Patents

Literature

75results about How to "Increase surface charge density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

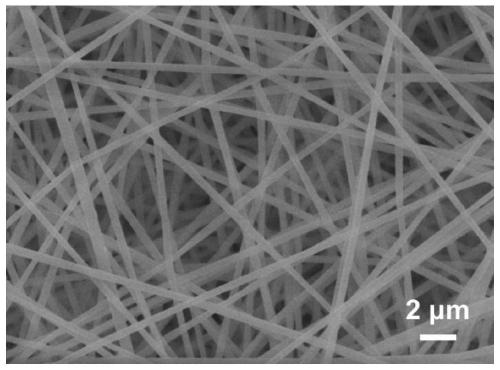

Friction nanometer power generator for converting mechanical energy to electric energy and fabrication method of friction nanometer power generator

ActiveCN109412456ASolve the problem of not being able to make nanofibersSolve the problem that most fluorine-containing materials, except polyvinylidene fluoride, cannot be directly prepared into nanofibers by electrospinningFriction generatorsFiberElectricity

The invention relates to a friction nanometer power generator for converting mechanical energy to electric energy and a fabrication method of the friction nanometer power generator. The fabrication method comprises the steps of packaging a flexible substrate layer I, an electrode material layer I, an electrical negative friction layer, an electrical positive friction layer, an electrode material layer II and a flexible substrate layer II according to a sequence, and then connecting the two flexible substrate layer at the outmost layer so that the electrical negative friction layer and the electrical positive friction layer are arranged at intervals to fabricate the friction nanometer power generator, wherein the electrical negative friction layer is fabricated by automatically assembly a friction electrical negative substance on a surface of aerogel. The fabricated friction nanometer power generator for converting the mechanical energy to the electric energy comprises the electrical negative friction layer and the electrical positive friction layer, and the electrical negative frication layer mainly comprises nanometer fiber of the self-assembled friction electrical negative substance. The fabrication method is simple, the fabricated product is low in cost, the sensitivity on mechanical energy of tiny biology is high, the electrical output performance is excellent, and the frication nanometer power generator has favorable application prospect in the field of self power supply sensing and wearability.

