Patents

Literature

53 results about "EGG SHELL MEMBRANE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing classifying porous aluminum oxide nano heat insulating material

InactiveCN101100307AReduce heat transferSmall coefficient of thermal expansionNanostructure manufactureChemical industryCeramic sinteringEGG SHELL MEMBRANE

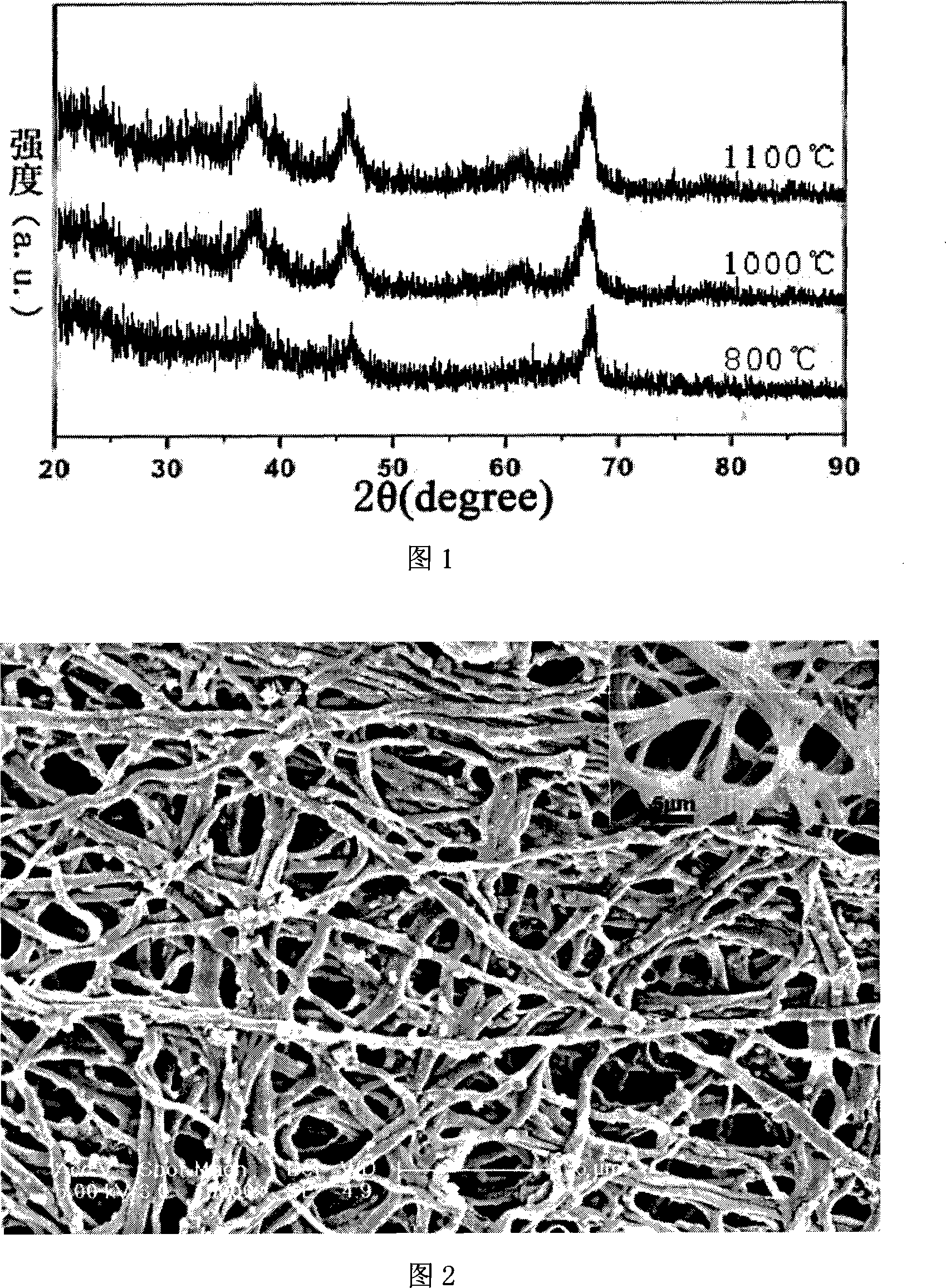

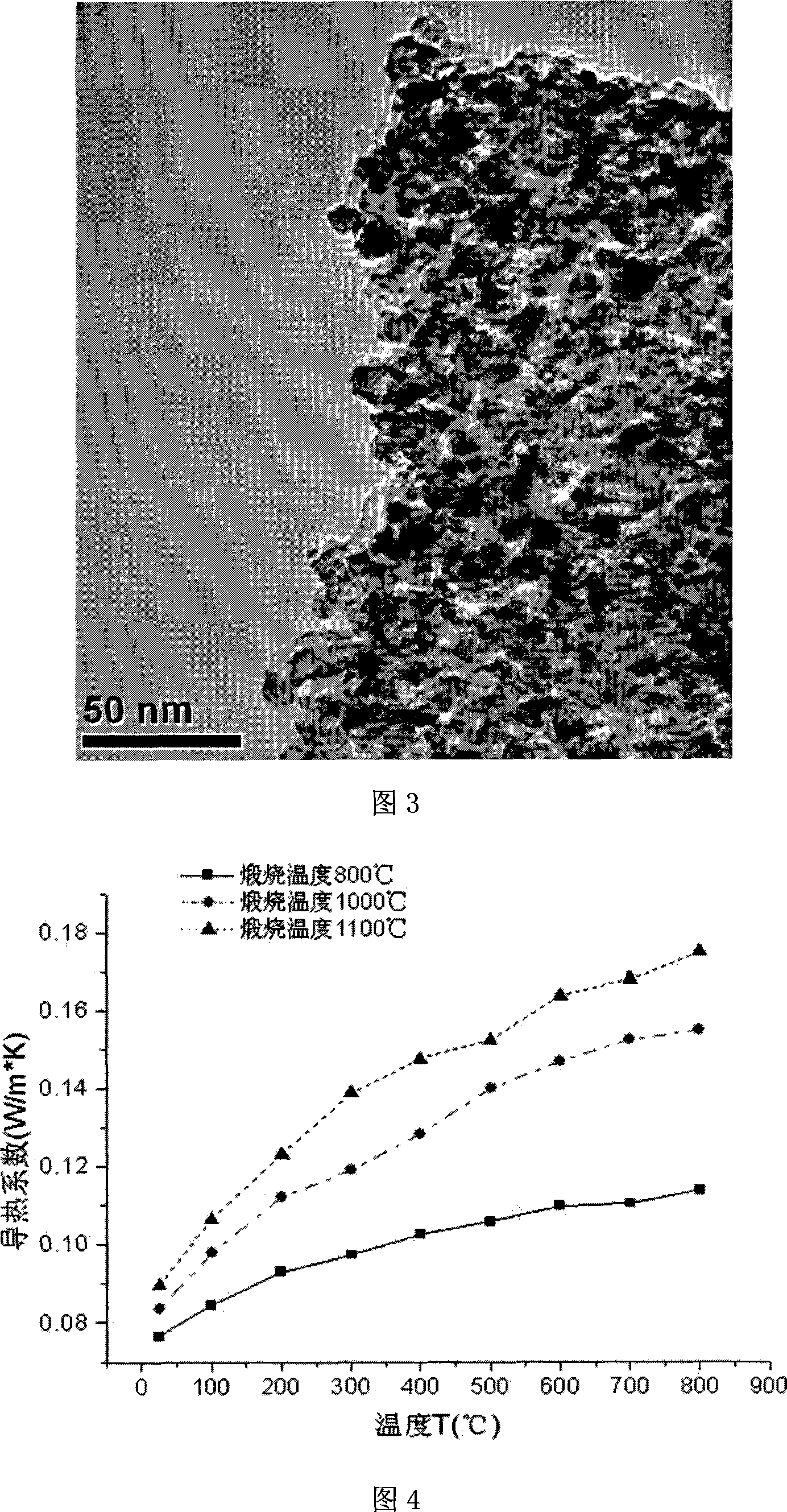

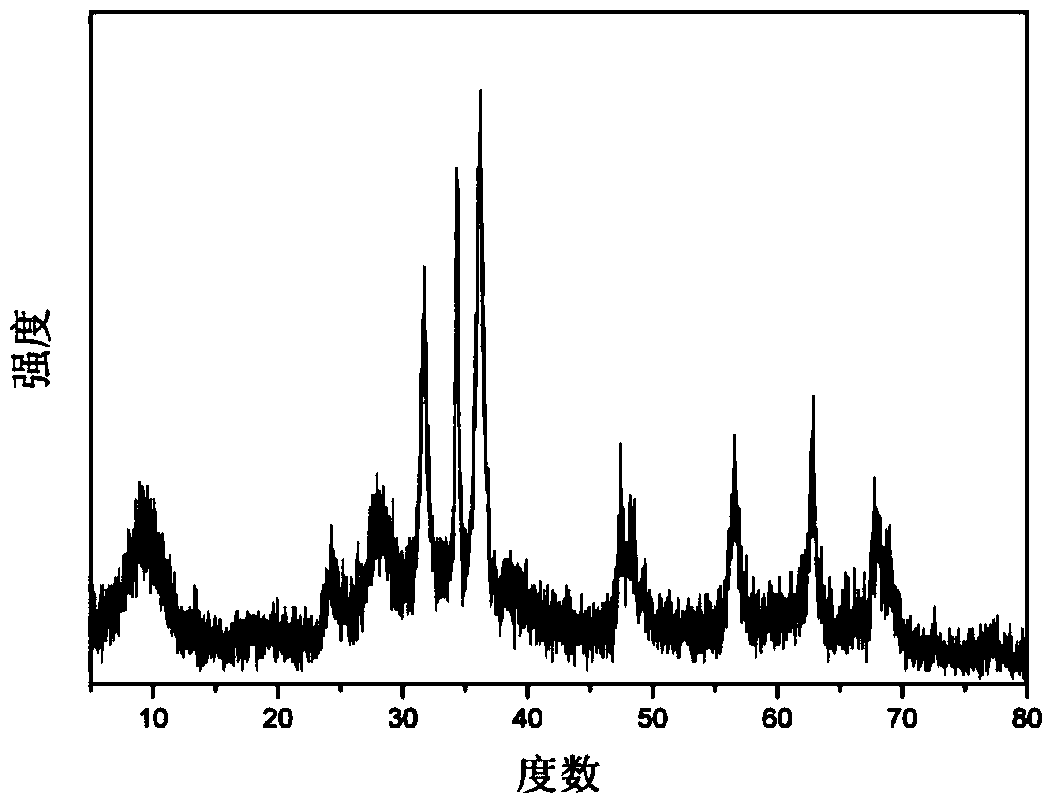

This invention relates to the production of classified porous alumina nanometer thermal insulating material, based-on biological templet synthesis technique, by using waste egg shell membrane as raw material. First, the membrane is pretreated by separation and washing, followed by dipping in prodromal liquid aluminium salt solution, then oxidized burnt, forming alumina nanometer material in situ under the effect of biological templet. This invention has advantages of: simple process, low cost, being able to control the granule size and aperture dimension by regulating the burning temperature and speed of stepping-up temperature. The product has advantages of small heat conductivity, low expansion coefficient, well property of anti-heat shock, able to be used in field of metallurgical industry, ceramic furnace as excellent heat insulation refractory.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of zinc oxide/titanium dioxide composite material with network structure

InactiveCN103566921AEnhanced glowEnhance photocatalytic performanceWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsEGG SHELL MEMBRANELuminescence

The invention provides a preparation method of a zinc oxide / titanium dioxide composite material with a network structure. The method is characterized by comprising following steps: preparing a biological template; preparing a zinc-alcohol solution; preparing a butyl titanate-alcohol solution; taking out an egg-shell membrane dipped with normal saline, and dipping into the zinc-alcohol solution and the butyl titanate-alcohol solution separately for 4-12 h; putting the air dried egg-shell membrane into a muffle furnace for sintering at a sintering temperature of 550 DEG C to 700 DEG C with a temperature rising rate of 2 DEG C / min to 5 DEG C / min and a temperature maintaining time of 2-4 h; and cooling to room temperature to obtain the zinc oxide / titanium dioxide composite material with the network structure. According to the zinc oxide / titanium dioxide composite material with the network structure prepared by the simple biological template method, ZnO and TiO2 particles in the product has coupling and synergistic effects, thus enhancing and improving a gas-sensitive performance, a luminescence performance, photocatalysis, and other performances. In addition, interactions between the ZnO and the TiO2 can generate new physical phenomena and new functions can be utilized. The method has advantages of the easily available template, simple preparation technology and processes, low cost, strong repeatability, capability of synthesis in large scale, and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method of preparing C-doped porous nanometer TiO2 photocatalyst with egg shell membrane as template

InactiveCN1974000APromote absorptionImprove adsorption capacityPhysical/chemical process catalystsDecompositionWastewater

The present invention discloses process of preparing C-doped porous nanometer TiO2 photocatalyst with egg shell membrane as the template. One process includes the steps of soaking egg shell in hydrochloric acid, separating egg shell membrane, washing, dewatering, soaking in isopropanol solution of tetrabutyl titanate, taking out, drying at room temperature and final high temperature calcining to obtain C-doped porous nanometer TiO2 photocatalyst. One other process includes the steps of soaking clean egg shell membrane first in AgNO3 solution and then in clucose solution for 24 hr each, taking out, dewatering, soaking in isopropanol solution of tetrabutyl titanate, taking out, drying at room temperature and final high temperature calcining to obtain nanometer Ag crystal and C-doped porous nanometer TiO2 photocatalyst. The said process has rich material source and mild condition, and the prepared photocatalyst has high organic pollutant decomposition catalyzing capacity.

Owner:TIANJIN UNIV

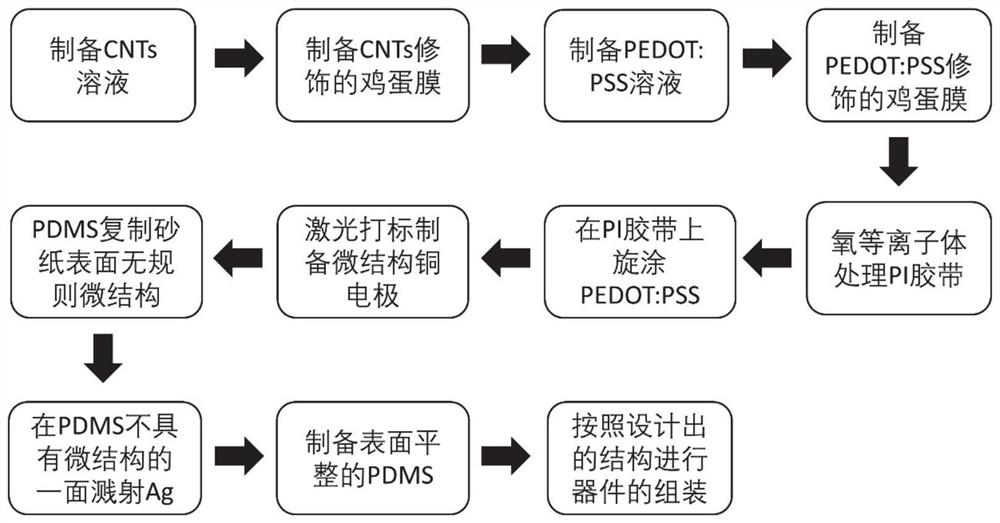

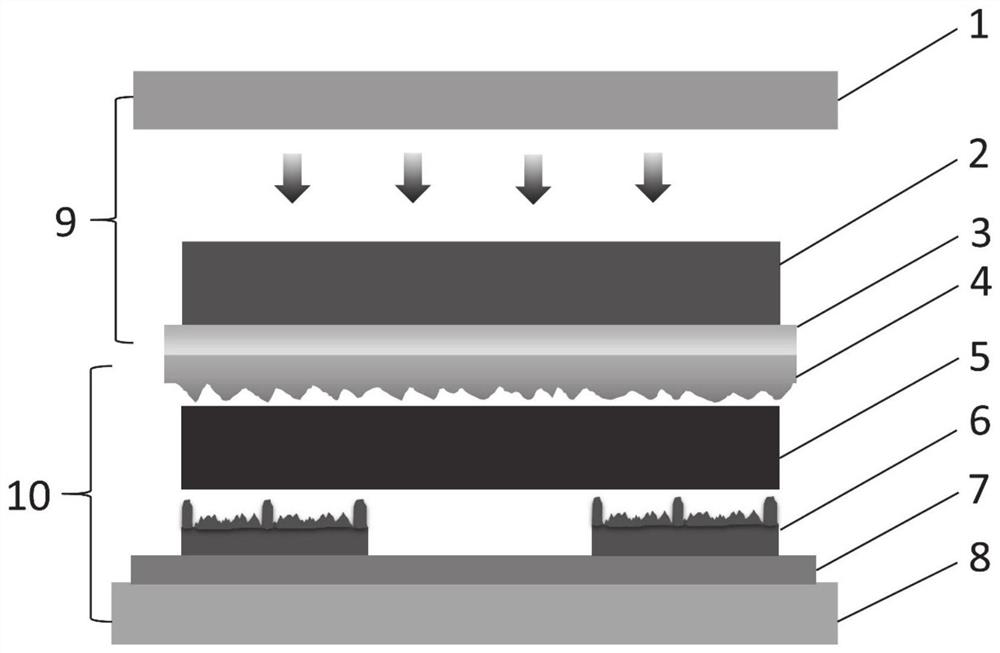

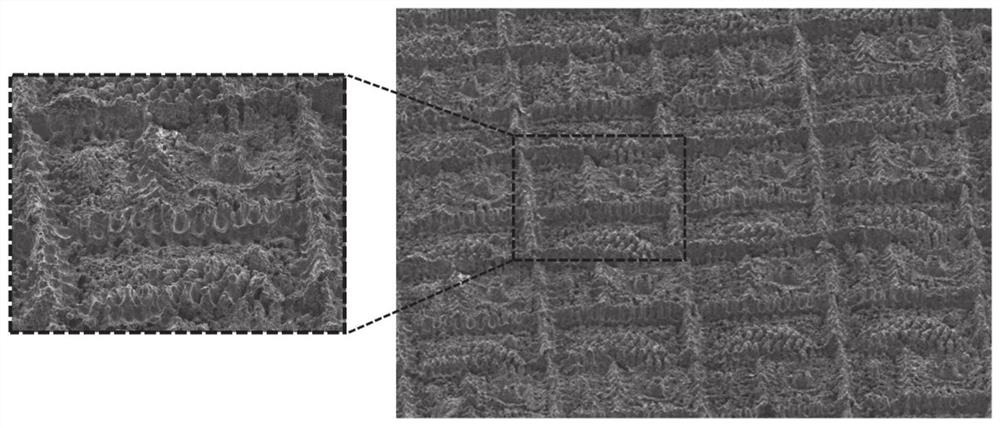

Self-powered flexible piezoresistive pressure sensor based on biofilm and preparation method and application thereof

