Method of preparing C-doped porous nanometer TiO2 photocatalyst with egg shell membrane as template

A nano-photocatalyst and eggshell membrane technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems that hinder the application of TiO2, and have not yet discovered the public report of research results, so as to facilitate separation , abundant sources and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After washing 50 g of fresh egg shells with tap water, soak them in 100 mL 2M HCl. After the calcium carbonate in the egg shells is decomposed, the egg shell membrane (EM) can be obtained after separation. Then, first clean the EM with deionized water, and then soak and dehydrate it with isopropanol, change the solvent at regular intervals to remove the water, and finally soak the obtained EM in isopropanol for later use. The dehydrated EM was soaked in a prepared 50 mL 10 wt% isopropyl alcohol solution of tetrabutyl titanate, taken out after 3 hours, and placed in the air to dry for 48 hours. Then, it was placed in a temperature-controlled muffle furnace, heated to 500°C at a rate of 5°C / min, and calcined for 3 hours to obtain carbon-doped TiO 2 Porous Nano Photocatalyst (C-TiO 2 ).

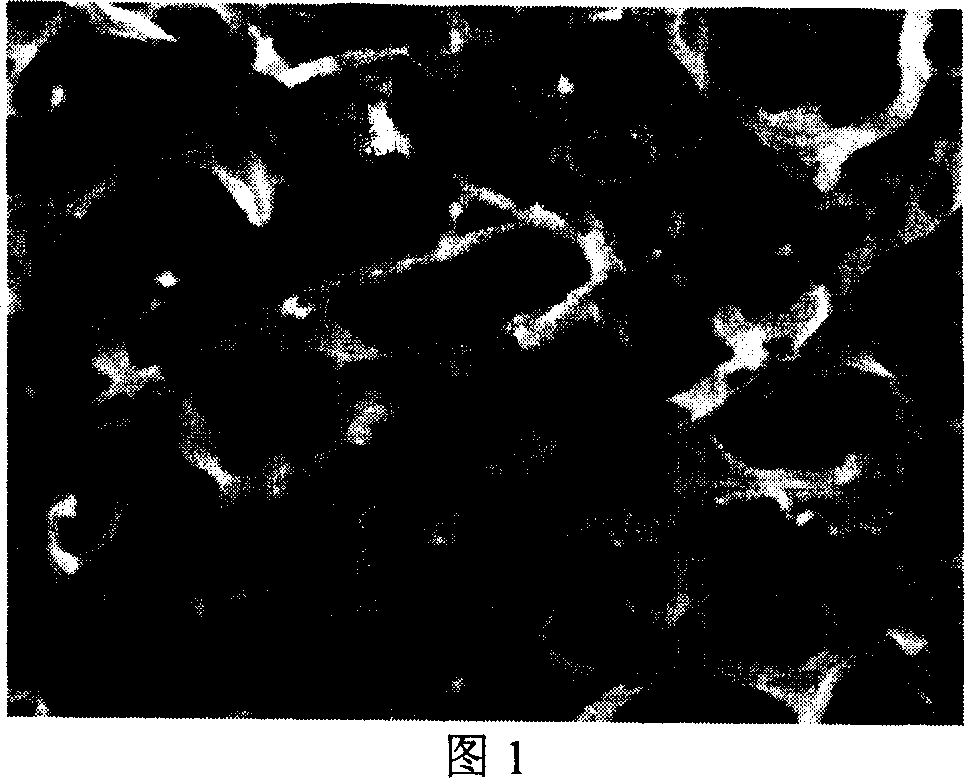

[0025] SEM analysis showed that the carbon-doped TiO prepared by the present invention 2 The porous nano photocatalyst is made of cross-linked TiO 2 Compared with the eggshell membrane templa...

Embodiment 2

[0027] Doping the carbon obtained in Example 1 with TiO 2 Porous nano photocatalyst put 0.02M AgNO 3 Soak in the solution for 24h, immediately after taking it out, soak in 0.02M glucose solution for reduction reaction, take it out after 24h, and dry at room temperature to obtain carbon-doped TiO deposited by silver nanocrystals 2 Porous Nano Photocatalyst (Ag / C-TiO 2 -1).

[0028] SEM analysis showed that the porous TiO deposited with silver nanocrystals prepared by the present invention 2 Nano photocatalyst, keeping TiO 2 A network structure of empty pipes. XRD analysis showed that the TiO 2 It is anatase crystal type with a particle size of 30-40nm, and silver exists as a simple substance. The DRS spectrum shows that the catalyst can absorb 55-65% of visible light in the 400-700nm range.

Embodiment 3

[0030] The preparation process is the same as in Example 1, except that the egg shell membrane is first in 0.02M AgNO 3 Soak in the solution for 24h, and then dehydrated at 20-30℃. Finally, silver nanocrystals and carbon doped TiO are obtained 2 Porous composite photocatalyst (Ag / C-TiO 2 -2)

