Sludge drying and feeding device and feeding method

A sludge drying and feeding device technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of easy blockage of conveying pipes, high moisture content of dehydrated cake, and uniform distribution of difficult sludge drying devices, etc., to achieve The effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

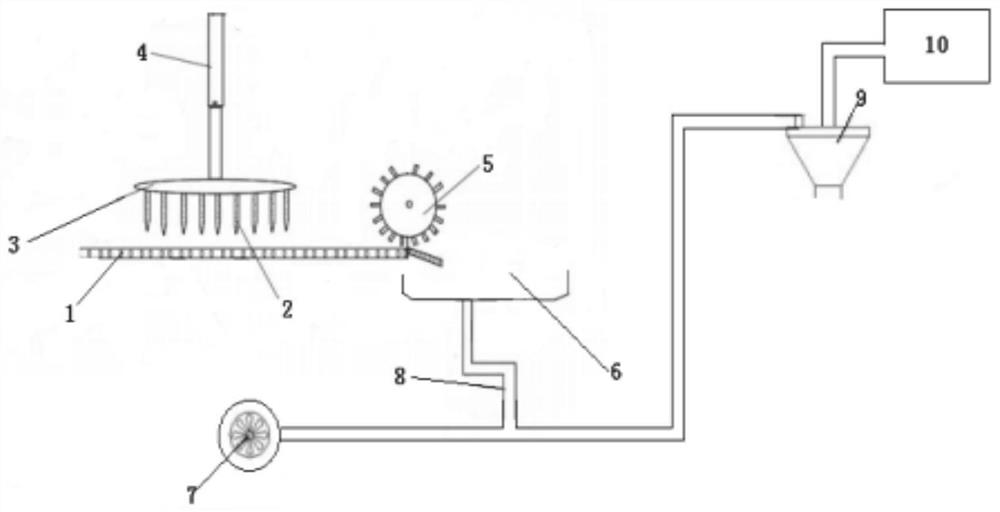

[0042] Such as figure 1 As shown, this embodiment provides a sludge drying and feeding device, including a dehydrated cake conveyor belt 1, a sludge dividing device 3 is provided on the dehydrated cake conveying belt 1, and the sludge dividing device 3 is a fork with spikes 2 Type structure, the dehydrated cake is divided into pieces, which is convenient for subsequent processing. The dehydrated cake conveyor belt 1 is a chain conveyor belt, and the chain conveyor belt is transported by a chain conveyor. There is a toggle device 5 at the end of the dehydrated cake conveyor belt 1 to prevent the dehydrated cake from being too viscous to fall into the hopper. The toggling device 5 is a turntable structure with a plurality of paddles.

[0043] At the end of the chain conveyor belt, each segment of the chain forms a gap with the gap between the chains, and the assembly position of the toggle device satisfies that the shortest distance between the entire toggle device and the con...

