Automatic recovery type air dryer

An air dryer and automatic recovery technology, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as inability to air dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

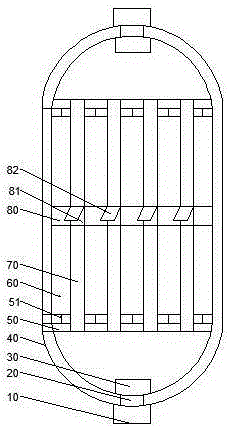

[0016] Such as figure 1 As shown, the automatic recovery air dryer has a scheme as follows: comprising a cylinder 40, the upper end of the cylinder 40 is provided with an air outlet one and a fan one connected with the air outlet one, and the lower end of the cylinder is provided with an air outlet two 20 and connected with the air outlet The blower fan 2 10 that tuyere 2 20 is connected to. The middle part of cylinder 40 is provided with air inlet 81, and cylinder 40 is provided with upper, middle and lower tube plates, and vertical drying layer 70 is arranged between upper and middle tube plates and between middle and lower tube plates, The tuyere 81 communicates with the drying layer 70 through the middle tube plate 80. The drying layer 70 contains a desiccant. The drying layer 70 is evenly arranged in the horizontal direction of the cylinder 40. A heating layer 60 is arranged between the drying layers 70. The air outlet and A humidity sensor 30 is provided inside the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com