ActiveCN112284579AHigh sensitivityStable initial resistance valueFluid pressure measurement using ohmic-resistance variationFilm/foil adhesivesFilm resistanceConductive polymer

The invention provides a self-powered flexible piezoresistive pressure sensor based on a biofilm, and a preparation method and application thereof; the self-powered flexible piezoresistive pressure sensor is of a laminated structure, and is provided with a polyimide adhesive tape layer, poly (3, 4-ethylenedioxythiophene)- polystyrene sulfonate conductive polymer film resistance layer, a copper foil, a carbon-nanotube- modified egg film, a polydimethylsiloxane film and a poly (3, 4-ethylenedioxythiophene)- polystyrene sulfonate-modified egg film sequentially from one side to other side. One surface of the copper foil is provided with a microstructure, and the microstructure is arranged towards the carbon-anotube- modified egg film; the egg film is an outer egg shell membrane; an irregular microstructure is processed on one side of the polydimethylsiloxane film, and a silver electrode is arranged on the other side of the polydimethylsiloxane film. A pressure sensor is ultrahigh in sensitivity, short in response and recovery time, wide in sensing range and capable of generating energy by itself.

Owner:UNIV OF JINAN

Dissolving and filming method of egg shell membrane

InactiveCN1432592AReduce dosageGood removal effectOther chemical processesPharmaceutical non-active ingredientsOrganic acidPhosphate

The present invention belongs to the field of biological material preparing technology. Egg shell membrane is first dissolved completely in water solution of beta-thiopropionic acid and organic acid as cosolvent through heating to 80-95 deg.c and stirring; after centrifugal separatino and elimination of precipitate, the separated liquid is cast directly onto glass plate or steel plate and dried to form film; and the film is washed with methanol, neutralized with buffering phosphate solution, washed with deionized water, dried and peeled to obtain planar egg shell film. Without residual toxic solvent and crosslinking agent used, the egg shell film can be used widely.

Owner:TSINGHUA UNIV

Reagent kit for extracting DNA in Chinese alligator chorion film and use method thereof

InactiveCN101368179AHigh purityIncrease concentrationMicrobiological testing/measurementDNA preparationHigh concentrationChinese alligator

The invention discloses a kit for extracting DNA in the egg shell membrane of Yangtze alligator and a use method thereof, and the kit comprises the following reagents: a reagent A, a reagent B, a reagent C, a reagent D, a reagent E and a reagent F. The template DNA which is extracted by the kit has good purity, and the kit can be used for gene amplification sequencing and typing. In the amplification of the 12S rRNA gene, the mitochondrial D-loop region and the Cyt b gene, all the extracted shell membrane DNA templates can be successfully amplified to obtain the fragment products with expected identical sizes, high concentration and high specificity. Microsatellite DNA marker specificity primers are utilized to obtain typing data through the PCR amplification to be used for the identification in disputed paternity of Yangtze alligator. In addition, the method also can be applied to the extraction of other ovipara such as the turtles, the birds and the like. The obtained template DNA can be widely applied to the studies of the ovipara on the fields such as population genetic analysis, molecular evolution, evolution of relationship among individuals and the like.

Owner:ANHUI NORMAL UNIV

Article for nursing hair

InactiveCN101692996AGood flexibilityImprove smoothnessCosmetic preparationsHair cosmeticsEGG SHELL MEMBRANEBULK ACTIVE INGREDIENT

The invention discloses an article for nursing hair. The article for nursing the hair comprises an egg membrane protein active ingredient. As the amino acid component contained in the egg membrane protein is similar to the component contained in human healthy hair, the article for nursing hair, containing the egg shell membrane protein, can make up the amino acid nutrient lost from the hair, thus improving the beneficial effect of the hair regulation.

Owner:JIANGSU LONGLIQI BIOSCIENCE CO LTD

Preparation method and application of egg shell membrane composite nano-silver thin film used for artificial skin

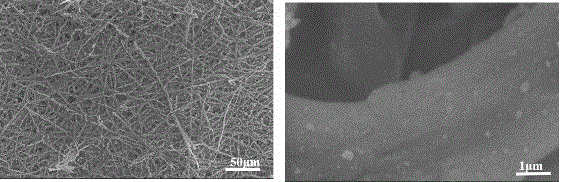

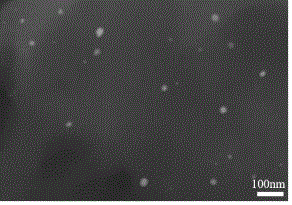

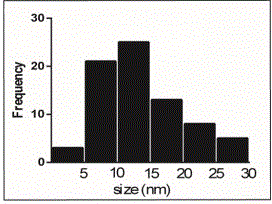

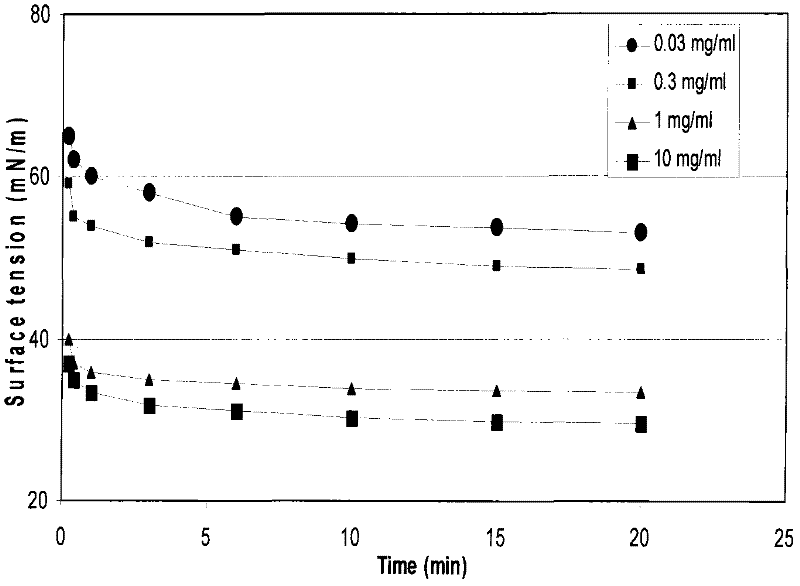

ActiveCN106310385AImprove antibacterial propertiesNo obvious biological toxicityAbsorbent padsProsthesisYolkHydrogen

The invention discloses a preparation method and application of an egg shell membrane composite nano-silver thin film used for an artificial skin. The preparation method comprises the following steps: removing egg white and yolks of fresh eggs and washing egg shells with de-ionized water; separating egg shell membranes and washing the egg shell membranes with the de-ionized water; cutting the egg shell membranes into sizes of (1cm-3cm)*(1cm-3cm) and putting the egg shell membranes into a hydrochloric acid solution with the concentration of 1mM to 100mM and the pH (Potential of Hydrogen) of 1 to 3; immersing for 1 to 4 days at room temperature and washing with the de-ionized water; then putting the egg shell membranes into a dopamine solution with the concentration of 2mg / mL to 4mg / mL and the pH of 8.5 to 9.5; immersing for 6h to 20h at room temperature and washing with the de-ionized water; then putting the egg shell membranes into a silver nitrate solution with the concentration of 10nM to 50nM; immersing for 6h to 20h at room temperature without light, and then washing with the de-ionized water; and naturally drying at room temperature to obtain the egg shell membrane composite nano-silver thin film used for the artificial skin. The prepared egg shell membrane composite nano-silver thin film is used for manufacturing the artificial skin, has excellent mold resistance, and has no obvious biological toxicity; and the preparation method is simple in process, less in consumed time and low in cost.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

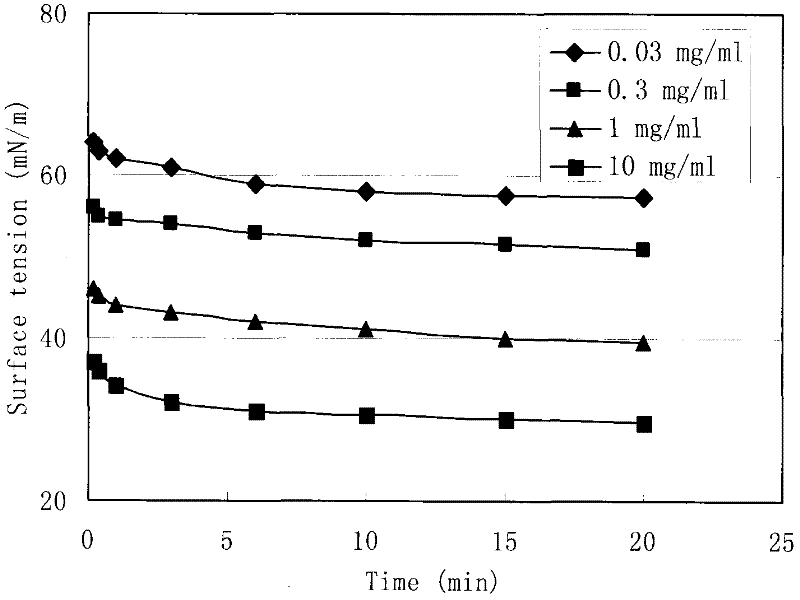

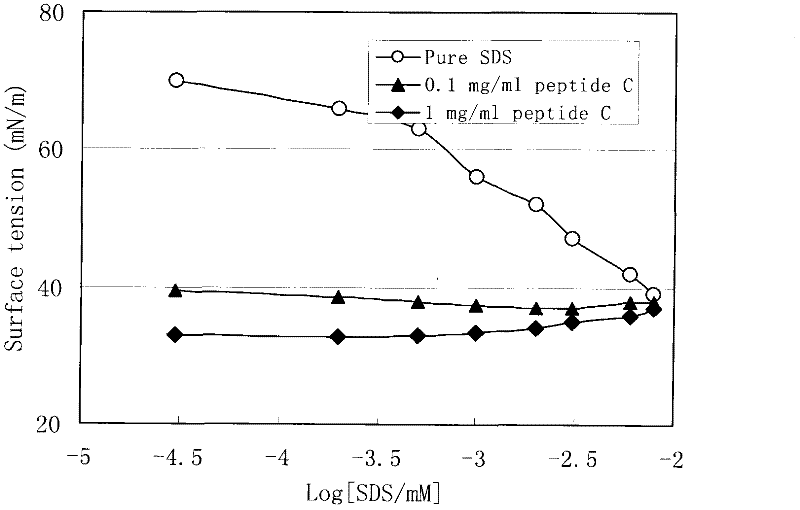

Production method and application of egg-shell membrane collagen peptides

InactiveCN102517363ANo pollutionPerformance tuning controlCosmetic preparationsToilet preparationsEGG SHELL MEMBRANEMixed materials

The invention discloses a production method and application of egg-shell membrane collagen peptides. The method comprises the following steps of: (1) taking an egg membrane out of an egg shell, and smashing to over 40 meshes; (2) adding egg membrane powder obtained in the step (1)into a papain solution with the concentration of 800-1,000 U / L, and stirring at the temperature of 35-50 DEG C for 2-3 hours to obtain a mixed material, wherein the solid-liquid ratio is 1:(2-5); (3) adding an NaOH solution into the mixed material obtained in the step (2) till the mass concentration of NaOH is 2-4.5 percent, stirring at the temperature of 45-85 DEG C for 3-4 hours, standing, and taking a supernatant; and (4) adjusting the pH value of the supernatant obtained in the step (3) to 7-11 with dilute hydrochloric acid to obtain an egg-membrane collagen peptide liquid, desalting, concentrating and drying to obtain egg-shell membrane collagen peptides. The production method has simple operation steps and simple conditions, egg-shell membrane collagen peptides can be produced on a large scale, energy consumption is low, environmental pollution is avoided simultaneously, and two or more polypeptide surfactants can be produced simultaneously; and by changing operation conditions, the performance of the polypeptide surfactant can be adjusted and controlled.

