Self-powered flexible piezoresistive pressure sensor based on biofilm and preparation method and application thereof

A self-powered flexible, pressure sensor technology, applied in the direction of film/sheet adhesive, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the complex preparation of the sensing layer, lack of energy supply, and non-adjustable sensitivity and other problems to achieve fast response and recovery time, reduce stickiness and hysteresis, and expand the response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

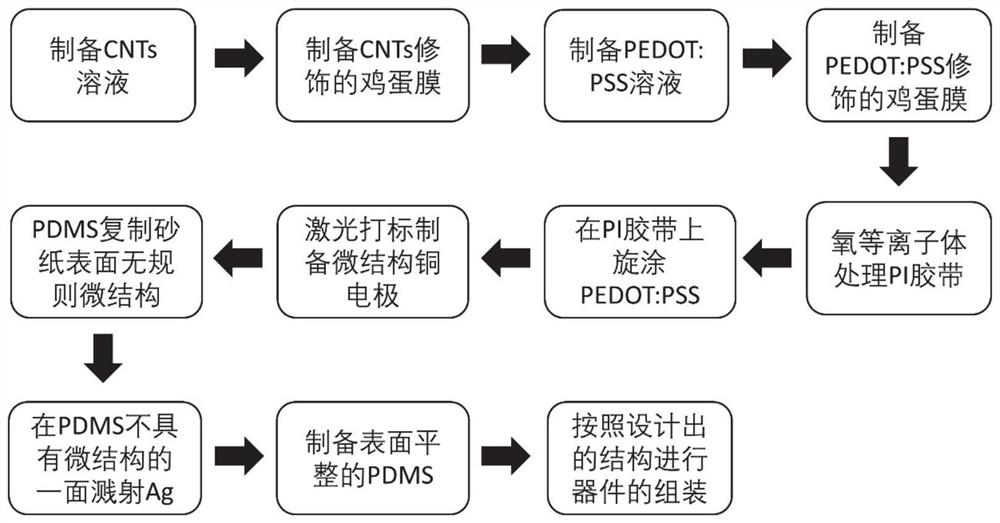

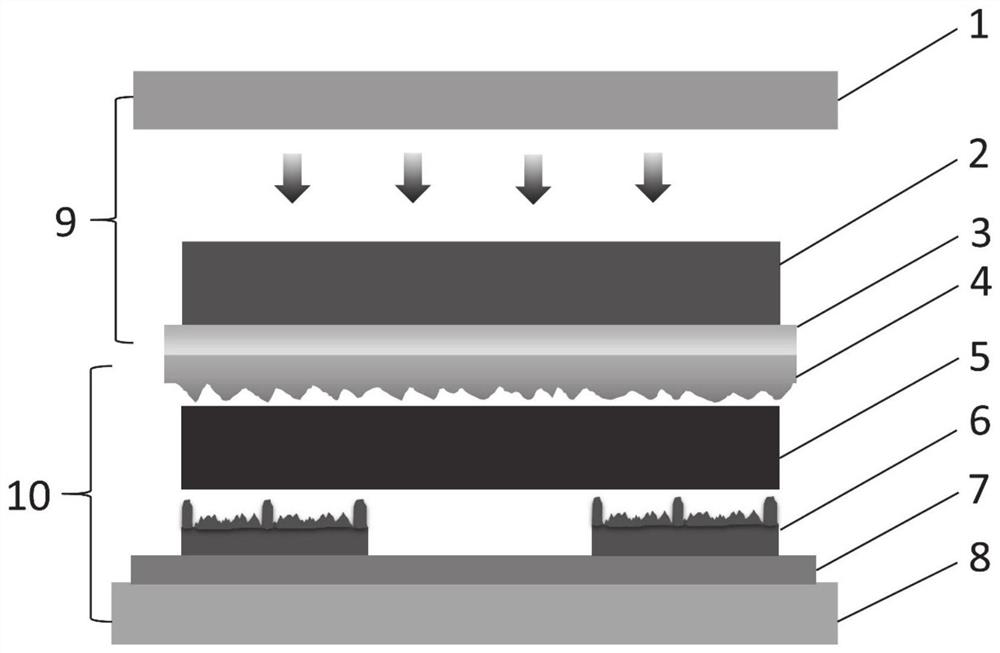

[0048] In a second aspect, the present invention provides a method for preparing the biofilm-based self-powered flexible piezoresistive pressure sensor, comprising the steps of:

