Municipal solid waste drying device

A technology of municipal solid waste and drying equipment, applied in the field of municipal solid waste drying equipment, can solve the problems of increasing air humidity, affecting boilers, consumption, etc., and achieve the effect of reducing water vapor and improving drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

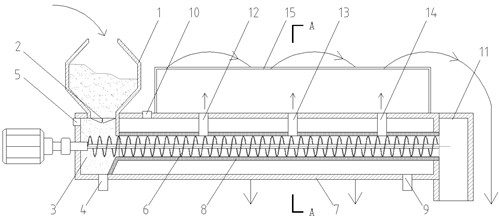

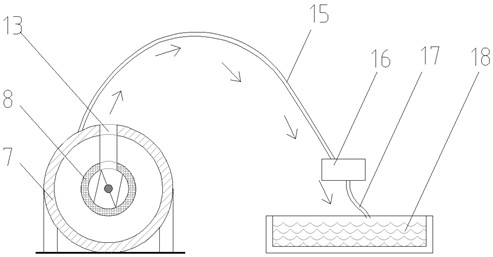

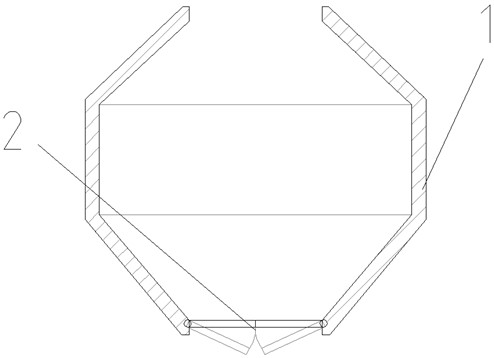

[0014] The present invention provides a drying device for municipal solid waste, the specific structure of which is as follows: Figures 1~3 As shown, it includes feeding port 1, throttle baffle 2, heating chamber 3, primary air inlet 4, primary air outlet 5, screw feeder 6, drying outer wall 7, drying inner wall 8, secondary air inlet 9 , secondary air outlet 10, collecting bucket 11, water vapor discharge port one 12, water vapor discharge port two 13, water vapor discharge port three 14, arc deflector 15, filter 16, overflow hose 17, Collection tank 18.

[0015] The throttling baffle 2 is provided at the bottom of the feed port 1, the primary air inlet 4 is provided at the bottom of the heating chamber 3, and the side of the heating chamber 3 away from the drying cylinder is provided with a primary air outlet 5; the drying outer wall 7 is provided with the drying inner wall 8 coaxially; the bottom of the end of the drying outer wall 7 away from the feed port 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com