Owner:DONGHUA UNIV

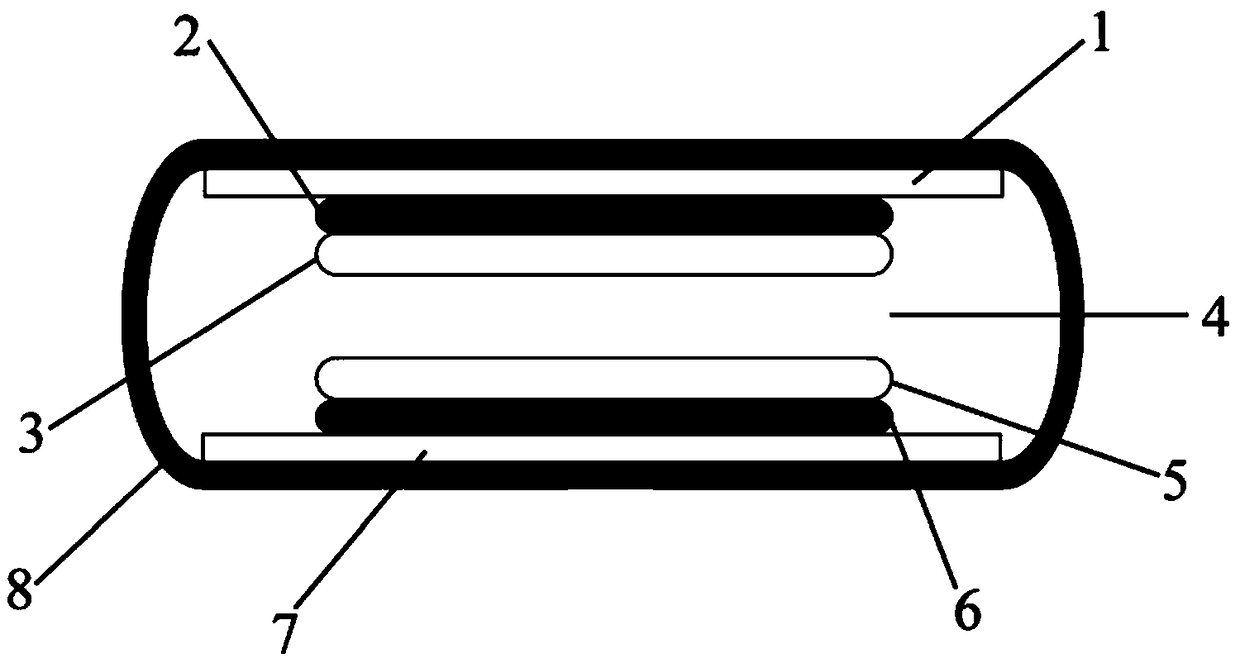

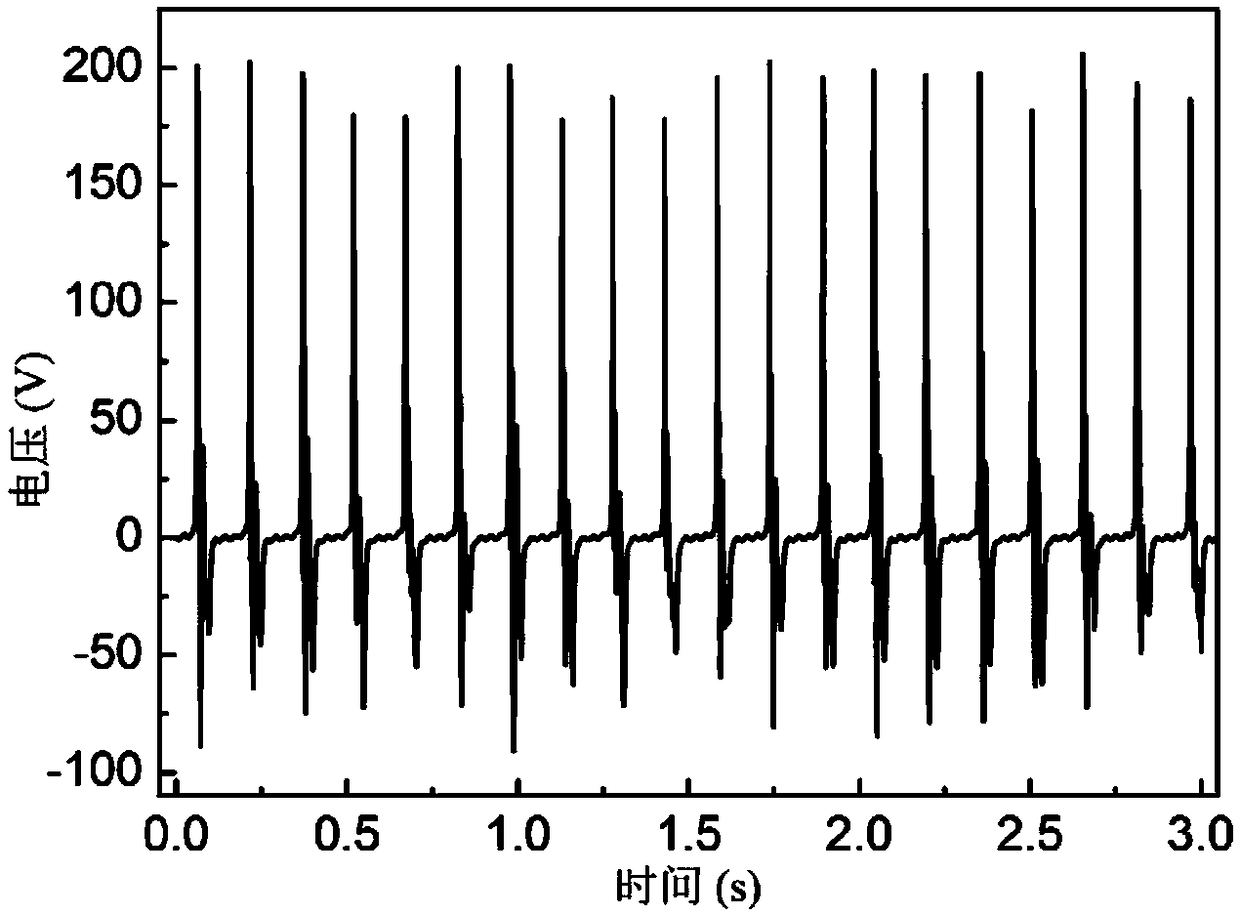

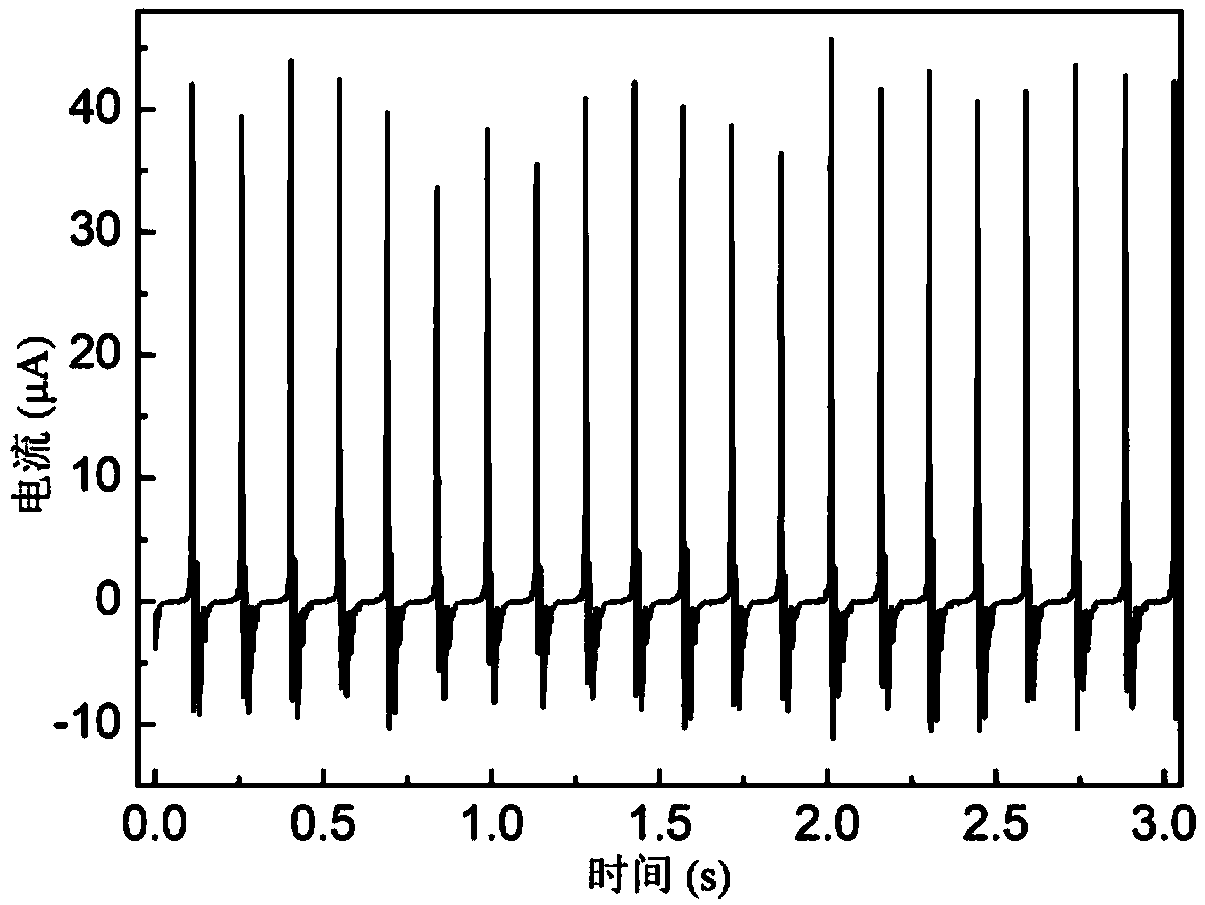

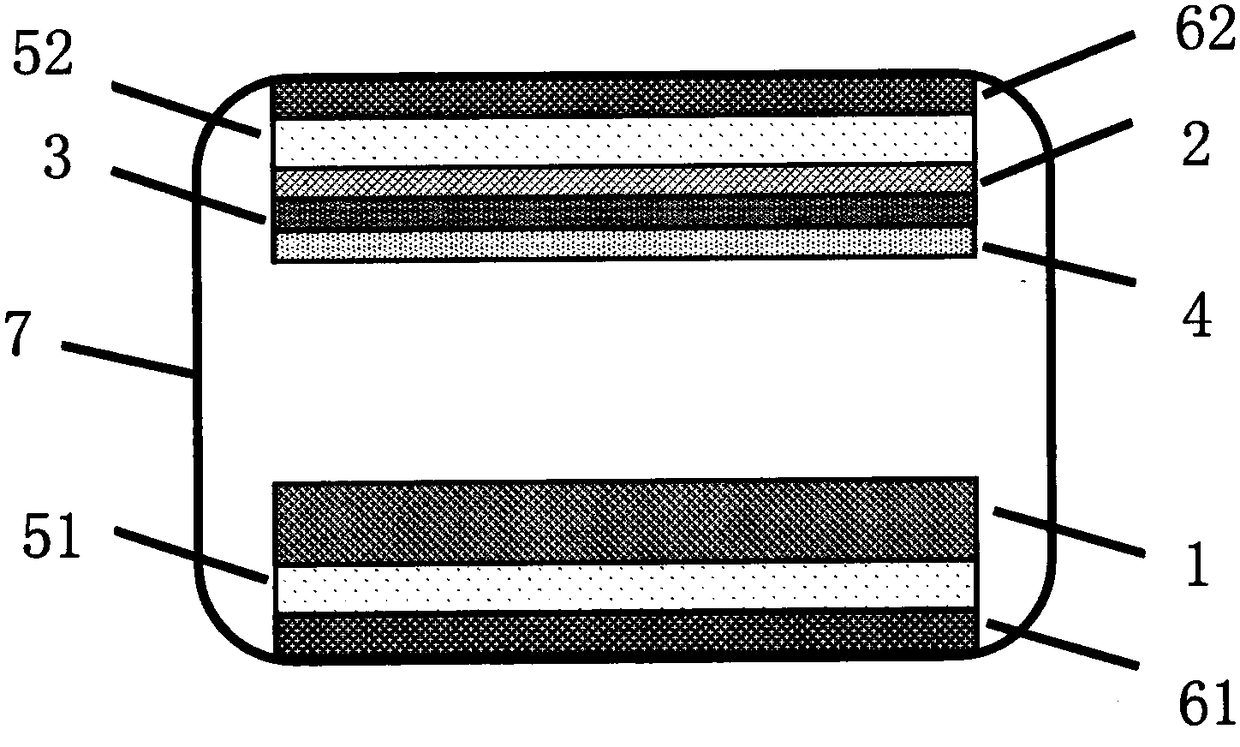

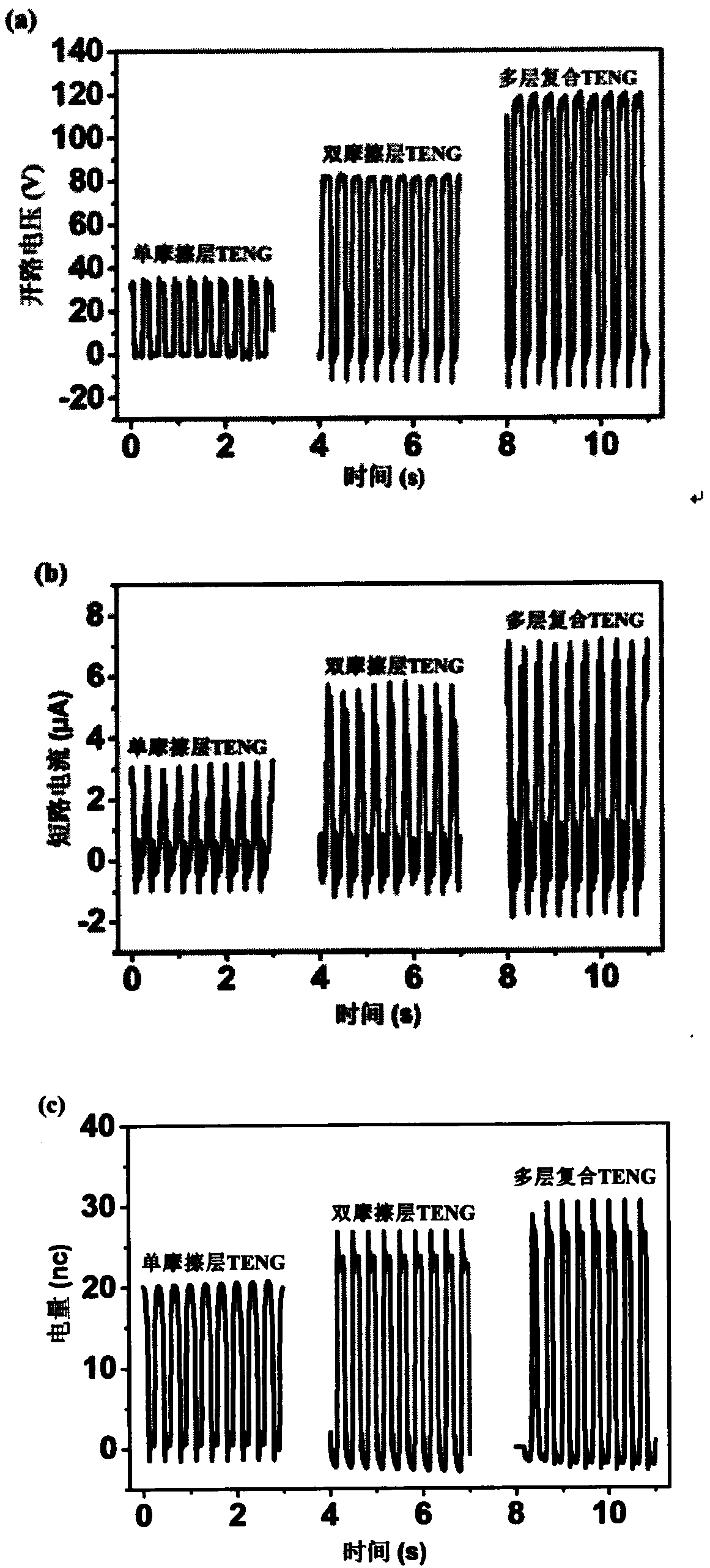

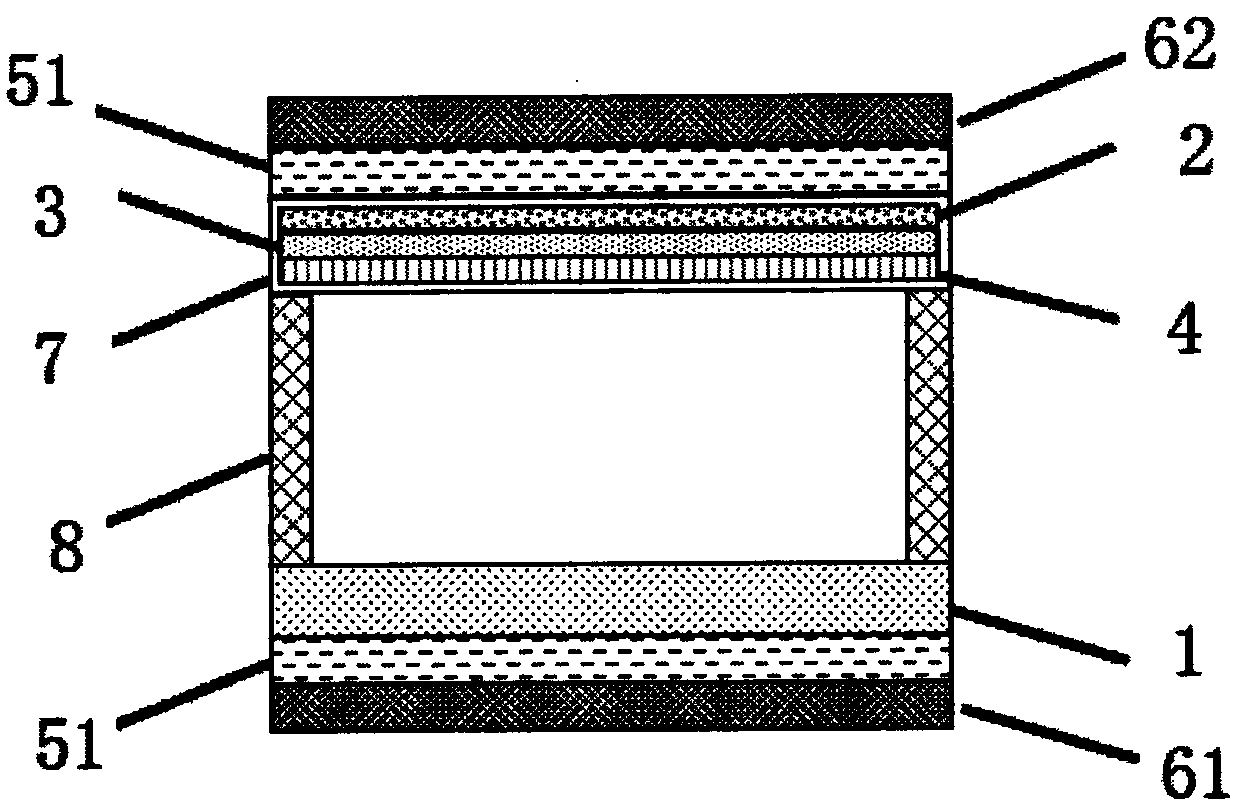

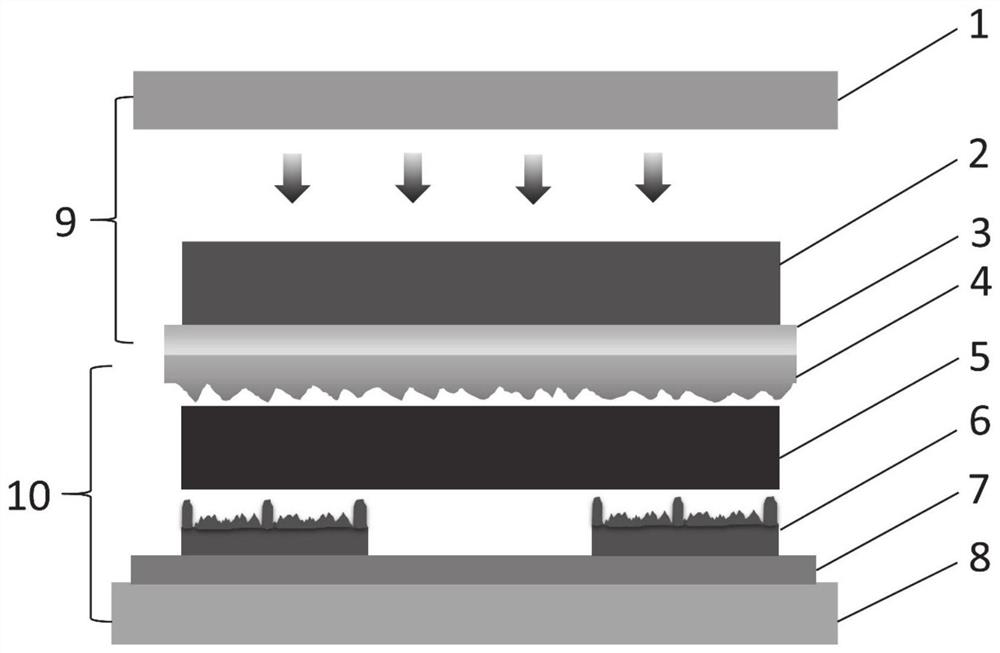

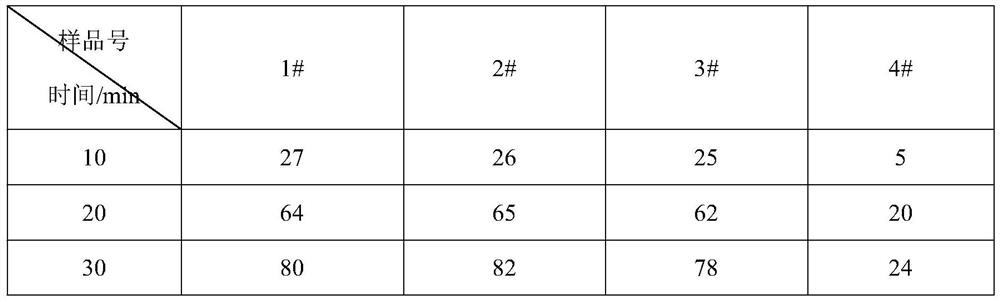

Fiber base multilayer structure friction nanometer power generator and preparation method thereof

InactiveCN108616225ALarge specific surface areaHigh porosityFriction generatorsFiberMechanical energy

The invention provides a fiber base multilayer structure friction nanometer power generator and a preparation method thereof. The fiber base multilayer structure friction nanometer power generator ischaracterized in that the power generator comprises an electropositive friction layer and a multilayer structure electronegative friction layer; the electropositive friction layer and the multilayer structure electronegative friction layer are static spinned nanofiber films; the multilayer structure electronegative friction layer comprises an electric storage layer, a conductive layer and a friction contact layer, wherein the electric storage layer, the conductive layer and the friction contact layer are successively arranged from bottom to top; and the electropositive friction layer and the electronegative friction layer can contact with each other or be separated from each other for generating electric charges. The prepared multilayer structure friction nanometer power generator has advantages of increasing shortcircuit current by 40-150%, boosting open-circuit voltage by 100-250%, and increasing electric quantity by 40-100%. The friction nanometer power generator according to the invention has advantages of high surface charge density, low volume mass, simple structure and short process flow. The fiber base multilayer structure friction nanometer power generator can efficientlycollect mechanical energy generation in human body movement and has wide application range in the field of microelectronics.

Owner:DONGHUA UNIV

Process for increasing the charge on a lignocellulosic material

InactiveUS6187136B1Avoid reactionIncrease surface charge densityFungiPaper/cardboardCatalytic oxidationCellulose fiber

A process for production of a lignocellulosic material modified by conjugation thereto of a phenolic substance comprising a substituent which, in the conjugated form of the phenolic substance, is, or may become, negatively or positively charged, respectively, comprises: reacting a lignocellulosic fibre material and the phenolic substance with an oxidizing agent in the presence of an enzyme capable of catalyzing the oxidation of phenolic groups by the oxidizing agent; and reacting together the products of the reactions; with the proviso that the phenolic substance is not a phenolic polysaccharide. A strengthened lignocellulose-based product (e.g. a paper product) may be prepared by a procedure wherein a product produced in accordance with the latter process is treated with a strengthening agent having an ionic charge of sign opposite to that which is conferred on the modified lignocellulosic material by the charge-conferring substituent.

Owner:NOVOZYMES AS

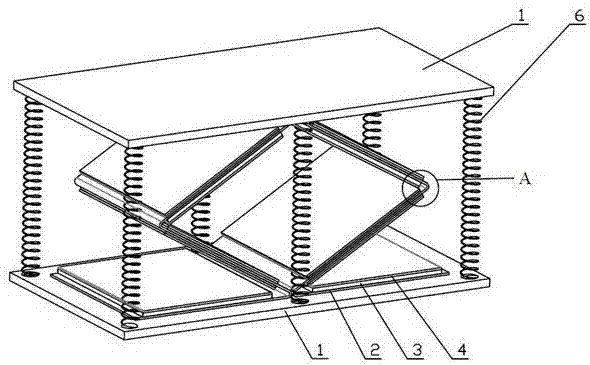

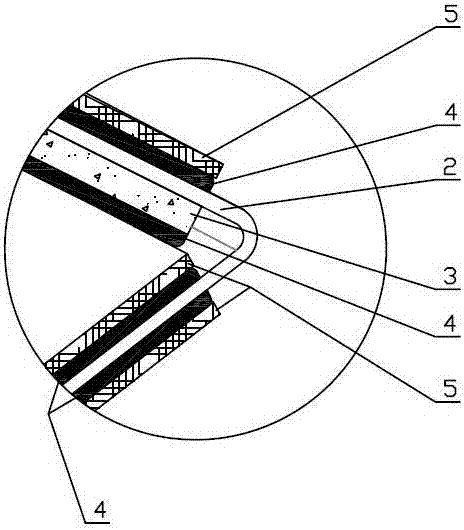

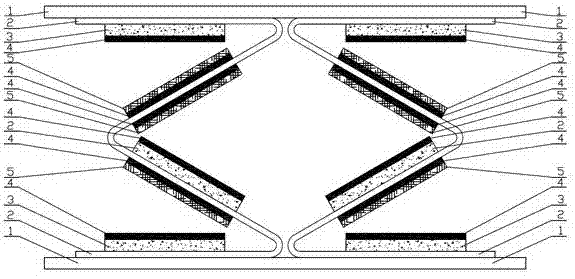

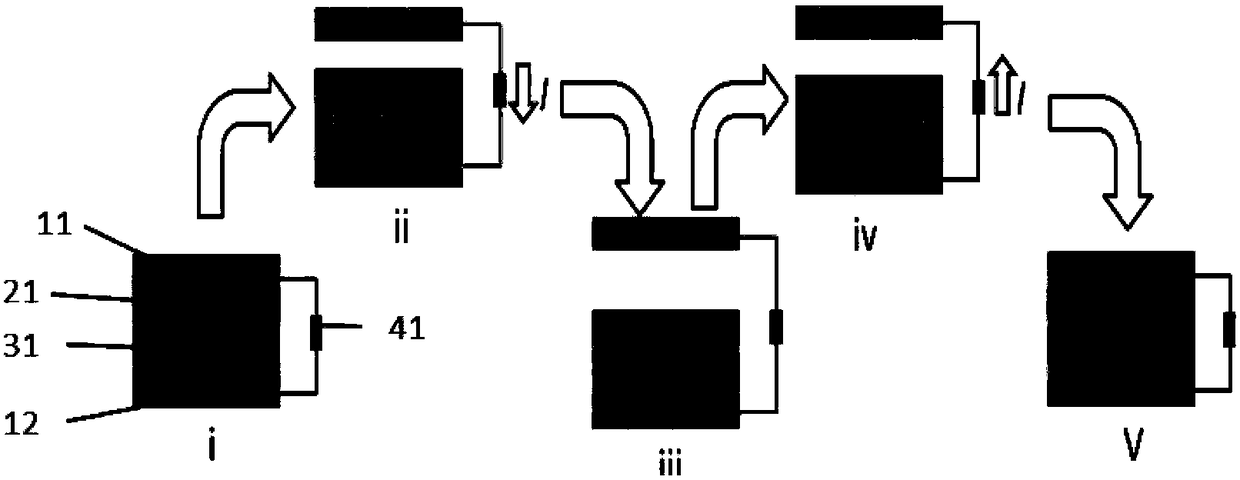

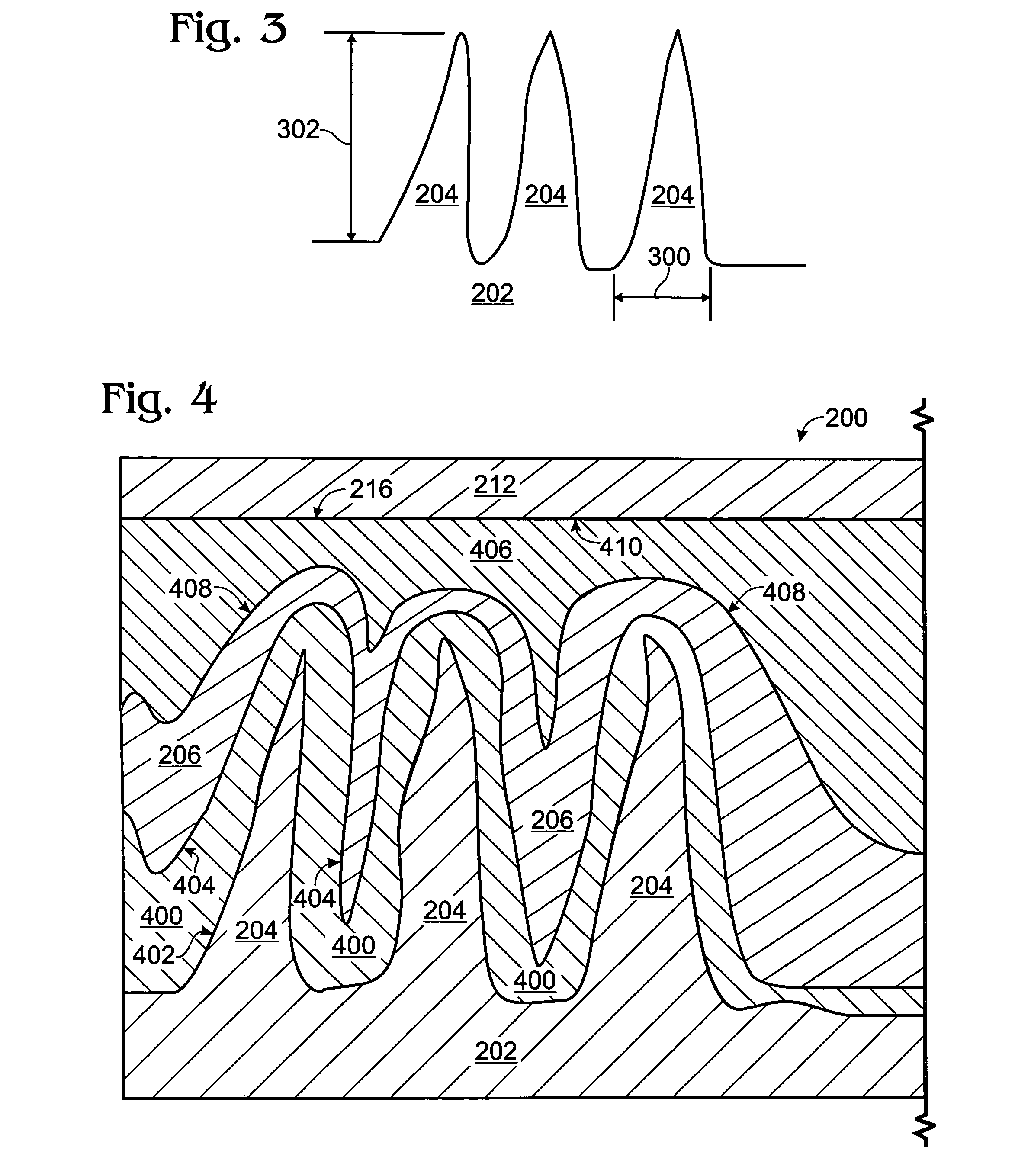

Multi-layer, flexible and folded friction power generator

InactiveCN107342702ASynchronized and consistent output performanceImprove output performanceFriction generatorsReciprocating motionMechanical energy

The invention discloses a multi-layer, flexible and folded friction power generator, and belongs to the technical field of power generators. The multi-layer, flexible and folded friction power generator comprises an upper support plate, a lower support plate and springs, wherein the springs are connected between the upper support plate and the lower support plate, at least one friction power generation unit is arranged between the upper support plate and the lower support plate and comprises a flexible and folded substrate, a first friction unit and a second friction unit, the flexible and folded substrate is fixed between the upper support plate and the lower support plate, the first friction unit and the second friction unit are arranged at two sides of the flexible and folded substrate at intervals, and the friction units contacted with the flexible and folded substrate are respectively the first friction unit and the second friction unit. The multi-layer, flexible and folded friction power generator is mainly used for solving the technical problems of small output power and unstable output performance when mechanical energy is converted to electric energy in vibration or reciprocating motion.

Owner:HENAN NORMAL UNIV

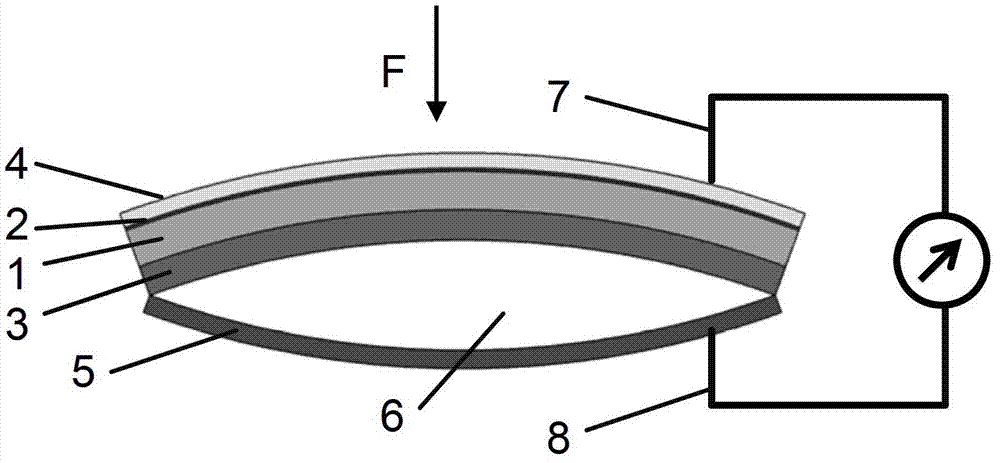

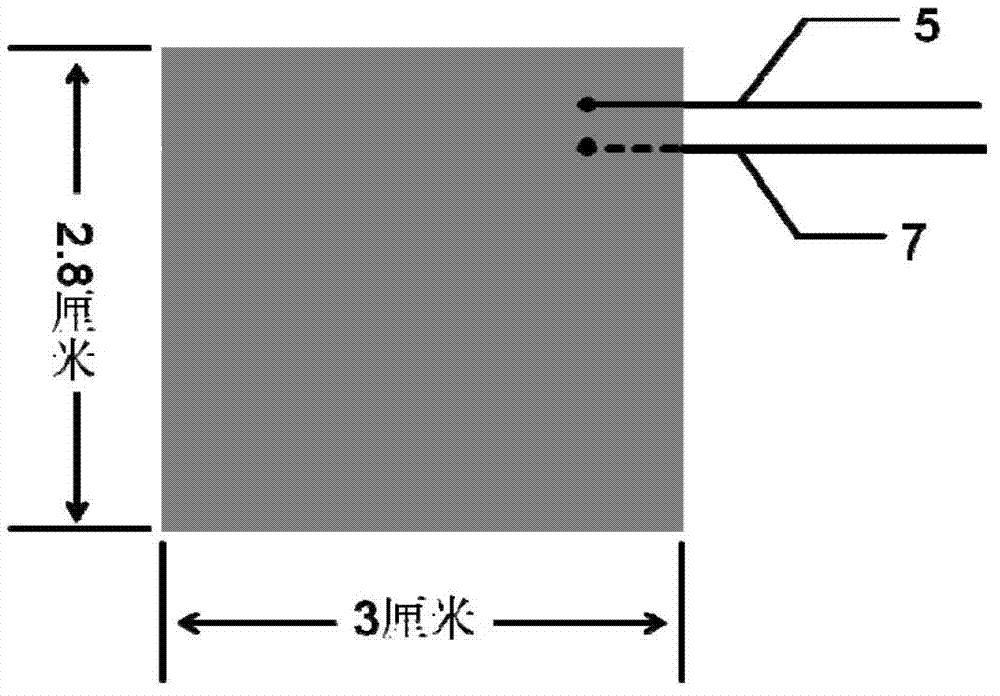

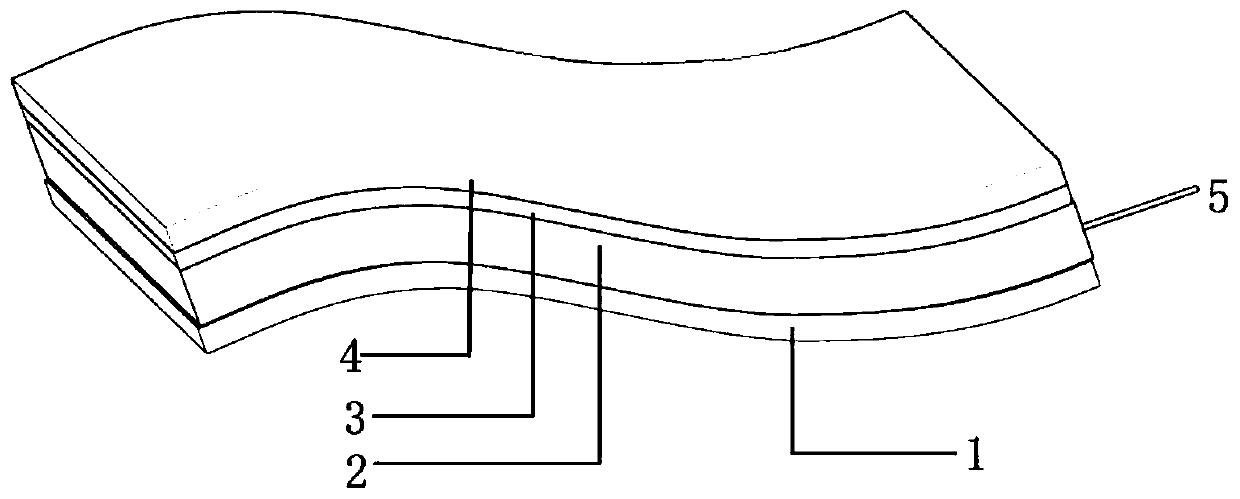

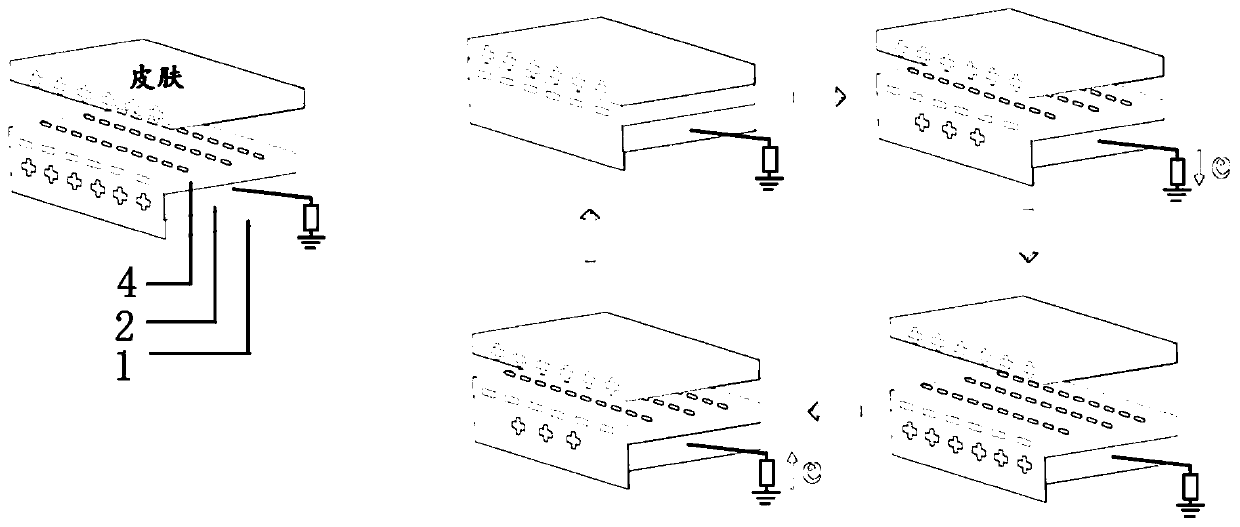

Electrostatic generator, manufacturing method thereof and self-driven sensing system

