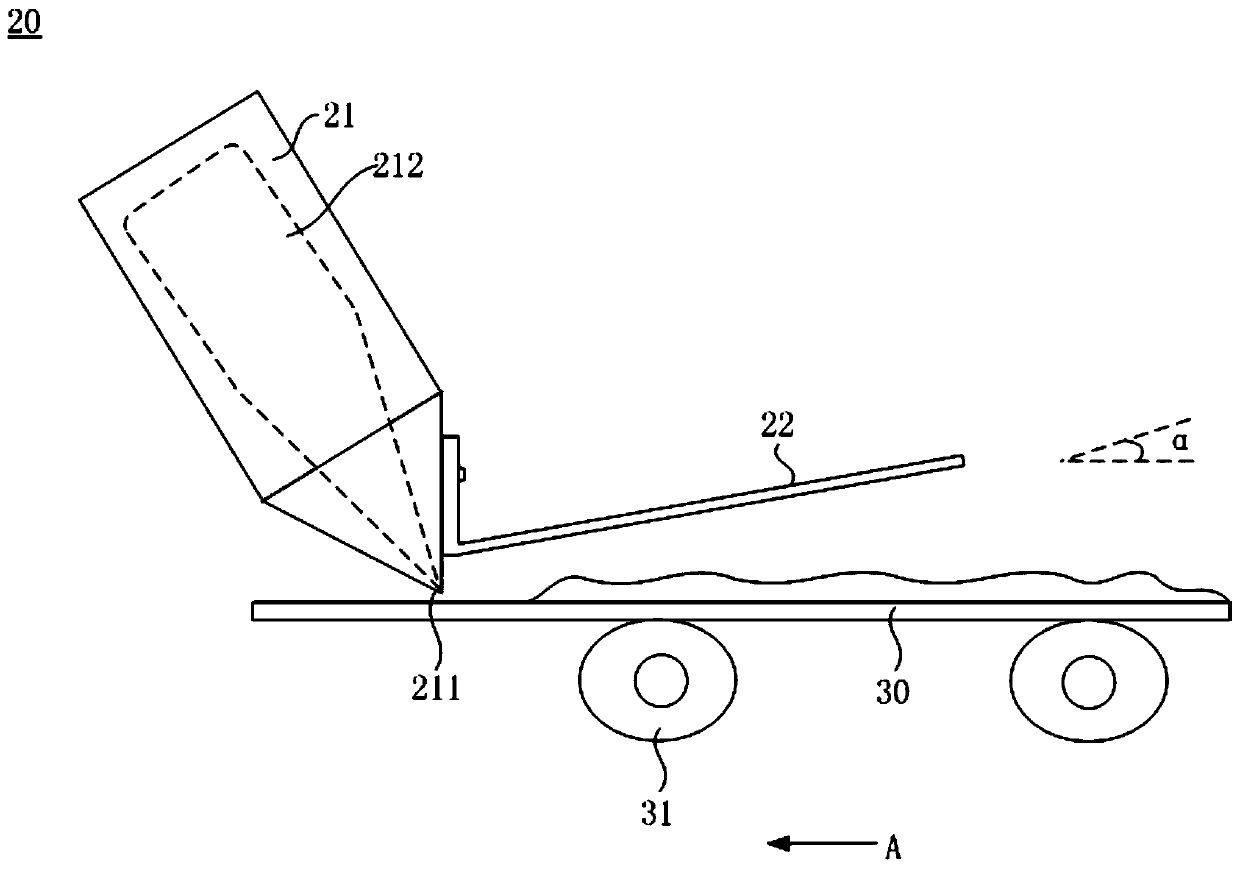

[0030] The specific implementation of the air knife provided by the present invention and the drying device using the air knife will be described in detail below in conjunction with the accompanying drawings.

[0031] figure 2 It is a side view structural schematic diagram of an embodiment of the air knife of the present invention, image 3 It is a schematic side view of the working state of the air knife of the present invention, Figure 4 It is a top view structure schematic diagram of the working state of the air knife of the present invention. see figure 2 , image 3 and Figure 4 , The air knife 20 of the present invention includes a main air knife 21 and a deflector 22 .

[0032] The main air knife 21 is used to deliver a drying gas to a substrate 30 to be dried. Specifically, the main air knife 21 has an air outlet 211 , the air outlet 211 faces the substrate 30 to be dried, and the drying gas is blown toward the substrate 30 to be dried from the outlet 211 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com