High-corrosion-resistance hot galvanizing aluminum-magnesium-nickel rare earth alloy coated steel plate and production method thereof

A technology of alloy coating and production method, which is applied in the direction of hot-dip coating process, metal material coating process, coating, etc., can solve problems such as the advent of market-oriented products, and achieve improved coating adhesion, improved oxidation resistance, and improved corrosion resistance. Effect of blackening properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

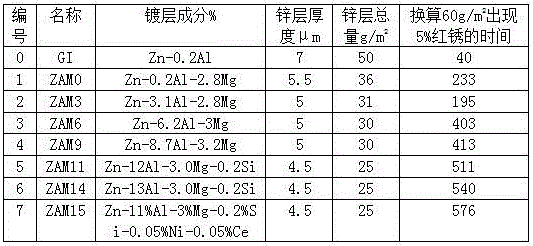

[0013] The following technical scheme is adopted: the coating composition is (5~25%Al)-(1~5%Mg)-(0.1~0.3%Si)-(0.01~0.1%Ni)-(0.01~0.1Ce)-Zn high Corrosion-resistant hot-dip galvanized aluminum-magnesium-nickel rare earth alloy coated steel plate, the base plate is made of low carbon steel.

[0014] The process route is: cold-rolled raw material plate→electrolytic degreasing→annealing in vertical annealing furnace heated by full radiant tube→induction heating zinc pot coating→pure nitrogen air knife→cooling after plating→passivation→drying →Electrostatic oiling →Inspection and packing into storage.

[0015] The annealing stage: set the heating rate to 10±5°C / s, the annealing temperature to 700±50°C, the holding time to 50±15s, and the control atmosphere in the annealing stage to be 5%H 2 -95%N 2 , the dew point is -30±5℃.

[0016] The hot-dip plating process: set the temperature of the zinc pot at 480±25°C, the temperature of the zinc pot at 500±25°C, the dipping time of 5±2s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com