ActiveCN103368446AIncrease surface charge densityImprove output performanceNanotechnologyElectrostatic generators/motorsPolymer thin filmsOptoelectronics

The invention provides an electrostatic generator, which comprises a bent flexible base, a polymer thin film layer and a metal thin film, wherein the outer surface of the base is provided with an electrode layer, the polymer thin film layer is pasted on the inner surface of the base, the metal thin film is pasted with the edge of the polymer thin film layer, and an arched cavity is formed between the metal thin film and the polymer thin film. Correspondingly, the invention also provides a manufacturing method of the electrostatic generator and a self-driven sensing system which uses the electrostatic generator. As the polymer thin film layer and the metal thin film have different electron accepting abilities, and moreover the arched cavity structure is formed between the polymer thin film layer and the metal thin film, the surface charge density at the interface when the polymer thin film layer is contacted with the metal thin film is increased, the charge separation process of the metal thin film and the polymer thin film is effectively actuated, and the output performance of the electrostatic nano generator can be improved.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

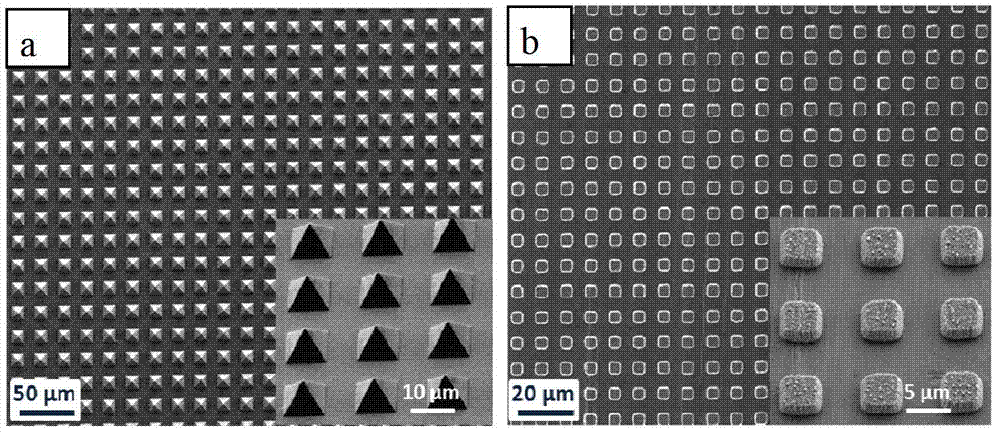

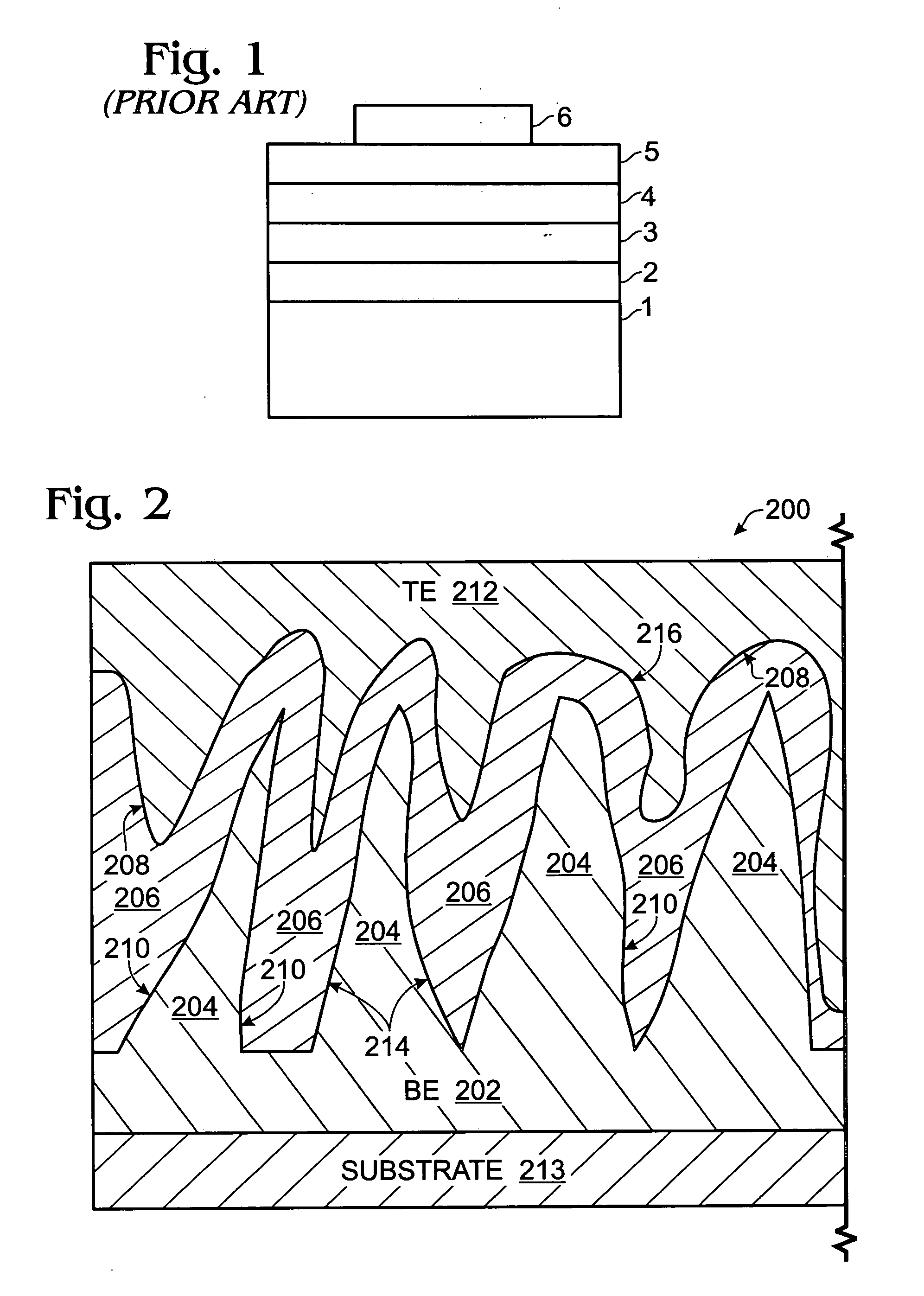

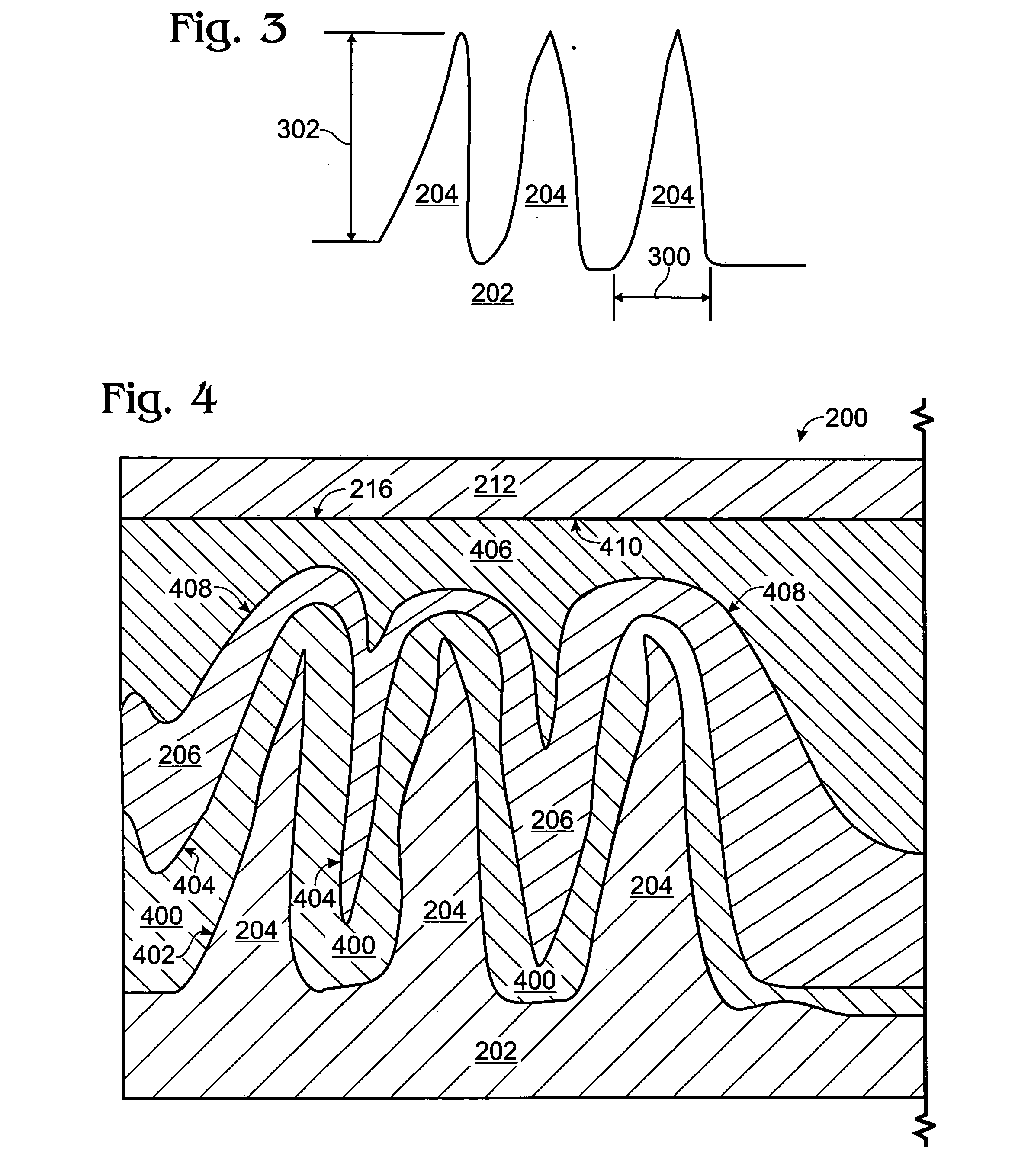

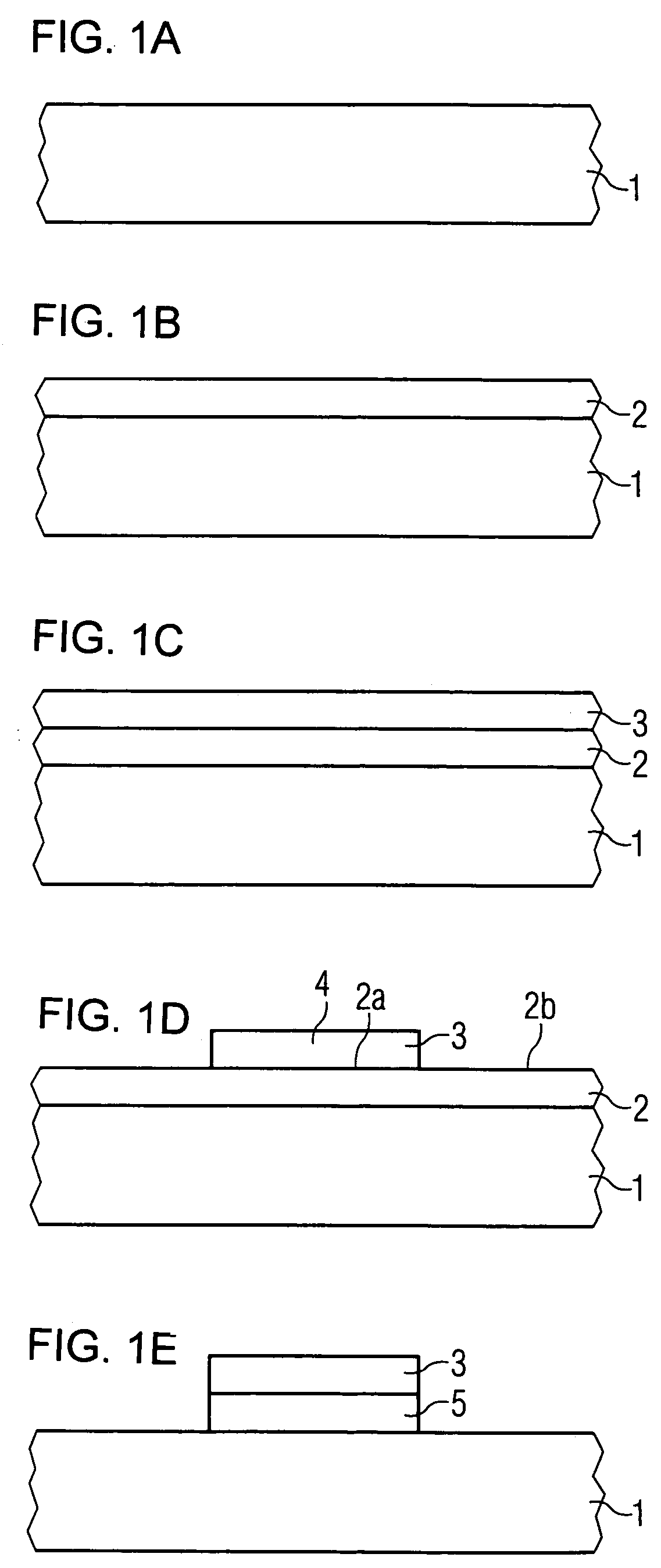

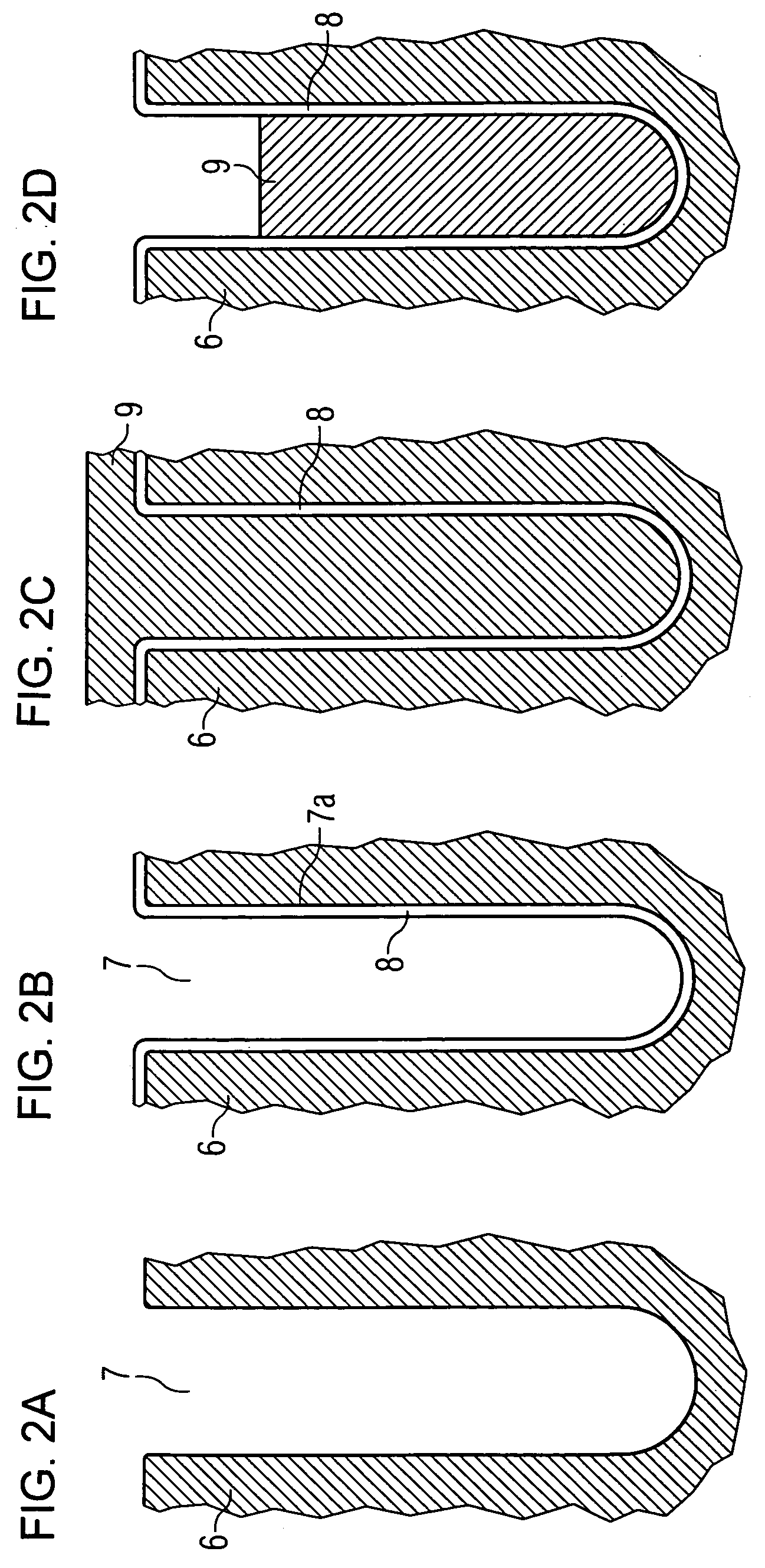

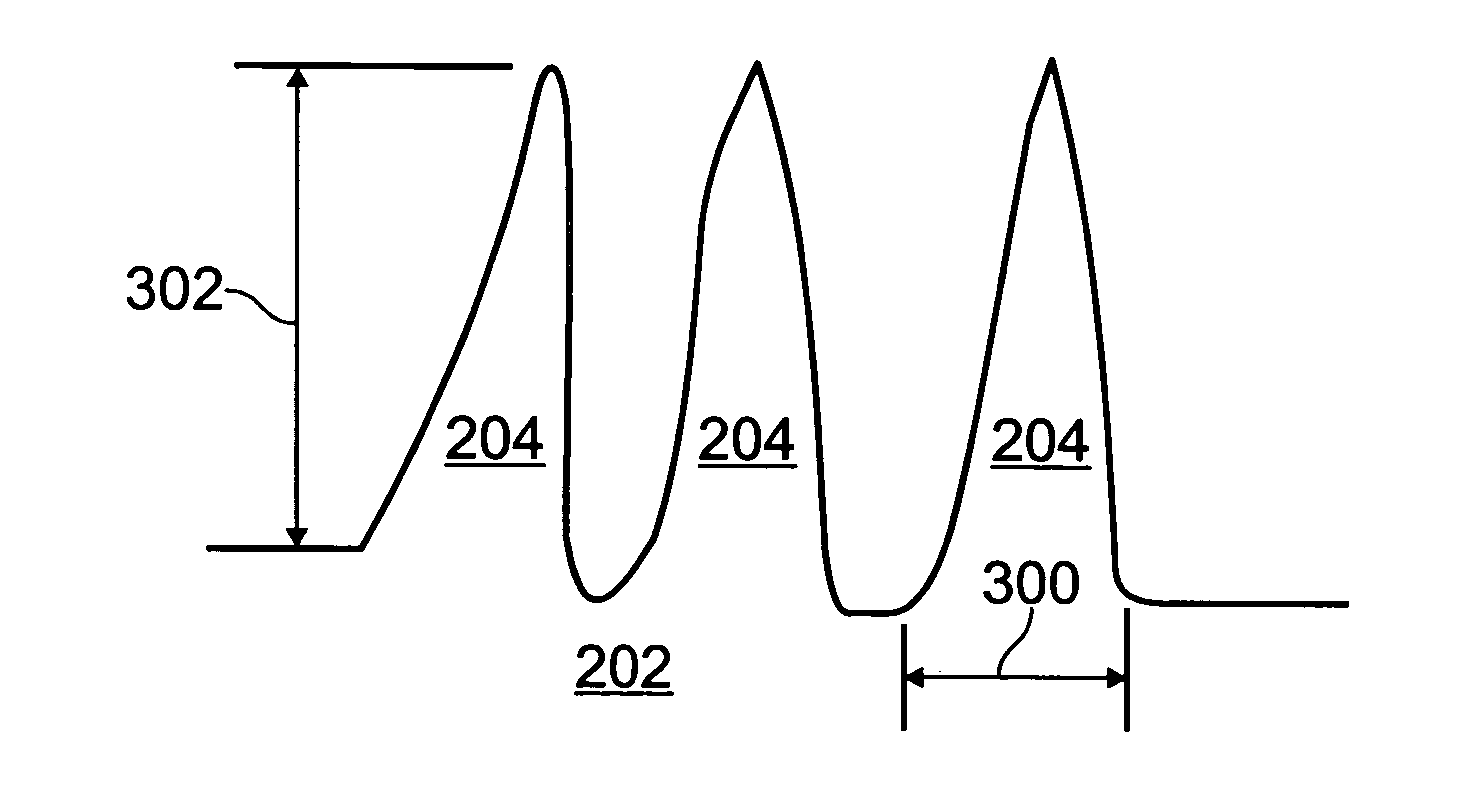

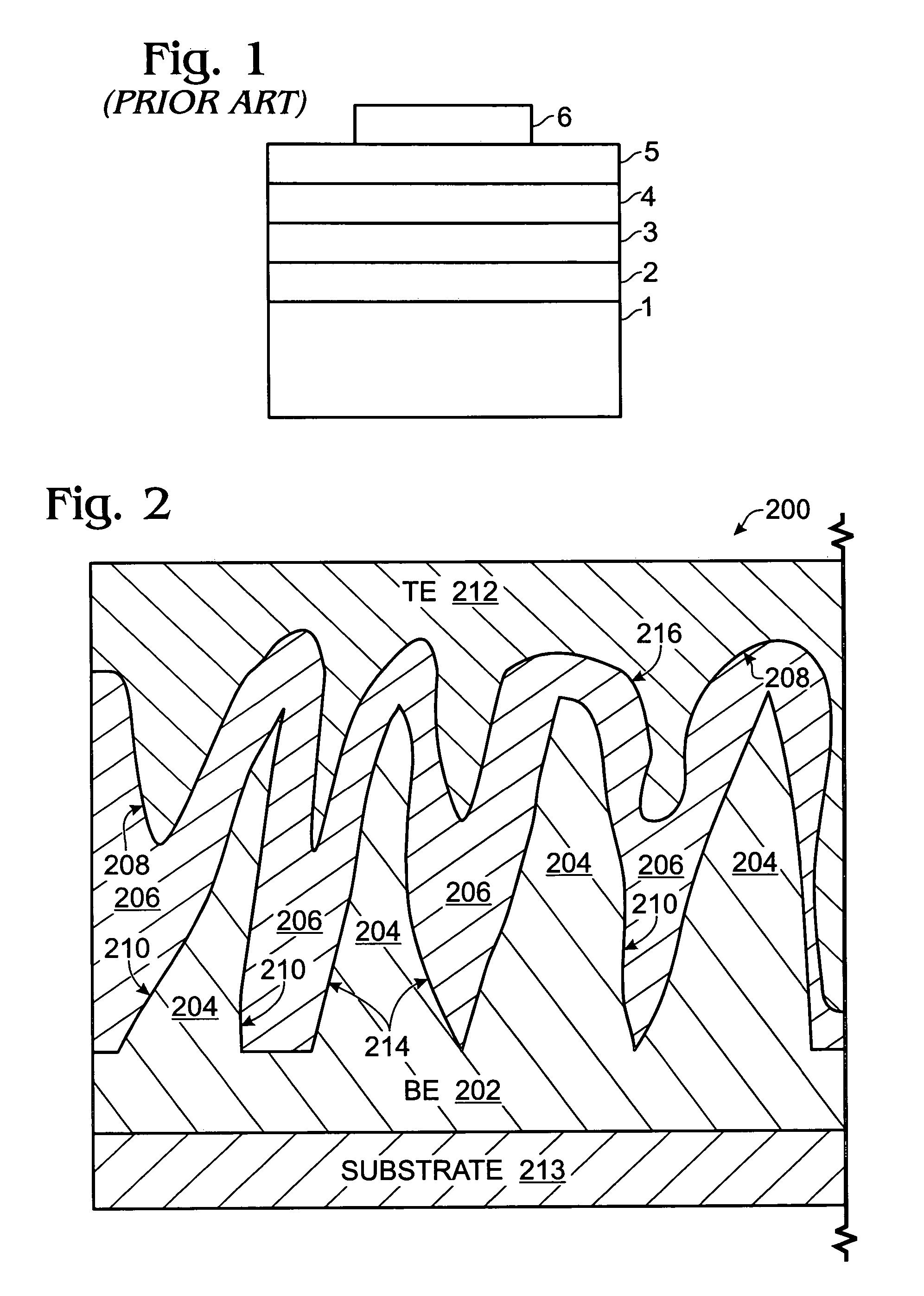

Nanotip electrode electroluminescence device with contoured phosphor layer

InactiveUS20060197438A1Increasing surrounding electric fieldIncrease surface charge densityDischarge tube luminescnet screensElectroluminescent light sourcesDielectricPhosphor

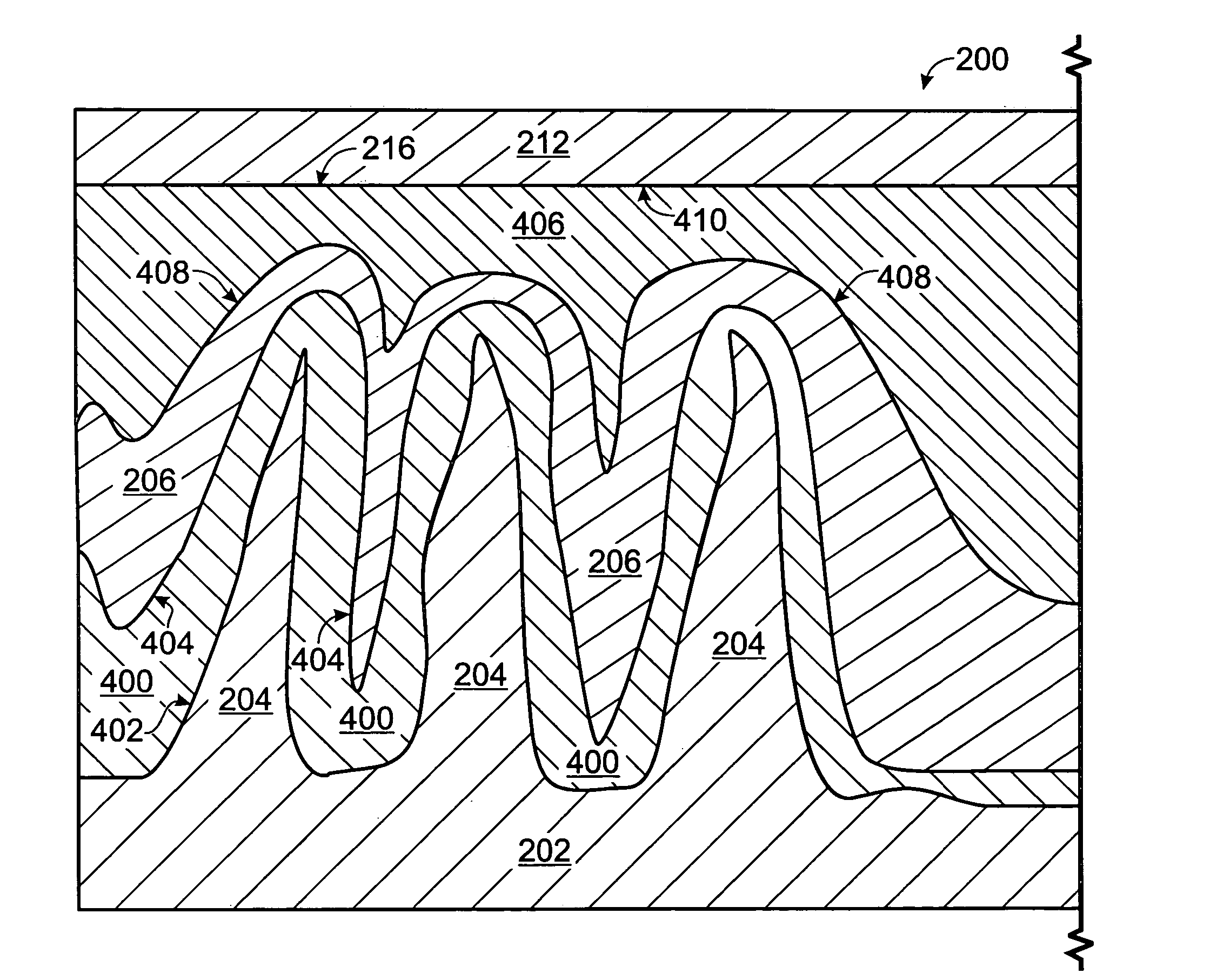

A device and a fabrication method are provided for an EL device with a nanotip-contoured phosphor layer. The method comprises: forming a bottom electrode with nanotips; forming a phosphor layer overlying the bottom electrode, having irregularly-shaped top and bottom surfaces; and, forming a top electrode overlying the phosphor layer. The bottom electrode top surface has a nanotip contour, and the phosphor layer irregularly-shaped top and bottom surfaces have contours approximately matching the bottom electrode top surface nanotip contour. In one aspect, a contoured bottom dielectric is interposed between the bottom electrode and the phosphor layer, having top and bottoms surfaces with contours approximately matching the nanotip contour. Likewise, a top dielectric may be interposed between the top electrode and the phosphor layer, having a bottom surface with a contour approximately matching the contour of phosphor layer top surface.

Owner:SHARP KK

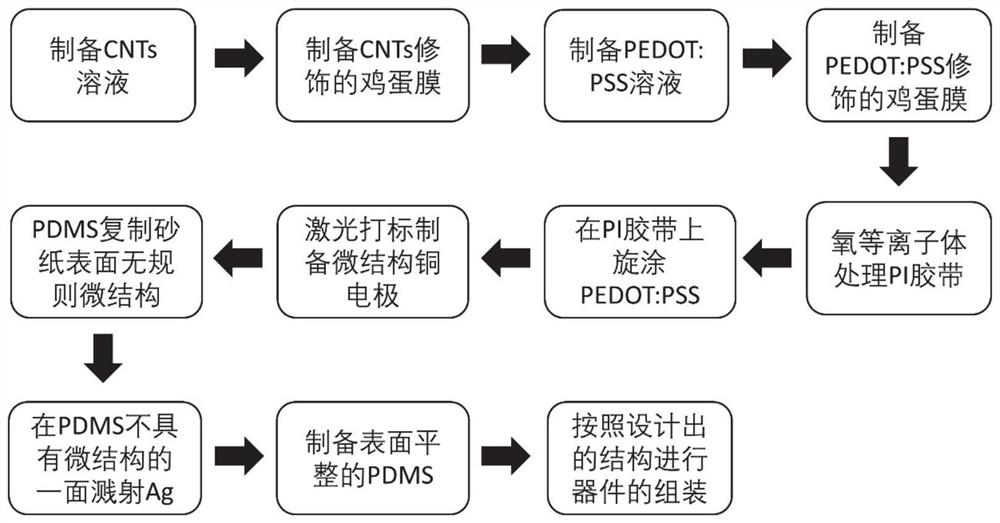

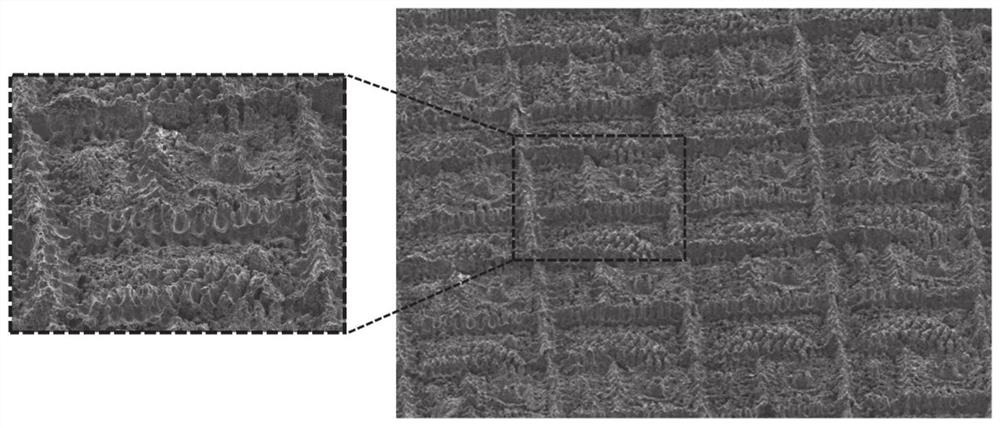

Self-powered flexible piezoresistive pressure sensor based on biofilm and preparation method and application thereof

ActiveCN112284579AHigh sensitivityStable initial resistance valueFluid pressure measurement using ohmic-resistance variationFilm/foil adhesivesFilm resistanceConductive polymer