[0049] The polyimide tape was intercepted, treated with oxygen plasma, and poly(3,4-ethylenedioxythiophene)-polystyrene sulfonate (PEDOT:PSS) conductive polymer film resistance layer was spin-coated on its surface to obtain P-PI tape;

[0050] Laser marking is performed on the copper foil, and a micro-fence structure is prepared on the surface of the copper foil, and micro-cone structures are evenly distributed in the micro-fence structure;

[0051] The egg membrane is taken out from the eggshell, and the inner eggshell membrane is torn off to obtain the outer eggshell membrane;

[0052] Immerse the outer eggshell membrane in the carbon nanotube suspension and ultrasonically treat it to prepare the C-egg membrane;

[0053] Copy the surface microstructure of sandpaper on one side of the polydimethyl...

Embodiment 1

[0082] 1) Prepare P-PI tape, the specific steps are as follows:

[0083] (1-1) Take a section of PI adhesive tape, clean it with ethanol first, then clean it with deionized water, after drying, treat it with oxygen plasma, the oxygen flow rate is 20sccm, the power is 65W, and the time is 30s;

[0084](1-2) Spin-coat a layer of PEDOT:PSS solution on the treated PI tape at a speed of 400rmp, and then dry it on a hot plate at 60°C for 2 hours. After the PEDOT:PSS is dry, a P-PI tape is obtained;

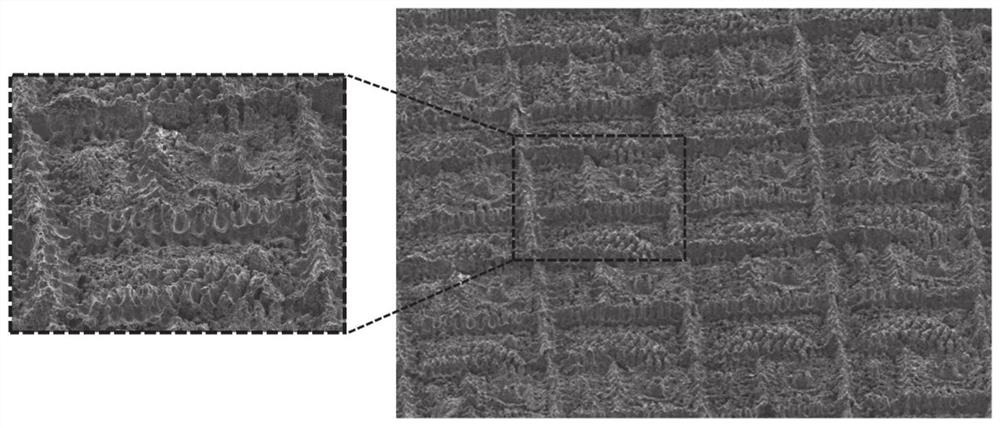

[0085] 2) Preparation of copper foil with micro-barriers and evenly distributed micro-cone structures: Clean the copper foil with ethanol and deionized water and dry it for later use. Through the designed wiring method, the power is 20%, and the frequency is 5KHz. The laser with a speed of 200mm / s directly prepares the microstructure on the surface of the copper foil according to the laid lines. The field emission scanning electron microscope (FESEM) picture of the microstructure is as ...

Embodiment 2

[0103] 1) Prepare P-PI tape, the specific steps are as follows:

[0104] (1-1) Take a section of PI adhesive tape, wash it with ethanol first, then clean it with deionized water, after drying, treat it with oxygen plasma, the oxygen flow rate is 10sccm, the power is 85W, and the time is 40s;

[0105] (1-2) Spin-coat a layer of PEDOT:PSS solution on the treated PI tape at a speed of 800rmp, and then dry it on a hot plate at 80°C for 1.5h. After the PEDOT:PSS is dry, a P-PI tape is obtained. ;

[0106] 2) Preparation of copper foil with micro-barriers and evenly distributed micro-cone structures: Clean the copper foil with ethanol and deionized water and dry it for later use. Through the designed wiring method, the power is 30%, and the frequency is 15KHz. The laser with a speed of 500mm / s directly prepares the microstructure on the surface of the copper foil according to the laid lines;

[0107] 3) The preparation of C-egg membrane, the specific steps are as follows:

[0108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com