Owner:淮安鸿玛生物科技有限公司

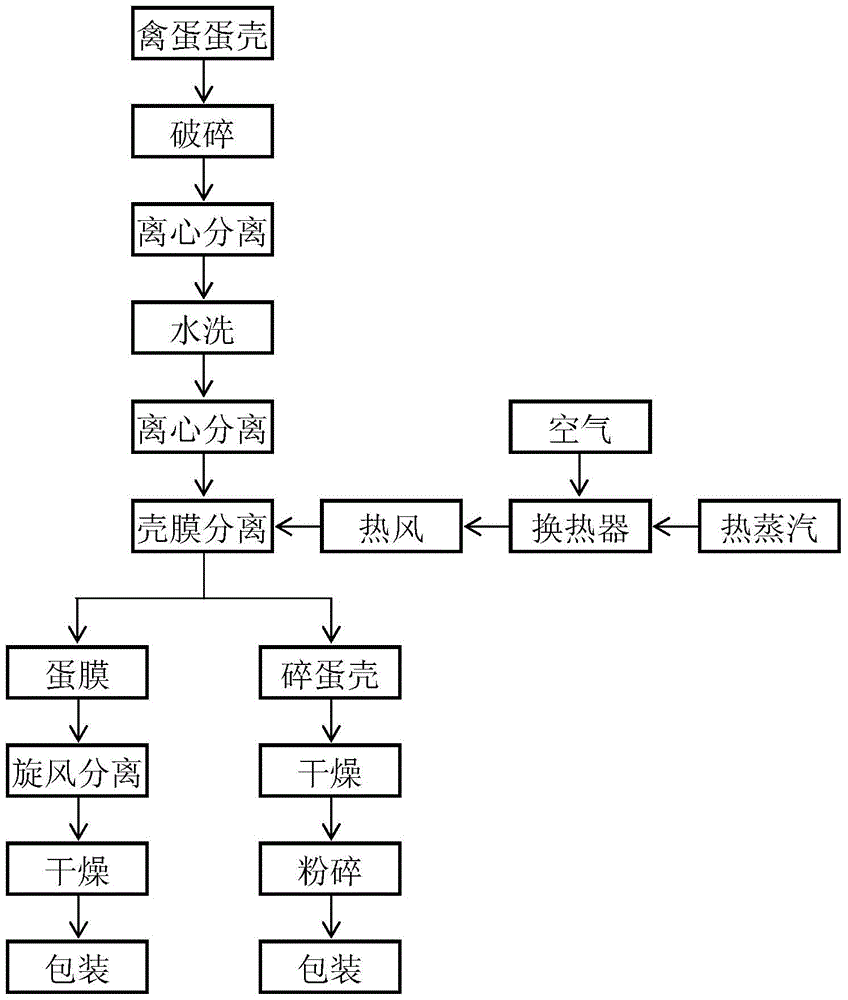

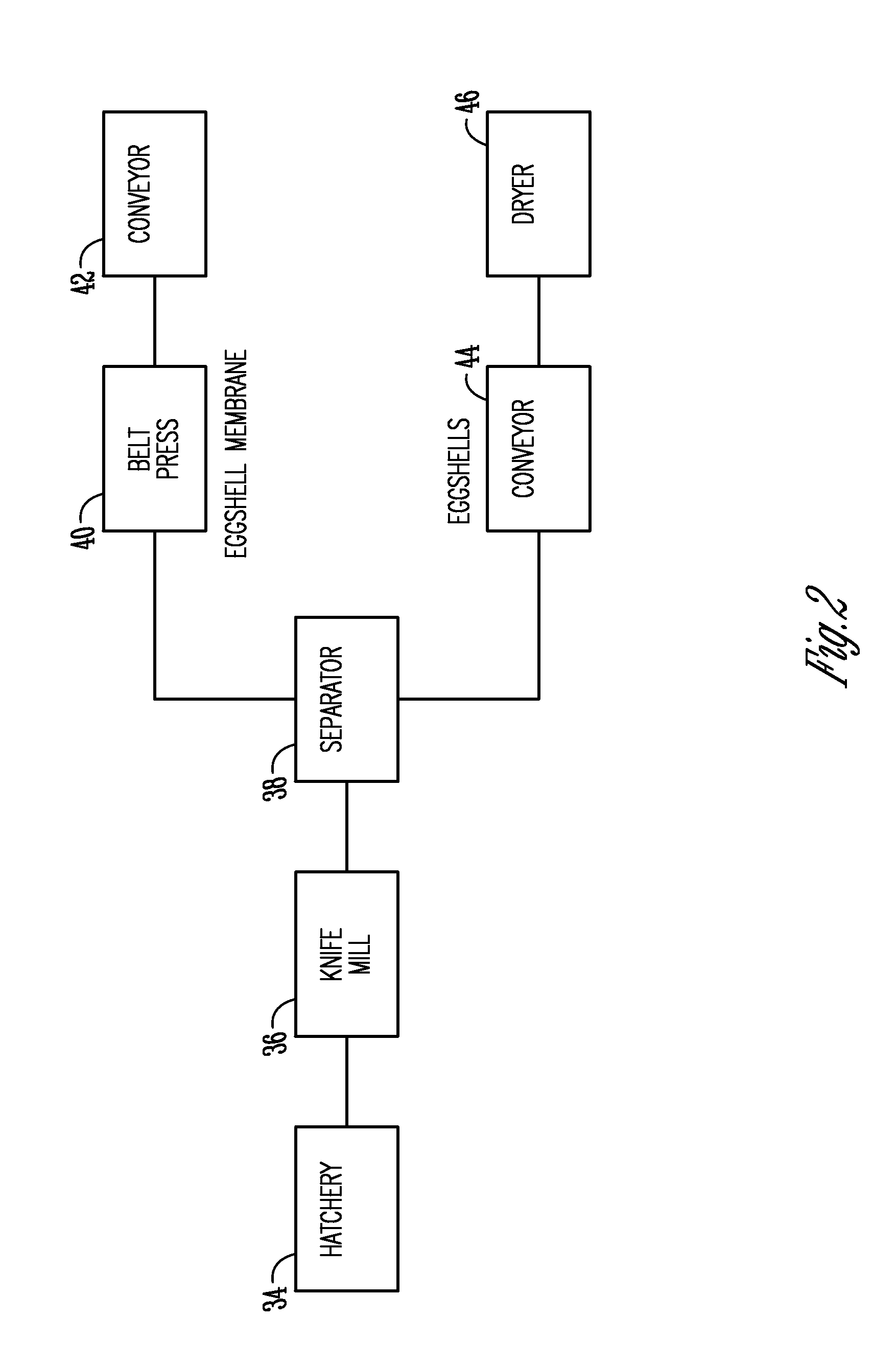

Poultry egg shell-membrane separation technology

The invention discloses a poultry egg shell-membrane separation technology. The shell-membrane separation technology comprises the following steps: firstly, preliminarily breaking the egg shells, allowing the broken egg shells to enter a centrifugal machine and separating egg liquid residues off the egg shells; then, washing the egg shells with clean water so as to thoroughly wash the egg liquid which is still on the egg shells after separation, and carrying out centrifugal separation again; allowing the dewatered egg shells to enter a shell-membrane separator, wherein hot-air inlet temperature of the shell-membrane separator is 160-185 DEG C and hot-air outlet temperature of the shell-membrane separator is 75-85 DEG C, so that the egg membranes are separated from the egg shells under the action of the hot air; the egg membranes enter a cyclone separator along with the hot air, the water vapor is discharged along with the hot air, the egg membranes are collected by a collector, and after drying, the collected egg membranes are packed and the packed egg membranes are warehoused; and the egg shells separated by the shell-membrane separator is sent into a dryer by a stranding cage, and then, the egg shells are dried, the dried egg shells are crushed, the crushed egg shells are packed and the packed egg shells are warehoused. The hot air utilized in the technology is prepared by heating air with hot steam through a heat exchanger. Industrial production of the poultry egg shell-membrane separation technology can be realized, so as to smoothly separate the egg shells and the egg membranes; moreover, the technology is simple and feasible, and causes no damage to the nutrients of the egg membranes due to the adoption of the physical changes.

Owner:HEILONGJIANG ZHONGNONG XINGHE BIOTECHNOLOGY CO LTD

Fiber Treatment Agent, Fiber Treated With Such Fiber Treatment Agent, Fiber Fabric, Laminate And Method For Treating Fiber

A fiber treatment agent contains components (a) and (b). A fiber treated with the fiber treatment agent and a fiber fabric including the fiber are also provided. The component (a) an insoluble egg-shell membrane fine powder with a mean particle size of 0.1 to 10 μm while the component (b) is a synthetic resin emulsion or a synthetic resin solution.

Owner:IDEATEX JAPAN

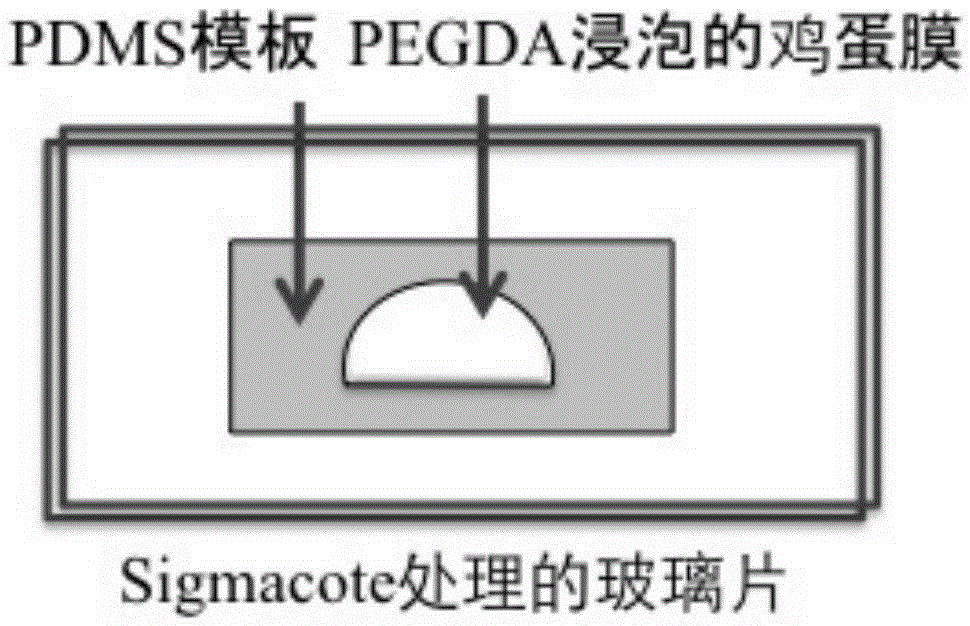

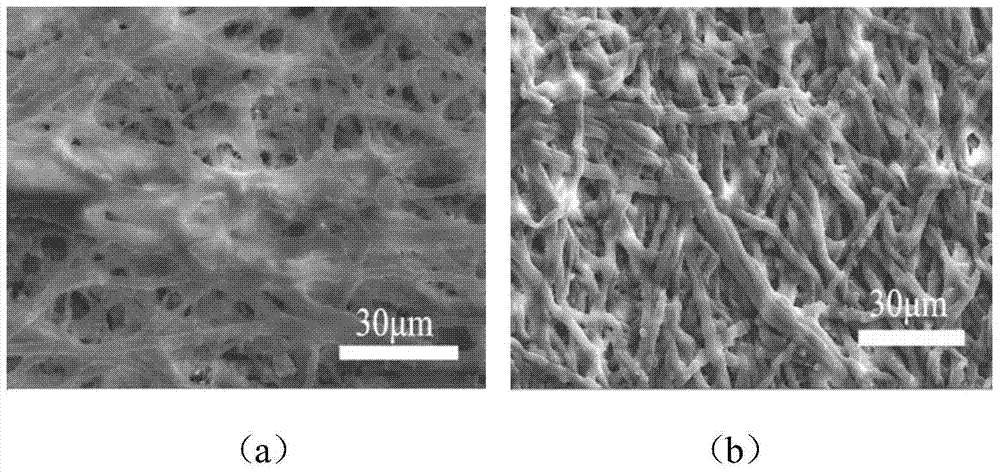

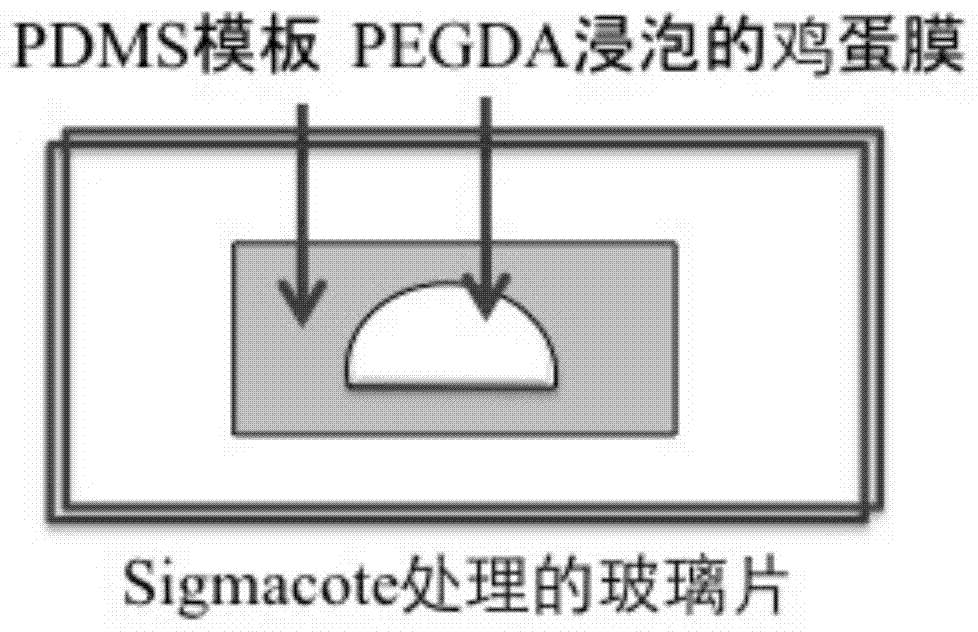

Method of preparing polyethylene glycol and protein fiber combined artificial cardiac valve

ActiveCN105326581APrevent enzymatic degradationIncreased durabilityHeart valvesDecompositionEGG SHELL MEMBRANE

The invention discloses a method of preparing a polyethylene glycol and protein fiber combined artificial cardiac valve and belongs to the field of biomedical materials. The method comprises: covering egg shell membrane protein fiber with photo-crosslinked polyethylene glycol hydrogel to obtain a composite material, and preparing the composite lamellar artificial cardiac valve through crosslinking by further using a molecular crosslinking agent (such as glutaraldehyde). The polyethylene glycol hydrogel is prepared by means of photo-crosslinking, ensuring the integrity of artificial valve materials, protecting the covered protein fiber from the in-vivo enzymatic decomposition and preventing calcification of the artificial valve. The artificial cardiac valve material prepared by the method simulates the lamellar structure of human aortic valves and has mechanical properties similar to those of the human aortic valves, with good biocompatibility guaranteed, and the need of a replacement receptor for high valve durability, good tissue compatibility and dispensing with a lifetime of anticoagulation can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

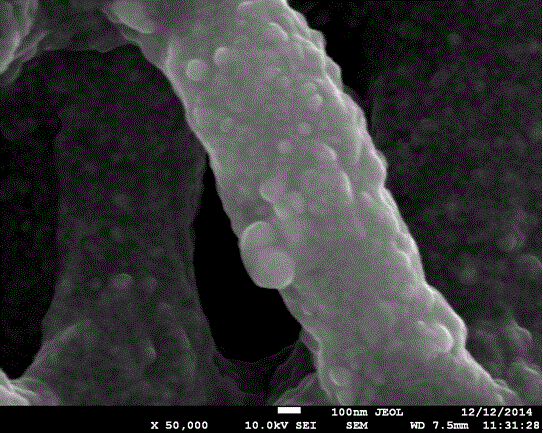

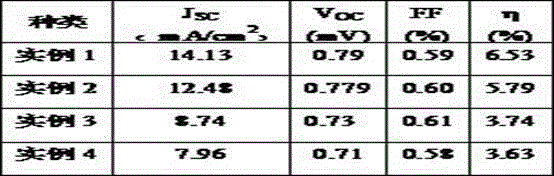

Dye-sensitized solar cell counter electrode material prepared by using eggshell membrane and method

InactiveCN105070508AImprove cycle stabilityImprove photoelectric conversion efficiencyLight-sensitive devicesPhotovoltaic energy generationElectrolytic agentCarbon fibers

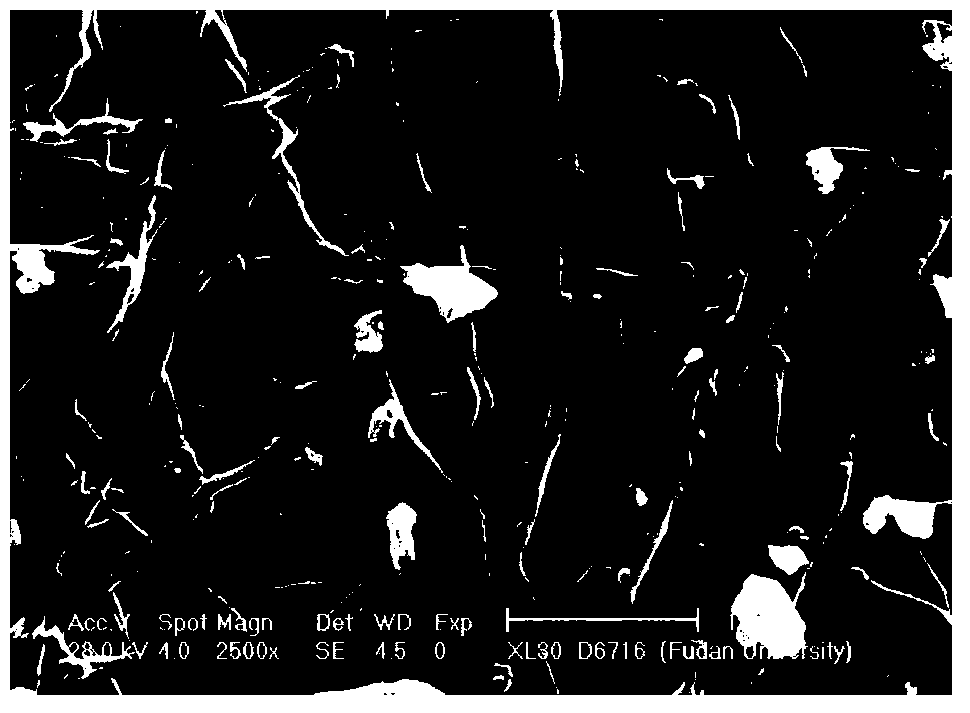

The present invention relates to a method for preparing a dye-sensitized solar cell counter electrode material by using an eggshell membrane. An eggshell membrane which is common garbage in daily life is used as a raw material, and through the methods of acid treatment, liquid phase immersion and carbonization, the three-dimensional porous sub-micron carbon fiber network material of a load copper sulfide indium nanocrystal is prepared and is applied to the counter electrode of a dye-sensitized solar cell. The specific preparation method comprises the steps of peeling an eggshell internal membrane from a fresh egg and processing the eggshell internal membrane by using dilute hydrochloric acid, after washing and drying, placing the eggshell internal membrane in a solution containing a copper sulfide indium former body, and obtaining the carbonized eggshell membrane of the load copper sulfide indium nanocrystal. According to the method, the eggshell membrane is used to prepare the dye-sensitized solar cell counter electrode material, a three-dimensional porous network structure is provided, a fiber scale is in a sub-micron level, the copper sulfide indium nano particles of the load have a large specific surface area, the penetration of the electrolyte and the transmission of electrons are facilitated, and more catalytically active sites are provided for the oxidation-reduction reaction of an electrolysis pair.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Skin soothing regenerating protein film cream and preparation method thereof

InactiveCN105919908AIncrease elasticityAnti-agingCosmetic preparationsToilet preparationsMirabilis jalapaWrinkle skin

The invention relates to skin soothing and regenerating protein film cream and a preparation method of the skin soothing regenerating protein film cream, relating to the technical field of cosmetics. The skin soothing regenerating protein film cream is prepared from the following components: water, neopentyl glycol diheptanoate, butanediol, glycerol, an oat extract, fucogel-1, glycosphingolipids, wheat fine powder lipid, a plankton extract, a mirabilis jalapa extract, a hydrolyzed egg shell membrane and the like. The skin soothing regenerating protein film cream can permeate to the stratum corneum of skin and form a reticular protective film in the skin, so that the problems of ultraviolet ray invasion and skin dryness and ageing can be solved, meanwhile, the synthesis of collagens from fibroblasts is promoted, therefore, the formation of skin wrinkles is reduced, the skin aging is resisted, the skin elasticity is improved, the skin is enabled to be tender, fine and smooth, as well as full and plump, and is full of beautiful youth gloss, the outside contamination resistance of the skin is enhanced, the self-protection ability of the skin is enhanced, the cell ageing is prevented, and thus the skin ageing is delayed, the youthful vigor of the skin is recovered, the skin is tender and full, and the beautiful skin with the real lasting health is realized from inside to outside.