The invention provides a self-powered flexible piezoresistive pressure sensor based on a biofilm, and a preparation method and application thereof; the self-powered flexible piezoresistive pressure sensor is of a laminated structure, and is provided with a polyimide adhesive tape layer, poly (3, 4-ethylenedioxythiophene)- polystyrene sulfonate conductive polymer film resistance layer, a copper foil, a carbon-nanotube- modified egg film, a polydimethylsiloxane film and a poly (3, 4-ethylenedioxythiophene)- polystyrene sulfonate-modified egg film sequentially from one side to other side. One surface of the copper foil is provided with a microstructure, and the microstructure is arranged towards the carbon-anotube- modified egg film; the egg film is an outer egg shell membrane; an irregular microstructure is processed on one side of the polydimethylsiloxane film, and a silver electrode is arranged on the other side of the polydimethylsiloxane film. A pressure sensor is ultrahigh in sensitivity, short in response and recovery time, wide in sensing range and capable of generating energy by itself.

Owner:UNIV OF JINAN

Improved friction nano-generator

ActiveCN109149992AEnhanced ability to capture chargeIncrease triboelectric charge densityFriction generatorsHigh power densityCharge density

The invention relates to the field of generators, and discloses an improved friction nano-generator, comprising a first power generation part and a second power generation part, wherein the first power generation part comprises a first friction layer; and a first ferroelectric layer; wherein the first friction layer is disposed on a surface of the first ferroelectric layer; the second power generation part includes a second electrode; the second electrode outputs electrical energy when mutual friction of the second power generating part and the first friction layer occurs. By polarization of the built-in medium introduced to the ferroelectric layer material, the friction charge density of the friction layer is improved and the generator output with higher power density can be obtained.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

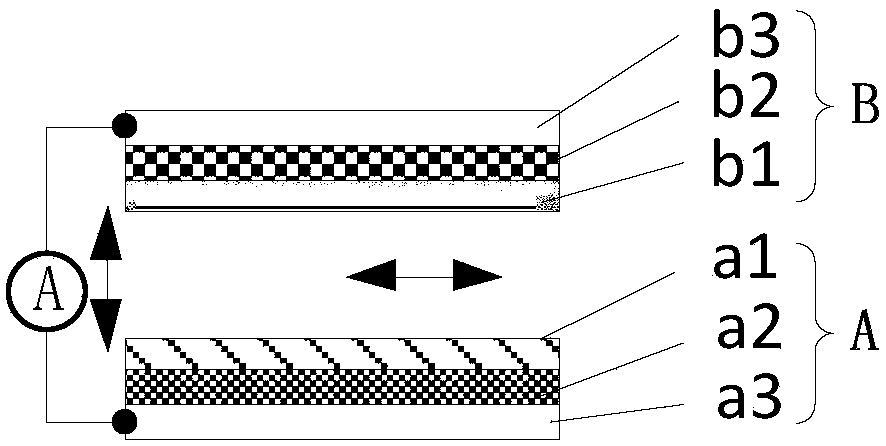

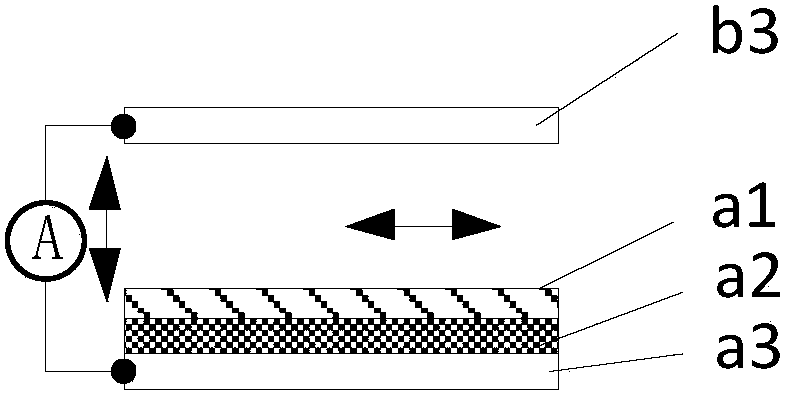

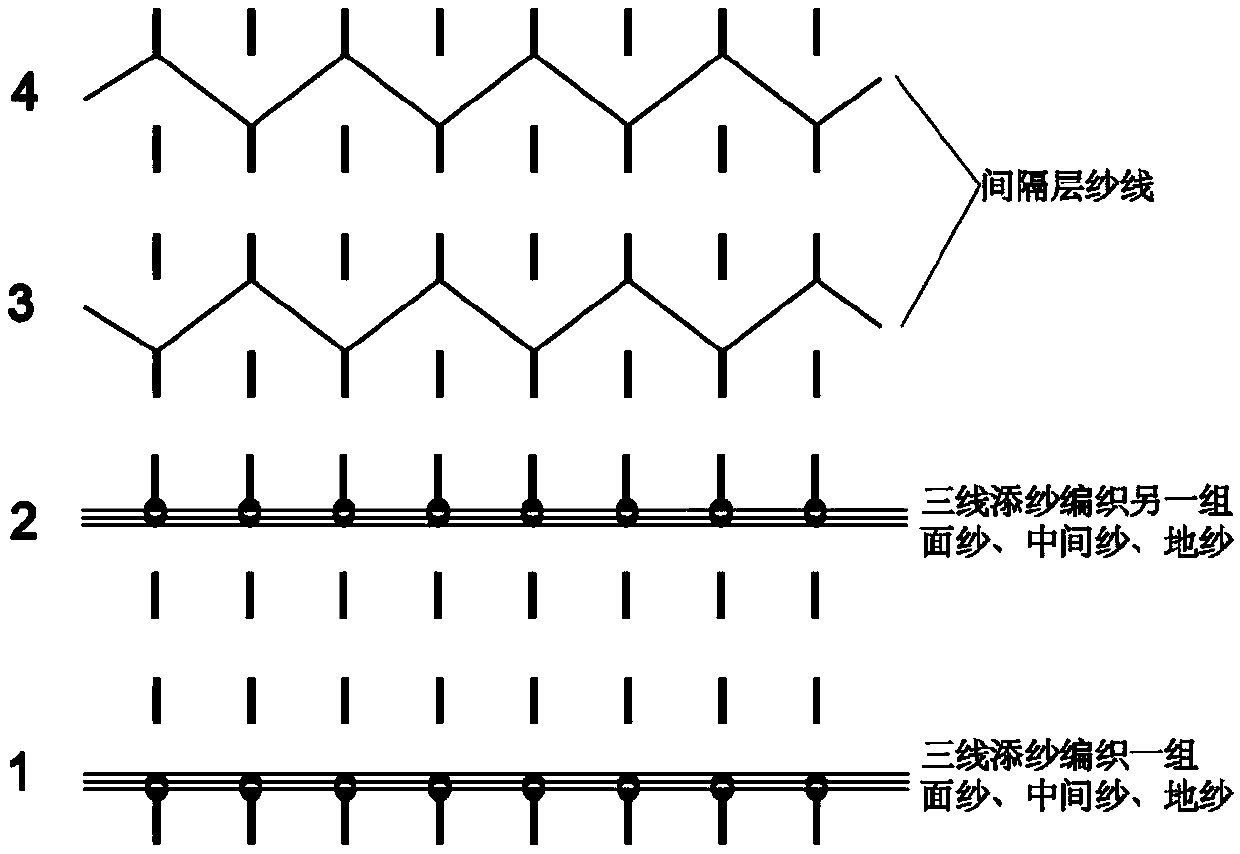

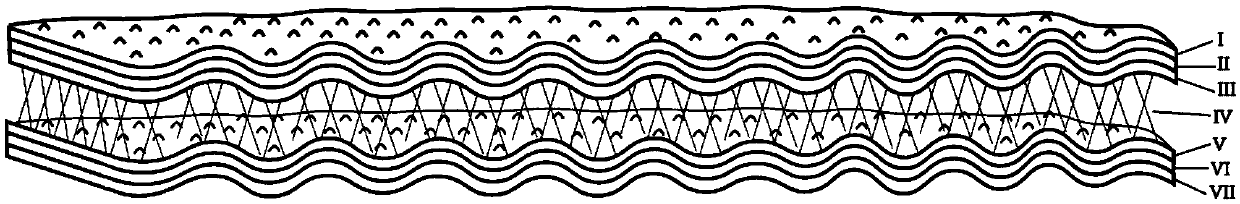

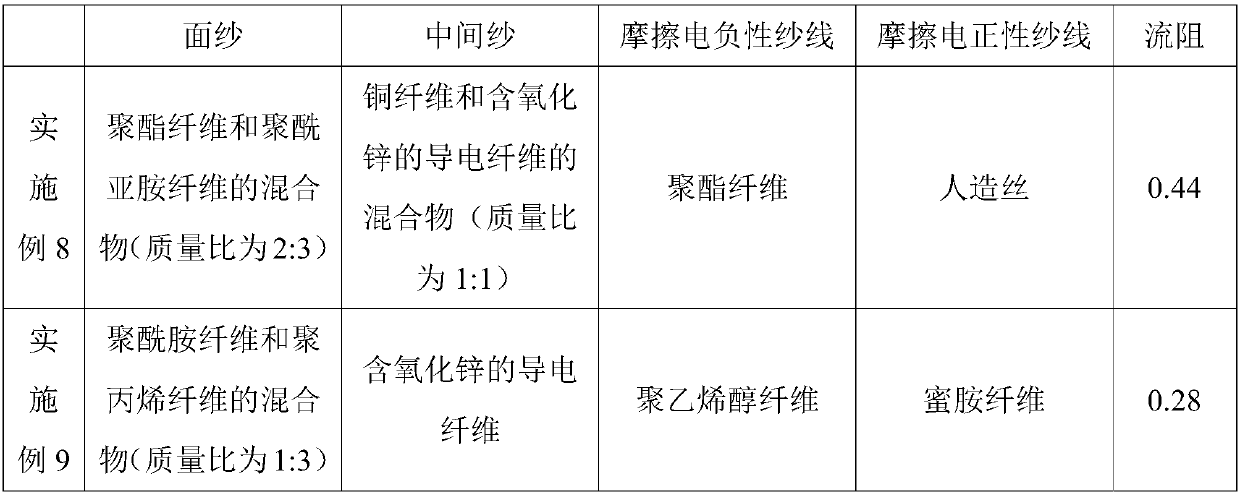

Breathable knitted spacer fabric friction generator and preparation method thereof

ActiveCN109525140APlay a supporting roleOvercome the disadvantage of poor air permeabilityFriction generatorsEngineeringConductive yarn

The invention relates to a breathable knitted spacer fabric friction generator and a preparation method thereof. The method comprises the steps of weaving a top layer and a bottom layer by using a three-wire plating process, controlling the yarn angles of surface yarns, intermediate yarns and ground yarns respectively such that the three yarns are sequentially arranged according to a certain positional relationship and then are woven, at the same time, in the weaving process, performing alternate tucking of spacer wires between a top layer ground yarn and a bottom layer ground yarn with a certain number of spacing stitches to form the breathable knitted spacer fabric friction generator, wherein a top layer surface yarn and a bottom layer surface yarn are at the outmost sides of a compositelayer and are insulating yarns, a top layer intermediate yarn and a bottom layer intermediate yarn are conductive yarns, the top layer ground yarn and the bottom layer ground yarn are opposite and are a triboelectric negative yarn and a triboelectric positive yarn correspondingly, and a spacer layer is composed of a set of spacer wires that are simultaneously connected to the top layer ground yarn and bottom layer ground yarn. The preparation method of the invention has the advantages of simple process and high weaving efficiency, and the obtained knitted spacer fabric friction generator hasgood gas permeability and has excellent promotion value.

