Dye-sensitized solar cell counter electrode material prepared by using eggshell membrane and method

A technology of solar cells and dye sensitization, which is applied in the field of solar cells, can solve the problems of loss, electron collection and conversion efficiency reduction, expensive platinum electrodes, etc., and achieve simple process and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

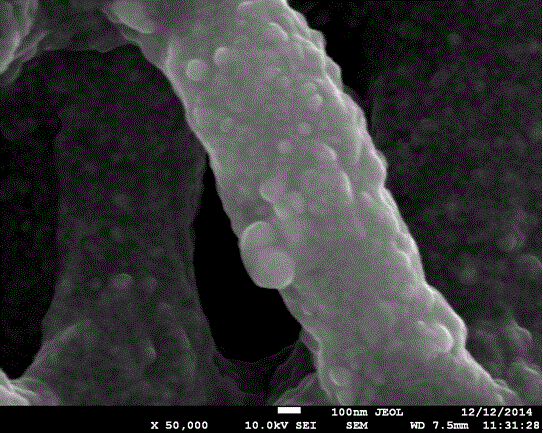

Image

Examples

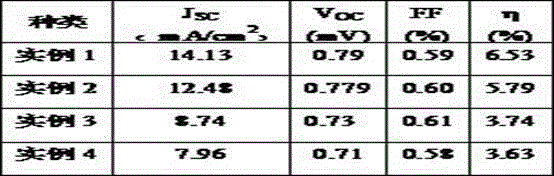

Embodiment 1

[0019] The method for preparing a dye-sensitized solar cell counter electrode material using eggshell membranes adopts the following steps:

[0020] (1) Take a fresh eggshell, peel off the white egg membrane inside the shell, wash and dry it with deionized water, and soak it in 0.6mol / L hydrochloric acid for 5 hours. Then rinse with deionized water for 3 times and dry in a drying oven at 60°C;

[0021] (2) According to the principle that the molar ratio of Cu:In:S atoms in the solution is 1:0.5:2, copper sulfate (CuSO 4 ), indium chloride (InCl 3 ) and thioacetamide (C 2 h 5 NS), stirred at room temperature for 5 to obtain a copper-sulfur-indium precursor;

[0022] (3) Put the eggshell membrane obtained in step (1) into the CuInS obtained in step (2) 2 Precursor solution, soaked at room temperature for 10 hours, then rinsed with deionized water for 3 times, and dried at 50°C for 10 hours;

[0023] (4) Place the egg membrane with the copper-sulfur-indium precursor adsorbe...

Embodiment 2

[0027] The method for preparing a dye-sensitized solar cell counter electrode material using eggshell membranes adopts the following steps:

[0028] (1) Take a fresh eggshell, peel off the white egg membrane inside the shell, wash and dry it with deionized water, and soak it in 0.7mol / L hydrochloric acid for 7 hours. Then rinse with deionized water for 3 times, and dry in a drying oven at 70°C;

[0029] (2) Add copper sulfate (CuSO 4 ), indium chloride (InCl 3 ) and thioacetamide (C 2 h 5 NS), stirred at room temperature for 6h to obtain the precursor solution of copper-sulfur-indium;

[0030] (3) Put the eggshell membrane obtained in step (1) into the CuInS obtained in step (2) 2 Precursor solution, soaked at room temperature for 12 hours, then rinsed with deionized water for 3 times, and dried at 60°C for 10 hours;

[0031] (4) Place the egg film with the copper-sulfur-indium precursor adsorbed in step (3) in a vacuum sintering furnace, and carbonize at 550°C for 3h in...

Embodiment 3

[0034]The method for preparing a dye-sensitized solar cell counter electrode material using eggshell membranes adopts the following steps:

[0035] (1) Take a fresh eggshell, peel off the white egg membrane inside the shell, wash and dry it with deionized water, and soak it in 1.0mol / L hydrochloric acid for 15 hours. Then rinse with deionized water for 3 times and dry in a drying oven at 80°C;

[0036] (2) Add copper sulfate (CuSO 4 ), indium chloride (InCl 3 ) and thioacetamide (C 2 h 5 NS), stirred at room temperature for 12h to obtain a copper-sulfur-indium precursor;

[0037] (3) Put the eggshell membrane obtained in step (1) into the CuInS obtained in step (2) 2 Precursor solution, soaked at room temperature for 16 hours, then rinsed with deionized water for 3 times, and dried at 80°C for 10 hours;

[0038] (4) Put the egg film adsorbed with copper-sulfur-indium precursor obtained in step (3) in a vacuum sintering furnace, and carbonize at 700°C for 5h in an argon a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com