Owner:广州雷诺生物科技有限公司

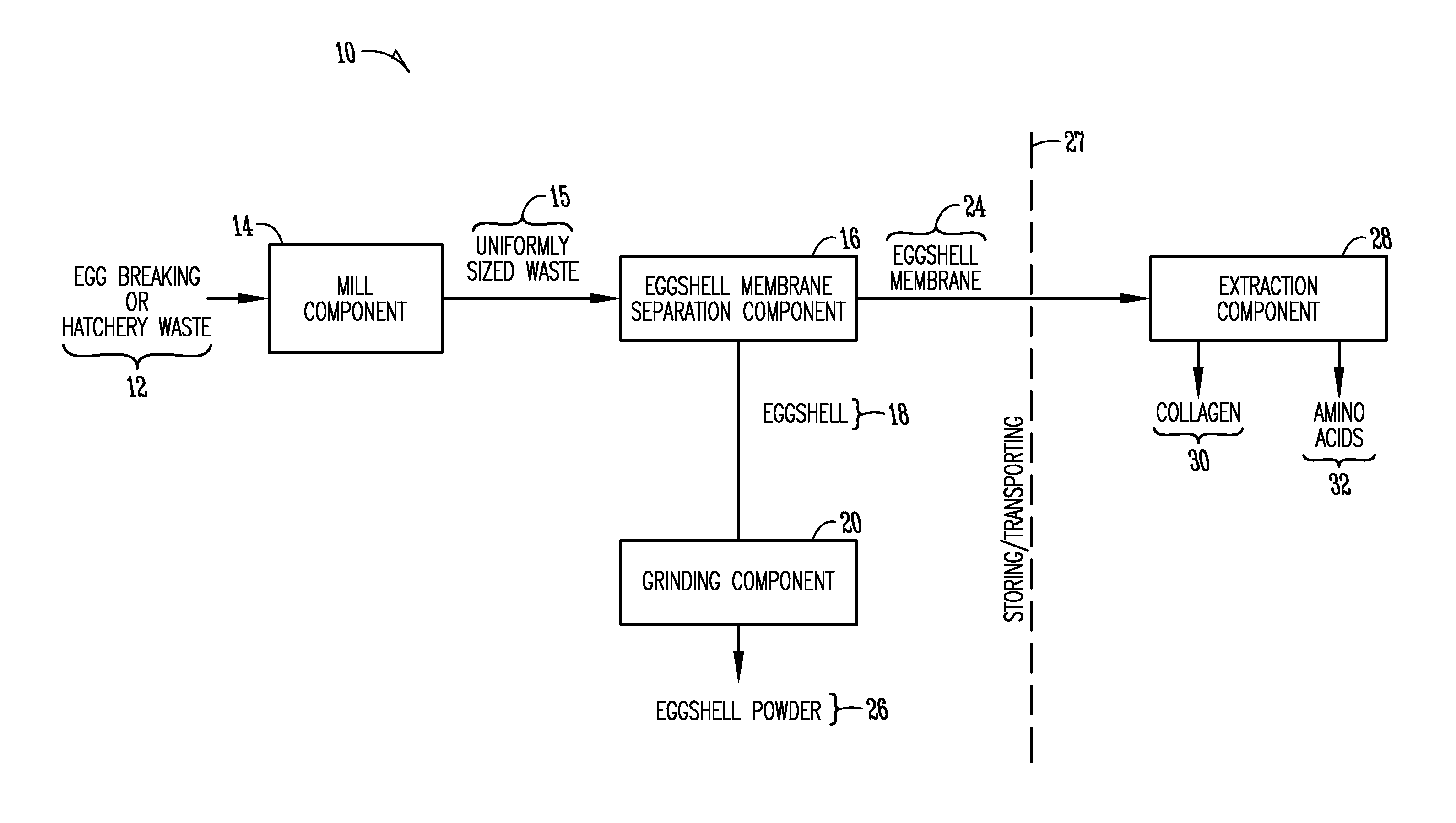

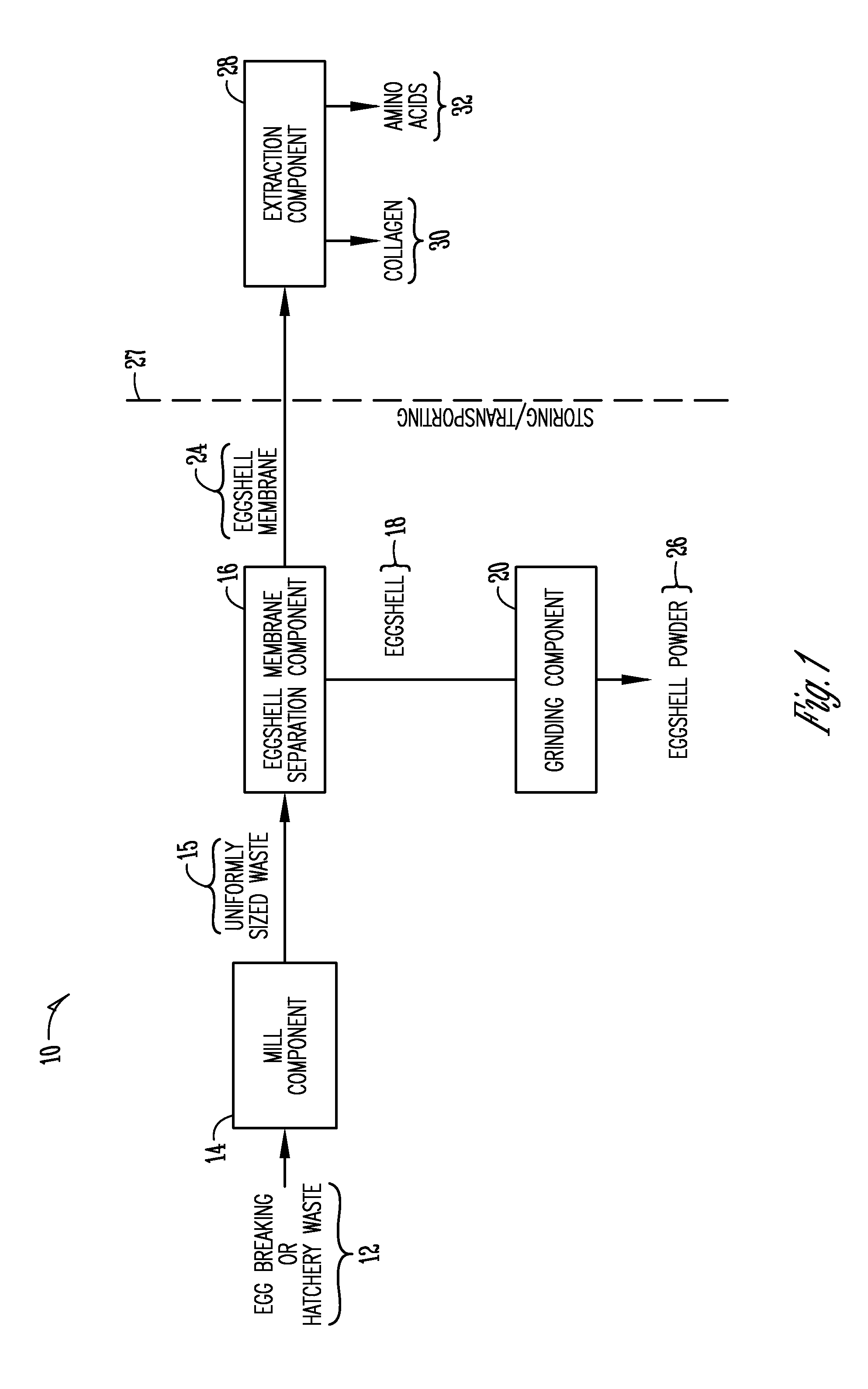

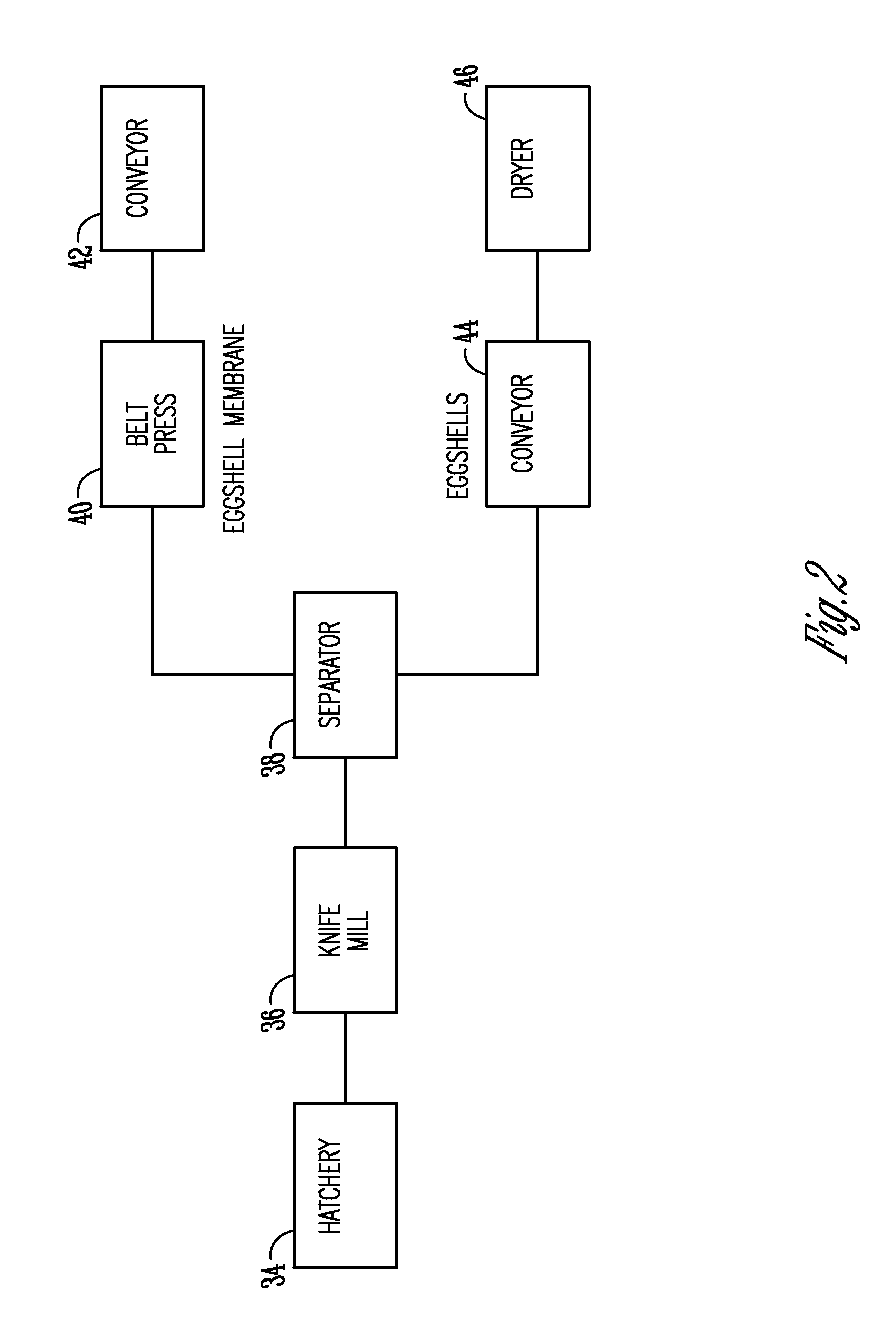

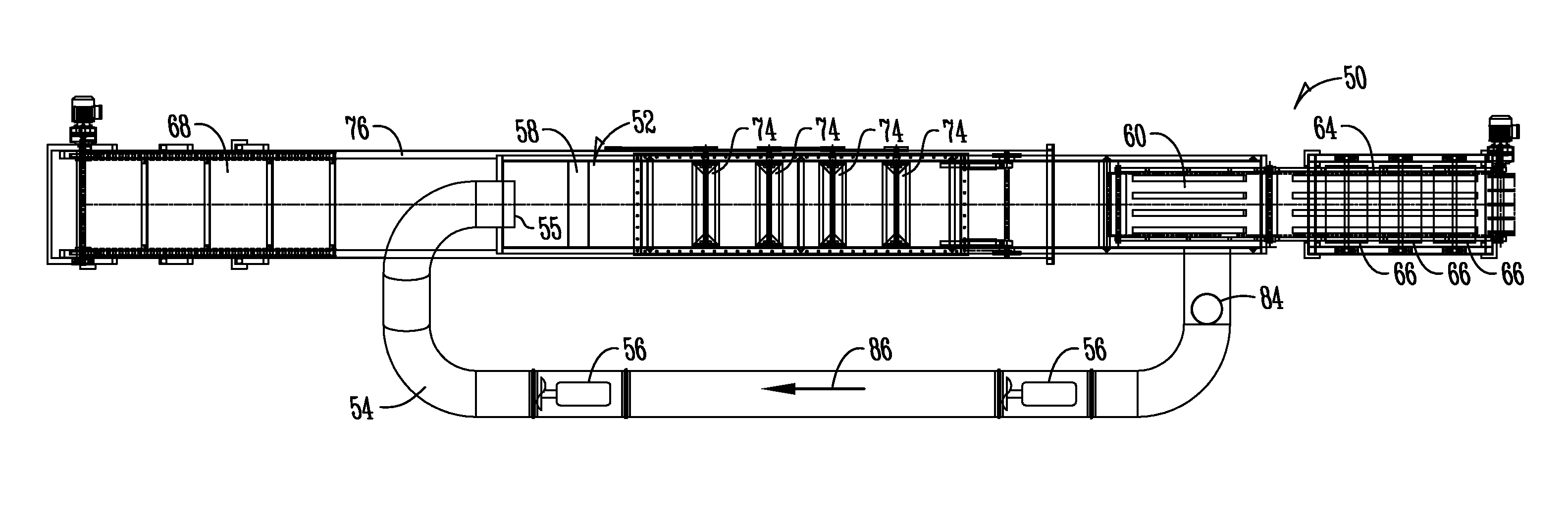

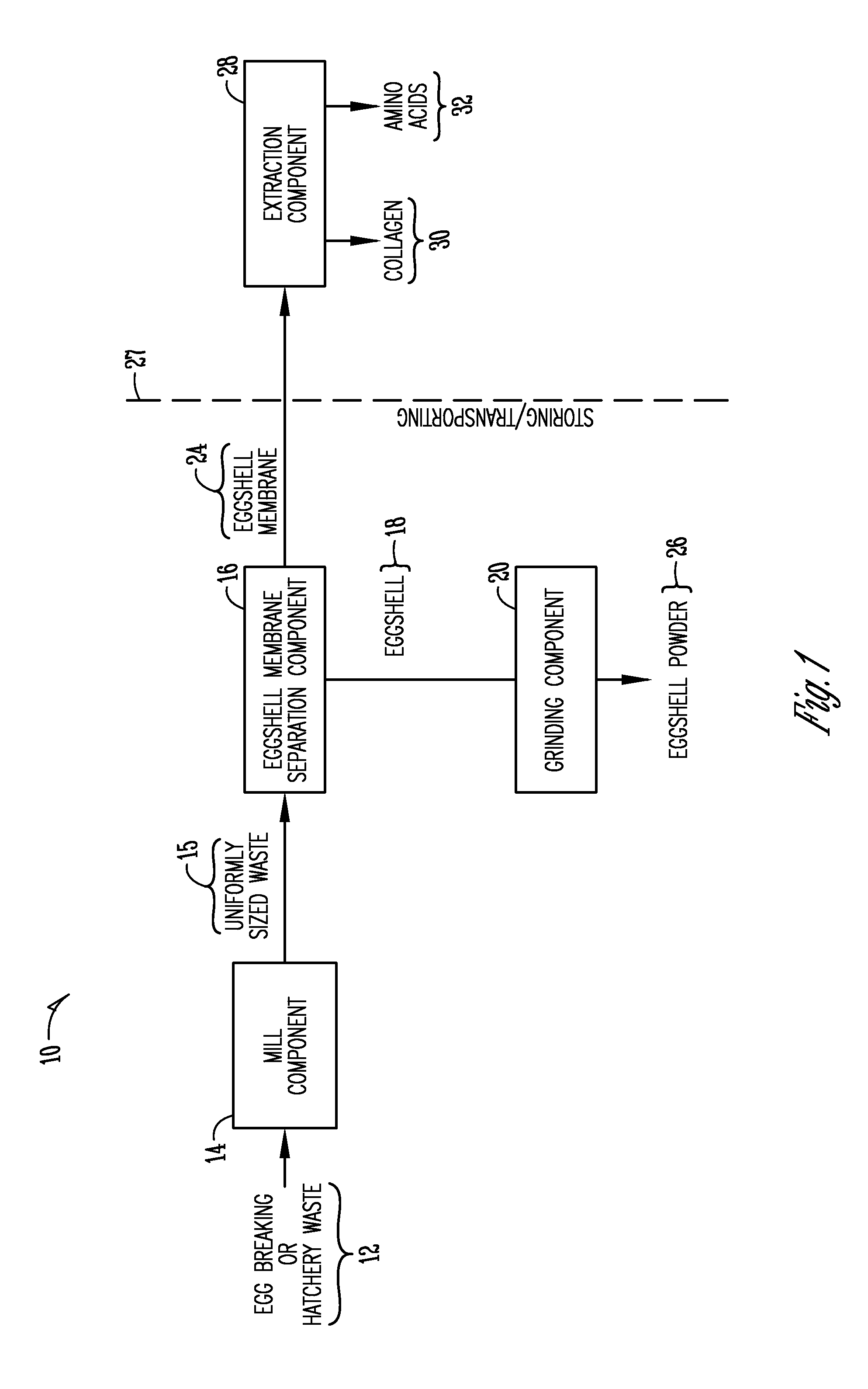

Egg shell membrane separation

ActiveUS8418943B2Reduce wasteNew revenue streamJuice extractionGas current separationAnimal scienceCavitation

A method for processing unseparated egg shells includes placing unseparated egg shells in a separation tank containing fluid, applying cavitation to the unseparated egg shells in the fluid to thereby separate the egg shell membranes from the egg shells, and recovering the egg shell membranes. An apparatus for processing unseparated egg shells includes a separation tank for holding a fluid, a recirculating loop operatively connected to the separation tank, and at least one submersible mixer in the recirculating loop to recirculate the fluid and egg shell membranes and egg shells within the fluid. The apparatus further includes a membrane collection conveyor for conveying egg shell membranes from the separation tank and a shell conveyor positioned beneath the separation tank for conveying egg shells away from the separation tank.