Owner:HANGZHOU TIANYE JACQUARD

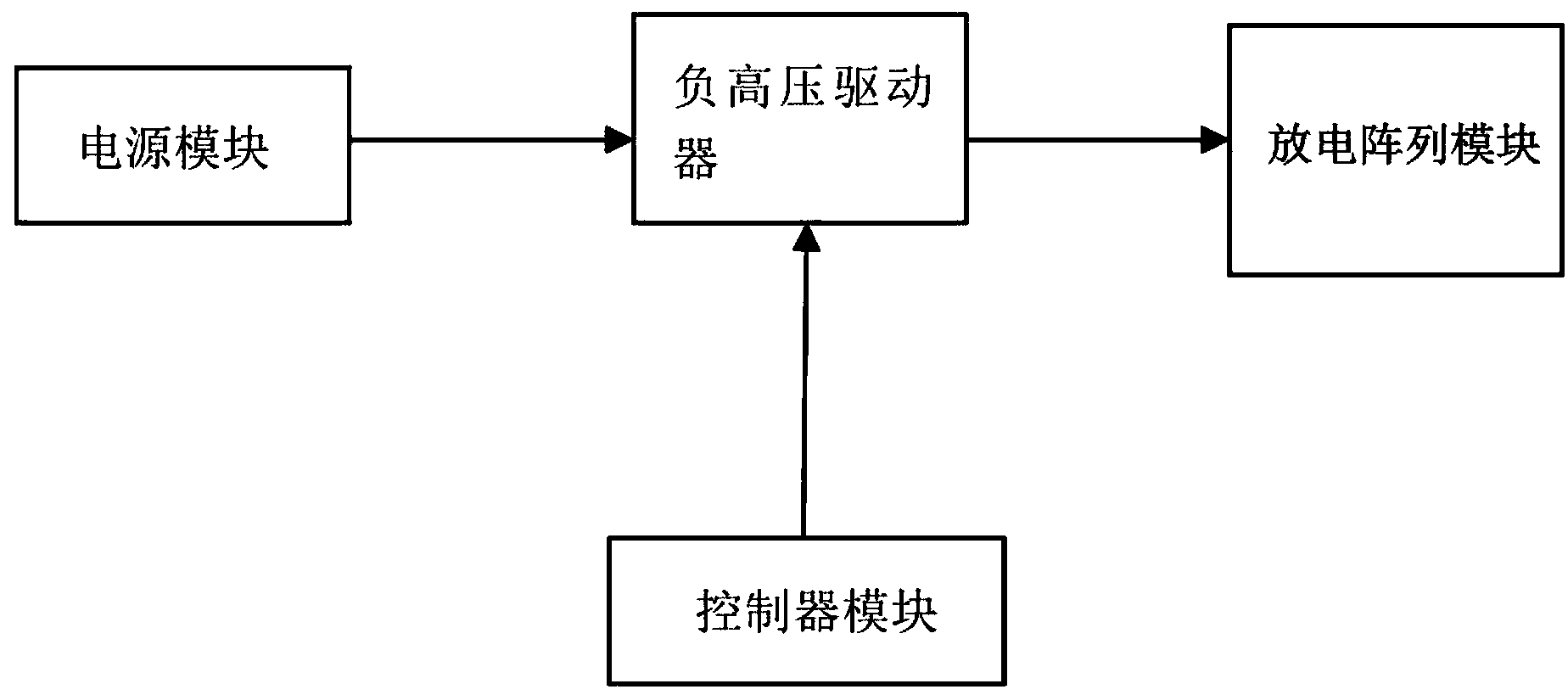

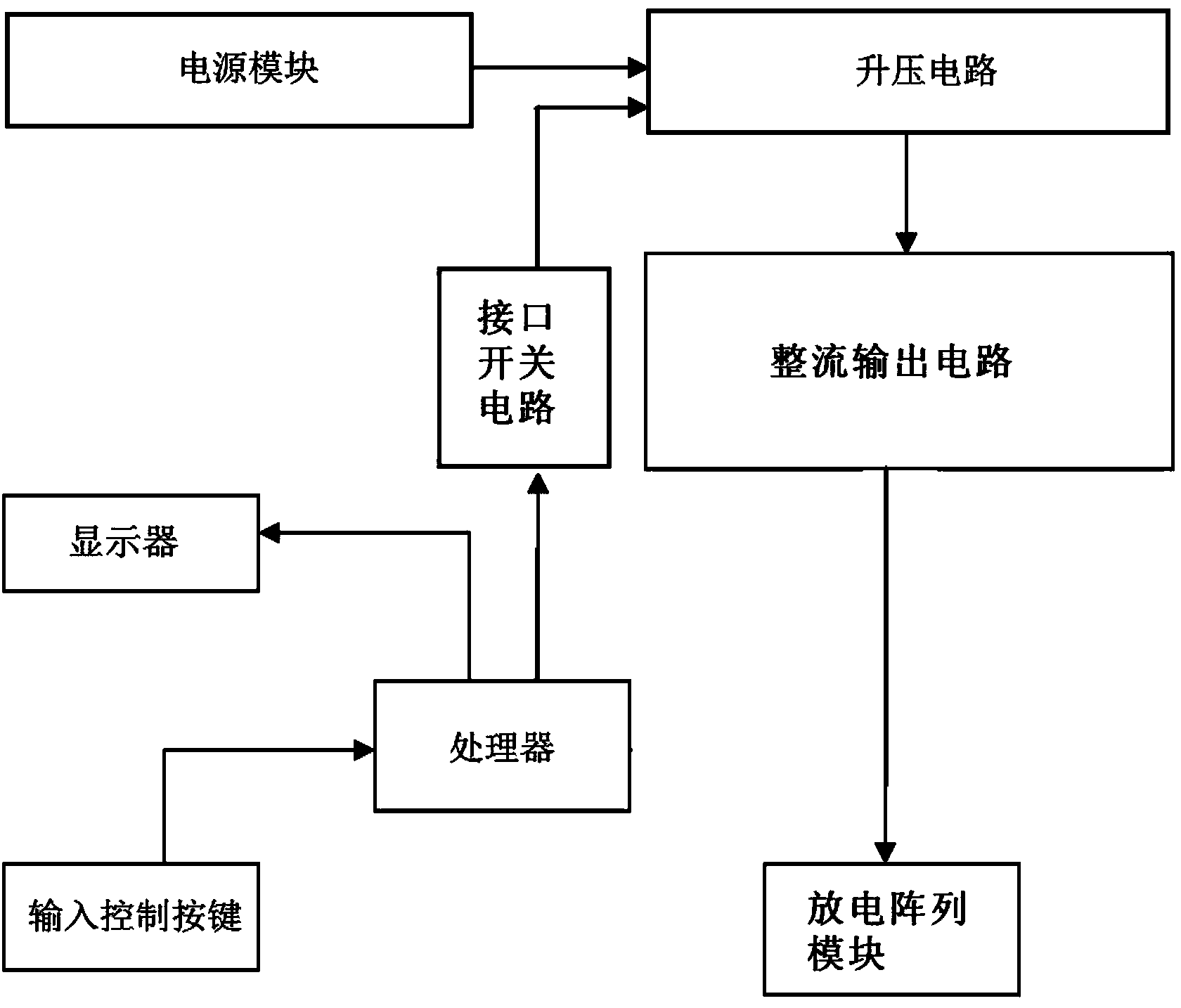

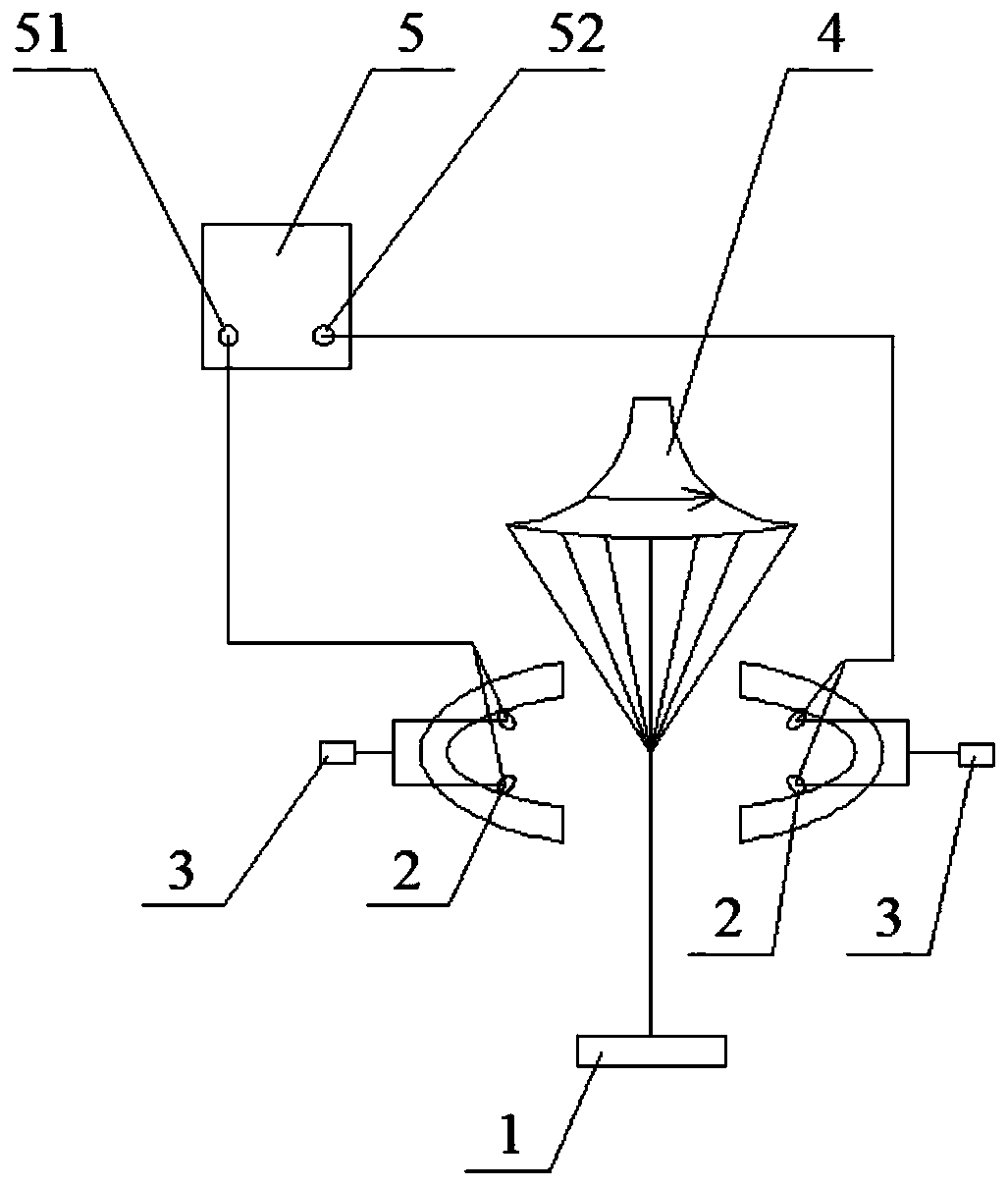

High-concentration small-granule anion generator system

InactiveCN104269744ALarge surface curvatureIncrease surface charge densityElectrical apparatusLighting and heating apparatusYarnHigh concentration

The invention provides a high-concentration small-granule anion generator system. The high-concentration small-granule anion generator system is structurally characterized in that a power source module provides a 110V AC or 220V AC power source for a negative high voltage driver module connected with the power source module, the negative high voltage driver module boosts the power source to a 3000V DC-9000V DC negative voltage and transmits the negative voltage to a discharging array module. The discharging array module comprises a plurality of discharging units connected to a PCB substrate, each discharging unit comprises a cylindrical structure formed by combining a plurality of discharge tubes and an electrode needle wrapped inside the cylindrical structure, and each discharge tube is a needle-shaped object composed of carbon fiber yarn which a nano-graphene coating adheres to. According to the high-concentration small-granule anion generator system, electrons in the nano-graphene are quite active, and therefore the nano-graphene can still release a large number of high-speed high-concentration electrons even under low negative high voltage; a controller module can conveniently control the number and speed of the electrons released by the discharging array.

