Novel spiral drying machine

A spiral dryer, a new type of technology, applied in the direction of progressive dryers, dryers, drying, etc., can solve the problems of cumbersome adjustment process, large space, occupation, etc., and achieve the effect of improving the drying effect and increasing the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

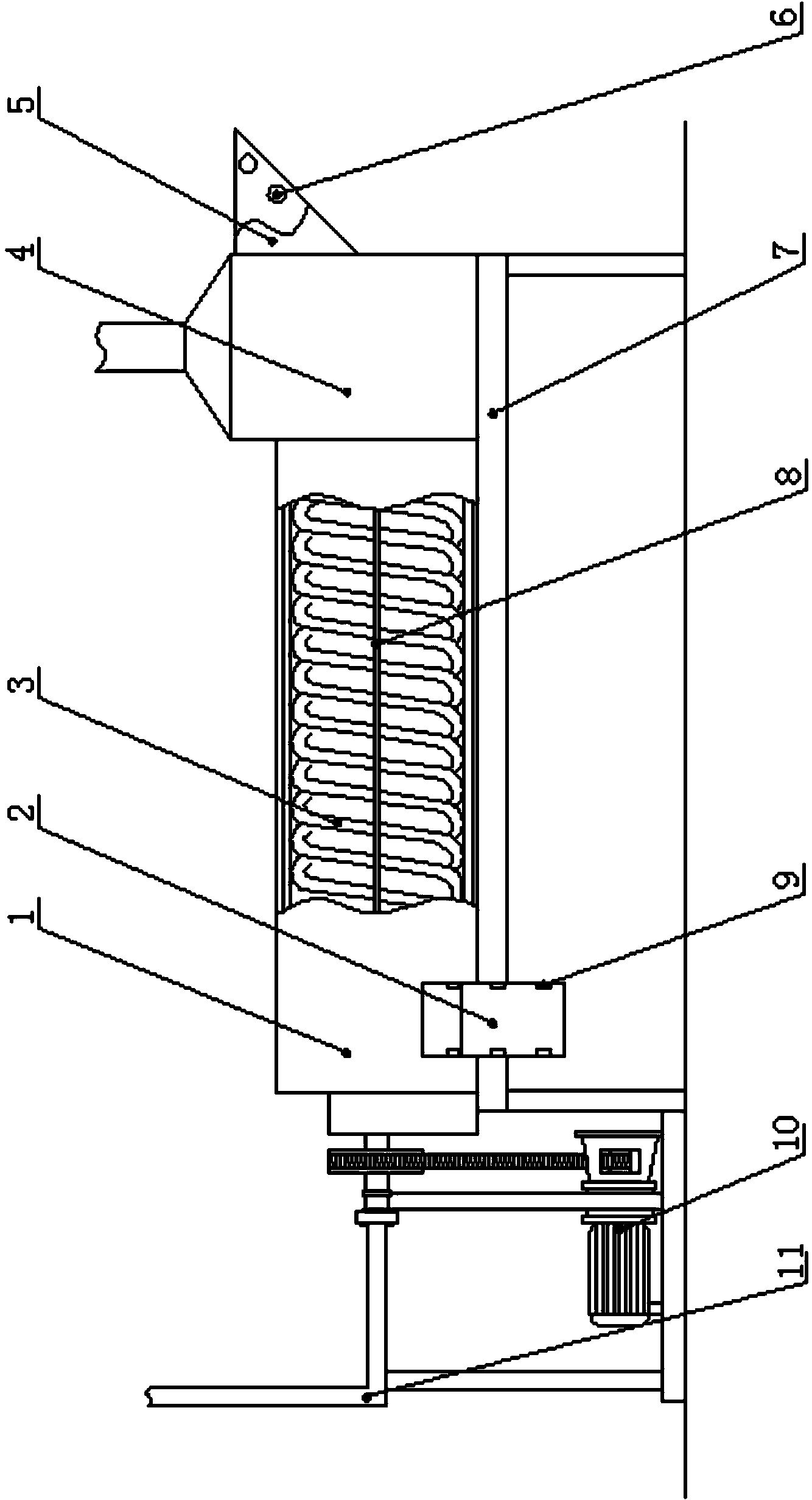

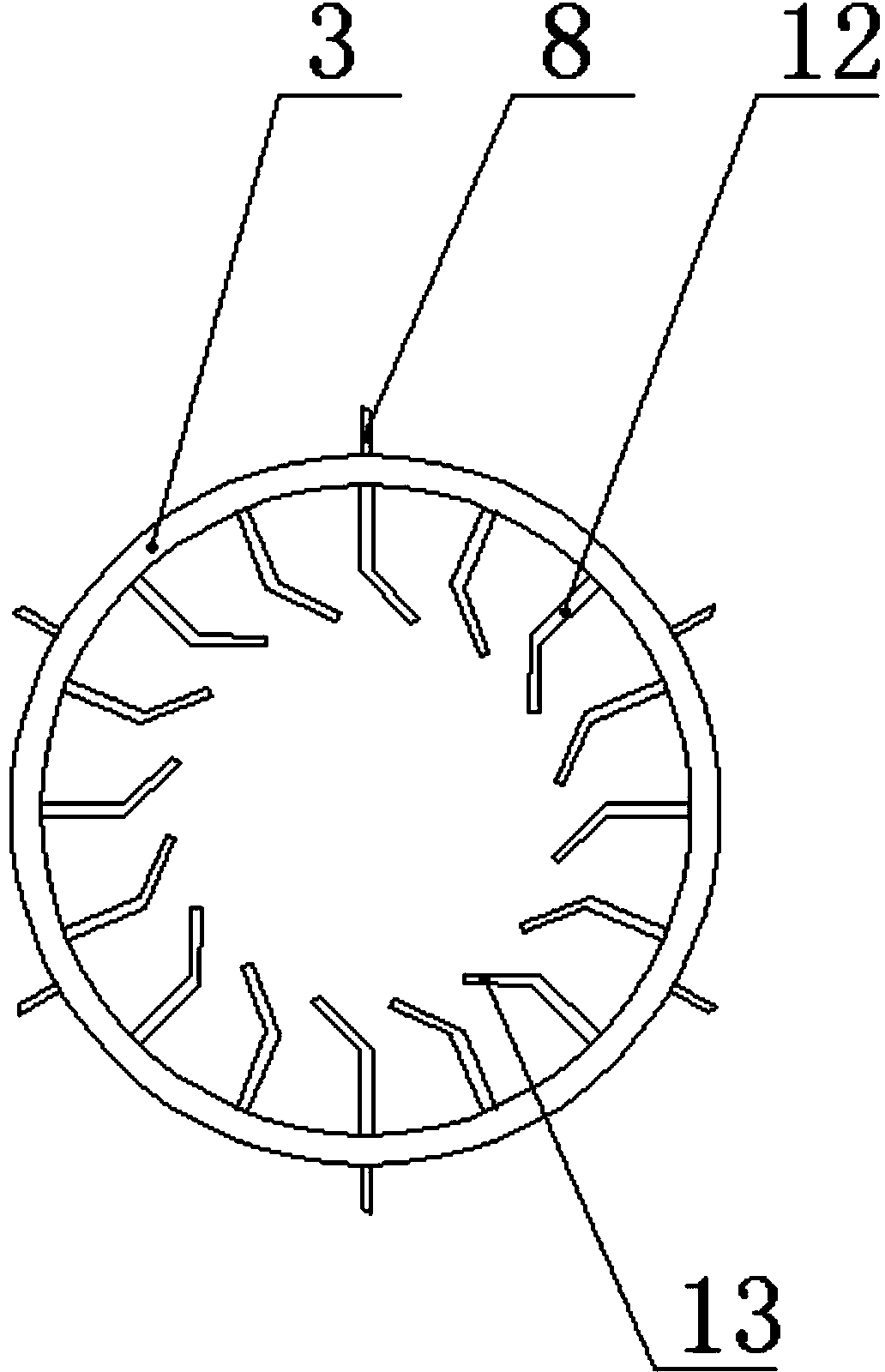

[0015] A new type of spiral dryer, which is composed of a frame 7, a feeding bin 4, a drying bin 1, a motor 10 and a spiral heating tube 3, one side of the feeding bin is connected with the drying bin, and the other side of the feeding bin is made of There is a feed hopper 5, a discharge hopper 2 is made at the rear of the drying bin, a motor is arranged under the drying bin, and the spiral heating tube is rotatably installed inside the feeding bin and the drying bin, and the spiral heating tube is driven by the drying bin The side wall extends outward and is connected with the motor and the heat supply pipe 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com