Owner:BIOVA

Composite absorption material capable of removing phosphate radical in water as well as preparation method thereof

InactiveCN102989422AImprove adsorption capacityDosage removal rate increasedOther chemical processesWater/sewage treatment by sorptionHigh absorptionPhosphate ion

The invention discloses a novel efficient composite absorption material prepared by loading modified wheatgrass straw negative ions on an egg shell membrane, and belongs to the field of water treatment. The invention also discloses a method for removing phosphate radical in water by utilizing the egg shell membrane loaded with the modified wheatgrass straw negative ions, namely, the composite absorption material can be used for absorbing and removing phosphate radical ions in water under a neutral condition. The novel efficient composite absorption material can be used for effectively absorbing the phosphate radical ions in the water, and solves the pollution problem of the phosphate radical fundamentally. The novel efficient composite absorption material has the characteristics of large specific surface area, high absorption efficiency, availability of raw materials, low material cost, high recovery rate and the like, is simple to operate, and is low in cost, and materials can be obtained easily, so that the novel efficient composite absorption material capable of removing the phosphate radical ions in the water, provided by the invention, has favorable economic and environment benefits.

Owner:CHANGZHOU UNIV

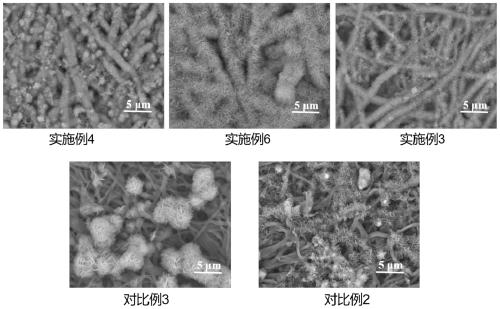

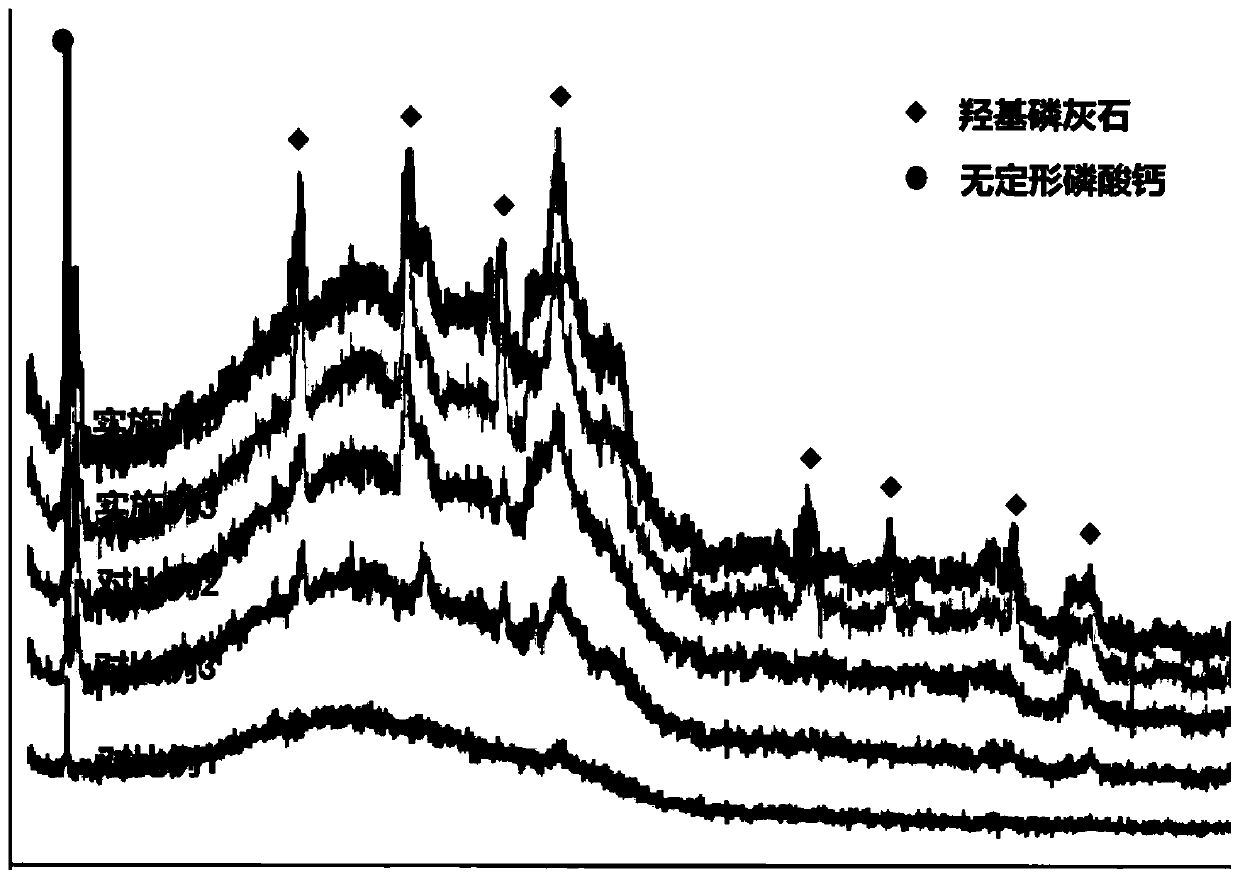

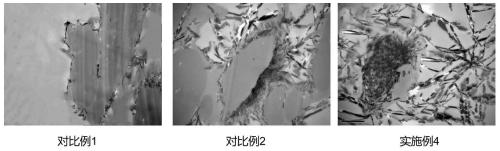

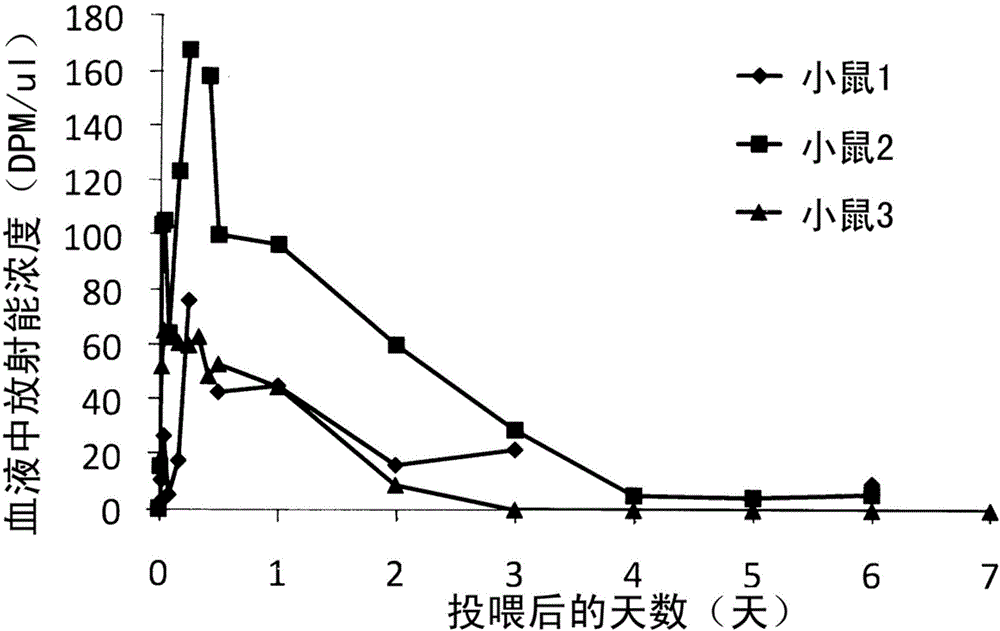

Biomimetic mineralized membrane prepared based on layered eggshell membrane and protein induction, preparation method and application

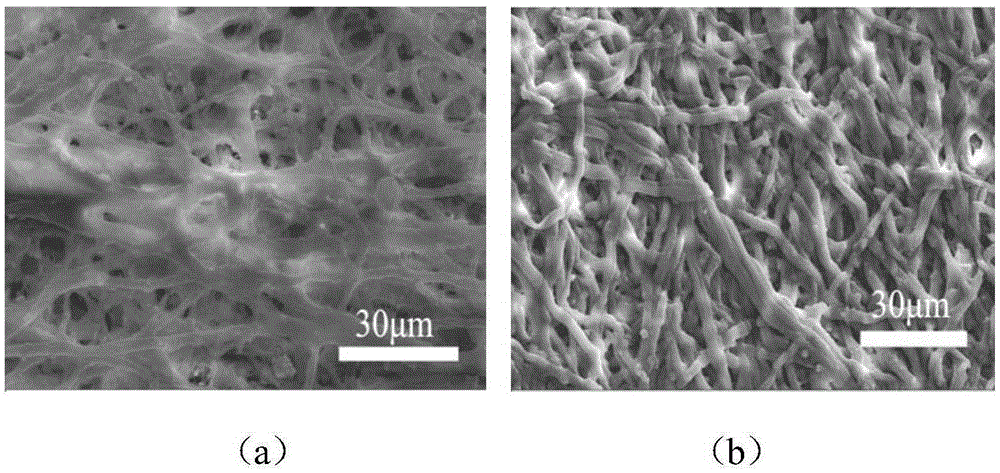

ActiveCN111330078AIrregular fiber network structureUniform fiber network structureTissue regenerationProsthesisProteaseEGG SHELL MEMBRANE

The invention belongs to the technical field of medical biomimetic materials, and particularly relates to a biomimetic mineralized membrane prepared based on layered eggshell membrane and protein induction, a preparation method and application. The preparation method comprises the following steps of: S1, material preparation, including three parts of preparing an eggshell membrane, preparing enzymatic hydrolysate and preparing protein mineralized liquid, wherein the enzymatic hydrolysate is prepared by dissolving protease and a reducing agent in deionized water and adjusting the pH to 6-9, andthe protein mineralized liquid is prepared by dissolving water-soluble protein in mineralized liquid; and S2, preparation of the biomimetic mineralized membrane, namely soaking the inner eggshell membrane and / or the outer eggshell membrane in the enzymatic hydrolysate to obtain a modified eggshell membrane; and placing the modified eggshell membrane in the protein mineralized liquid for treatmentto obtain the biomimetic mineralized membrane prepared based on layered eggshell membrane and protein induction. The biomimetic mineralized membrane can be used as a bone tissue repair material, andthe preparation process has the characteristics of high mineralization efficiency, short preparation cycle time and good mineralization effect.

Owner:HUAZHONG AGRI UNIV

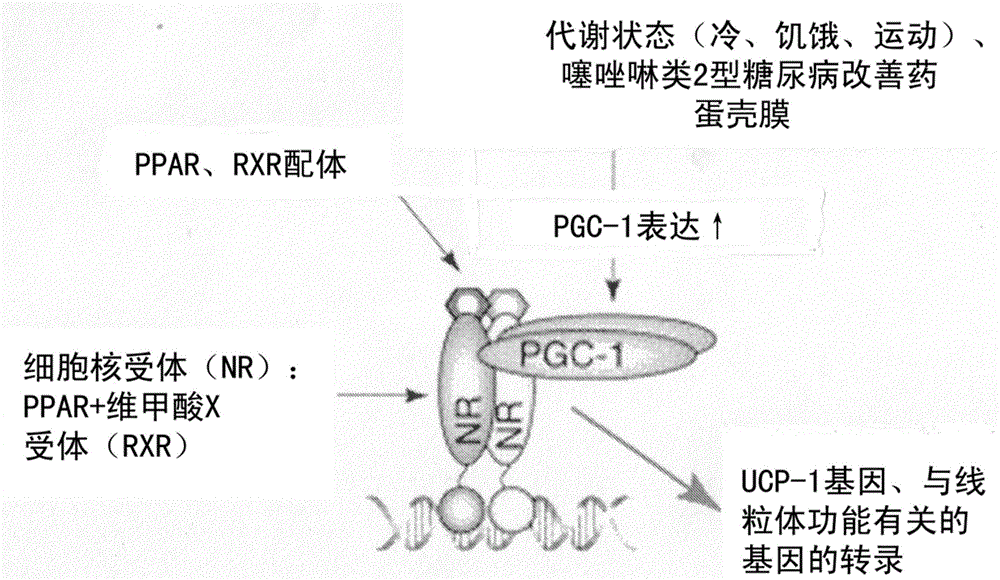

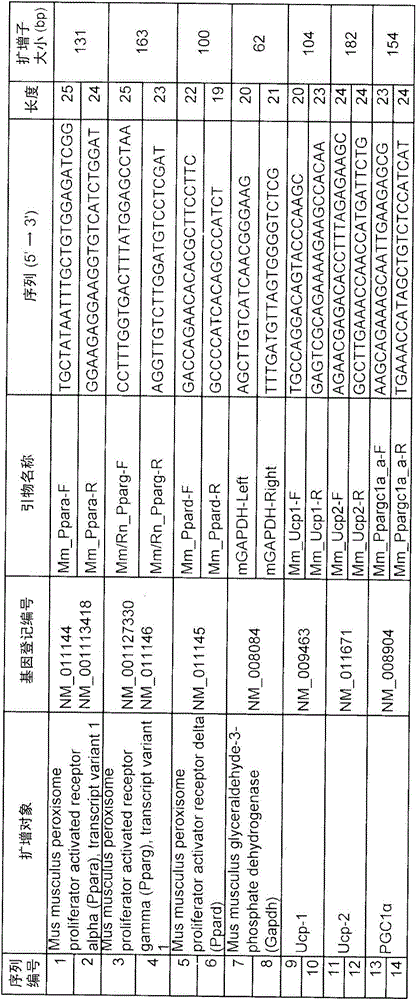

Insulin-sensitiizing Agents Containing Egg Shell Membrane Ingredient And Composition Using The Same

InactiveCN104666349AReduce riskEfficient use ofCosmetic preparationsMetabolism disorderAdditive ingredientEGG SHELL MEMBRANE

To provide an insulin resistance-improving agent, and the application thereof. The insulin resistance-improving agent contains an eggshell membrane component, for example, an eggshell membrane-containing powder or a soluble eggshell membrane component. Further, the eggshell membrane-containing powder to be used is a fine powder, and preferably has a volume average particle size of 6 μm or less, and / or a volume maximum particle size of 20 μm or less, but these particle sizes are not limited to the values.

Owner:THE UNIV OF TOKYO +1

Egg shell membrane separation

ActiveUS20110303771A1Reduce wasteNew revenue streamJuice extractionGas current separationAnimal scienceCavitation

A method for processing unseparated egg shells includes placing unseparated egg shells in a separation tank containing fluid, applying cavitation to the unseparated egg shells in the fluid to thereby separate the egg shell membranes from the egg shells, and recovering the egg shell membranes. An apparatus for processing unseparated egg shells includes a separation tank for holding a fluid, a recirculating loop operatively connected to the separation tank, and at least one submersible mixer in the recirculating loop to recirculate the fluid and egg shell membranes and egg shells within the fluid. The apparatus further includes a membrane collection conveyor for conveying egg shell membranes from the separation tank and a shell conveyor positioned beneath the separation tank for conveying egg shells away from the separation tank.