Owner:广州市汇研微电子技术有限公司

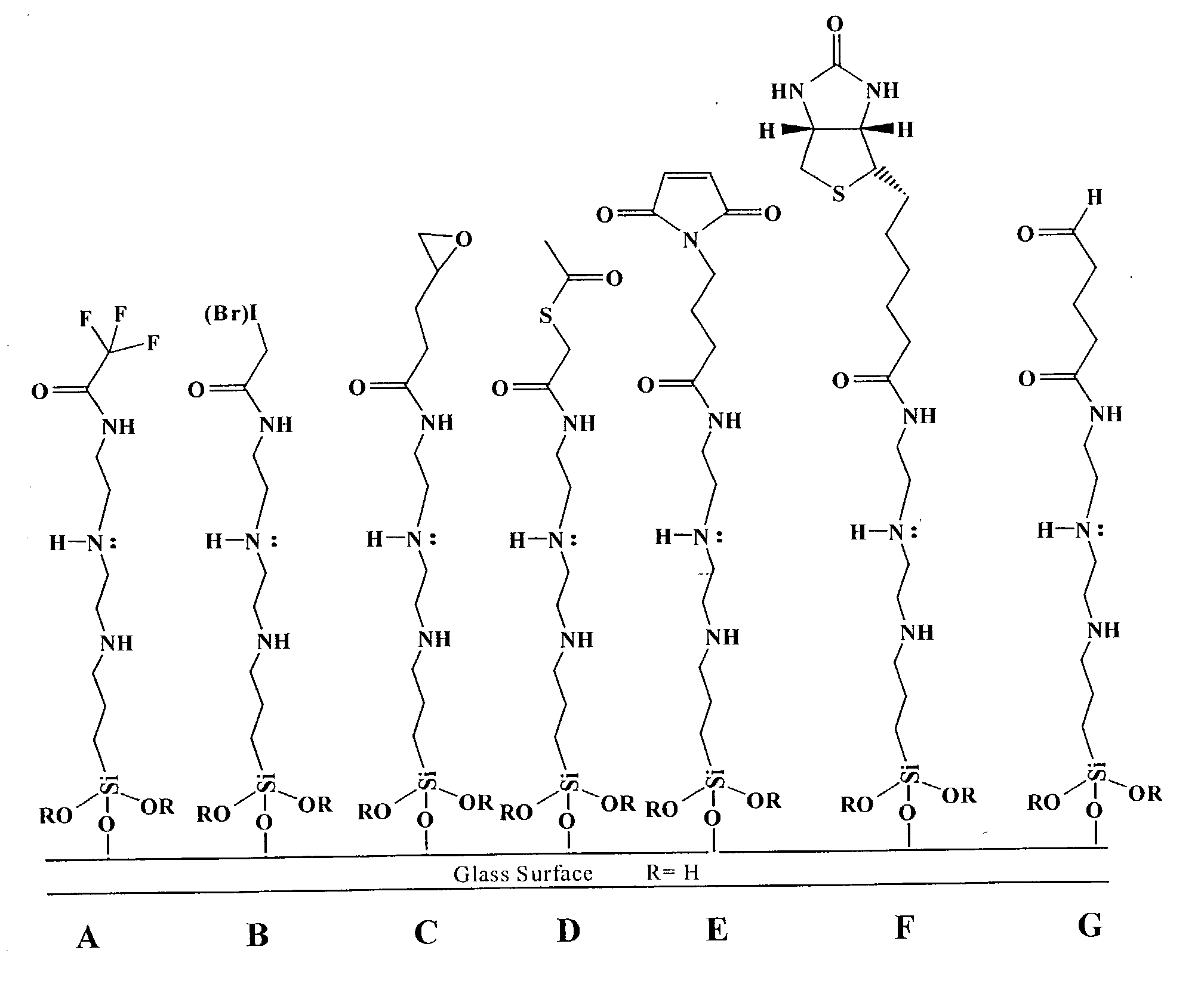

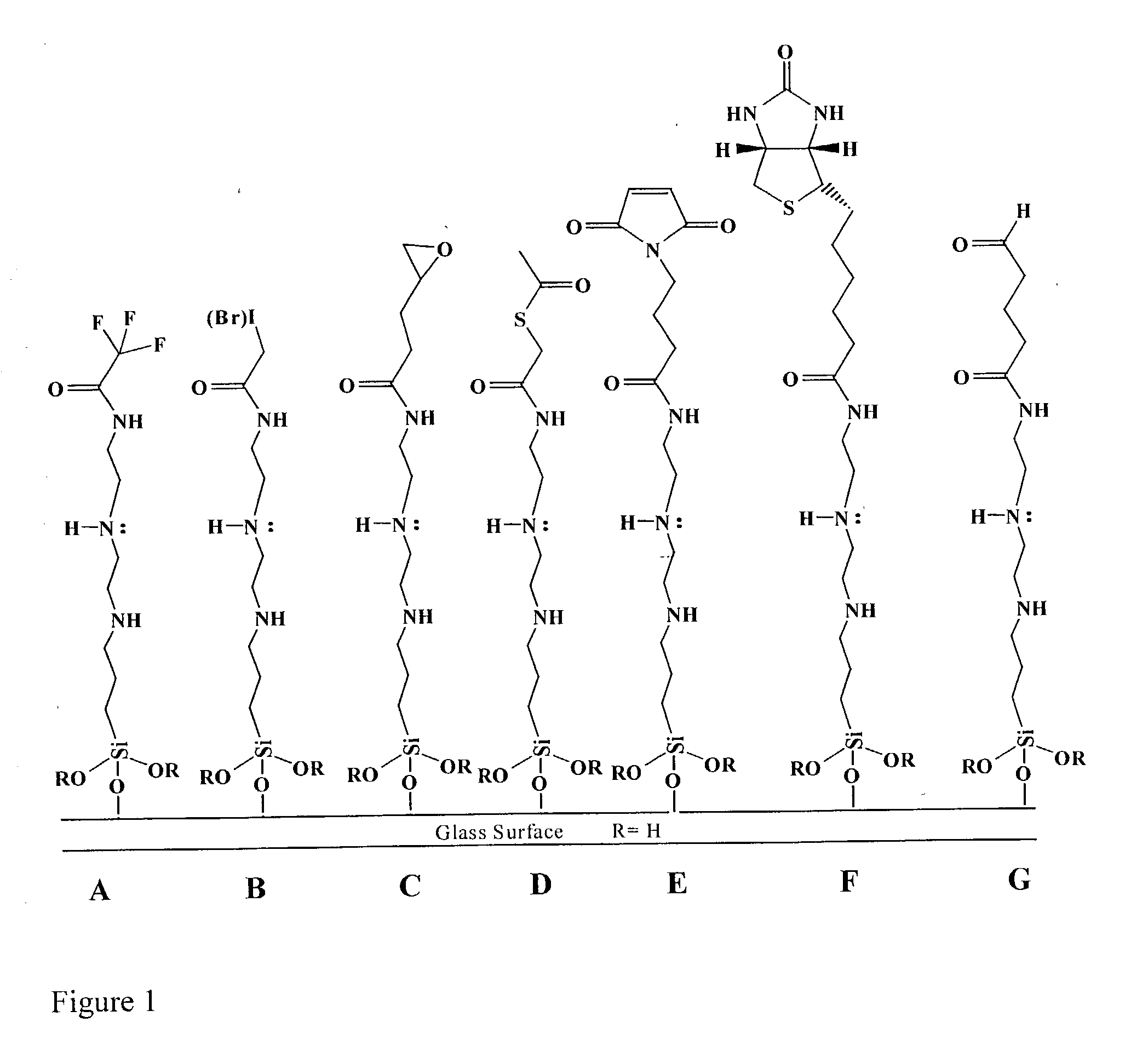

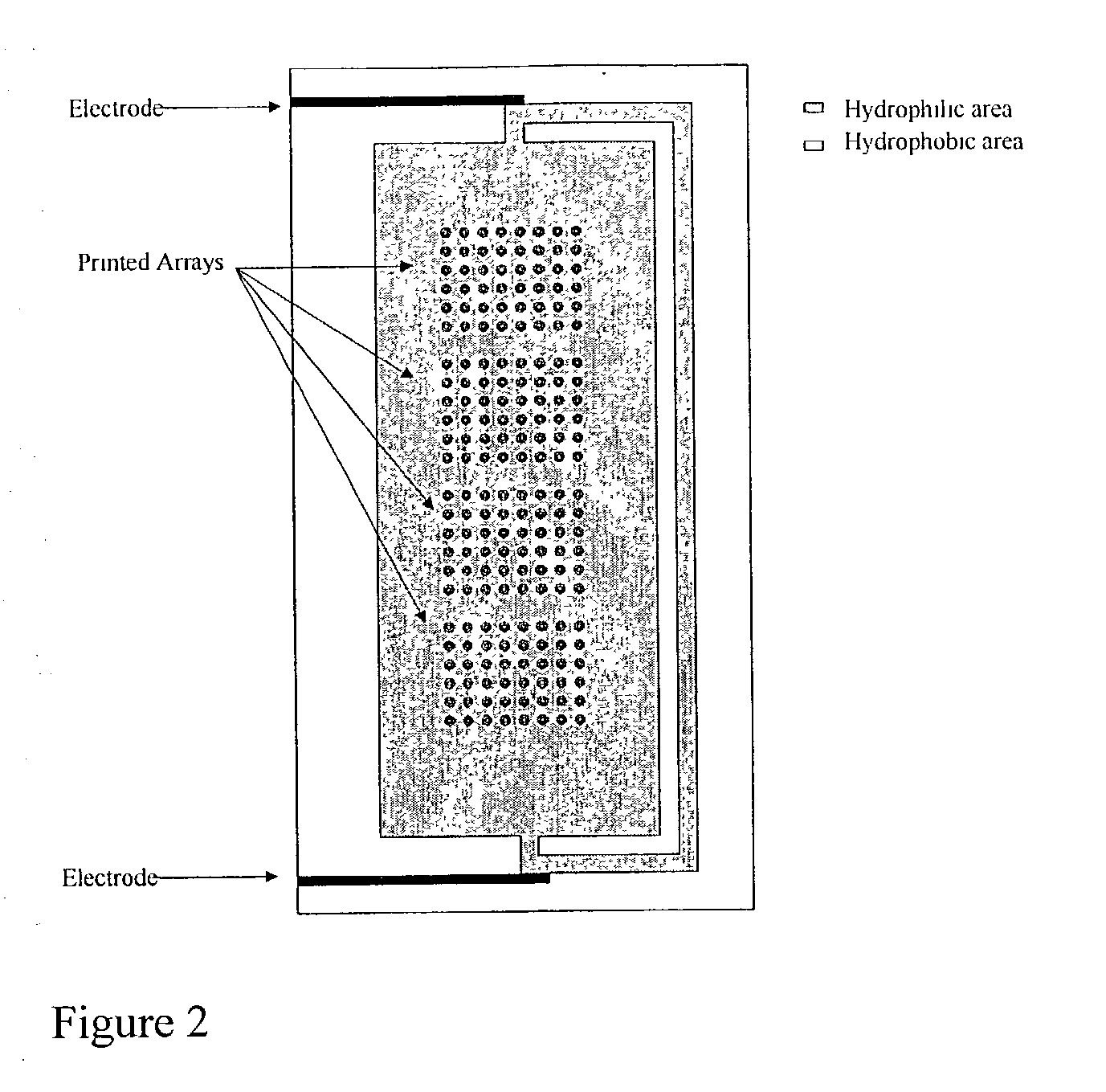

Supports treated with triamine for immobilizing biomolecules

InactiveUS20040086939A1Increase the number ofStrong interactionBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryBiomolecule

Owner:CORNING INC

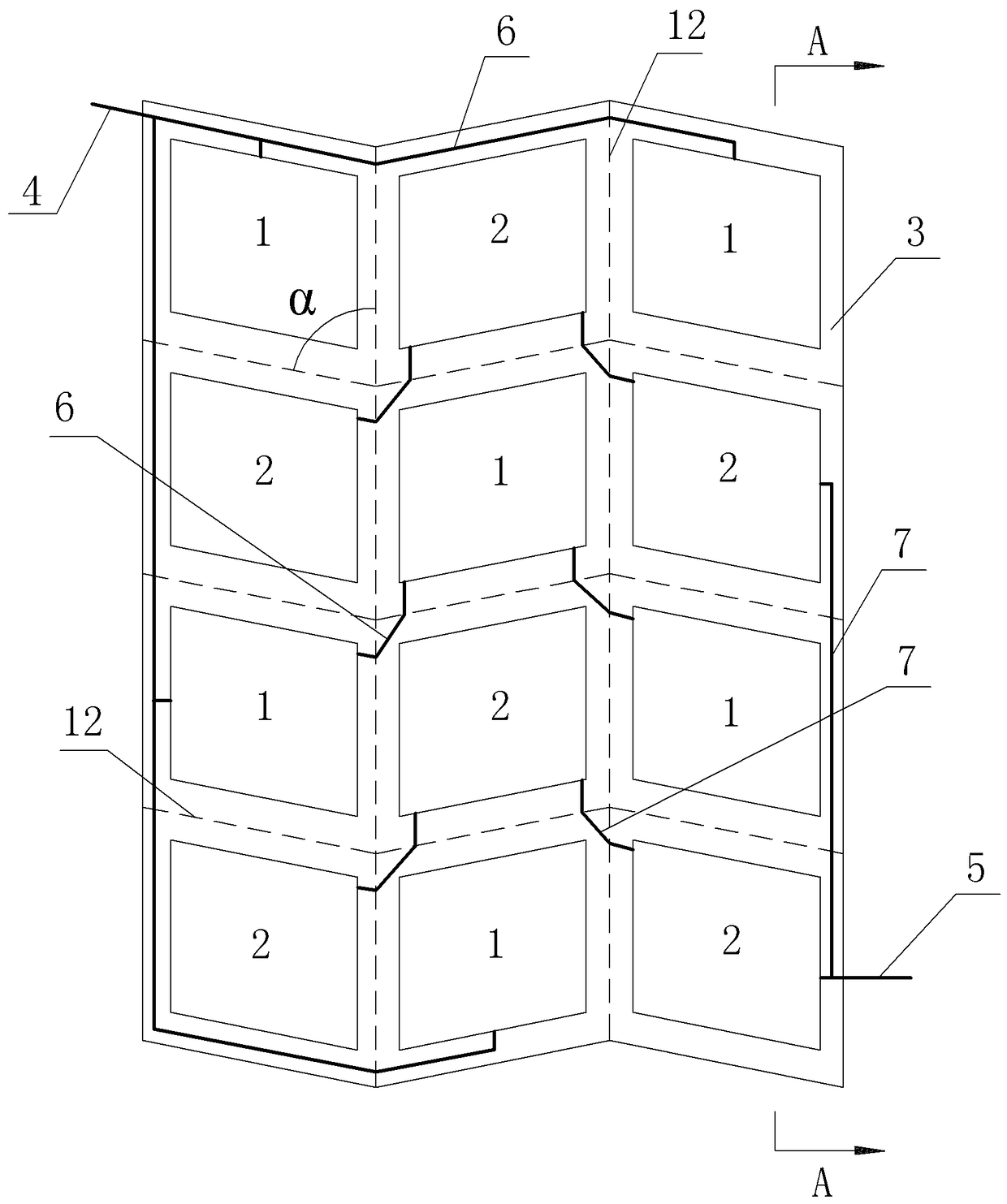

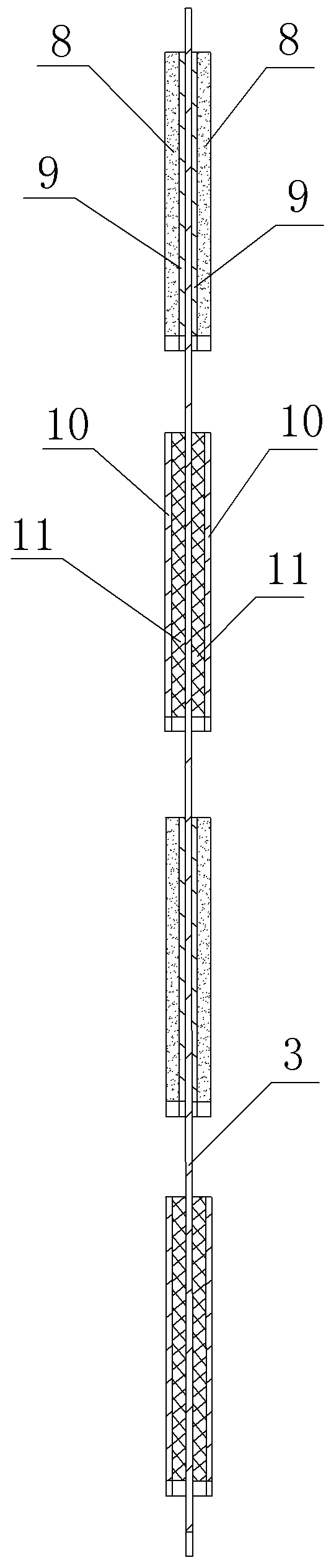

Frictional power generator with piezoelectric enhancement effect based on miura-ori folding

The invention relates to a frictional power generator with a piezoelectric enhancement effect based on miura-ori folding, and the generator comprises a miura-ori folding support base layer, and the support base layer is folded into M*N folded blocks, wherein the front and back surfaces of each folded block are provided with plate-shaped power generation modules. The power generation modules are divided into first modules and second modules, wherein the first and second modules are respectively set at intervals on the row and column of the folded block matrix. Each first module comprises a friction layer and a bottom electrode layer, and each second module comprises a top electrode layer and a piezoelectric enhancement layer. The bottom electrode layers of all first modules are connected together to form one power output end through a first conductive film line attached to the surface of the support base layer. The top electrode layers of all second modules are connected together to form one power output end through a second conductive film line attached to the surface of the support base layer. The generator is small in size, and is strong in output capability.

Owner:CHONGQING UNIV

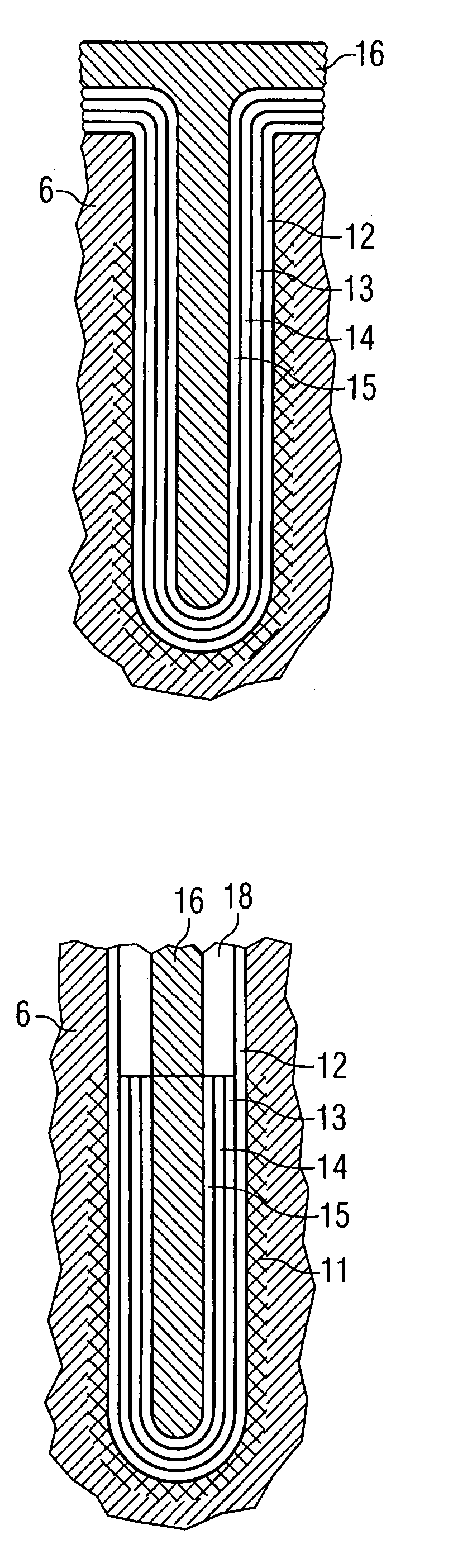

Capacitor with electrodes made of ruthenium and method for patterning layers made of ruthenium or ruthenium

InactiveUS7170125B2Lower resistanceIncrease surface charge densityTransistorSolid-state devicesCapacitorPhotochemistry

A method for patterning layers made of ruthenium or ruthenium(IV) oxide and a capacitor comprising at least one electrode which is constructed from ruthenium or ruthenium(IV) oxide at least in sections. A layer made of ruthenium or ruthenium(IV) oxide is deposited on a substrate and said layer is subsequently covered with a covering layer at least in sections. Through heat treatment of the construction thus obtained in an oxygen atmosphere, the ruthenium is converted into RuO4 in the uncovered sections and removed by sublimation. The method enables the simple patterning of layers made of ruthenium or ruthenium(IV) oxide and the construction of complex structures, such as trench capacitors, for example.