Embodiment 2

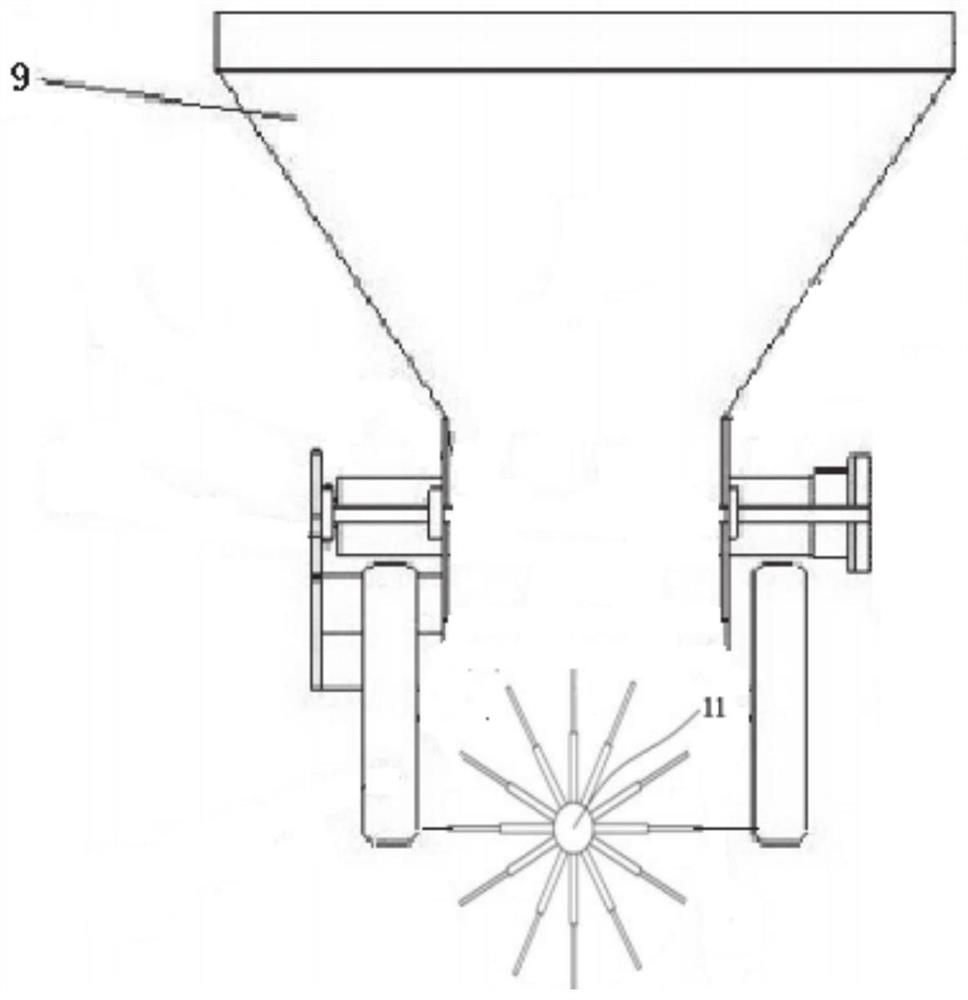

[0050] This embodiment provides a sludge drying and feeding method, which is carried out in the sludge drying and feeding device shown in Example 1. It includes the following steps: place the dehydrated cake on the dehydrated cake conveyor belt 1, the dehydrated cake moves with the dehydrated cake conveyor belt 1, falls into the lower hopper 6 at the end of the dehydrated cake conveyor belt, and enters the dilute phase conveyance along the outlet of the lower hopper 6 The pipeline 8 starts the fan 7 to divide the dehydrated cake into small pieces of sludge, and enters the gas-material separation device 9 along the dilute phase conveying pipeline 8. The sludge exits the sludge outlet of the gas-material separation device 9, and the gas is separated from the gas material. The gas outlet of the device 9 enters the suction device 10 . Start the windmill 11, and the windmill 11 rotates to provide wind power, and the sludge is thrown out along the tangential direction of the windmil...

Embodiment 3

[0056] This embodiment provides a sludge drying and feeding method, which is carried out in the sludge drying and feeding device shown in Example 1. It includes the following steps: place the dehydrated cake on the dehydrated cake conveyor belt 1, the dehydrated cake moves with the dehydrated cake conveyor belt 1, falls into the lower hopper 6 at the end of the dehydrated cake conveyor belt, and enters the dilute phase conveyance along the outlet of the lower hopper 6 The pipeline 8 starts the fan 7 to divide the dehydrated cake into small pieces of sludge, and enters the gas-material separation device 9 along the dilute phase conveying pipeline 8. The sludge exits the sludge outlet of the gas-material separation device 9, and the gas is separated from the gas material. The gas outlet of the device 9 enters the suction device 10 . Start the windmill 11, and the windmill 11 rotates to provide wind power, and the sludge is thrown out along the tangential direction of the windmil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com