Owner:BIOVA

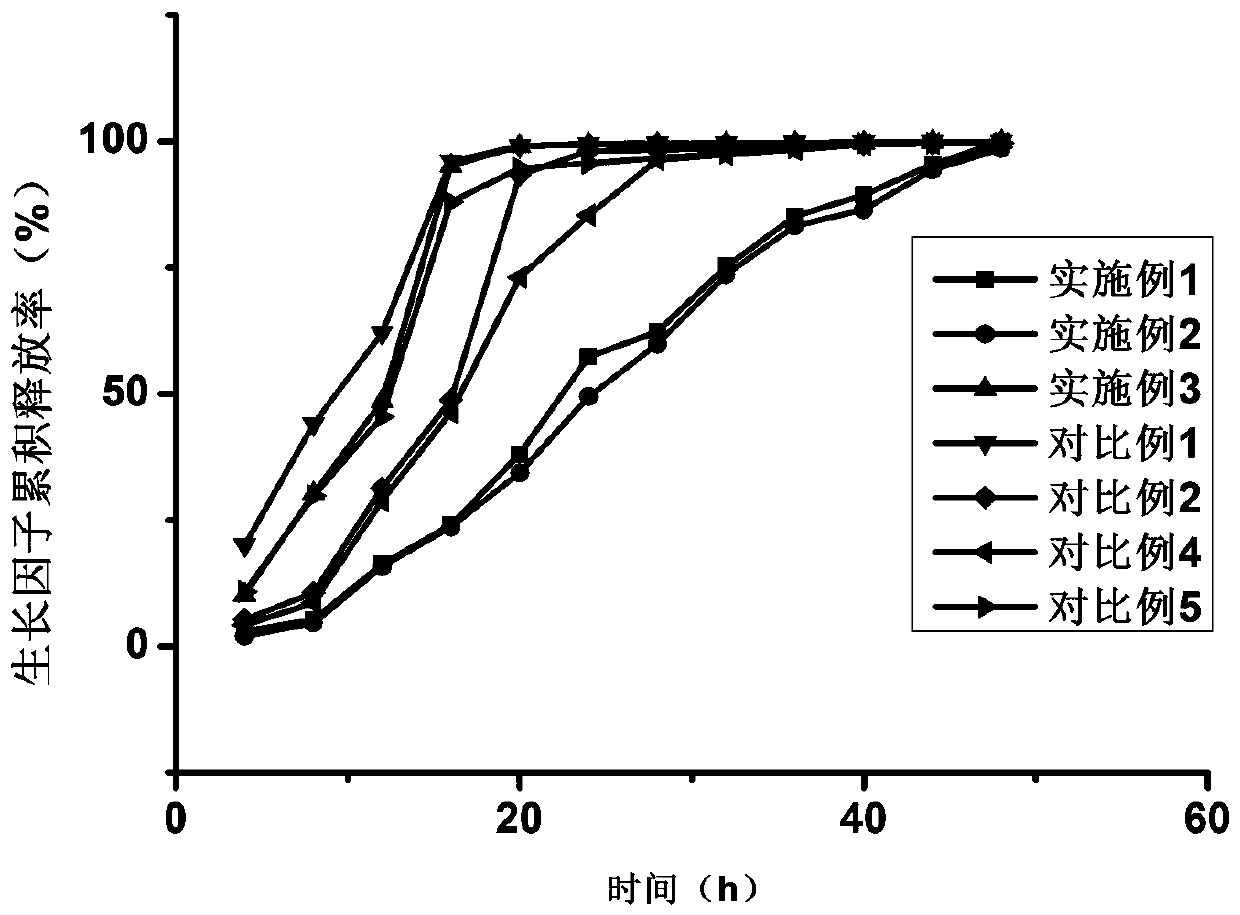

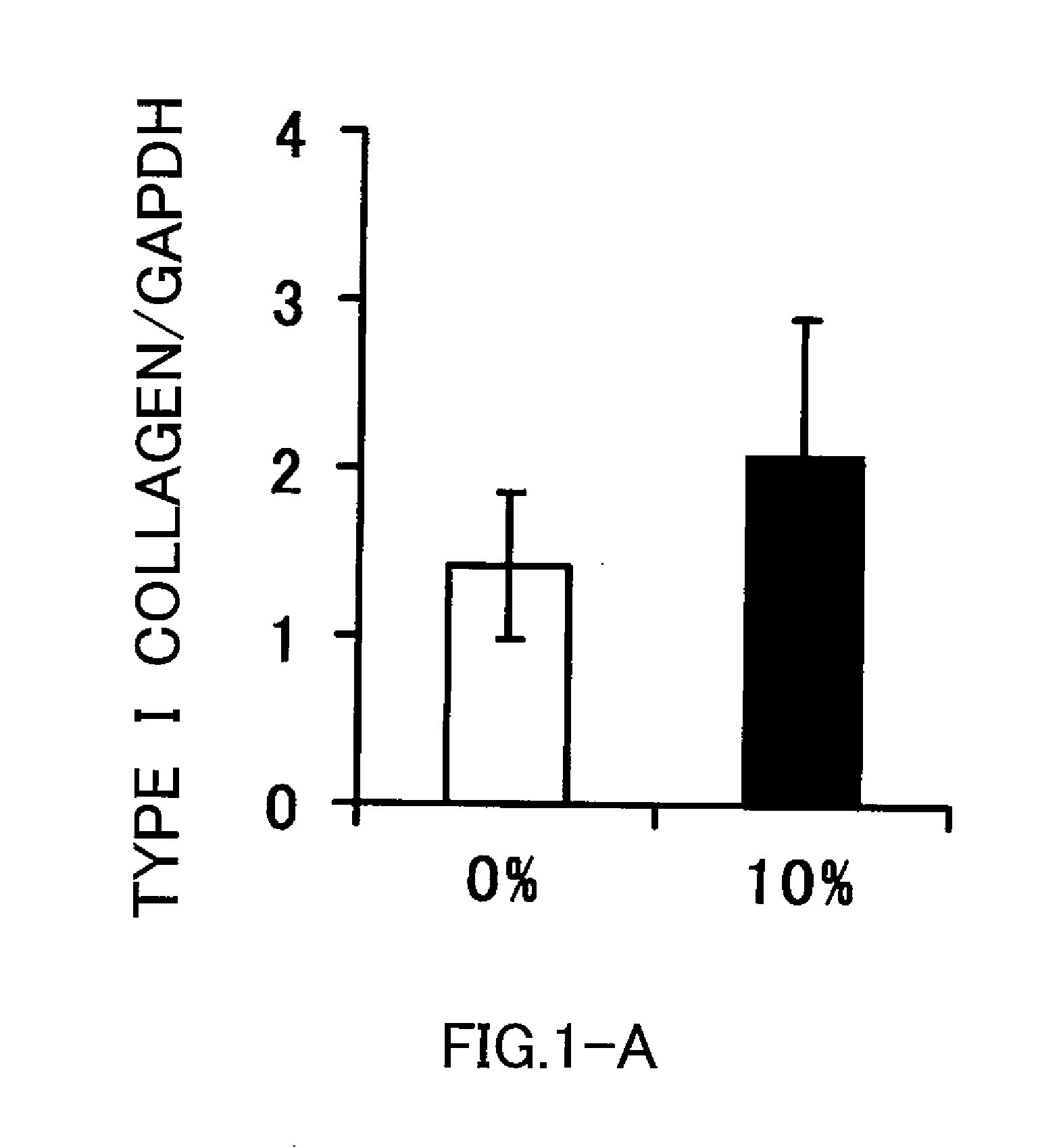

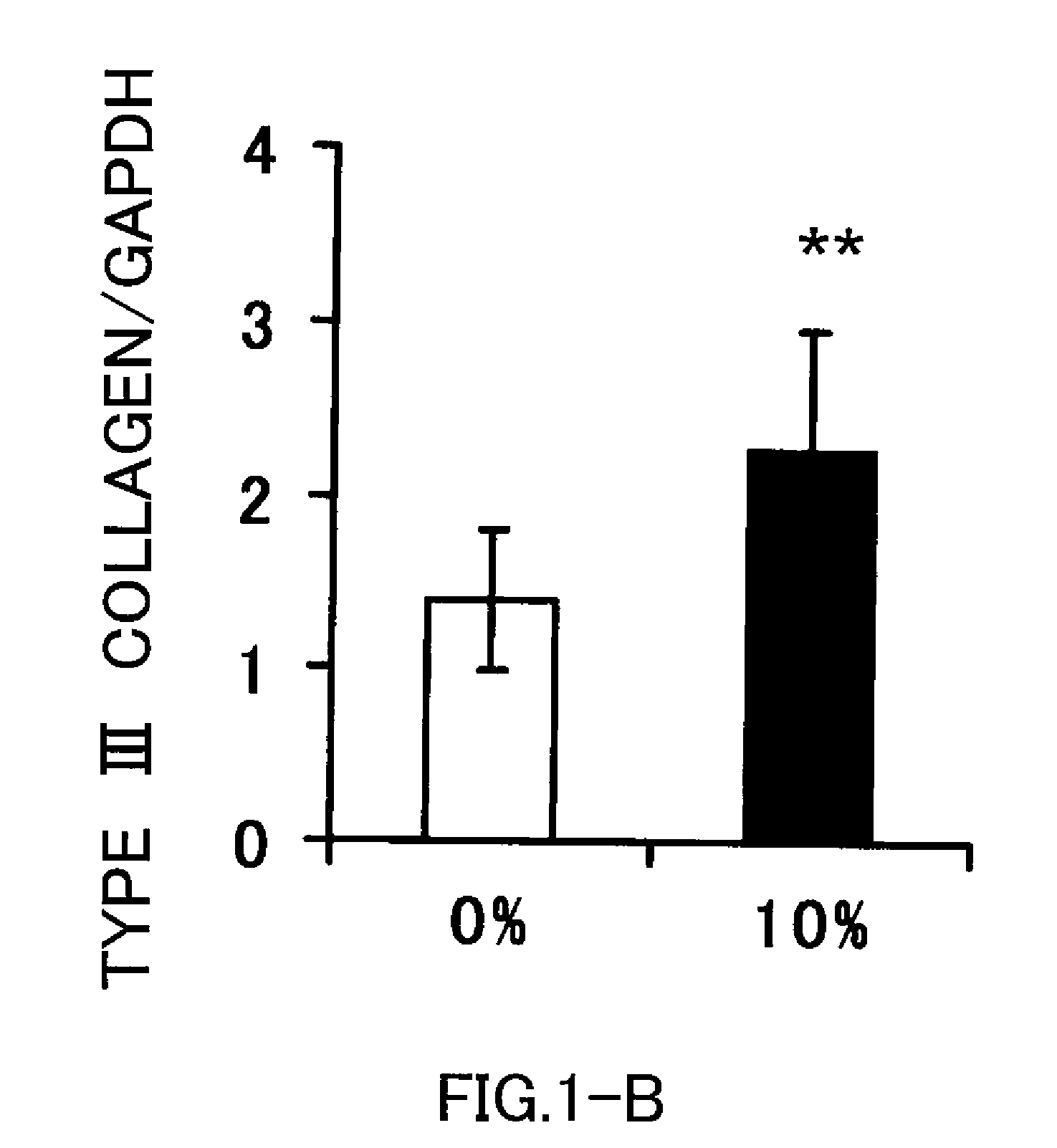

Growth factor-loaded micro-nano composite membrane

The invention discloses a growth factor-loaded micro-nano composite membrane. The micro-nano composite membrane is composed of a growth factor-loaded egg shell membrane, a protein membrane, a hydrophilic micro-nano fiber layer and a hydrophobic micro-nano fiber layer; the micro-nano composite membrane takes the egg shell membrane as a direct carrier of a growth factor, and meanwhile protein servesas a coating layer to be deposited on the surface of the growth factor-loaded egg shell membrane to form the protein membrane through salting out, and then the hydrophilic micro-nano fiber membrane and the hydrophobic micro-nano fiber membrane wrap the surface of the protein membrane in sequence through an electrostatic spinning technology; the protein membrane is obtained through salting-out sedimentation by adopting poultry egg white. The micro-nano composite membrane is reasonable in structural design, so that the loaded growth factor has the slow-release property, and the materials forming the membrane layers have the effect of keeping the growth factor activity.

Owner:HENAN YADU IND

Agent for activating sirtuin gene containing egg shell membrane ingredient and composition using the same

InactiveUS20140356450A1Method securityReduce riskCosmetic preparationsHair cosmeticsAdditive ingredientEGG SHELL MEMBRANE

Providing an agent for activating a sirtuin gene and an application thereof. The agent for activating a sirtuin gene is characterized to contain an egg shell membrane ingredient, for example an egg shell membrane-containing powder or soluble egg shell membrane ingredient.

Owner:THE UNIV OF TOKYO +1

Method of preparing C-doped porous nanometer TiO2 photocatalyst with egg shell membrane as template

InactiveCN100435938CPromote absorptionImprove adsorption capacityPhysical/chemical process catalystsDecompositionRoom temperature

The present invention discloses process of preparing C-doped porous nanometer TiO2 photocatalyst with egg shell membrane as the template. One process includes the steps of soaking egg shell in hydrochloric acid, separating egg shell membrane, washing, dewatering, soaking in isopropanol solution of tetrabutyl titanate, taking out, drying at room temperature and final high temperature calcining to obtain C-doped porous nanometer TiO2 photocatalyst. One other process includes the steps of soaking clean egg shell membrane first in AgNO3 solution and then in clucose solution for 24 hr each, taking out, dewatering, soaking in isopropanol solution of tetrabutyl titanate, taking out, drying at room temperature and final high temperature calcining to obtain nanometer Ag crystal and C-doped porous nanometer TiO2 photocatalyst. The said process has rich material source and mild condition, and the prepared photocatalyst has high organic pollutant decomposition catalyzing capacity.

Owner:TIANJIN UNIV

Elastic memory mask cream simulating effect of eggshell membrane and preparation method thereof

InactiveCN104069052AWith nourishing and repairing functionsFirming and whitening effectCosmetic preparationsToilet preparationsTricholoma matsutakeEggshell membrane

The invention relates to an elastic memory mask cream simulating the effect of an eggshell membrane and a preparation method thereof; the memory mask cream disclosed by the invention is composed of a component A, a component B, a component C and a component D; dual effects of skin cream and a peel-off mask are combined; the effect of the eggshell membrane is simulated by adopting a polyurethane high polymer memory function material; after the elastic memory mask cream is smeared on facial skin, the skin is obviously compact, brightened and fresh; with the help of the skin whitening and repairing effects of Acetyl carnosine-8 active peptide, the tricholoma matsutake extract and nicotinamide, fibroblast fibrocyte for promoting skin elasticity is increased and skin elasticity is improved while whitening and moisturizing; the elastic memory mask cream disclosed by the invention integrates the nourishing and repairing functions of the cream and the compacting and whitening effects of the mask, and therefore, the conventional multiple nursing problems are solved through one step.

Owner:陈来成

Pure natural lotion and preparation method thereof

InactiveCN106798721APromote blood circulationIncrease nutrient supplyCosmetic preparationsToilet preparationsWrinkle skinPropolis

The invention provides pure natural lotion and a preparation method thereof. The pure natural lotion comprises the following raw materials in parts by weight: 4-8 parts of dendrobii officmalis caulis, 10-15 parts of rhizoma polygonati odorati, 4-8 parts of propolis, 4-6 parts of molasses, 2-4 parts of radix angelicae dahuricae, 3-6 parts of radix angelicae pubescentis, 5-10 parts of radix ginseng leachate, 10-20 parts of goat milk, 3-6 parts of medulla spinalis caprinus, 2-4 parts of pearl powder and 3-6 parts of egg shell membrane powder. The pure natural lotion provided by the invention is made of a plurality of raw materials, can realize multiple effects of beautifying, skin care and bacterial inhibition simultaneously, enhances elasticity of the skin, activates cells, delays appearing of wrinkles, can be applied to the whole body, and is suitable for long-term use, simple in preparation method and convenient to popularize and use.