Owner:POLARIS INNOVATIONS

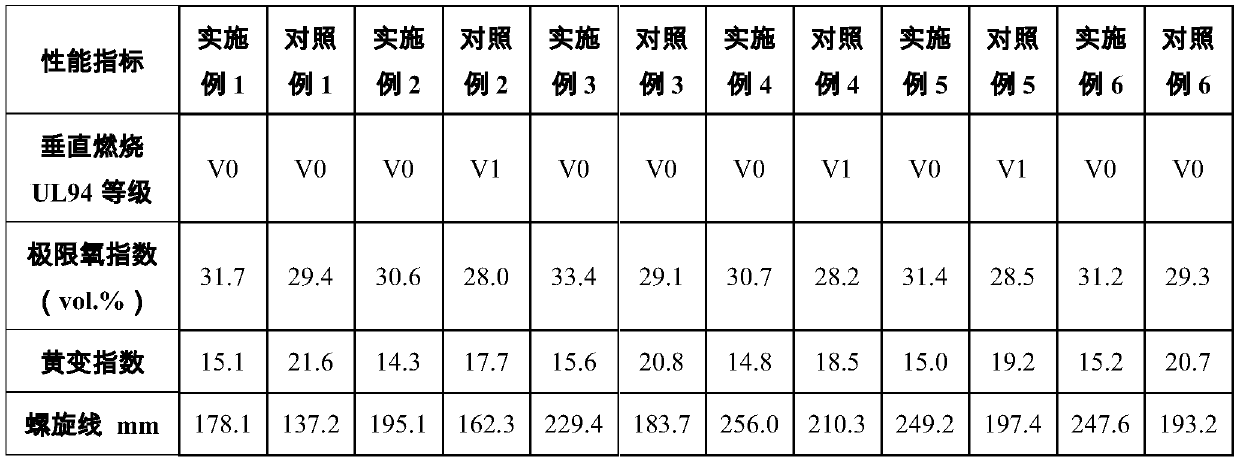

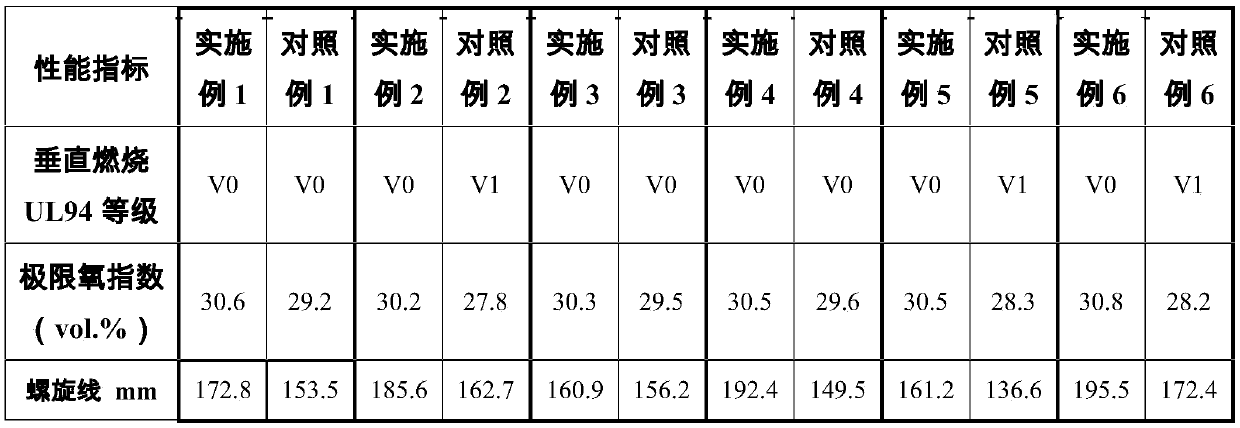

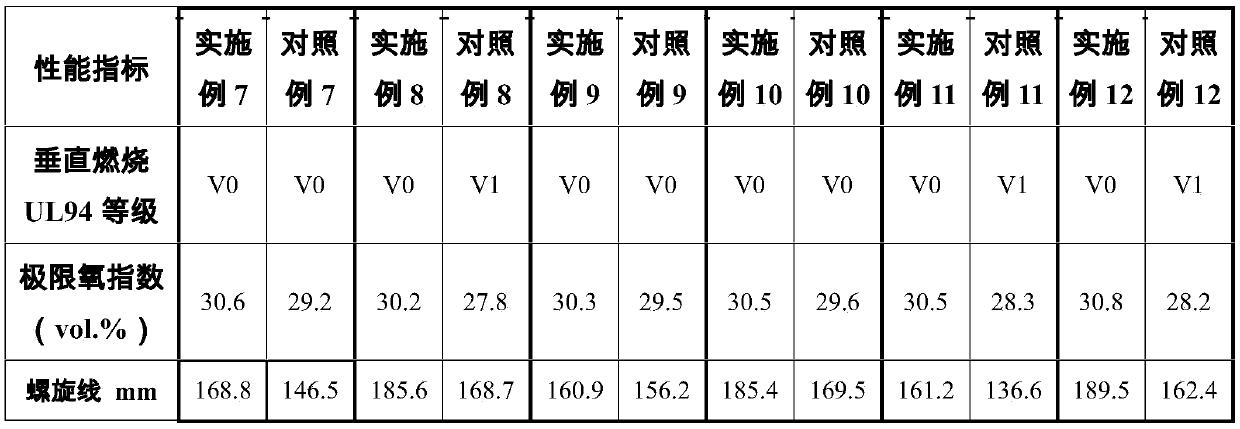

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

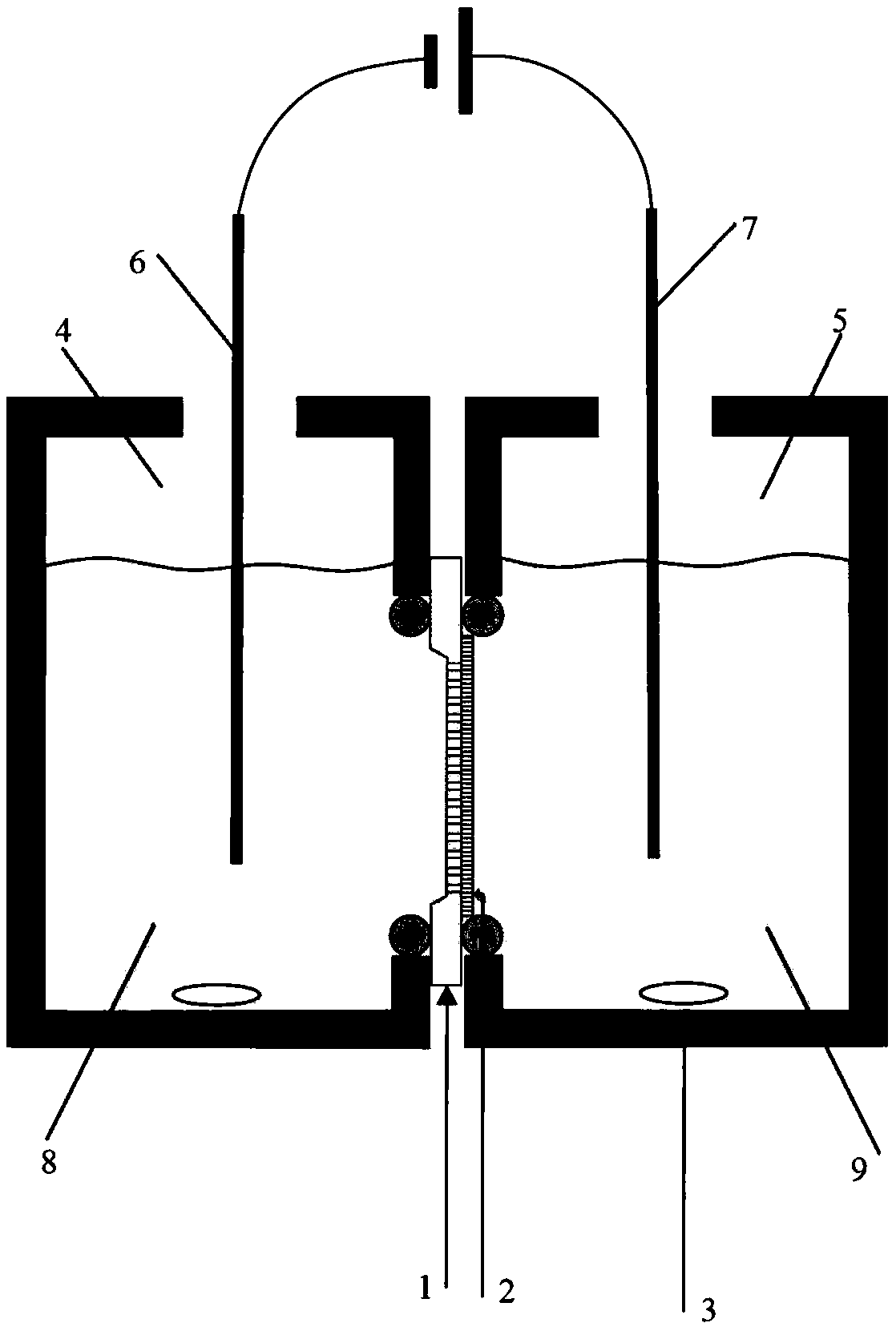

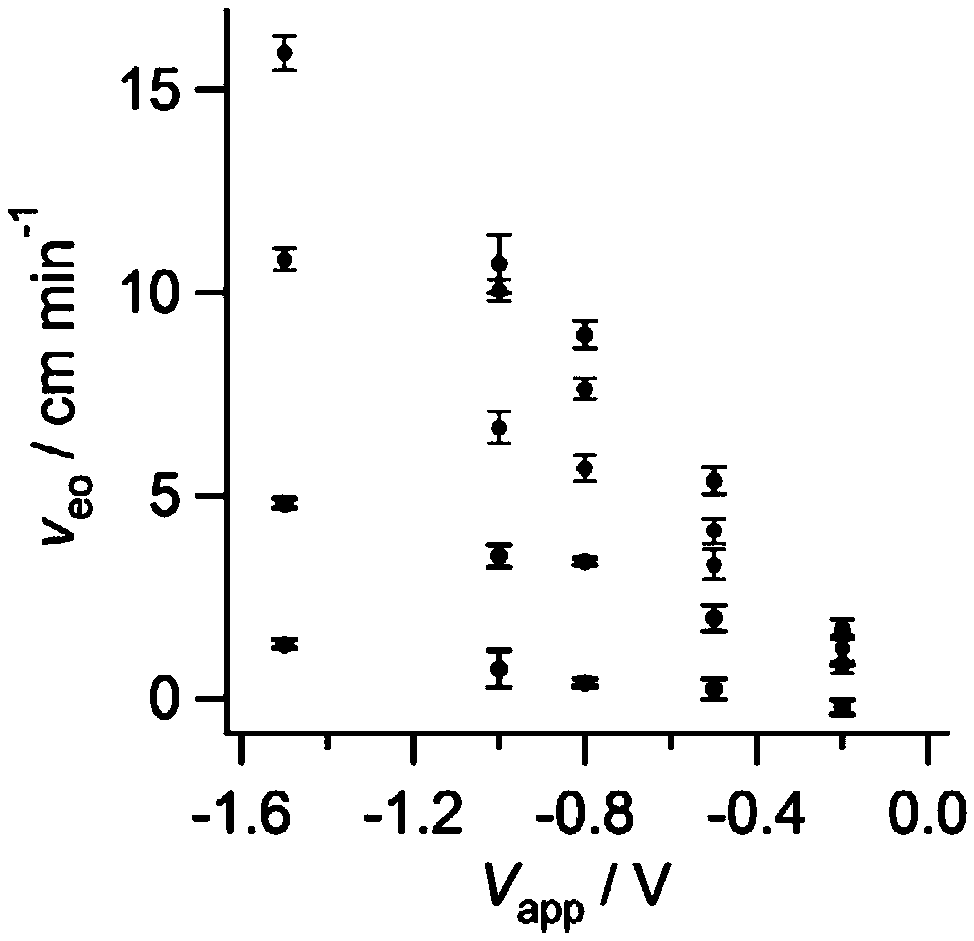

Low-pressure electroosmosis pump based on nano porous thin film

ActiveCN109482248AImprove performanceHigh porosityLaboratory glasswaresFluid controllersComposite filmNanoporous membrane

The invention discloses a low-pressure electroosmosis pump based on an ultra-thin nano porous film. The pump comprises a first cavity chamber, a second cavity chamber and a nano porous thin film arranged in the middle of the first cavity chamber and the second cavity chamber, wherein the first cavity chamber and the second cavity chamber are filled with electrolyte solutions, and a first driving electrode and a second driving electrode are respectively mounted in the first cavity chamber and the second cavity chamber; and the nano porous thin film is a composite film of a nano porous silicon dioxide film and a silicon nitride micron porous film. The low-pressure electroosmosis pump is simple in structure, easy to operate and easy to realize, and the electroosmosis pump can drive fluid to move under a driving voltage of 0.2V, so that no bubble is generated in the reaction, and the problem that the efficiency is reduced or even the fluid stops transmitting due to the blocking of pore channels by bubbles does not need to be considered.

Owner:ZHEJIANG UNIV

Nanotip electrode electroluminescence device with contoured phosphor layer

InactiveUS7589464B2Increase surface charge densityIncreasing the surrounding electric fieldDischarge tube luminescnet screensElectroluminescent light sourcesDielectricFluorescence

Owner:SHARP KK

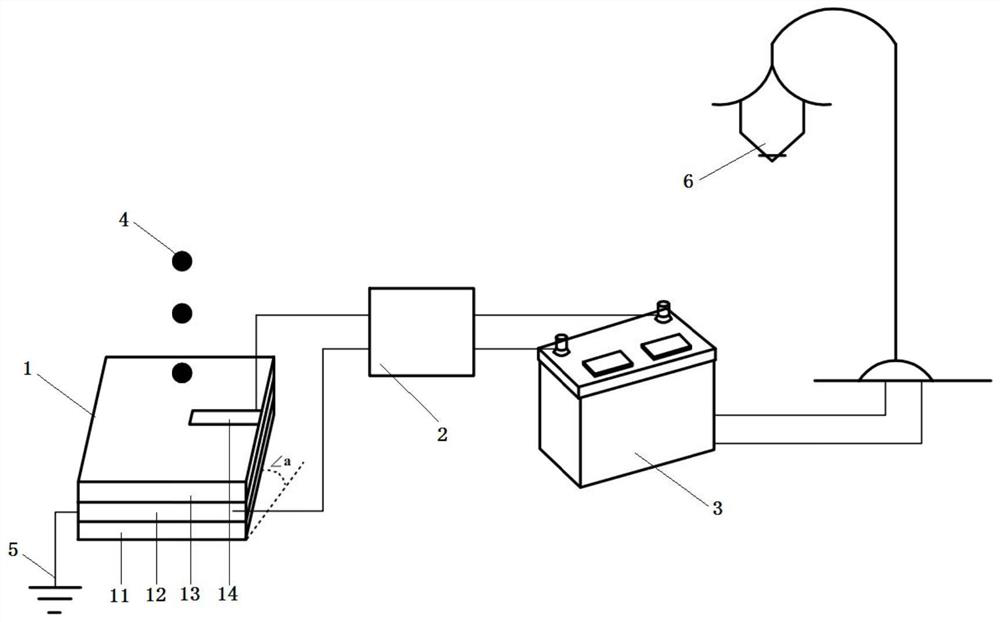

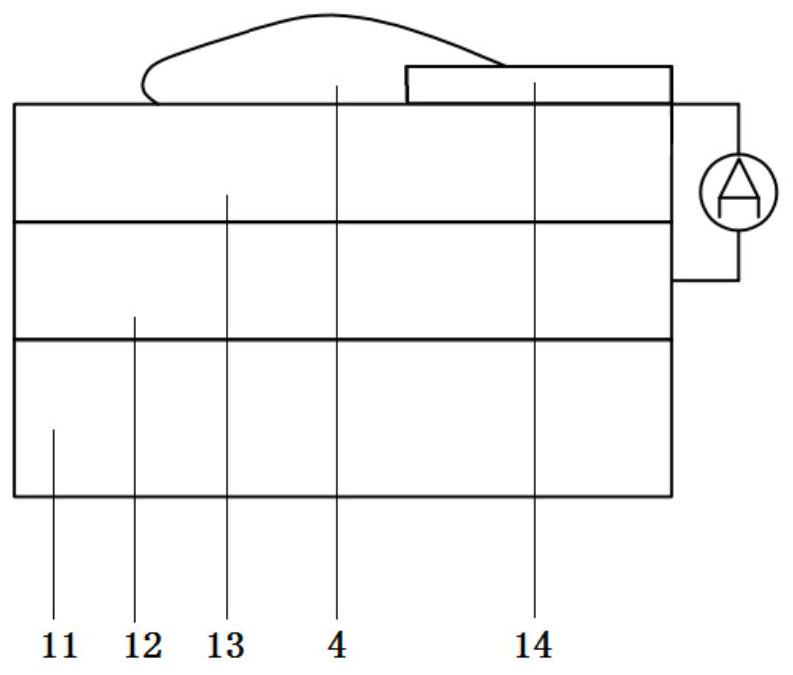

Droplet power generation device and using method thereof

PendingCN112072946AIncrease surface charge densityImprove power generation efficiencyBatteries circuit arrangementsElectric powerEngineeringField-effect transistor

The invention discloses a droplet power generation device and a use method. The liquid drop power generation device comprises a liquid drop power generation unit and a power storage unit; the dropletpower generation unit comprises an insulating bottom plate, a first electrode, a polytetrafluoroethylene film and a second electrode which are sequentially arranged from bottom to top, wherein the second electrode is partially laid on the polytetrafluoroethylene film; the first electrode is further provided with a ground wire making contact with the ground. the power storage unit comprises a rectifier and a storage battery, the rectifier is connected with the first electrode and the second electrode through wires, and the storage battery is connected with the rectifier. The droplet power generation device provided by the invention can effectively utilize low-frequency disordered water motion energy to collect electric energy generated when droplets are in contact with the surface of a flatplate, and has relatively high power generation efficiency by combining the structural design of a field effect transistor and high surface charge density.

Owner:GUANGDONG UNIV OF TECH

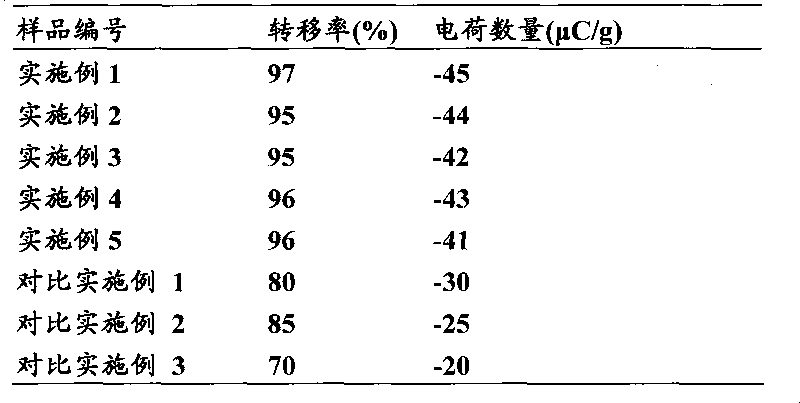

Polymerized toner having high resolution

InactiveCN101727031AIncrease surface charge densityHigh quality imagingDevelopersSurface chargesSURFACTANT BLEND

A polymerized toner is provided. The polymerized toner comprises a reactive anionic surfactant having at least one reactive functional group. The reactive anionic surfactant is added simultaneously with a dispersant to prepare an aqueous dispersion or is added within 2 hour after a polymerization reaction of a monomer mixture is initiated in an aqueous dispersion. This simultaneous or rapid addition allows the reactive anionic surfactant to be dispersed on the surface of the toner particles. The reactive anionic surfactant is located over the entire surface of the toner particles to increase the surface charge density of the toner, achieving good charge stability and excellent imaging characteristics.

Owner:LG CHEM LTD

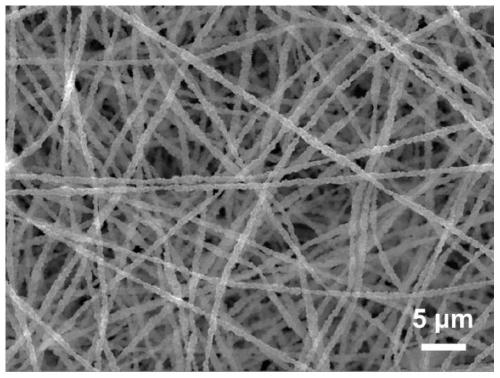

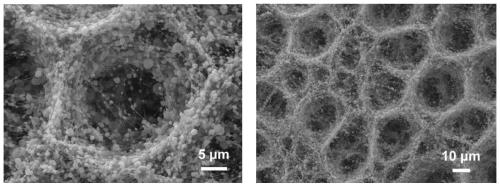

High-specific-surface-area honeycomb-like structure nano fiber material and preparing method thereof

ActiveCN111575917AExcellent one-way moisture directionGood moisture absorption and quick drying effectElectro-spinningNon-woven fabricsSpinningElectrospinning

The invention relates to a high-specific-surface-area honeycomb-like structure nano fiber material and a preparing method thereof. The preparing method comprises the steps that a polymer solution in which a nanoscale metal-organic framework is scattered is subjected to electrostatic spinning, an insulating material subjected to charge eliminating treatment serves as a receiving base material, andthe high-specific-surface-area honeycomb-like structure nano fiber material is prepared; and the finally-prepared material has a certain thickness and is of a three-dimensional honeycomb-like communication hole way structure microcosmically, a hole way is a conical direct-through hole way, the big-end hole diameter of the hole way is 20-100 microns, the small-end hole diameter of the hole way is 5-25 microns, single fiber is in a moniliform shape and is rough and porous, and the specific surface area is 600 m<2> / g. According to the high-specific-surface-area honeycomb-like structure nano fibermaterial and the preparing method thereof, a template is not needed, the nano fiber material with the three-dimensional honeycomb-like communication hole way structure can be prepared through one step, the prepared honeycomb-like structure nano fiber material has the conical direct-through hole way so that water vapor can be rapidly transmitted in an oriented manner in the thickness direction, oriented fiber communicating in the hole way effectively promotes horizontal diffusion of water, and wide application prospects are achieved in the fields of water guiding and dehumidification.

Owner:DONGHUA UNIV

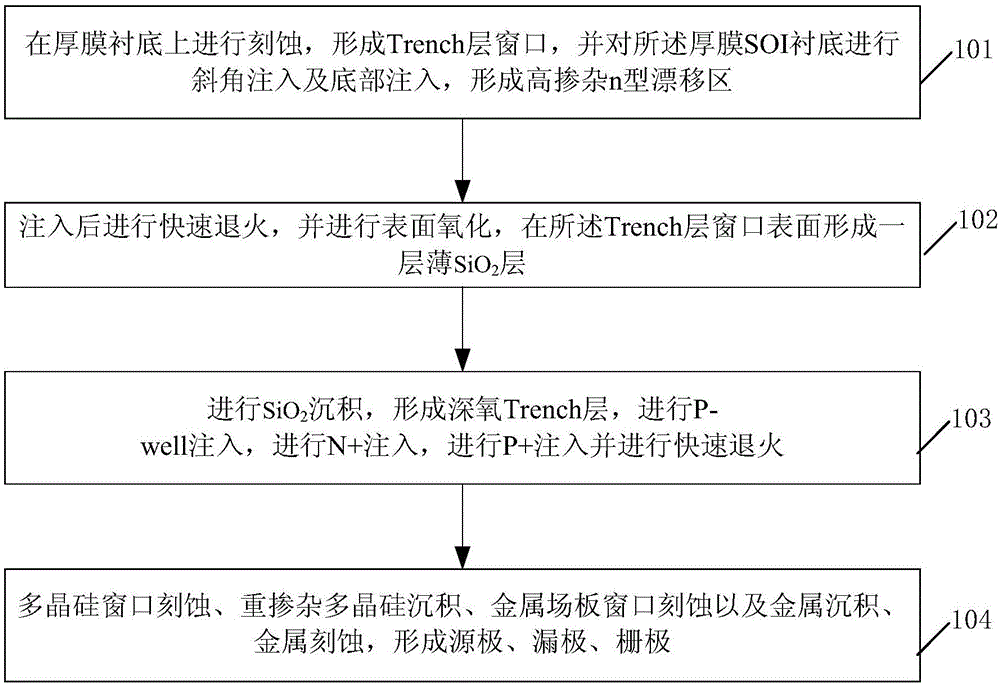

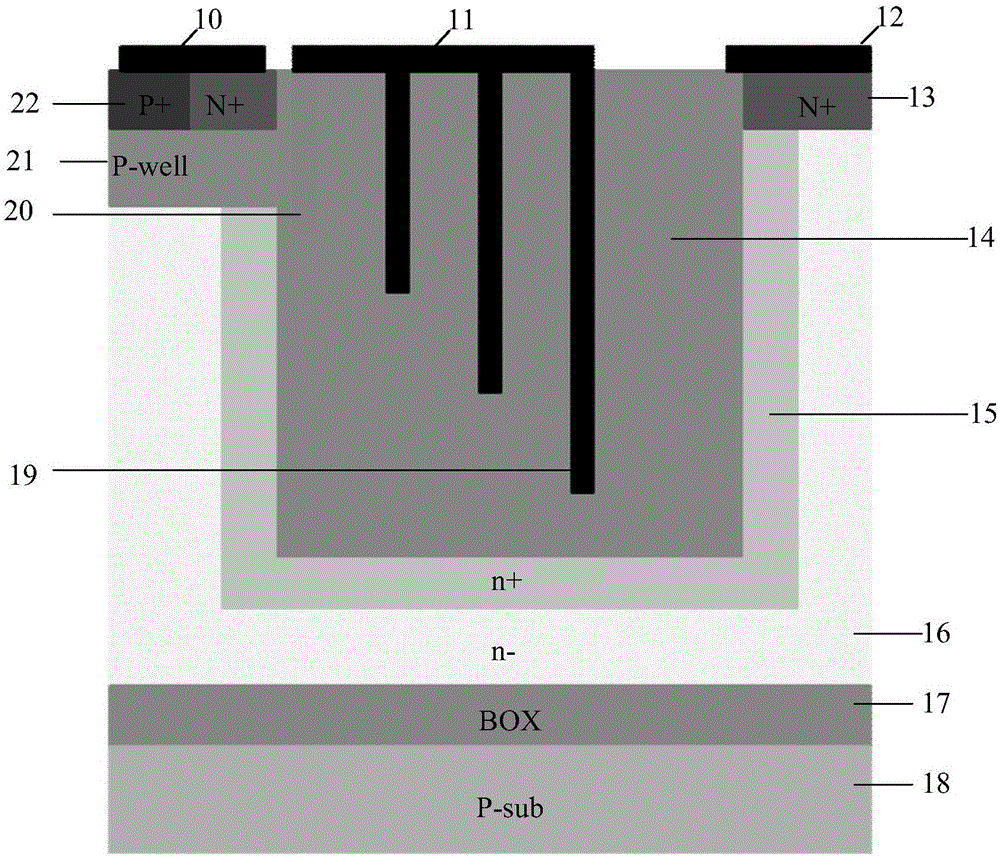

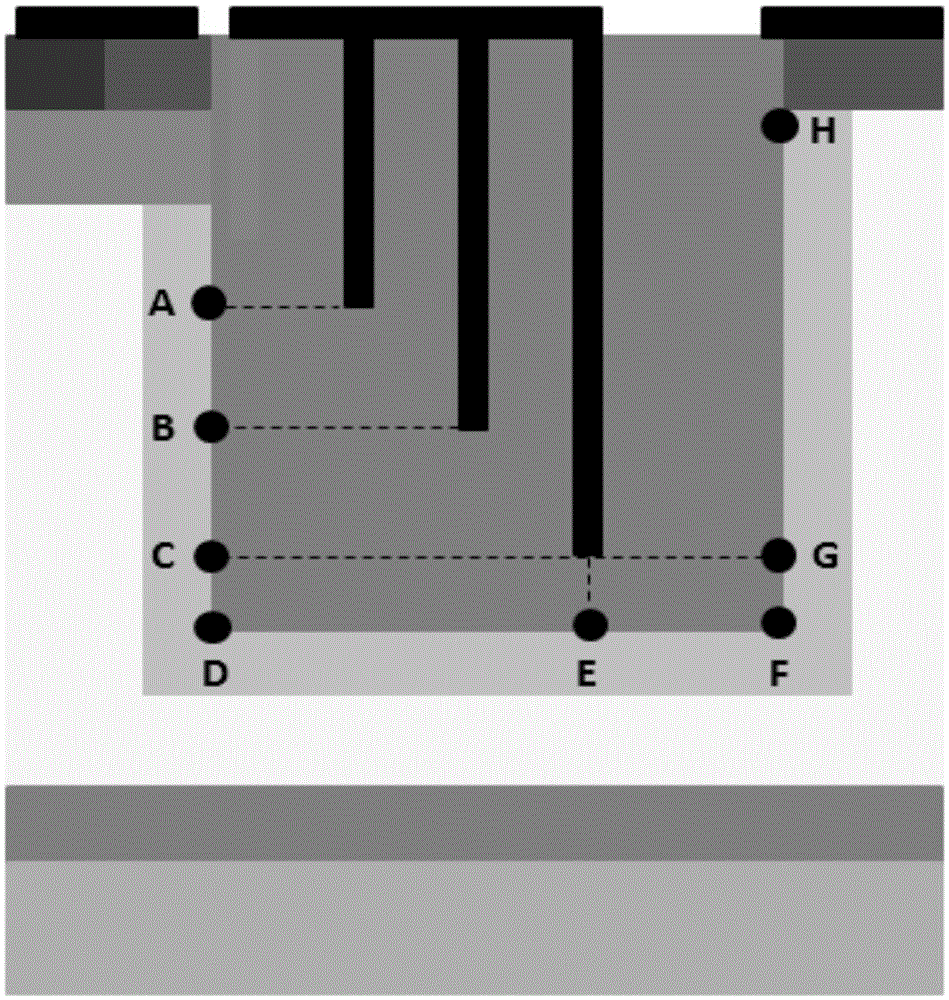

Preparation method for semiconductor power device structure, and structure

ActiveCN105070758AImprove breakdown voltageAvoid premature breakdownTransistorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceLDMOS

The embodiment of the invention discloses a preparation method for a semiconductor power device structure, and a structure. A Trench layer of a conventional lateral power device Trench LDMOS structure is provided with a plurality of longitudinal metal field plates at different depths, and a drift region is provided with a heavily-doped n-type layer. In order to improve the breakdown voltage of a device, the metal field plates with different lengths at different layers can introduce a plurality of new electric field peak values in a drift region, and enables a surface high electric field to be introduced into a body, thereby protecting the surface of the device from being broken down in advance. After complete loss, the heavily-doped n-type layer improves the surface charge density of the Trench layer, improves the electric fields of the Trench layer and the drift region, and improves the breakdown voltage of the device. In order to reduce the conduction resistance of the device, a deep oxygen Trench layer reduces the length of the lateral drift region.

