Poultry egg shell-membrane separation technology

A technology of shell-membrane separation and membrane separation, which is applied in the field of membrane separation process and poultry egg shell, can solve the problems of production process without forming, and achieve the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further explained below:

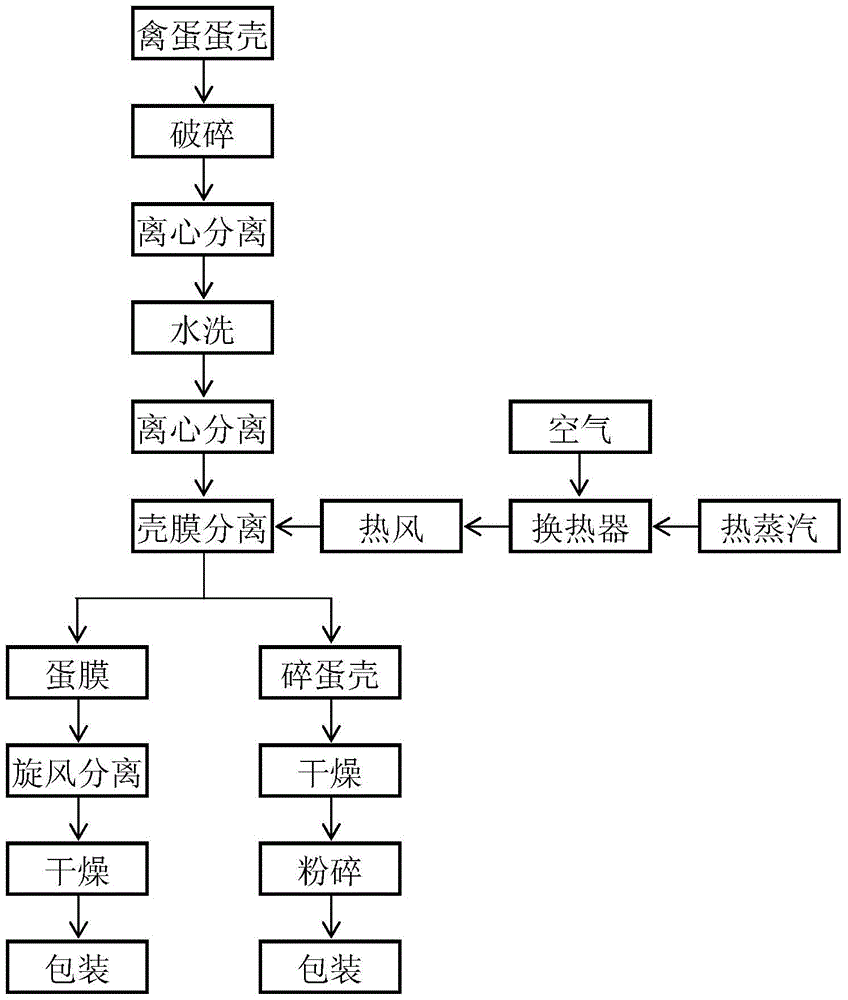

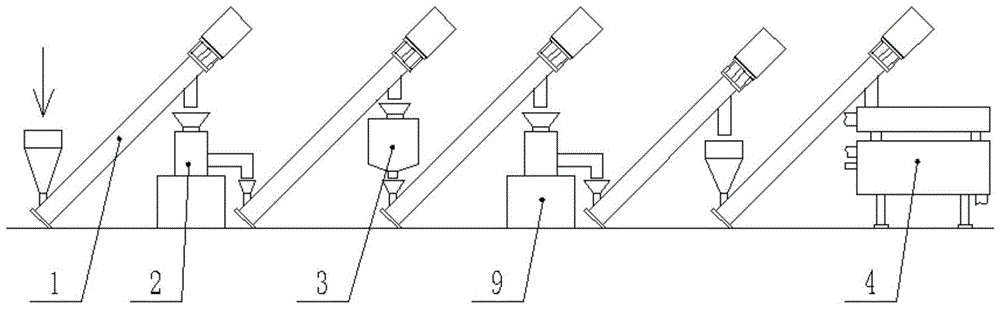

[0010] The poultry egg shell and membrane separation process of the present application includes the following steps: first, the egg shell is pulverized initially, and the purpose of pulverization is to facilitate the separation of the egg shell and the egg liquid in the next step. Machine 2. Separate the egg liquid attached to the eggshell. The egg liquid is mainly attached to the egg membrane inside the eggshell. The purpose of separating the egg liquid attached to the egg membrane is to make the egg membrane easy to dry under the action of hot air. It is conducive to separation. Second, it can reduce the weight of the egg membrane and is also conducive to separation. After separation, it is easy to be carried away by hot air into the cyclone separator. The egg shell washing machine 3 that separates the egg liquid uses clean water to clean the egg shell, cleans the egg liquid that has not been separated on the egg shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com