Owner:夏战利

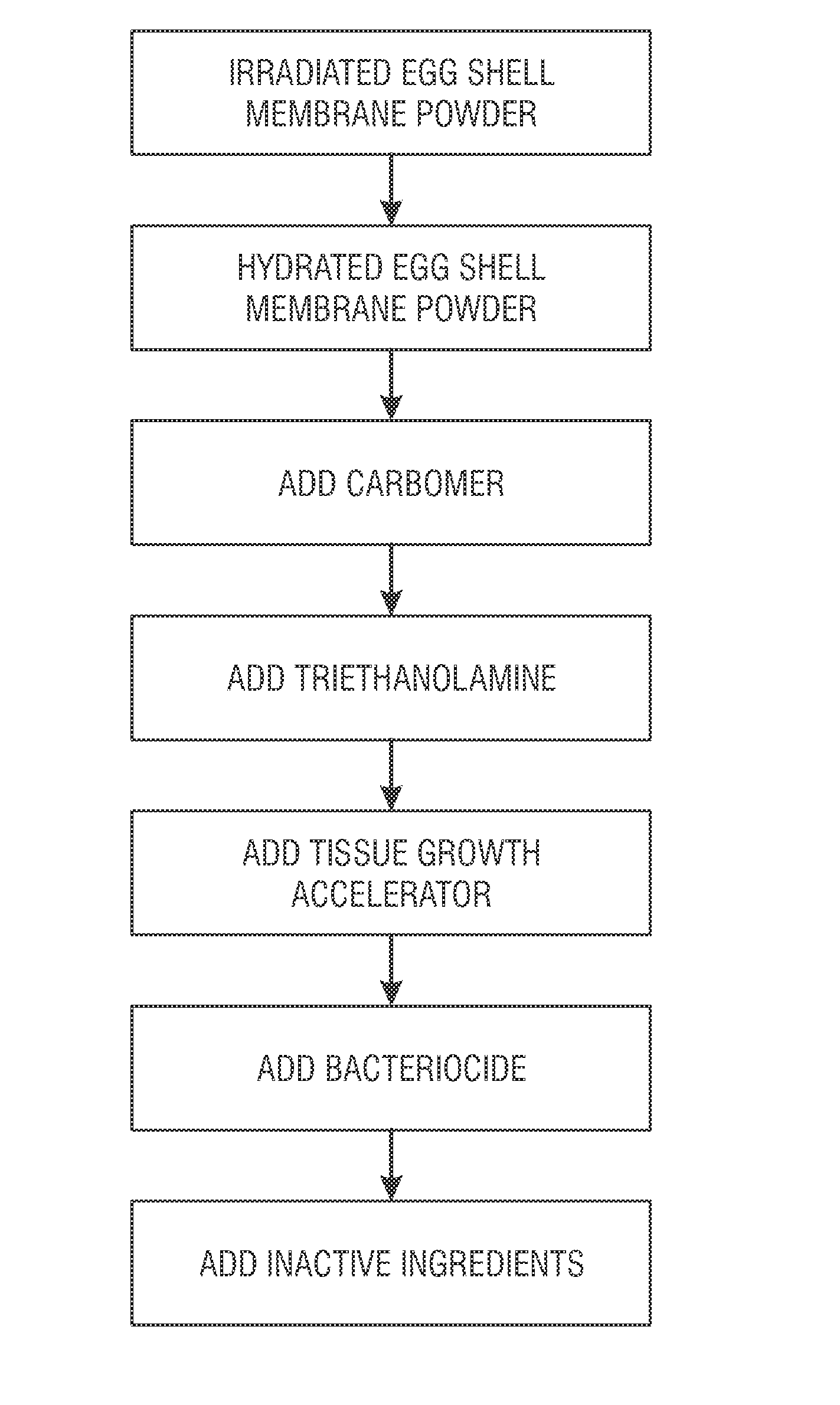

Wound care product with egg shell membrane

ActiveUS20140348939A1Prohibit migrationSatisfactory shelf lifeMammal material medical ingredientsBird material medical ingredientsMedicineWound care

A wound care product in the form of a gel is provided, and contains protein from egg shell membrane. The gel is made by first hydrating the egg shell membrane powder and then adding carbomer to partially neutralize the egg shell membrane. The neutralization is completed with the addition of triethanolamine, so as to form a homogeneous gel with a smooth consistency. An antimicrobial compound and a tissue growth accelerator are added to the gel. The gel, infused with egg shell membrane, is applied directly to the wound tissue to form a barrier trapping the active ingredients adjacent the wound site and inhibiting penetration of outside bacteria into the wound site.

Owner:BLAINE LAB

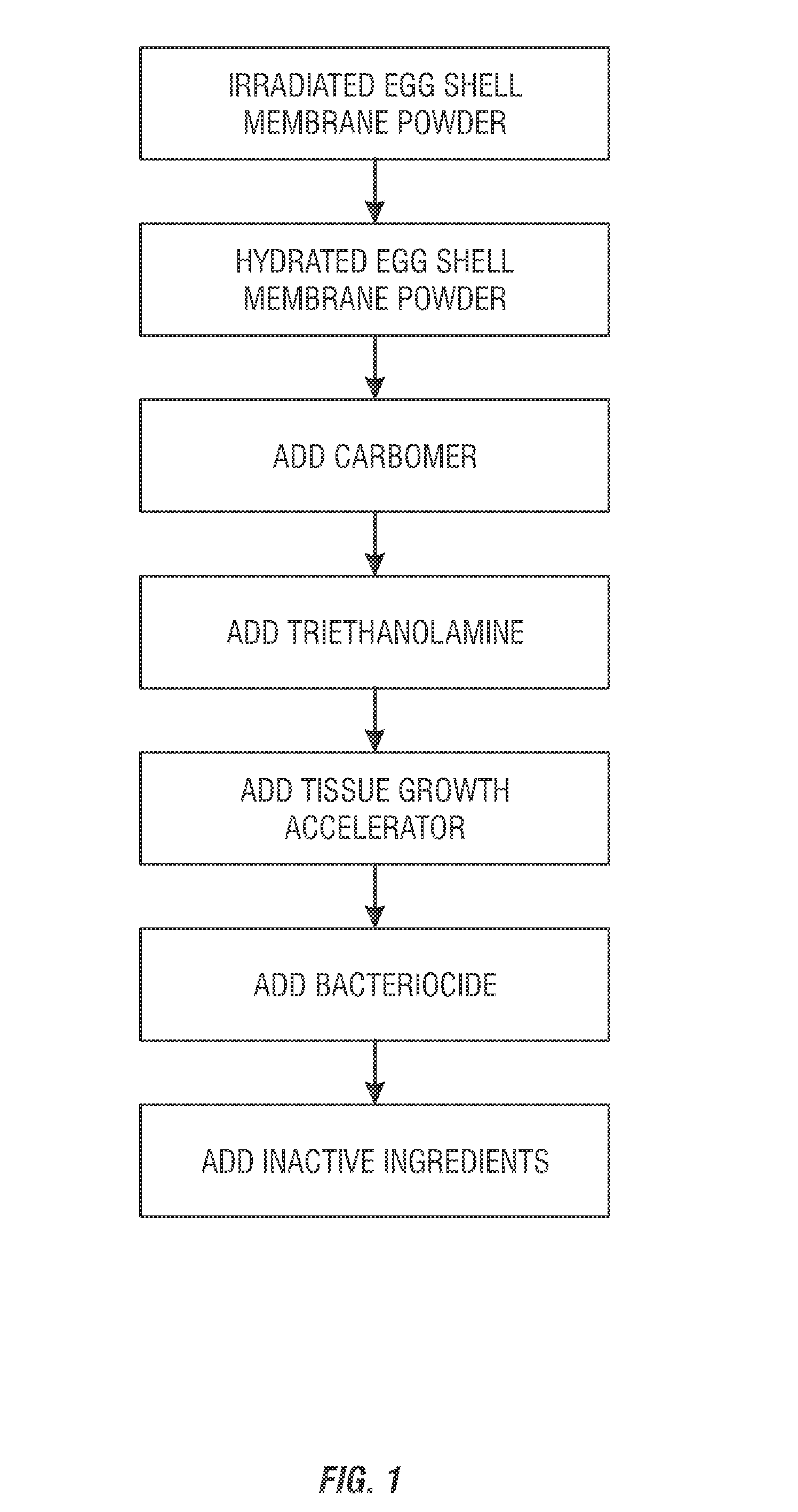

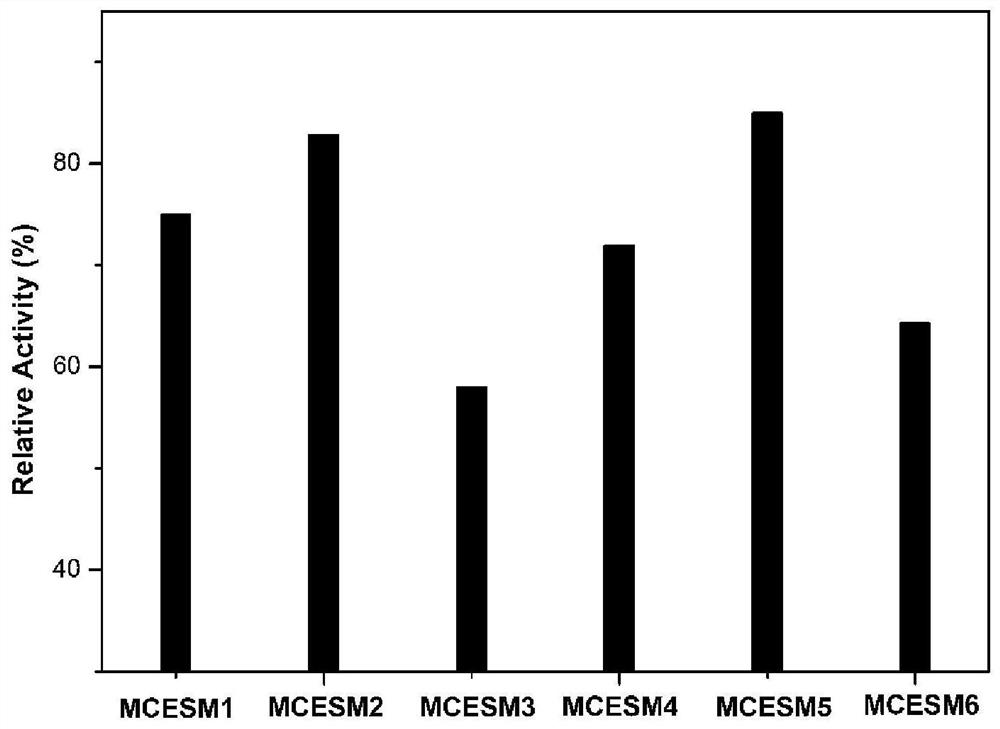

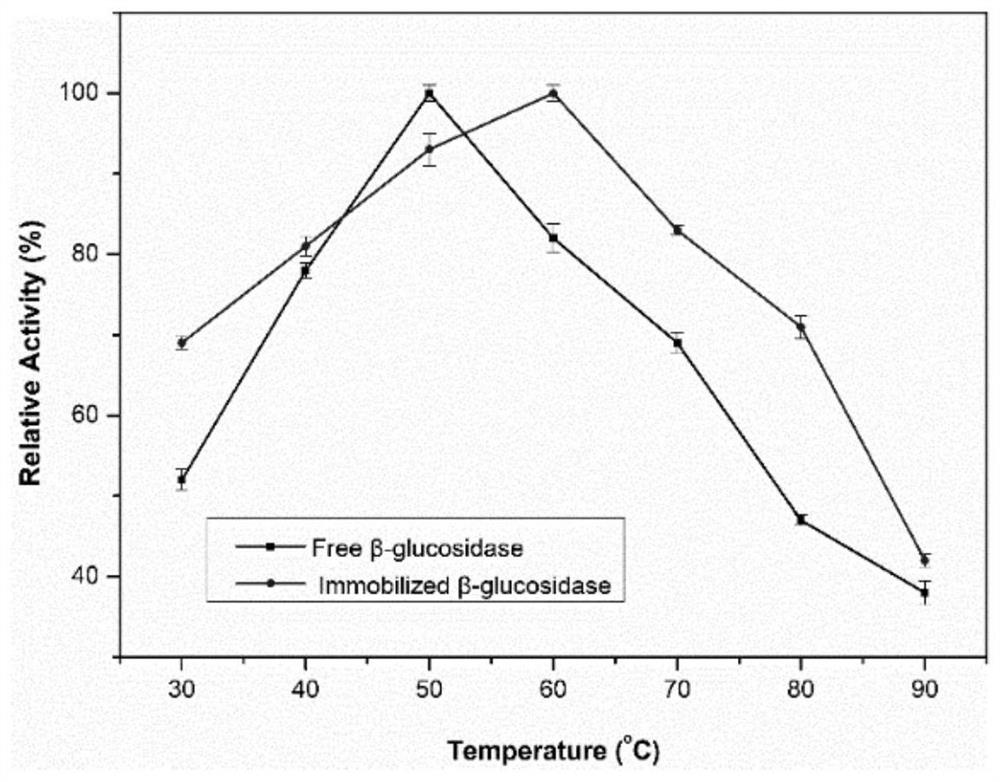

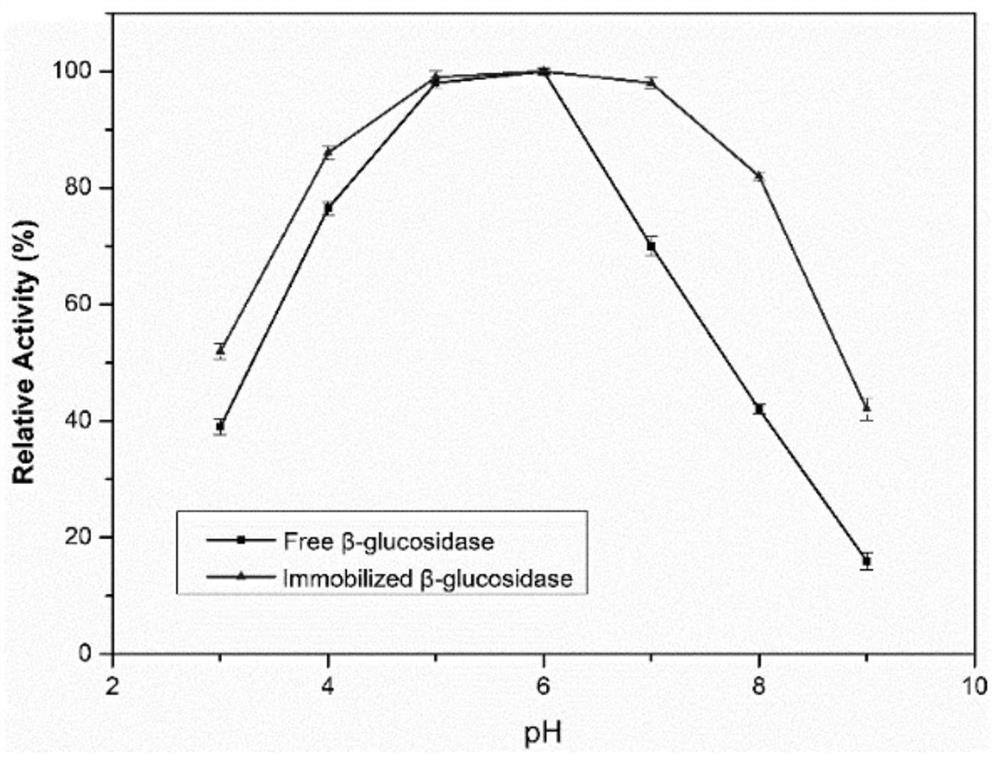

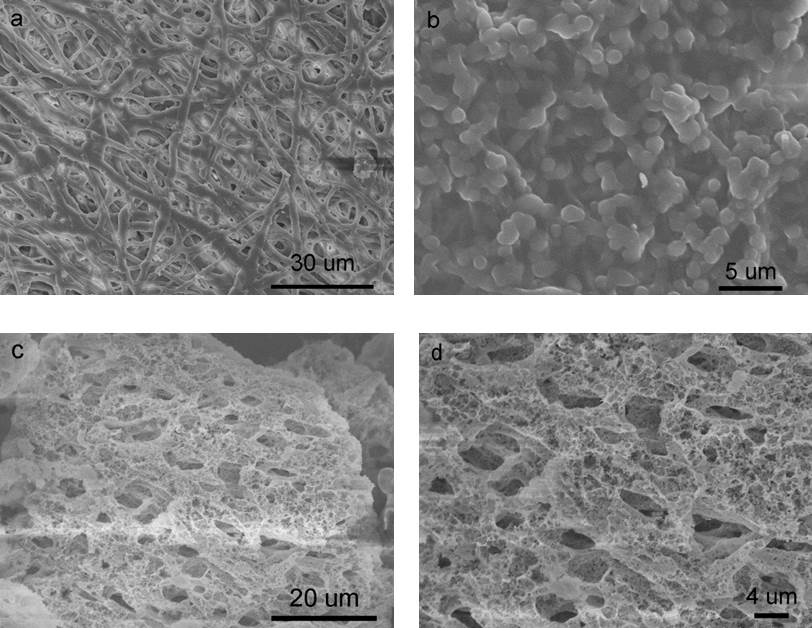

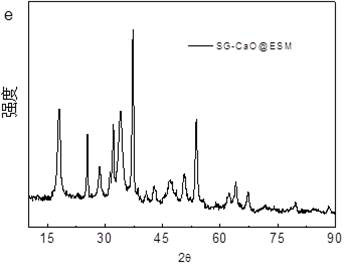

Immobilized enzyme carrier, immobilized enzyme and preparation method

PendingCN113652415AImprove structural rigidityEasy to separate and collectOn/in organic carrierOn/in inorganic carrierEnzyme structureGenipin

The invention discloses an immobilized enzyme carrier, an immobilized enzyme and a preparation method. According to the method, macromolecular particles of chitosan are attached to the surface of an egg shell membrane, magnetic Fe3O4 is uniformly precipitated and distributed on the egg shell membrane in a co-precipitation mode, the prepared magnetic Fe3O4 / CS / ESMP serves as an enzyme carrier of immobilized beta-glucosidase, the rigidity and tolerance of an enzyme structure are improved, and good operation stability is achieved; in addition, the prepared Fe3O4 / CS / ESM@BG can be repeatedly used, and the operation is simple and convenient. The Fe3O4 / CS / ESMP@BG is easy to separate and collect under the action of a magnetic field so as to be recycled, the use efficiency of enzyme is improved, and the prepared Fe3O4 / CS / ESMP@BG can be applied to biosynthesis of genipin.