Owner:工业和信息化部电子第五研究所华东分所

High-output self-healing single-electrode friction nano generator and preparation method thereof

ActiveCN111355402AHigh dielectric constantIncrease surface charge densityFriction generatorsThin membraneElectrically conductive

The invention relates to a high-output self-healing single-electrode friction nano generator and a preparation method thereof, and belongs to the technical field of nano energy. The high-output self-healing single-electrode friction nano generator includes a wire, a triboelectrification layer which is in contact with the skin, and the cross-linking layer, the self-healing electrode layer and the supporting layer which hare sequentially located below the triboelectrification layer. The triboelectrification layer is a CNTs / PDMS composite film; the cross-linking layer is a mixture formed by PDMSand PMHS; the self-healing electrode layer is PVA hydrogel added with graphene and glycerin; the PDMS film serves as support layer. According to the nano-generator, graphene is added into PVA hydrogelto serve as a conductive reinforcing phase, meanwhile, crystal lattices are refined, and the mechanical property of the material is improved; glycerol is added, so that rapid self-healing can be realized in air; CNT is added into PDMS to serve as a reinforcing phase, so that the friction layer has high dielectric property, and the output of the friction nano generator is improved. The cross-linking agent enables the self-healing electrode layer and the friction layer to have good physical cross-linking.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Special nylon resin modification flame-retardant synergetic functional master batch and preparation method thereof

InactiveCN110591243AImprove thermal stabilityImprove thermal protection performanceAcrylonitrilePolystyrene

The invention relates to the technical field of plastic modification processing and in particular discloses a special nylon resin modification flame-retardant synergetic functional master batch and apreparation method thereof. The functional master batch adopts multiple composite coated brominated polystyrene as main body flame retardant, and comprises the following components in percentage by mass: 55.0-70.0wt.% of multiple composite coated brominated polystyrene, 15.0-30.0wt.% of anhydrous zinc borate, 8.0-10.0wt.% of nylon 6 resin, 2.0-3.0wt.% of starlike nylon, 0.5-1.0wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0wt.% of a dispersant and 0.3-0.5wt.% of a lubricant. Compared with a conventional plastic flame-retardant functional master batch, the flame-retardant synergetic functional master batch disclosed by the invention is capable of improving the thermal stability and the flowing dispersibility of domestic brominated flame retardant, so that theflame retardance efficiency can be improved, a flame retardance effect identical to that of a conventional flame-retardant functional master batch can be achieved with a less master batch addition amount, and in addition, the mechanical performance loss of a modified high-temperature-resistant nylon resin composite material can be effectively reduced.

Owner:江苏万纳普新材料科技有限公司

Bacteriostatic and deodorant fiber material for face towel and preparation method of bacteriostatic and deodorant fiber material

InactiveCN113529196AGood hygroscopicityGood deodorizing effectArtificial filaments from cellulose derivativesArtifical filament manufactureBiotechnologyCyclodextrin

The invention discloses a bacteriostatic and deodorant fiber material for a face towel and a preparation method of the material. The bacteriostatic and deodorant fiber material is prepared by stranding synergistic fibers, acrylic fibers and vinylon; the synergistic fibers are good in moisture absorption performance; a large amount of beta-cyclodextrin is grafted to the fibers; the beta-cyclodextrin has a very good deodorant effect; meanwhile, the surface is also provided with a large number of quaternary ammonium salt structures and halamine structures, so that the surface charge density is high, and bacteria can be well adsorbed; and when the bacteria are in contact with the synergistic fibers, positively charged halogen positive ions released by a halamine compound are combined with receptors in cells, so that the enzyme synthesis or cell metabolism process is hindered; meanwhile, quaternary ammonium salt can be combined with a phospholipid bilayer in a bacterial cell membrane to destroy the composition of the cell membrane, cause the leakage of RNA, DNA and potassium ions in the cell and further kill the bacteria; and meanwhile, compared with traditional antibacterial fibers, the fiber material is more lasting in antibacterial effect, and the situation that the antibacterial effect is reduced due to repeated use of the towel is avoided.

Owner:安徽新虹新材料科技有限公司

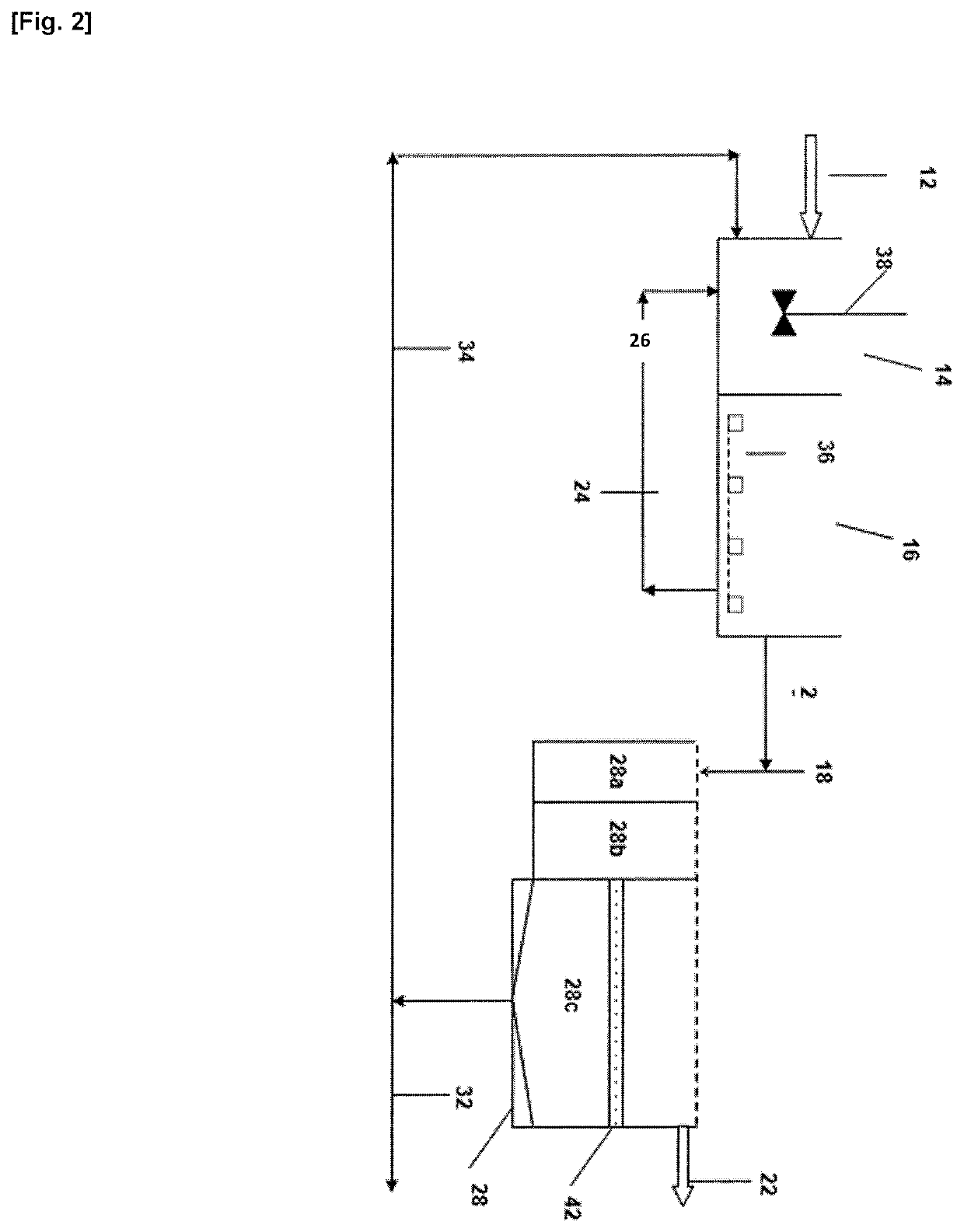

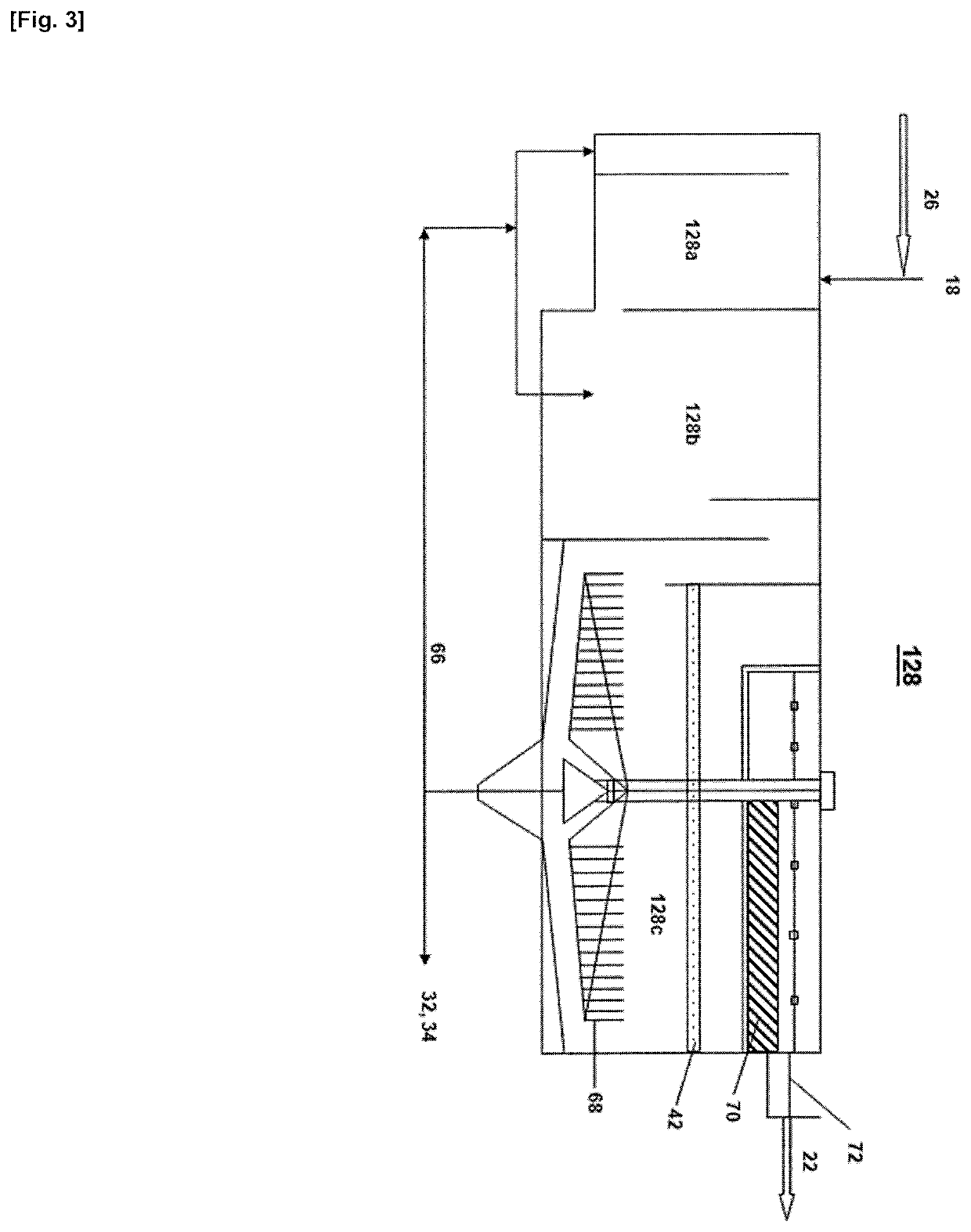

Process and System for Treating Waste Water

InactiveUS20200001208A1Reduce dwell timeSufficient phosphorus removalOther chemical processesWater/sewage treatment with mechanical oscillationsPre treatmentSurface charges

The present invention relates to a waste water treatment process and system for treatment of waste water utilizing a diatomite treatment agent containing about 98 to 99.9% by weight of diatomite particles, wherein the diatomite particles comprise unbalanced surface charges and is substantially free of counter ions being electrostatically coupled to the unbalanced surface charges, and wherein the diatomite treatment agent is obtained from the disclosed pre-treatment process. This diatomite treatment agent has posed several advantages in a waste water treatment process, particularly acting as a biomass carrier, physical coagulant and adsorbent in a system for treatment of waste water, the system comprising a specially designed clarifier.

Owner:KYTOLINK TECH PTE LTD

Antibacterial and anti-sticking agent for gum dipping process and preparation method of antibacterial and anti-sticking agent

ActiveCN114481682AImprove biological propertiesImprove the potential field of applicationVegetable material additionWax additionBiotechnologyPuerarin

The invention relates to the field of anti-sticking agents, in particular to an antibacterial anti-sticking agent for a gum dipping process and a preparation method of the antibacterial anti-sticking agent. The antibacterial agent is added, according to the preparation method of the antibacterial agent, puerarin is grafted on chitosan to obtain nano modified chitosan, and the nano technology can improve the biological property and potential application field of an active compound grafted on a polymer, so that the active compound can inhibit the growth of bacteria and stabilize free radicals with increased specific surface area. Organic silicon resin grafted talcum powder, an antibacterial agent, a cactus ethanol solution, beewax, an emulsifier and a pH regulator are further mixed to prepare the antibacterial and anti-sticking agent for the gum dipping process, and the antibacterial and anti-sticking agent has good antibacterial performance.

Owner:东莞市伟邦新材料科技有限公司

Flame-retardant synergistic functional master batch special for polyethylene modification and preparation method thereof

PendingCN110643098AImprove flame retardant effectReduce usageBrominated flame retardantPolytetrafluoroethylene

The invention relates to the technical field of plastic modification processing, in particular to a flame-retardant synergistic functional master batch special for polyethylene modification and a preparation method thereof. The functional master batch takes multi-composite coated decabromodiphenylethane as a main flame retardant, and the functional master batch comprises the following components by mass percentage: 55.0-70.0 wt.% of multi-composite coated decabromodiphenylethane, 15.0-30.0 wt.% of antimony trioxide, 9.0-13.0 wt.% of an ethylene-octene copolymer, 1.0-2.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersant, and 0.3-0.5 wt.% of a lubricant. Compared with traditional flame-retardant functional master batch, the functional masterbatch prepared by the invention significantly improves the thermal stability of brominated flame retardants, effectively reduces the material yellowing phenomenon in the thermal machining process, and enhances the flame-retardant effect of domestic brominated flame retardants on polyethylene.

Owner:江苏万纳普新材料科技有限公司

Special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and preparation method thereof

The invention relates to the technical field of plastic modification processing, in particular to special halogen-free flame-retardant synergistic functional masterbatch for polyolefin resin modification and a preparation method thereof. According to the functional masterbatch, multiple composite coated ammonium polyphosphate is used as a phosphorus-based flame retardant; the functional masterbatch is prepared from the following components in percentage by mass: 55.0-65.0 wt.% of the multiple composite coated ammonium polyphosphate, 25.0-35.0 wt.% of a nitrogen flame retardant, 7.0-11.0 wt.% of carrier resin, 0.5-1.0 wt.% of styrene-acrylonitrile copolymer coated polytetrafluoroethylene, 0.5-1.0 wt.% of a dispersing agent and 0.3-0.5 wt.% of a lubricating agent. Compared with the traditional flame-retardant functional masterbatch, the functional masterbatch prepared by the invention has the advantages that the thermal stability of ammonium polyphosphate is remarkably improved, and thewater resistance of the ammonium polyphosphate is enhanced, so that the flame-retardant effect of the ammonium polyphosphate on polyolefin resin is more effectively improved.

Owner:江苏万纳普新材料科技有限公司

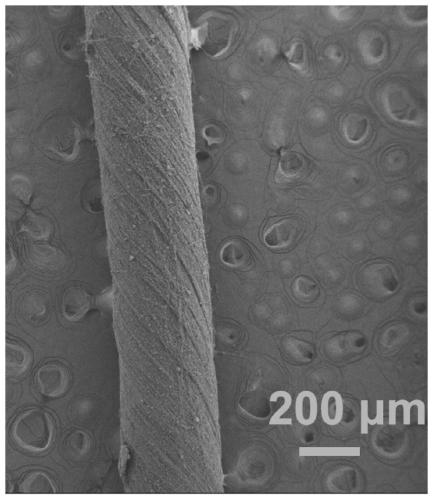

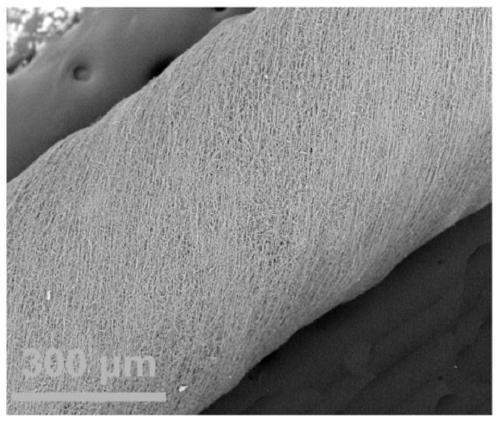

Preparation method of wearable friction generator based on flexible PU/PVDF composite nanofiber yarn

The invention discloses a preparation method of a wearable friction generator based on flexible PU / PVDF composite nanofiber yarn. A unique double-layer coaxial structure is adopted, elastic conductivecore yarn is used as stretchable elastic core yarn, the surface of core yarn is sequentially coated with PVDF and PU nanofiber layers through conjugate electrostatic spinning, a certain gap structureis constructed between the two layers of nanofibers by coating a water-soluble material, and the friction generator of the PU / PVDF composite nanofiber yarn with the double-layer coaxial structure ismanufactured. According to the friction generator, low-frequency kinetic energy is collected and converted into electric energy through contact separation and electrostatic induction between the PU nano fiber layer and the PVDF nano fiber layer in a stretched or pressed state, due to the fact that the nanofibers have the advantages of being high in specific surface area and superfine in size, theeffective contact area between the PU nanofiber layer and the PVDF nanofiber layer is maximized, the surface charge density is improved, and the output performance of the wearable friction generator is remarkably improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

IgY liposome spray and preparation method thereof

PendingCN111888469AUniform particle size distributionIncrease surface charge densityAntipyreticAerosol deliveryInflammatory factorsDisease

The present invention discloses an IgY liposome spray and belongs to the technical field of biology. A main point of a technical solution is as follows: the IgY liposome spray comprises the followingcomponents in weight percentages: 0.5-2% of a humectant, 0.5-2% of a preservative, 1-3% of liposomal lecithin, 0.5-1% of a stabilizer, 2-5% of IgY antibodies and the balance distilled water. The prepared antibody spray can target inflamed parts, effectively neutralizes and eliminates over-expressed and secreted inflammatory factors in the skin tissues, achieves a purpose of fundamentally curing diseases, at the same time, can enable the antibodies to penetrate the skin to reach the site of action faster by using a liposome spraying mode, and thus achieves a more effective treatment effect.

Owner:苏州瑞微生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com