Automatic cleaning method and device for aluminium alloy composite boards

An automatic cleaning and composite board technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficulty in ensuring the stability of cleaning quality, large occupation of sewage treatment equipment, and failure to meet environmental protection requirements, etc. problems, to achieve the effects of efficiency improvement, high social and economic benefits, and large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

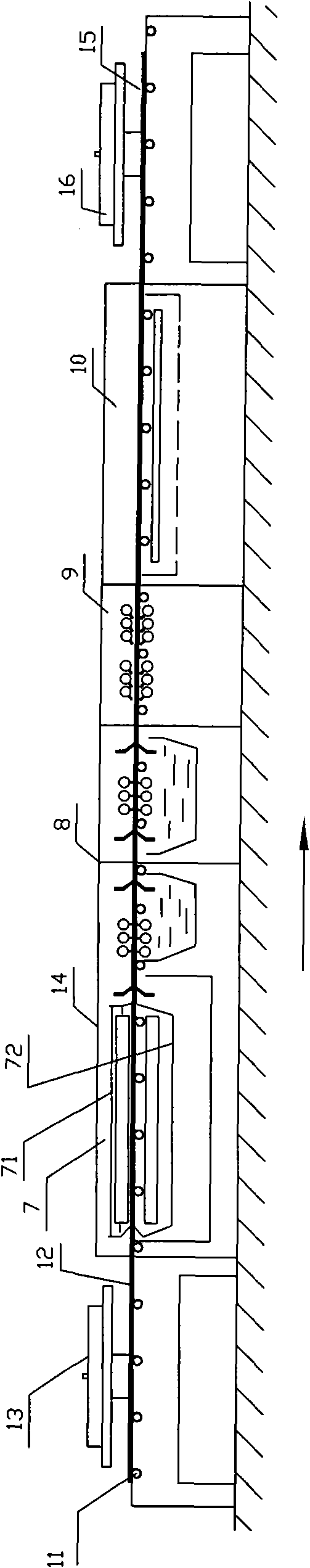

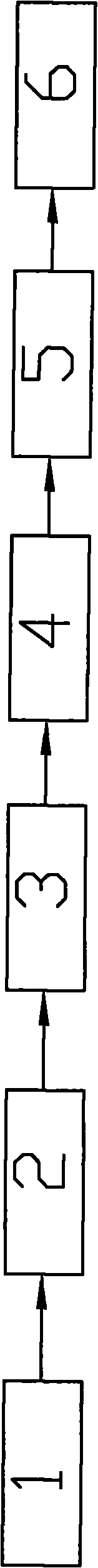

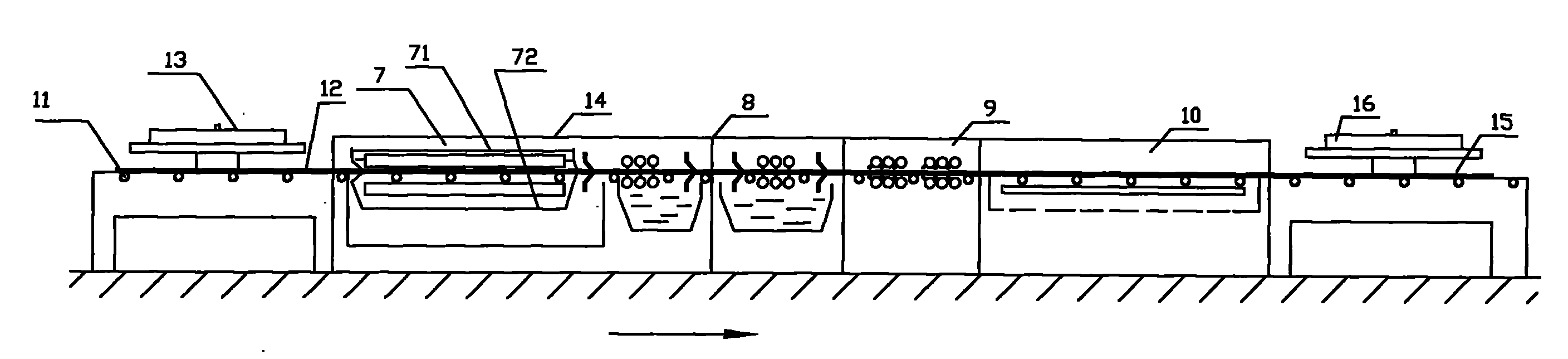

[0017] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the automatic cleaning method of the aluminum alloy composite panel of the present invention is: placing the composite panel on the feeding platform, that is, automatic feeding 1, and sequentially transporting the composite panel to the ultrasonic cleaning area through the transmission mechanism for ultrasonic cleaning 2, Spray rinsing 3 in the spray rinsing area, wind cutting blow 4 and hot air drying 5 in the blow drying area, and finally carry out automatic blanking 6 through the transmission mechanism; after the composite board is transported to the ultrasonic cleaning area, it passes through the set The ultrasonic cleaning mechanism performs ultrasonic cleaning on both sides of the composite board in order to remove pollutants and a part of oxides on the board surface. At the rear end of the ultrasonic cleaning area, a spray rinsing mechanism is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com