Owner:SOUTHEAST UNIV

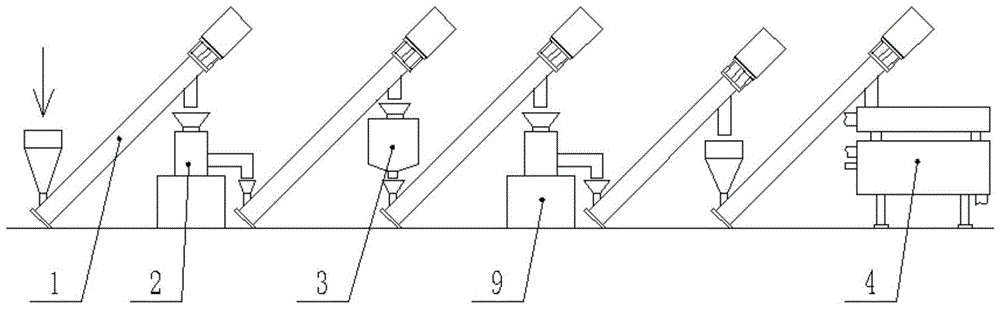

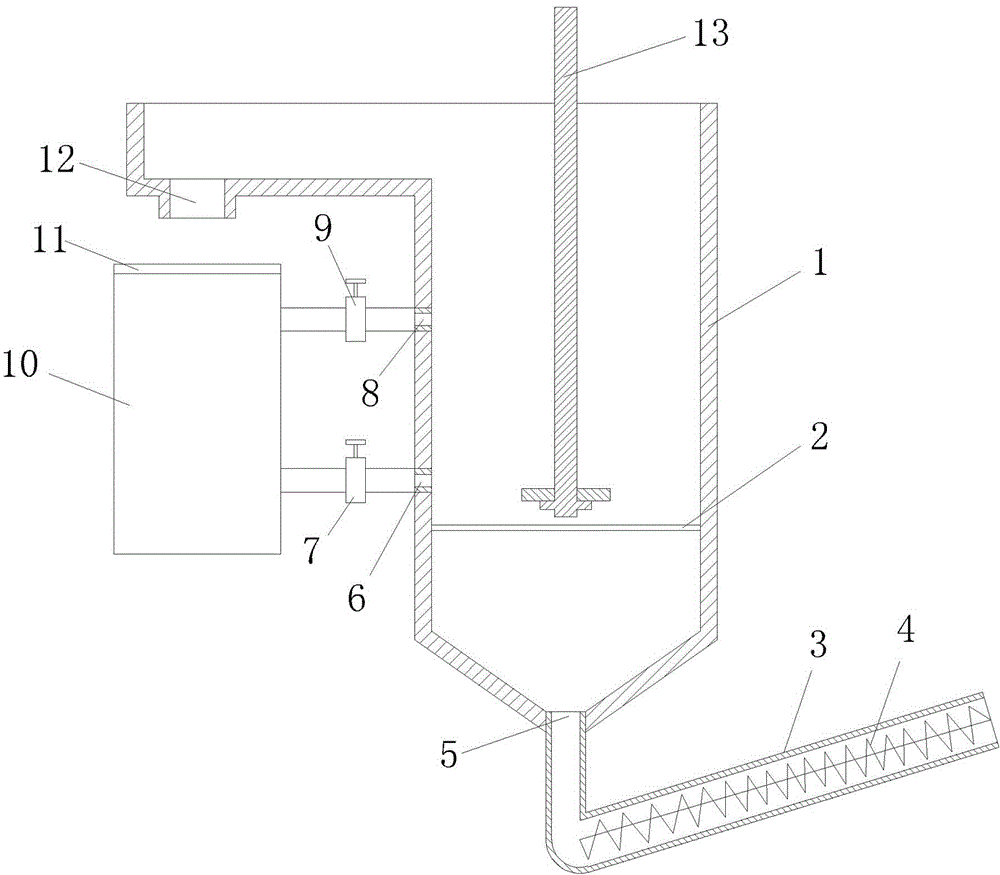

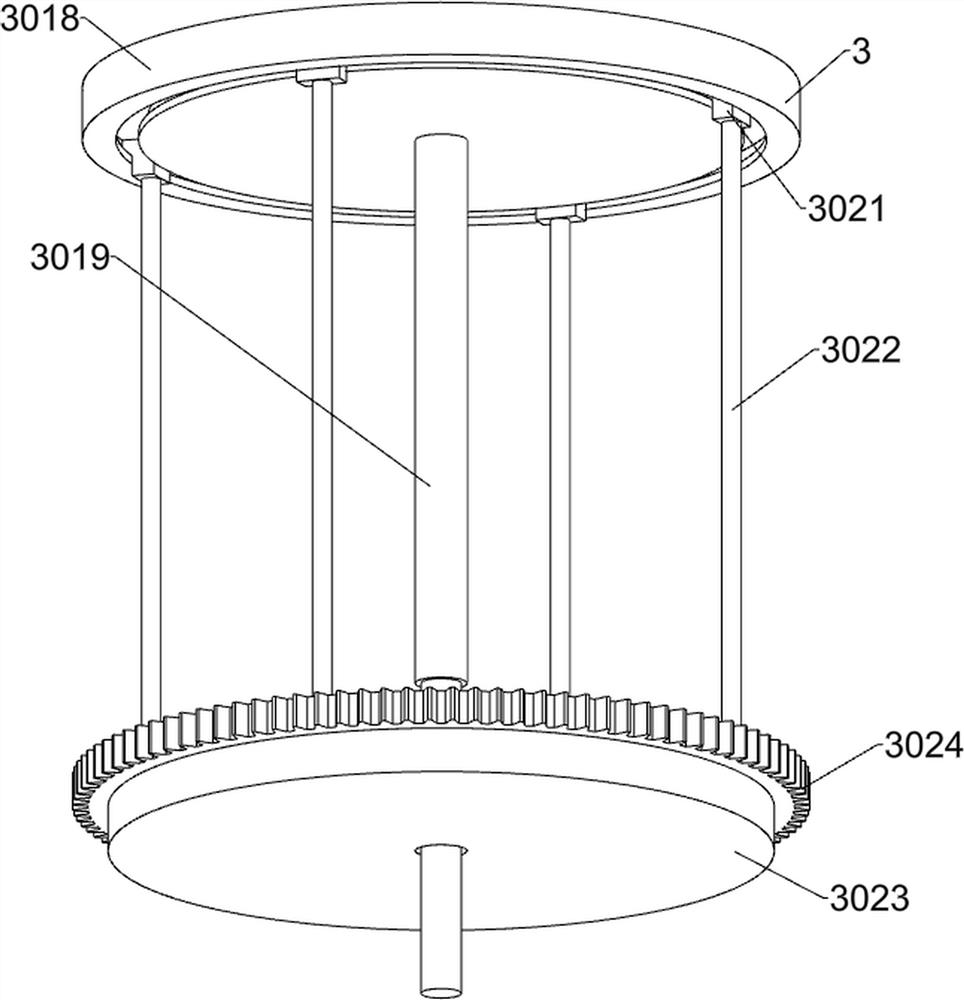

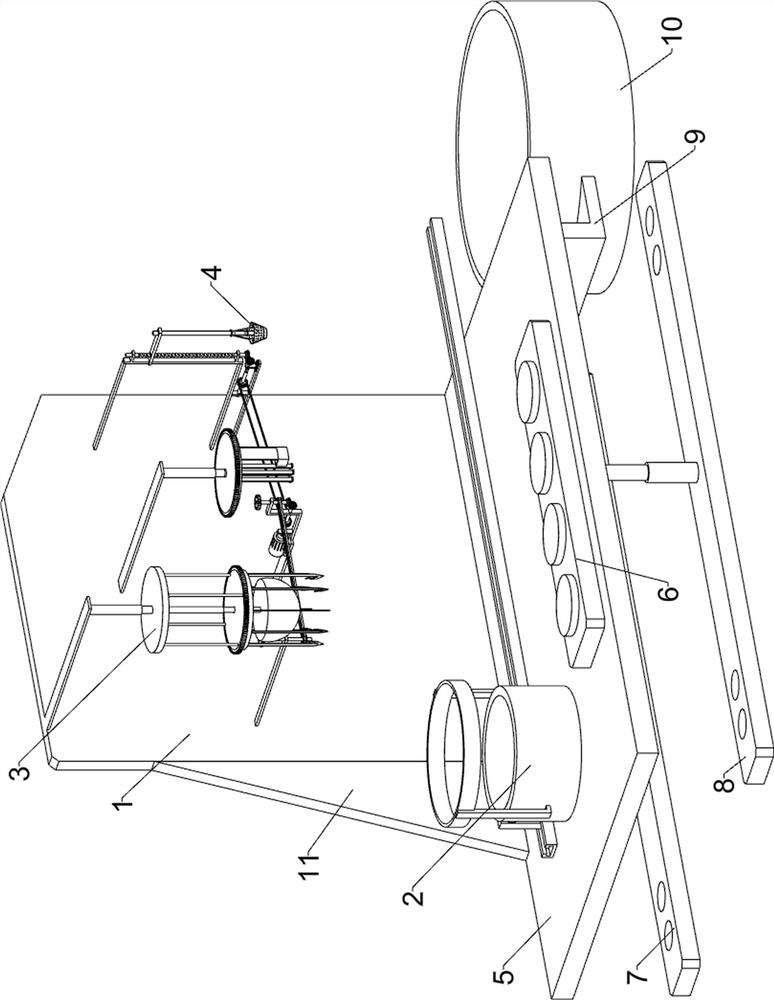

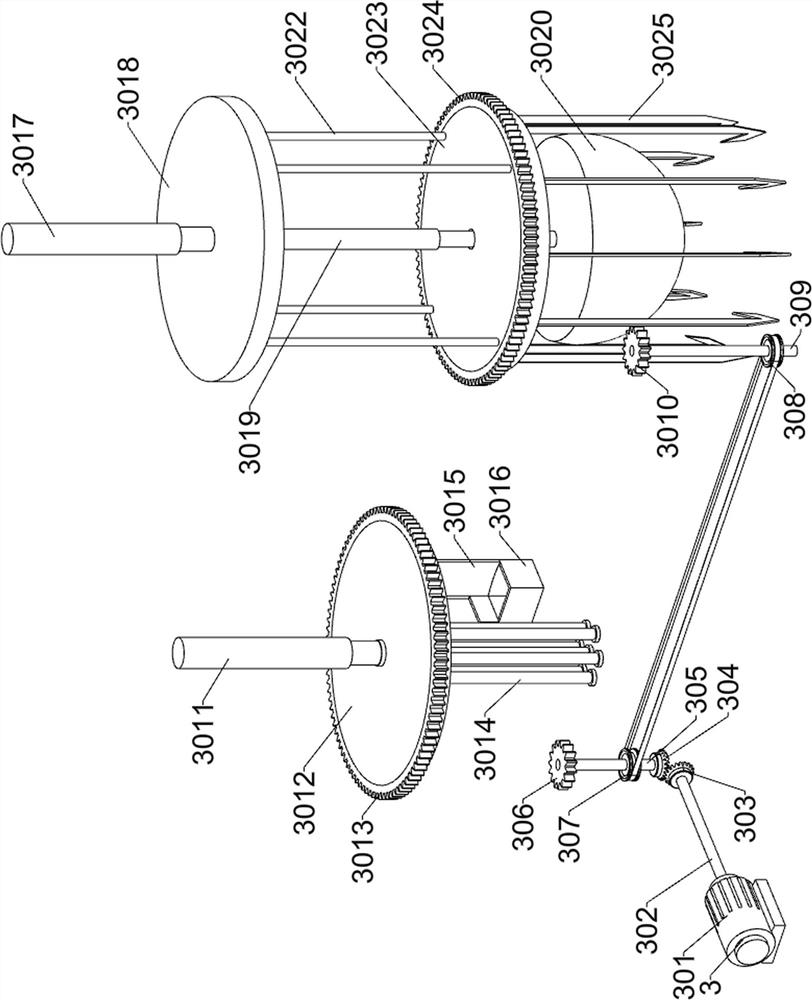

Poultry egg shell-membrane separation equipment

ActiveCN103340441BSimple processLow costSolid waste disposalFood preparationWater sourceEGG SHELL MEMBRANE

The invention discloses poultry egg shell-membrane separation equipment comprising a cylinder body for water injection. A membrane outlet is formed in the side wall of the top of a cylinder body. The bottom of the cylinder body is provided with a shell outlet. A stirring device for stirring to separate a shell from a membrane is arranged in the cylinder body. The side wall of the middle part of the cylinder body is provided with an upper water inlet and a lower water inlet which are connected with a pressure water source via pipelines. The pipelines are provided with control valves for controlling the flow of the upper water inlet and the lower water inlet respectively. After being impacted and separated by the pressure water flow of the cylinder body from the upper water inlet and the lower water inlet, the shell-under membrane and the egg shell are distributed at the top and bottom of the cylinder body. The poultry egg shell-membrane separation equipment disclosed by the invention has the advantages of simple technology, low equipment cost and operation cost, quickness in shell-membrane separation, and convenience for large-scale industrial production, and the like.

Owner:北京二商健力食品科技有限公司 +1

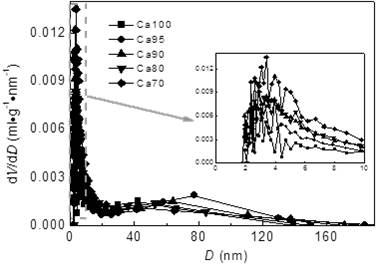

Method for preparing porous calcium-based material from eggshell and application of porous calcium-based material in thermochemical energy storage

ActiveCN113512409AImprove cycle stabilityImprove performanceHeat storage plantsHeat-exchange elementsEGG SHELL MEMBRANEPhysical chemistry

The invention discloses a method for preparing a porous calcium-based material from eggshells and application of the porous calcium-based material in thermochemical energy storage, and belongs to the technical field of thermochemical energy storage. The preparation method comprises the following steps: preparing calcium nitrate by taking egg shells as a calcium source, preparing a calcium nitrate-coated egg shell membrane material by taking an egg shell membrane as a template and citric acid as a gelling agent and adopting a sol-gel method, then cleaning and filtering the obtained material, and calcining at high temperature of 650 DEG C for 2 hours to remove the egg shell membrane template to obtain the porous calcium-based material. The magnesium-doped calcium-based material prepared in the invention has good cycle stability and shows good energy storage performance in calcium carbonate / calcium oxide / carbon dioxide cycle, and the preparation method has the advantages of low cost and simple preparation process, and is suitable for industrial scale-up production in the future.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

A method for preparing polyethylene glycol-protein fiber composite artificial heart valve

ActiveCN105326581BPrevent enzymatic degradationIncreased durabilityHeart valvesProsthetic valveDecomposition

The invention discloses a method of preparing a polyethylene glycol and protein fiber combined artificial cardiac valve and belongs to the field of biomedical materials. The method comprises: covering egg shell membrane protein fiber with photo-crosslinked polyethylene glycol hydrogel to obtain a composite material, and preparing the composite lamellar artificial cardiac valve through crosslinking by further using a molecular crosslinking agent (such as glutaraldehyde). The polyethylene glycol hydrogel is prepared by means of photo-crosslinking, ensuring the integrity of artificial valve materials, protecting the covered protein fiber from the in-vivo enzymatic decomposition and preventing calcification of the artificial valve. The artificial cardiac valve material prepared by the method simulates the lamellar structure of human aortic valves and has mechanical properties similar to those of the human aortic valves, with good biocompatibility guaranteed, and the need of a replacement receptor for high valve durability, good tissue compatibility and dispensing with a lifetime of anticoagulation can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sunken type influenza virus chick embryo allantoic fluid extraction device

InactiveCN113444627ASolve pollutionReduce scatterBioreactor/fermenter combinationsBiological substance pretreatmentsEGG SHELL MEMBRANEAllantois

The invention relates to the field of viruses, and particularly relates to a sunken type influenza virus chick embryo allantoic fluid extraction device. The sunken type influenza virus chick embryo allantoic fluid extraction device comprises a transportation assembly, a shell breaking assembly, a fluid extraction assembly, a bottom plate, a control button and the like; the bottom plate is fixedly connected with a first fixing plate; and a first connecting block is fixedly connected with a first channel block. When the device is used, the upper cavity position of an eggshell is automatically broken into a cracking state, then the cracked eggshell and an eggshell membrane are torn off together, the phenomenon that the eggshell is scattered is reduced, meanwhile, the phenomenon that the eggshell falls into the chorio-allantoic membrane when the middle of the chorio-allantoic membrane is opened is completely eradicated, meanwhile, the phenomenon that the eggshell falls into the chorio-allantoic membrane when touching the edge of the opening of the chick embryo in the liquid taking process is avoided, pollution is avoided, and overflowing allantoic liquid is automatically prevented from contaminating the eggshell left on the periphery of the upper part of the chorio-allantoic membrane.

Owner:刘玉清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com