Production method and application of egg-shell membrane collagen peptides

A production method, membrane collagen technology, applied in the field of peptides, can solve problems such as product quality control, operability and energy consumption, and achieve the effect of simple operation steps and conditions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Take 1000 grams of fresh egg shells, wash them with water to remove foreign matter, crush the shells to remove the egg shells, and then prepare the protease solution (200ml, concentration 800U / L) with egg membranes containing a small amount of shells, set the temperature at 60°C , after stirring for 2 hours, slowly add NaOH solution, so that the mass concentration of NaOH in the mixture is 3%, and the temperature is 65°C, stir for 3 hours, and let stand. Take the supernatant, adjust the pH value to 7 with dilute hydrochloric acid to obtain a membrane protein solution, the volume of the membrane protein solution is 3 times of the original supernatant. Use 1k membrane equipment to desalt and concentrate, and spray dry at a temperature below 180°C to obtain egg membrane collagen polypeptide product A (about 37 grams).

Embodiment 2

[0038] Take 1000 grams of fresh egg shells, rinse with water to remove foreign matter, crush the shells to remove the egg shells, and then prepare the protease solution (200ml, concentration 1000U / L) with egg membranes containing a small amount of shells, set the temperature at 35°C , after stirring for 3 hours, slowly add NaOH solution, so that the mass concentration of NaOH in the mixture is 3%, and the temperature is 50°C, stir for 4 hours, and let stand. Take the supernatant, adjust the pH value to 9 with dilute hydrochloric acid to obtain a membrane protein solution, the volume of the membrane protein solution is 3 times of the original supernatant. Use a membrane with a membrane pore size of 300k to filter the concentrated membrane protein solution, add pure water to elute the salt in the solution to bring the pH value back to 7, and recover the concentrated solution and filtrate. The concentrated solution is spray-dried or freeze-dried at a temperature below 180° C. to ...

Embodiment 3

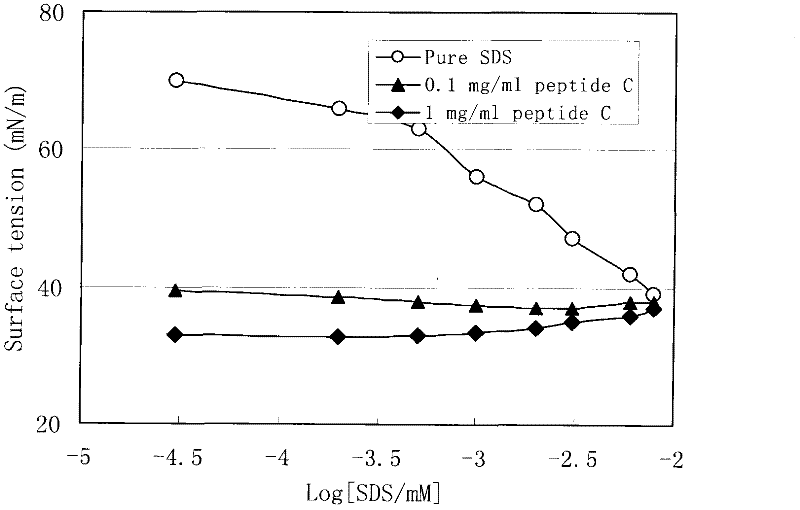

[0040] The filtrate obtained by preparing product B in Example 2 was separated by a 30k membrane, and the intercepted liquid and the secondary filtrate were recovered. The resulting intercepted solution was spray-dried at a temperature below 180° C. to obtain product C (about 15 grams) of the egg membrane collagen polypeptide.

PUM

| Property | Measurement | Unit |

|---|---|---|

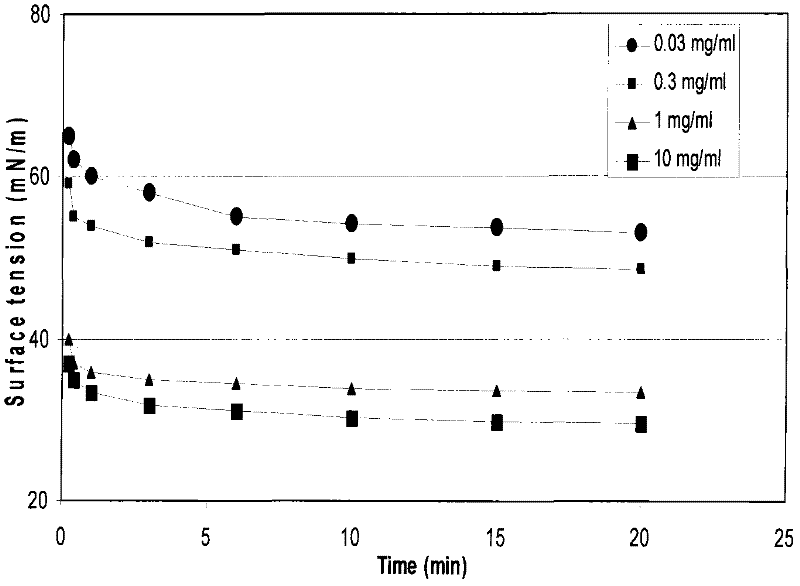

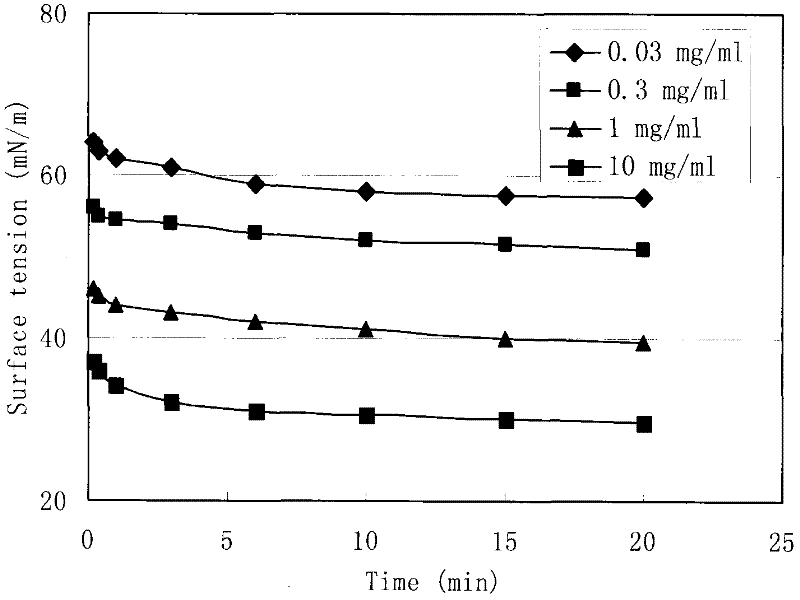

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com