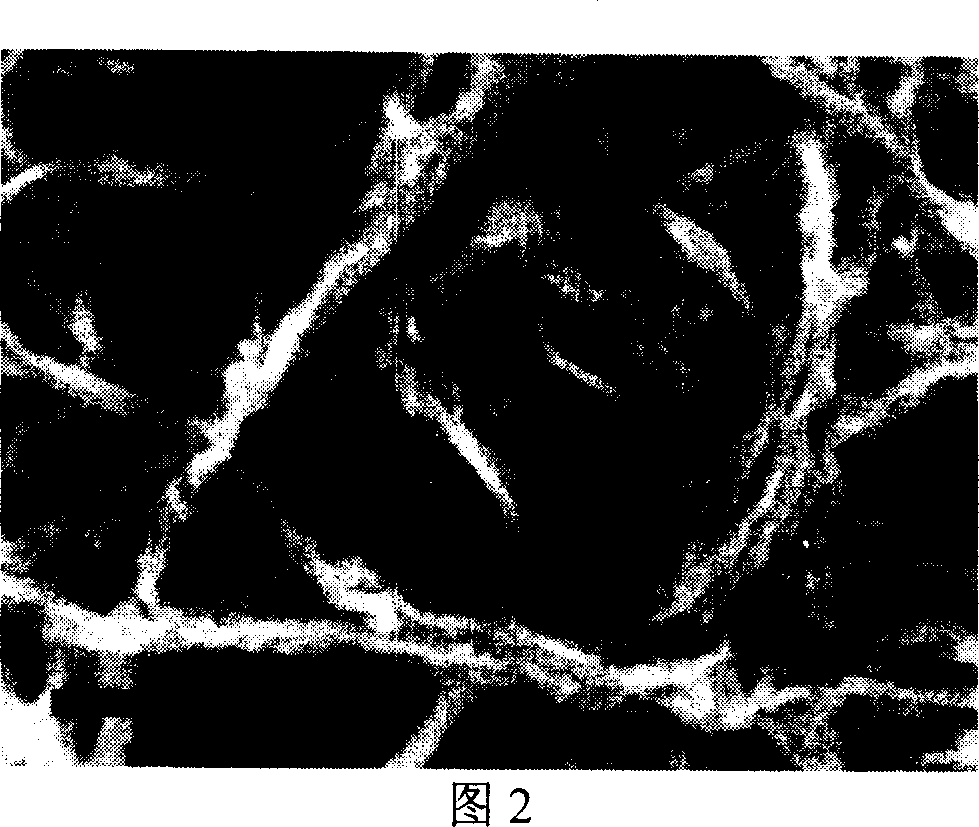

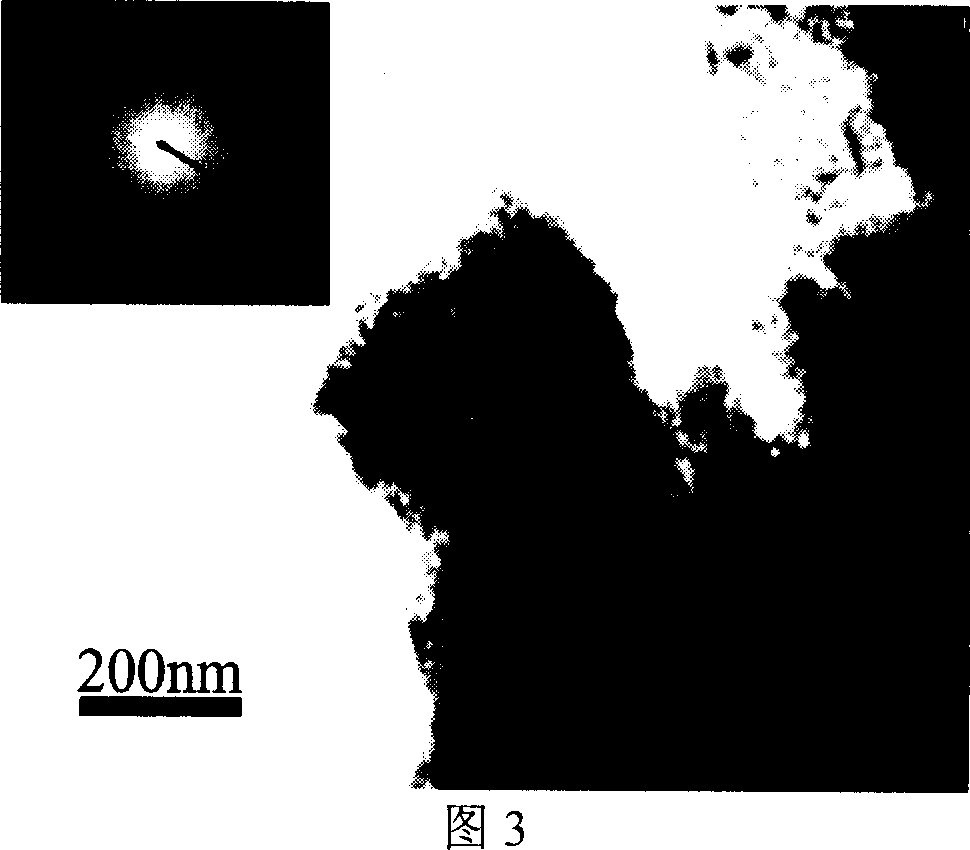

[0031] SEM analysis showed that the silver nanocrystals prepared by the present invention and carbon doped TiO 2The porous composite photocatalyst is made of TiO 2 Compared with the original EM template, the diameter of the fibers and the diameter of the macropores are slightly shrunk. TEM analysis shows that TiO 2 The fiber is a hollow tube structure, and the tube wall is composed of nanoparticles with a diameter of about 10-40 nm. XRD analysis further showed that the TiO 2 Nanoparticles are in the anatase crystal form, while silver exists as a simple substance, with a particle size of 70-80nm. The DRS spectrum shows that the photocatalyst can absorb 60-65% of visible light with a wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com